How to Use PTFE for Breakthrough Engineering?

JUN 27, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

PTFE Technology Evolution and Objectives

Polytetrafluoroethylene (PTFE), commonly known as Teflon, has been a revolutionary material in engineering since its accidental discovery by Roy Plunkett in 1938. This synthetic fluoropolymer has evolved from a niche material to a versatile engineering solution across various industries. The technology behind PTFE has continuously advanced, driven by the need for materials with exceptional chemical resistance, low friction, and high-temperature stability.

The evolution of PTFE technology can be traced through several key milestones. Initially used in military applications during World War II, PTFE found its way into consumer products in the 1950s, most notably in non-stick cookware. The 1960s and 1970s saw the expansion of PTFE into industrial applications, including chemical processing equipment and aerospace components. In recent decades, advancements in polymer science have led to the development of modified PTFE materials with enhanced properties, such as improved wear resistance and lower cold flow.

The primary objective of PTFE technology development has been to exploit its unique properties while overcoming its limitations. These objectives include enhancing mechanical strength, improving processability, and expanding its temperature range of operation. Researchers and engineers have focused on developing new grades of PTFE with specific characteristics tailored for different applications, from medical implants to high-performance seals in extreme environments.

Current technological trends in PTFE research are centered on nanotechnology integration, surface modification techniques, and the development of PTFE composites. These advancements aim to create materials that maintain PTFE's beneficial properties while addressing its shortcomings, such as poor wear resistance and difficulties in bonding to other materials.

The future objectives for PTFE technology include the development of more environmentally friendly production methods, as traditional PTFE manufacturing processes involve the use of perfluorooctanoic acid (PFOA), which has raised environmental concerns. Additionally, there is a push towards creating PTFE-based materials with self-healing properties and improved recyclability, aligning with the growing emphasis on sustainable engineering solutions.

As we look towards breakthrough engineering applications, the goals for PTFE technology are multifaceted. They include expanding its use in emerging fields such as flexible electronics, advanced filtration systems, and next-generation energy storage devices. The pursuit of these objectives drives ongoing research into PTFE's molecular structure and processing techniques, aiming to unlock new possibilities for this versatile material in solving complex engineering challenges across diverse industries.

The evolution of PTFE technology can be traced through several key milestones. Initially used in military applications during World War II, PTFE found its way into consumer products in the 1950s, most notably in non-stick cookware. The 1960s and 1970s saw the expansion of PTFE into industrial applications, including chemical processing equipment and aerospace components. In recent decades, advancements in polymer science have led to the development of modified PTFE materials with enhanced properties, such as improved wear resistance and lower cold flow.

The primary objective of PTFE technology development has been to exploit its unique properties while overcoming its limitations. These objectives include enhancing mechanical strength, improving processability, and expanding its temperature range of operation. Researchers and engineers have focused on developing new grades of PTFE with specific characteristics tailored for different applications, from medical implants to high-performance seals in extreme environments.

Current technological trends in PTFE research are centered on nanotechnology integration, surface modification techniques, and the development of PTFE composites. These advancements aim to create materials that maintain PTFE's beneficial properties while addressing its shortcomings, such as poor wear resistance and difficulties in bonding to other materials.

The future objectives for PTFE technology include the development of more environmentally friendly production methods, as traditional PTFE manufacturing processes involve the use of perfluorooctanoic acid (PFOA), which has raised environmental concerns. Additionally, there is a push towards creating PTFE-based materials with self-healing properties and improved recyclability, aligning with the growing emphasis on sustainable engineering solutions.

As we look towards breakthrough engineering applications, the goals for PTFE technology are multifaceted. They include expanding its use in emerging fields such as flexible electronics, advanced filtration systems, and next-generation energy storage devices. The pursuit of these objectives drives ongoing research into PTFE's molecular structure and processing techniques, aiming to unlock new possibilities for this versatile material in solving complex engineering challenges across diverse industries.

Market Demand for PTFE Applications

The market demand for PTFE applications has been steadily growing across various industries due to its unique properties and versatile nature. PTFE, known for its exceptional chemical resistance, low friction coefficient, and high-temperature stability, has found widespread use in sectors ranging from automotive and aerospace to electronics and healthcare.

