Analyzing PTFE‑powered droplet manipulation in lab‑on‑chip devices

JUN 27, 20258 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

PTFE Droplet Tech Background

Polytetrafluoroethylene (PTFE) has emerged as a pivotal material in the development of lab-on-chip devices, particularly in the realm of droplet manipulation. The journey of PTFE in this field began in the late 1990s when researchers first recognized its potential for creating hydrophobic surfaces essential for droplet-based microfluidics. PTFE's unique properties, including its extremely low surface energy and chemical inertness, made it an ideal candidate for controlling the behavior of liquid droplets at the microscale.

The evolution of PTFE-powered droplet manipulation has been closely tied to the broader development of microfluidic technologies. Initially, PTFE was primarily used as a coating material to modify the surface properties of microfluidic channels. However, as the field progressed, more sophisticated applications of PTFE emerged, including the creation of patterned surfaces and the development of PTFE-based actuators for active droplet control.

A significant milestone in this technological progression was the introduction of electrowetting-on-dielectric (EWOD) systems in the early 2000s. PTFE played a crucial role in these systems, serving as the hydrophobic layer that enabled precise control over droplet movement through electrical manipulation. This breakthrough opened up new possibilities for digital microfluidics and lab-on-chip applications.

The current trajectory of PTFE-powered droplet manipulation is focused on enhancing the precision, speed, and versatility of droplet control. Researchers are exploring novel PTFE-based materials and structures, such as nanostructured PTFE surfaces, to achieve even greater control over droplet behavior. Additionally, there is a growing interest in combining PTFE with other materials and technologies to create hybrid systems that can perform complex fluidic operations.

Looking ahead, the field is poised for further advancements. The integration of PTFE-based droplet manipulation with other emerging technologies, such as artificial intelligence and advanced sensing systems, is expected to lead to more sophisticated and autonomous lab-on-chip devices. These developments aim to address current limitations in areas such as droplet size control, multi-droplet interactions, and the handling of complex biological samples.

The overarching goal of this technological evolution is to create more efficient, reliable, and versatile lab-on-chip devices capable of performing a wide range of analytical and diagnostic tasks. By harnessing the unique properties of PTFE, researchers and engineers are working towards miniaturized systems that can revolutionize fields such as medical diagnostics, environmental monitoring, and chemical synthesis.

The evolution of PTFE-powered droplet manipulation has been closely tied to the broader development of microfluidic technologies. Initially, PTFE was primarily used as a coating material to modify the surface properties of microfluidic channels. However, as the field progressed, more sophisticated applications of PTFE emerged, including the creation of patterned surfaces and the development of PTFE-based actuators for active droplet control.

A significant milestone in this technological progression was the introduction of electrowetting-on-dielectric (EWOD) systems in the early 2000s. PTFE played a crucial role in these systems, serving as the hydrophobic layer that enabled precise control over droplet movement through electrical manipulation. This breakthrough opened up new possibilities for digital microfluidics and lab-on-chip applications.

The current trajectory of PTFE-powered droplet manipulation is focused on enhancing the precision, speed, and versatility of droplet control. Researchers are exploring novel PTFE-based materials and structures, such as nanostructured PTFE surfaces, to achieve even greater control over droplet behavior. Additionally, there is a growing interest in combining PTFE with other materials and technologies to create hybrid systems that can perform complex fluidic operations.

Looking ahead, the field is poised for further advancements. The integration of PTFE-based droplet manipulation with other emerging technologies, such as artificial intelligence and advanced sensing systems, is expected to lead to more sophisticated and autonomous lab-on-chip devices. These developments aim to address current limitations in areas such as droplet size control, multi-droplet interactions, and the handling of complex biological samples.

The overarching goal of this technological evolution is to create more efficient, reliable, and versatile lab-on-chip devices capable of performing a wide range of analytical and diagnostic tasks. By harnessing the unique properties of PTFE, researchers and engineers are working towards miniaturized systems that can revolutionize fields such as medical diagnostics, environmental monitoring, and chemical synthesis.

Lab-on-Chip Market Analysis

The lab-on-chip (LOC) market has been experiencing significant growth in recent years, driven by the increasing demand for point-of-care diagnostics, personalized medicine, and miniaturized analytical systems. The global LOC market was valued at approximately $5.2 billion in 2020 and is projected to reach $10.8 billion by 2026, growing at a CAGR of 12.9% during the forecast period.

The market is segmented based on technology, application, and end-user. In terms of technology, microfluidics dominates the market, accounting for the largest share due to its ability to manipulate small volumes of fluids precisely. The application segment is led by clinical diagnostics, followed by genomics and proteomics research. Healthcare facilities, including hospitals and diagnostic centers, represent the largest end-user segment.