In the automotive industry, PTFE is increasingly utilized in engine components, fuel systems, and brake systems. The material's low friction properties contribute to improved fuel efficiency and reduced wear on moving parts. As the automotive sector continues to focus on sustainability and performance, the demand for PTFE in this area is expected to rise significantly.

The aerospace sector represents another major market for PTFE applications. The material's ability to withstand extreme temperatures and harsh chemical environments makes it ideal for use in aircraft engines, hydraulic systems, and seals. With the growing emphasis on lightweight materials in aerospace engineering, PTFE's low density further enhances its appeal in this industry.

In the electronics sector, PTFE's excellent dielectric properties and thermal stability have led to its increased use in printed circuit boards, cable insulation, and semiconductor manufacturing. As the demand for smaller, more powerful electronic devices continues to grow, so does the need for high-performance materials like PTFE.

The healthcare industry has also seen a surge in PTFE applications. The material's biocompatibility and non-stick properties make it valuable in medical devices, implants, and pharmaceutical processing equipment. With an aging global population and advancements in medical technology, the demand for PTFE in healthcare is projected to expand significantly.

Industrial applications of PTFE, such as in chemical processing, oil and gas, and food processing, continue to drive market growth. The material's resistance to corrosion and chemicals, coupled with its non-stick properties, make it indispensable in these sectors.

The global PTFE market is expected to experience substantial growth in the coming years. Factors such as increasing industrialization, technological advancements, and the growing demand for high-performance materials in emerging economies are likely to fuel this expansion. Additionally, ongoing research and development efforts aimed at enhancing PTFE's properties and exploring new applications are expected to open up new market opportunities.

However, it's important to note that environmental concerns regarding the production and disposal of PTFE may pose challenges to market growth. As a result, there is an increasing focus on developing more sustainable manufacturing processes and exploring eco-friendly alternatives, which could shape the future direction of the PTFE market.

In the automotive industry, PTFE is increasingly utilized in engine components, fuel systems, and brake systems. The material's low friction properties contribute to improved fuel efficiency and reduced wear on moving parts. As the automotive sector continues to focus on sustainability and performance, the demand for PTFE in this area is expected to rise significantly.

The aerospace sector represents another major market for PTFE applications. The material's ability to withstand extreme temperatures and harsh chemical environments makes it ideal for use in aircraft engines, hydraulic systems, and seals. With the growing emphasis on lightweight materials in aerospace engineering, PTFE's low density further enhances its appeal in this industry.

In the electronics sector, PTFE's excellent dielectric properties and thermal stability have led to its increased use in printed circuit boards, cable insulation, and semiconductor manufacturing. As the demand for smaller, more powerful electronic devices continues to grow, so does the need for high-performance materials like PTFE.

The healthcare industry has also seen a surge in PTFE applications. The material's biocompatibility and non-stick properties make it valuable in medical devices, implants, and pharmaceutical processing equipment. With an aging global population and advancements in medical technology, the demand for PTFE in healthcare is projected to expand significantly.

Industrial applications of PTFE, such as in chemical processing, oil and gas, and food processing, continue to drive market growth. The material's resistance to corrosion and chemicals, coupled with its non-stick properties, make it indispensable in these sectors.

The global PTFE market is expected to experience substantial growth in the coming years. Factors such as increasing industrialization, technological advancements, and the growing demand for high-performance materials in emerging economies are likely to fuel this expansion. Additionally, ongoing research and development efforts aimed at enhancing PTFE's properties and exploring new applications are expected to open up new market opportunities.

However, it's important to note that environmental concerns regarding the production and disposal of PTFE may pose challenges to market growth. As a result, there is an increasing focus on developing more sustainable manufacturing processes and exploring eco-friendly alternatives, which could shape the future direction of the PTFE market.

PTFE Properties and Engineering Challenges

Polytetrafluoroethylene (PTFE), commonly known as Teflon, is a synthetic fluoropolymer with exceptional properties that make it valuable in various engineering applications. Its unique combination of characteristics presents both opportunities and challenges for breakthrough engineering solutions.

PTFE exhibits remarkable chemical inertness, resisting reaction with most chemicals and solvents. This property makes it ideal for use in corrosive environments and applications requiring high purity. The material's hydrophobic nature contributes to its non-stick properties, making it useful in cookware and industrial equipment where material adhesion is undesirable.