Geographically, North America holds the largest market share, attributed to the presence of major players, advanced healthcare infrastructure, and substantial R&D investments. However, the Asia-Pacific region is expected to witness the highest growth rate, driven by increasing healthcare expenditure, rising awareness about personalized medicine, and growing adoption of LOC technologies in emerging economies like China and India.

Key market drivers include the rising prevalence of chronic diseases, the need for rapid and accurate diagnostic tools, and the advantages of LOC devices in terms of portability, cost-effectiveness, and reduced sample volume requirements. The COVID-19 pandemic has further accelerated market growth, highlighting the importance of rapid, on-site testing capabilities.

Challenges facing the LOC market include the high cost of device development, regulatory hurdles, and the need for standardization across different platforms. However, ongoing technological advancements, such as the integration of artificial intelligence and the development of paper-based microfluidic devices, are expected to create new opportunities for market expansion.

The competitive landscape of the LOC market is characterized by the presence of both established players and innovative startups. Major companies in this space include Danaher Corporation, Thermo Fisher Scientific, Roche Diagnostics, and Abbott Laboratories. These companies are focusing on strategic collaborations, mergers and acquisitions, and product innovations to maintain their market positions and drive growth.

The market is segmented based on technology, application, and end-user. In terms of technology, microfluidics dominates the market, accounting for the largest share due to its ability to manipulate small volumes of fluids precisely. The application segment is led by clinical diagnostics, followed by genomics and proteomics research. Healthcare facilities, including hospitals and diagnostic centers, represent the largest end-user segment.

Geographically, North America holds the largest market share, attributed to the presence of major players, advanced healthcare infrastructure, and substantial R&D investments. However, the Asia-Pacific region is expected to witness the highest growth rate, driven by increasing healthcare expenditure, rising awareness about personalized medicine, and growing adoption of LOC technologies in emerging economies like China and India.

Key market drivers include the rising prevalence of chronic diseases, the need for rapid and accurate diagnostic tools, and the advantages of LOC devices in terms of portability, cost-effectiveness, and reduced sample volume requirements. The COVID-19 pandemic has further accelerated market growth, highlighting the importance of rapid, on-site testing capabilities.

Challenges facing the LOC market include the high cost of device development, regulatory hurdles, and the need for standardization across different platforms. However, ongoing technological advancements, such as the integration of artificial intelligence and the development of paper-based microfluidic devices, are expected to create new opportunities for market expansion.

The competitive landscape of the LOC market is characterized by the presence of both established players and innovative startups. Major companies in this space include Danaher Corporation, Thermo Fisher Scientific, Roche Diagnostics, and Abbott Laboratories. These companies are focusing on strategic collaborations, mergers and acquisitions, and product innovations to maintain their market positions and drive growth.

PTFE Droplet Tech Challenges

The manipulation of droplets in lab-on-chip devices using PTFE (Polytetrafluoroethylene) surfaces presents several significant technical challenges that researchers and engineers must address. These challenges stem from the unique properties of PTFE and the complex physics of droplet behavior at the microscale.

One of the primary challenges is achieving precise control over droplet movement. PTFE's hydrophobic nature, while beneficial for droplet formation, can make it difficult to guide droplets along specific paths or to precise locations within the device. The low surface energy of PTFE can lead to unpredictable droplet behavior, especially when dealing with small volumes typical in microfluidic applications.

Another significant hurdle is maintaining consistent droplet size and shape. The interaction between the liquid and the PTFE surface can cause variations in droplet geometry, which is critical for accurate analysis and reproducible results in lab-on-chip applications. Factors such as surface roughness, temperature fluctuations, and chemical composition of the droplets can all influence this interaction, making it challenging to achieve uniformity across multiple experiments.

The integration of PTFE-based droplet manipulation systems with other lab-on-chip components poses additional challenges. PTFE's chemical inertness, while advantageous in many ways, can make it difficult to bond or integrate with other materials commonly used in microfluidic devices. This can lead to issues in device fabrication and may limit the complexity of achievable designs.

Scaling up PTFE-powered droplet manipulation for high-throughput applications is another area of concern. As the number of droplets and the complexity of manipulation increase, so does the likelihood of errors and inconsistencies. Developing robust systems that can handle large numbers of droplets simultaneously while maintaining precision and reliability is a significant technical challenge.

The long-term stability and durability of PTFE surfaces in droplet manipulation devices is also an important consideration. While PTFE is known for its chemical resistance, prolonged exposure to various reagents and repeated droplet movements may alter its surface properties over time. This could lead to changes in droplet behavior and affect the overall performance and reliability of the device.