One of PTFE's most notable features is its extremely low coefficient of friction, the lowest of any known solid material. This property enables its use in bearings, seals, and other applications where reducing friction is critical. Additionally, PTFE maintains its properties over a wide temperature range, from -200°C to +260°C, making it suitable for both cryogenic and high-temperature applications.

PTFE's electrical insulation properties are exceptional, with high dielectric strength and low dielectric loss. These characteristics make it valuable in the electronics industry for cable insulation and printed circuit board substrates. The material's low dielectric constant also makes it useful in high-frequency applications.

Despite its many advantages, PTFE presents several engineering challenges. Its poor thermal conductivity limits its use in heat transfer applications. The material's high thermal expansion coefficient can cause issues in applications where dimensional stability is crucial, especially when paired with materials having different thermal expansion rates.

PTFE's low surface energy, while beneficial for non-stick applications, makes it difficult to bond with other materials. This property complicates the creation of composite materials or the joining of PTFE components with other parts. Engineers must develop specialized techniques or surface treatments to overcome this limitation.

The material's creep behavior under load, particularly at elevated temperatures, can lead to dimensional changes over time. This characteristic requires careful consideration in applications where maintaining precise dimensions is critical. Additionally, PTFE's poor wear resistance in certain conditions necessitates the development of reinforced or filled variants to improve its tribological properties.

In conclusion, while PTFE offers unique and valuable properties for engineering applications, its use also presents significant challenges. Overcoming these limitations through innovative material modifications, novel design approaches, and advanced manufacturing techniques is key to unlocking PTFE's full potential in breakthrough engineering solutions.

PTFE exhibits remarkable chemical inertness, resisting reaction with most chemicals and solvents. This property makes it ideal for use in corrosive environments and applications requiring high purity. The material's hydrophobic nature contributes to its non-stick properties, making it useful in cookware and industrial equipment where material adhesion is undesirable.

One of PTFE's most notable features is its extremely low coefficient of friction, the lowest of any known solid material. This property enables its use in bearings, seals, and other applications where reducing friction is critical. Additionally, PTFE maintains its properties over a wide temperature range, from -200°C to +260°C, making it suitable for both cryogenic and high-temperature applications.

PTFE's electrical insulation properties are exceptional, with high dielectric strength and low dielectric loss. These characteristics make it valuable in the electronics industry for cable insulation and printed circuit board substrates. The material's low dielectric constant also makes it useful in high-frequency applications.

Despite its many advantages, PTFE presents several engineering challenges. Its poor thermal conductivity limits its use in heat transfer applications. The material's high thermal expansion coefficient can cause issues in applications where dimensional stability is crucial, especially when paired with materials having different thermal expansion rates.

PTFE's low surface energy, while beneficial for non-stick applications, makes it difficult to bond with other materials. This property complicates the creation of composite materials or the joining of PTFE components with other parts. Engineers must develop specialized techniques or surface treatments to overcome this limitation.

The material's creep behavior under load, particularly at elevated temperatures, can lead to dimensional changes over time. This characteristic requires careful consideration in applications where maintaining precise dimensions is critical. Additionally, PTFE's poor wear resistance in certain conditions necessitates the development of reinforced or filled variants to improve its tribological properties.

In conclusion, while PTFE offers unique and valuable properties for engineering applications, its use also presents significant challenges. Overcoming these limitations through innovative material modifications, novel design approaches, and advanced manufacturing techniques is key to unlocking PTFE's full potential in breakthrough engineering solutions.

Current PTFE Engineering Solutions

01 PTFE manufacturing and processing methods

Various techniques for manufacturing and processing PTFE, including molding, extrusion, and sintering. These methods aim to improve the material's properties and performance for specific applications.- PTFE manufacturing and processing methods: Various techniques for manufacturing and processing PTFE, including molding, extrusion, and sintering. These methods aim to improve the material's properties and performance for specific applications.

- PTFE composites and blends: Development of PTFE-based composites and blends with other materials to enhance specific properties such as wear resistance, thermal conductivity, or electrical properties. These combinations create materials with unique characteristics for specialized applications.

- Surface modification of PTFE: Techniques for modifying the surface of PTFE to improve its adhesion, wettability, or compatibility with other materials. These modifications can include chemical treatments, plasma treatments, or the application of coatings.

- PTFE in membrane and filtration applications: Utilization of PTFE in the development of membranes and filtration systems, taking advantage of its non-stick and chemical-resistant properties. These applications can include water treatment, gas separation, and industrial filtration processes.

- PTFE in coating and lubrication technologies: Application of PTFE in coating and lubrication technologies, leveraging its low friction and non-stick properties. This includes the development of PTFE-based coatings for cookware, industrial equipment, and lubricants for various mechanical systems.

02 PTFE composites and blends

Development of PTFE-based composites and blends with other materials to enhance specific properties such as wear resistance, thermal conductivity, or electrical properties. These combinations create materials with unique characteristics for specialized applications.Expand Specific Solutions03 Surface modification of PTFE

Techniques for modifying the surface of PTFE to improve its adhesion, wettability, or compatibility with other materials. These modifications can include chemical treatments, plasma treatments, or the application of coatings.Expand Specific Solutions04 PTFE in membrane and filtration applications

Utilization of PTFE in the development of membranes and filtration systems due to its non-stick and chemical-resistant properties. These applications can include water treatment, gas separation, and industrial filtration processes.Expand Specific Solutions05 PTFE in coating and lubrication technologies

Application of PTFE in coating and lubrication technologies to reduce friction, improve wear resistance, and enhance non-stick properties in various industrial and consumer products.Expand Specific Solutions

Key PTFE Manufacturers and Suppliers

The use of PTFE for breakthrough engineering is in a mature stage of development, with a substantial market size and high technological readiness. Key players like DuPont de Nemours, W. L. Gore & Associates, and 3M Innovative Properties are driving innovation in this field. The competitive landscape is characterized by established companies with strong R&D capabilities, focusing on developing advanced PTFE applications across various industries. Emerging players from Asia, such as Shengyi Technology and Junkosha, are also making significant contributions, expanding the global market and fostering technological advancements in PTFE engineering solutions.

DAIKIN INDUSTRIES Ltd.

Technical Solution: Daikin Industries has made significant advancements in PTFE technology for engineering applications. Their NEOFLON™ PTFE resins offer high purity and thermal stability, suitable for demanding industrial environments[1]. Daikin has developed modified PTFE grades with improved mechanical properties and processability, expanding the material's use in automotive and aerospace industries[2]. Their research focuses on creating PTFE-based composites that combine low friction and chemical resistance with enhanced wear resistance and load-bearing capabilities[3]. Daikin's innovations also include PTFE micropowders for use as additives in lubricants and coatings, improving performance in extreme conditions[4].

Strengths: Strong focus on fluoropolymer technology, extensive product range, global manufacturing capabilities. Weaknesses: Potential environmental concerns related to fluoropolymer production, competition from alternative materials.

DuPont de Nemours, Inc.

Technical Solution: DuPont has developed advanced PTFE formulations for breakthrough engineering applications. Their Teflon™ PTFE fluoropolymer resins offer exceptional chemical resistance, low friction, and high-temperature stability[1]. DuPont's PTFE innovations include modified PTFE grades with improved mechanical properties and processability[2]. They have also developed PTFE-based composites that combine the material's inherent properties with enhanced strength and wear resistance[3]. DuPont's research focuses on expanding PTFE's use in critical industries such as automotive, aerospace, and electronics, where its unique properties can enable significant performance improvements and weight reduction[4].

Strengths: Extensive R&D capabilities, wide range of PTFE grades for various applications, strong brand recognition. Weaknesses: High production costs, potential environmental concerns related to fluoropolymer manufacturing.

Innovative PTFE Formulations and Processes

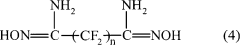

Crosslinkable polytetrafluoroethylene composition, cross-linked polytetrafluoroethylene powder, polytetrafluoro-ethylene moldings, resin blend compositions, and resin blend moldings

PatentInactiveCN101171296A

Innovation

- A cross-linked polytetrafluoroethylene composition containing polytetrafluoroethylene and a cross-linking agent is used to undergo a cross-linking reaction by heating to form a cyclic structure. The obtained cross-linked body can be manufactured by conventional methods such as compression molding and maintains Original strength and surface properties, avoiding anisotropy and inhomogeneity.