Lastly, the detection and sensing of droplets on PTFE surfaces present unique challenges. The optical properties of PTFE and its interaction with liquids can make it difficult to accurately track droplet position, size, and composition using conventional sensing methods. Developing reliable and sensitive detection systems that can work effectively with PTFE-based droplet manipulation is crucial for many lab-on-chip applications.

One of the primary challenges is achieving precise control over droplet movement. PTFE's hydrophobic nature, while beneficial for droplet formation, can make it difficult to guide droplets along specific paths or to precise locations within the device. The low surface energy of PTFE can lead to unpredictable droplet behavior, especially when dealing with small volumes typical in microfluidic applications.

Another significant hurdle is maintaining consistent droplet size and shape. The interaction between the liquid and the PTFE surface can cause variations in droplet geometry, which is critical for accurate analysis and reproducible results in lab-on-chip applications. Factors such as surface roughness, temperature fluctuations, and chemical composition of the droplets can all influence this interaction, making it challenging to achieve uniformity across multiple experiments.

The integration of PTFE-based droplet manipulation systems with other lab-on-chip components poses additional challenges. PTFE's chemical inertness, while advantageous in many ways, can make it difficult to bond or integrate with other materials commonly used in microfluidic devices. This can lead to issues in device fabrication and may limit the complexity of achievable designs.

Scaling up PTFE-powered droplet manipulation for high-throughput applications is another area of concern. As the number of droplets and the complexity of manipulation increase, so does the likelihood of errors and inconsistencies. Developing robust systems that can handle large numbers of droplets simultaneously while maintaining precision and reliability is a significant technical challenge.

The long-term stability and durability of PTFE surfaces in droplet manipulation devices is also an important consideration. While PTFE is known for its chemical resistance, prolonged exposure to various reagents and repeated droplet movements may alter its surface properties over time. This could lead to changes in droplet behavior and affect the overall performance and reliability of the device.

Lastly, the detection and sensing of droplets on PTFE surfaces present unique challenges. The optical properties of PTFE and its interaction with liquids can make it difficult to accurately track droplet position, size, and composition using conventional sensing methods. Developing reliable and sensitive detection systems that can work effectively with PTFE-based droplet manipulation is crucial for many lab-on-chip applications.

Current PTFE Droplet Solutions

01 PTFE-coated surfaces for droplet manipulation

PTFE coatings are used to create hydrophobic surfaces that facilitate droplet movement and control. These surfaces reduce friction and allow for precise manipulation of droplets in microfluidic devices, enhancing the efficiency of various analytical and diagnostic processes.- PTFE-coated surfaces for droplet manipulation: PTFE coatings are used to create hydrophobic surfaces that facilitate droplet movement and control. These surfaces reduce friction and allow for precise manipulation of liquid droplets in microfluidic devices and other applications.

- Electrowetting-based droplet manipulation: Electrowetting techniques are employed to manipulate droplets on PTFE-coated surfaces. By applying electrical potentials, the wettability of the surface can be dynamically altered, enabling controlled movement and positioning of droplets.

- Microfluidic devices for droplet manipulation: PTFE-based microfluidic devices are designed for precise droplet manipulation in various applications, including chemical analysis, biological assays, and drug discovery. These devices incorporate channels, reservoirs, and electrodes to control droplet movement and reactions.

- Droplet generation and sorting techniques: Advanced techniques for generating and sorting droplets using PTFE-based systems are developed. These methods enable the creation of uniform droplets and their subsequent sorting based on specific properties, enhancing the efficiency of droplet-based assays and experiments.

- Integration of sensors and actuators: PTFE-powered droplet manipulation systems are enhanced by integrating various sensors and actuators. These components allow for real-time monitoring and control of droplet properties, enabling more complex and automated droplet manipulation processes.

02 Electrowetting-based droplet manipulation

Electrowetting techniques are employed to manipulate droplets on PTFE-coated surfaces. By applying electrical potentials, the wettability of the surface can be dynamically altered, allowing for controlled movement, merging, and splitting of droplets in microfluidic systems.Expand Specific Solutions03 Digital microfluidic devices using PTFE

PTFE is utilized in the construction of digital microfluidic devices for droplet manipulation. These devices enable precise control over small volumes of liquids, facilitating applications in chemistry, biology, and medical diagnostics through automated droplet operations.Expand Specific Solutions04 PTFE-based droplet generators and sorters