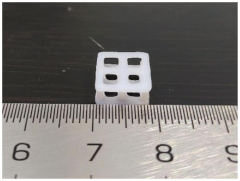

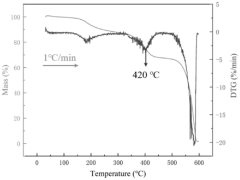

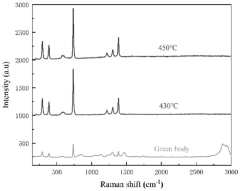

3D printing preparation method of polytetrafluoroethylene high-performance lattice structure

PatentPendingCN118219579A

Innovation

- Using light-curing 3D printing technology combined with Creo software to design the lattice structure, using materials such as polytetrafluoroethylene dispersion, cross-linking agent, photosensitive resin monomer and photoinitiator, and improving mechanics through multi-stage heat treatment (degreasing, sintering, recrystallization) performance, reduce the heat treatment temperature of the blank, and enhance printing accuracy and size control.

Environmental Impact of PTFE Usage

The environmental impact of PTFE usage is a critical consideration in its application for breakthrough engineering. PTFE, while offering exceptional chemical resistance and low friction properties, presents several environmental challenges throughout its lifecycle. During production, the use of perfluorooctanoic acid (PFOA) as a processing aid has raised concerns due to its persistence in the environment and potential health risks. However, many manufacturers have transitioned to alternative processing methods to mitigate these issues.

In terms of product use, PTFE's durability and resistance to degradation contribute to its longevity, reducing the frequency of replacement and associated waste. This characteristic aligns with sustainable design principles by extending product lifecycles. Nevertheless, the very properties that make PTFE valuable also pose challenges for end-of-life management. PTFE is not biodegradable and can persist in the environment for extended periods if not properly managed.

Recycling PTFE presents technical difficulties due to its high melting point and chemical inertness. Traditional recycling methods are often ineffective, leading to the exploration of advanced recycling technologies. Some promising approaches include chemical depolymerization and high-temperature pyrolysis, which aim to break down PTFE into its constituent monomers for reuse.

The incineration of PTFE waste can release harmful substances, including hydrogen fluoride and other fluorinated compounds. Consequently, specialized waste management protocols are essential to minimize environmental impact. Advanced incineration facilities equipped with proper emission control systems can mitigate these risks, but their availability and cost remain limiting factors in many regions.

In aquatic environments, the potential for PTFE to break down into microplastics is an emerging concern. While PTFE itself is considered non-toxic, the long-term effects of PTFE microparticles on marine ecosystems are not fully understood and require further research.

Efforts to improve the environmental profile of PTFE usage focus on several areas. These include developing more eco-friendly production processes, enhancing recycling capabilities, and exploring bio-based alternatives that maintain PTFE's desirable properties while offering improved end-of-life options. Additionally, the principles of green chemistry are being applied to create new fluoropolymers with reduced environmental impact.

As engineering applications continue to push the boundaries of material performance, balancing the unique benefits of PTFE with environmental stewardship remains a key challenge. Innovations in material science and processing technologies offer promising avenues for mitigating the environmental impact of PTFE while harnessing its breakthrough potential in engineering applications.

In terms of product use, PTFE's durability and resistance to degradation contribute to its longevity, reducing the frequency of replacement and associated waste. This characteristic aligns with sustainable design principles by extending product lifecycles. Nevertheless, the very properties that make PTFE valuable also pose challenges for end-of-life management. PTFE is not biodegradable and can persist in the environment for extended periods if not properly managed.

Recycling PTFE presents technical difficulties due to its high melting point and chemical inertness. Traditional recycling methods are often ineffective, leading to the exploration of advanced recycling technologies. Some promising approaches include chemical depolymerization and high-temperature pyrolysis, which aim to break down PTFE into its constituent monomers for reuse.

The incineration of PTFE waste can release harmful substances, including hydrogen fluoride and other fluorinated compounds. Consequently, specialized waste management protocols are essential to minimize environmental impact. Advanced incineration facilities equipped with proper emission control systems can mitigate these risks, but their availability and cost remain limiting factors in many regions.

In aquatic environments, the potential for PTFE to break down into microplastics is an emerging concern. While PTFE itself is considered non-toxic, the long-term effects of PTFE microparticles on marine ecosystems are not fully understood and require further research.

Efforts to improve the environmental profile of PTFE usage focus on several areas. These include developing more eco-friendly production processes, enhancing recycling capabilities, and exploring bio-based alternatives that maintain PTFE's desirable properties while offering improved end-of-life options. Additionally, the principles of green chemistry are being applied to create new fluoropolymers with reduced environmental impact.

As engineering applications continue to push the boundaries of material performance, balancing the unique benefits of PTFE with environmental stewardship remains a key challenge. Innovations in material science and processing technologies offer promising avenues for mitigating the environmental impact of PTFE while harnessing its breakthrough potential in engineering applications.

PTFE Recycling and Sustainability Initiatives

As the global focus on environmental sustainability intensifies, PTFE recycling and sustainability initiatives have gained significant traction in recent years. The unique properties of PTFE, including its chemical inertness and high thermal stability, present both challenges and opportunities in recycling efforts.

Traditional recycling methods for PTFE have been limited due to its resistance to chemical breakdown and high melting point. However, innovative approaches are emerging to address these challenges. One promising technique involves the use of supercritical water to depolymerize PTFE, allowing for the recovery of valuable monomers that can be used to produce new PTFE products. This process not only reduces waste but also decreases the demand for virgin raw materials.

Another area of focus is the development of mechanical recycling methods. These processes involve grinding used PTFE products into fine powders, which can then be reprocessed into new materials. While this approach does not fully restore the original properties of PTFE, it provides a viable option for creating lower-grade PTFE products or composites.

In addition to recycling, sustainability initiatives are exploring ways to reduce the environmental impact of PTFE production. This includes research into bio-based alternatives that could potentially replace traditional PTFE in certain applications. Some companies are investigating the use of plant-based precursors to create fluoropolymers with similar properties to PTFE, offering a more sustainable production pathway.

The PTFE industry is also making strides in improving manufacturing processes to minimize waste and energy consumption. Advanced production techniques, such as precision molding and additive manufacturing, are being employed to reduce material waste during fabrication. Furthermore, efforts are underway to optimize the energy efficiency of PTFE production facilities, reducing the overall carbon footprint of the industry.

Collaboration between industry players, research institutions, and regulatory bodies is crucial for advancing PTFE sustainability. Several initiatives have been launched to promote best practices in PTFE recycling and to establish industry-wide standards for sustainable production. These efforts aim to create a circular economy for PTFE, where materials are reused and recycled to the greatest extent possible.

As sustainability becomes increasingly important in engineering and manufacturing, the development of effective PTFE recycling methods and sustainable production practices will play a critical role in ensuring the continued use of this versatile material in breakthrough engineering applications.

Traditional recycling methods for PTFE have been limited due to its resistance to chemical breakdown and high melting point. However, innovative approaches are emerging to address these challenges. One promising technique involves the use of supercritical water to depolymerize PTFE, allowing for the recovery of valuable monomers that can be used to produce new PTFE products. This process not only reduces waste but also decreases the demand for virgin raw materials.

Another area of focus is the development of mechanical recycling methods. These processes involve grinding used PTFE products into fine powders, which can then be reprocessed into new materials. While this approach does not fully restore the original properties of PTFE, it provides a viable option for creating lower-grade PTFE products or composites.

In addition to recycling, sustainability initiatives are exploring ways to reduce the environmental impact of PTFE production. This includes research into bio-based alternatives that could potentially replace traditional PTFE in certain applications. Some companies are investigating the use of plant-based precursors to create fluoropolymers with similar properties to PTFE, offering a more sustainable production pathway.

The PTFE industry is also making strides in improving manufacturing processes to minimize waste and energy consumption. Advanced production techniques, such as precision molding and additive manufacturing, are being employed to reduce material waste during fabrication. Furthermore, efforts are underway to optimize the energy efficiency of PTFE production facilities, reducing the overall carbon footprint of the industry.

Collaboration between industry players, research institutions, and regulatory bodies is crucial for advancing PTFE sustainability. Several initiatives have been launched to promote best practices in PTFE recycling and to establish industry-wide standards for sustainable production. These efforts aim to create a circular economy for PTFE, where materials are reused and recycled to the greatest extent possible.

As sustainability becomes increasingly important in engineering and manufacturing, the development of effective PTFE recycling methods and sustainable production practices will play a critical role in ensuring the continued use of this versatile material in breakthrough engineering applications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!