PTFE materials are incorporated into droplet generators and sorters for microfluidic applications. These systems allow for the creation of uniform droplets and their subsequent sorting based on specific characteristics, enhancing the capabilities of high-throughput screening and analysis.Expand Specific Solutions05 Integration of PTFE in lab-on-a-chip devices

PTFE is integrated into lab-on-a-chip devices to improve droplet manipulation capabilities. The hydrophobic properties of PTFE enable efficient droplet transport, mixing, and analysis within miniaturized systems, advancing point-of-care diagnostics and analytical chemistry applications.Expand Specific Solutions

Key Lab-on-Chip Players

The field of PTFE-powered droplet manipulation in lab-on-chip devices is in its early growth stage, with significant potential for expansion. The market size is relatively small but growing rapidly as microfluidic technologies gain traction in various applications. The technology's maturity is advancing, with key players like Duke University, Waters Technology Corp., and Koninklijke Philips NV leading research and development efforts. Companies such as BOE Technology Group and Xi'an Jiaotong University are also contributing to technological advancements. While still evolving, the technology shows promise for revolutionizing point-of-care diagnostics and drug discovery processes, attracting interest from both academic institutions and industry players.

Duke University

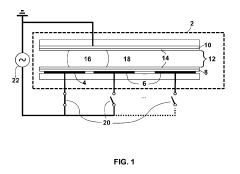

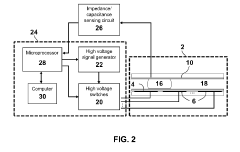

Technical Solution: Duke University has developed a novel approach for PTFE-powered droplet manipulation in lab-on-chip devices. Their technique utilizes a PTFE-coated surface with patterned electrodes to achieve precise control over droplet movement. The system employs electrowetting-on-dielectric (EWOD) principles, where applied voltages alter the wettability of the PTFE surface, enabling droplet actuation[1]. This method allows for droplet splitting, merging, and transport with high precision. The university has also integrated this technology with microfluidic channels to create a comprehensive lab-on-chip platform for various biomedical applications, including DNA amplification and protein analysis[3].

Strengths: High precision droplet control, versatile applications in biomedical research. Weaknesses: May require complex electrode patterning, potential for PTFE degradation over time.

Waters Technology Corp.

Technical Solution: Waters Technology Corp. has developed a PTFE-based droplet manipulation system for their lab-on-chip devices, focusing on analytical chemistry applications. Their approach utilizes a PTFE-coated microfluidic chip with integrated electrodes for droplet control. The system employs a combination of electrowetting and dielectrophoresis to manipulate droplets containing analytes[2]. Waters has optimized this technology for use in their mass spectrometry systems, allowing for precise sample preparation and introduction. The company has also developed specialized software for automated droplet routing and analysis, enhancing the overall efficiency of their lab-on-chip platforms[4].

Strengths: Integration with mass spectrometry systems, automated droplet handling. Weaknesses: May be limited to specific analytical chemistry applications, potentially high cost for integrated systems.

PTFE Droplet Core Innovations

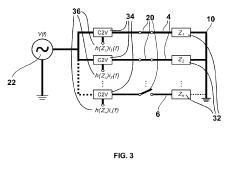

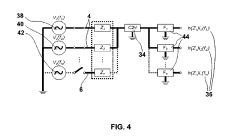

Multiplexed droplet actuation and sensing in digital microfluidics

PatentActiveUS20190201902A1

Innovation

- A multi-droplet sensing and actuation system that applies a linearly independent alternating current signal to each discrete actuation electrode, encoding the electrode's identity, and processes the combined impedance signal to decode the volume between each electrode and its corresponding counter electrode, enabling real-time tracking of liquid volume and droplet position.

Rapid and continuous analyte processing in droplet microfluidic devices

PatentActiveUS20180250678A1

Innovation

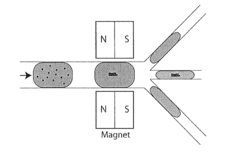

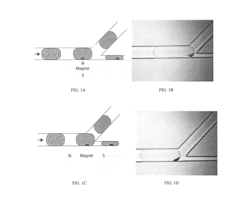

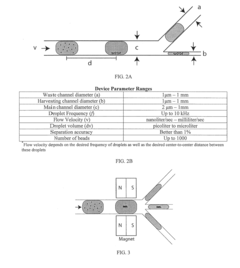

- The use of microfluidic devices with functionalized particles responsive to external fields, such as magnets or electric fields, to isolate and concentrate analytes within droplets, allowing for continuous processing and high-throughput analysis by manipulating droplets through channels with junctions that facilitate separation and dilution.

Microfluidics Regulations

Microfluidics, as an emerging field with significant potential in lab-on-chip devices, is subject to a complex regulatory landscape. The regulations governing PTFE-powered droplet manipulation in microfluidic systems span multiple domains, including medical devices, in vitro diagnostics, and laboratory equipment. These regulations aim to ensure the safety, efficacy, and reliability of microfluidic devices and their applications.

In the United States, the Food and Drug Administration (FDA) plays a crucial role in regulating microfluidic devices used for medical purposes. The FDA classifies these devices based on their intended use and risk level, with Class I devices being low-risk and Class III devices being high-risk. PTFE-powered droplet manipulation systems may fall under different classifications depending on their specific applications, such as diagnostics or drug delivery.

The European Union has implemented the In Vitro Diagnostic Regulation (IVDR) and the Medical Device Regulation (MDR), which came into effect in 2022. These regulations have significant implications for microfluidic devices, including those utilizing PTFE-powered droplet manipulation. Manufacturers must demonstrate compliance with these regulations through rigorous testing, risk assessment, and quality management systems.

International standards also play a crucial role in the regulation of microfluidic devices. The International Organization for Standardization (ISO) has developed several standards relevant to microfluidics, such as ISO 13485 for quality management systems in medical devices and ISO 14971 for risk management in medical devices. These standards provide guidelines for manufacturers to ensure the quality and safety of their microfluidic products.

Environmental regulations are another important consideration for PTFE-powered droplet manipulation systems. The use of PTFE, a fluoropolymer, may be subject to regulations concerning perfluoroalkyl and polyfluoroalkyl substances (PFAS). Various countries and regions have implemented or are considering restrictions on PFAS, which could impact the development and use of PTFE-based microfluidic devices.

As the field of microfluidics continues to advance, regulatory frameworks are evolving to keep pace with technological developments. Researchers and manufacturers working on PTFE-powered droplet manipulation in lab-on-chip devices must stay informed about these regulatory changes and ensure compliance throughout the product development lifecycle. This includes considering regulatory requirements during the design phase, conducting appropriate testing and validation, and maintaining proper documentation for regulatory submissions.

In the United States, the Food and Drug Administration (FDA) plays a crucial role in regulating microfluidic devices used for medical purposes. The FDA classifies these devices based on their intended use and risk level, with Class I devices being low-risk and Class III devices being high-risk. PTFE-powered droplet manipulation systems may fall under different classifications depending on their specific applications, such as diagnostics or drug delivery.

The European Union has implemented the In Vitro Diagnostic Regulation (IVDR) and the Medical Device Regulation (MDR), which came into effect in 2022. These regulations have significant implications for microfluidic devices, including those utilizing PTFE-powered droplet manipulation. Manufacturers must demonstrate compliance with these regulations through rigorous testing, risk assessment, and quality management systems.

International standards also play a crucial role in the regulation of microfluidic devices. The International Organization for Standardization (ISO) has developed several standards relevant to microfluidics, such as ISO 13485 for quality management systems in medical devices and ISO 14971 for risk management in medical devices. These standards provide guidelines for manufacturers to ensure the quality and safety of their microfluidic products.

Environmental regulations are another important consideration for PTFE-powered droplet manipulation systems. The use of PTFE, a fluoropolymer, may be subject to regulations concerning perfluoroalkyl and polyfluoroalkyl substances (PFAS). Various countries and regions have implemented or are considering restrictions on PFAS, which could impact the development and use of PTFE-based microfluidic devices.

As the field of microfluidics continues to advance, regulatory frameworks are evolving to keep pace with technological developments. Researchers and manufacturers working on PTFE-powered droplet manipulation in lab-on-chip devices must stay informed about these regulatory changes and ensure compliance throughout the product development lifecycle. This includes considering regulatory requirements during the design phase, conducting appropriate testing and validation, and maintaining proper documentation for regulatory submissions.

PTFE Environmental Impact

The environmental impact of PTFE (Polytetrafluoroethylene) in lab-on-chip devices is a critical consideration for researchers and manufacturers in the field of microfluidics. PTFE, known for its hydrophobic properties, plays a crucial role in droplet manipulation within these miniaturized systems. However, its production, use, and disposal raise significant environmental concerns.

PTFE manufacturing involves the use of perfluorooctanoic acid (PFOA), a persistent organic pollutant. Although efforts have been made to phase out PFOA, the environmental legacy of its production remains. The synthesis of PTFE also requires substantial energy inputs, contributing to greenhouse gas emissions. Moreover, the fluoropolymer industry's reliance on fluorine-based raw materials raises questions about resource depletion and the long-term sustainability of PTFE production.

In lab-on-chip applications, the use of PTFE coatings or components presents both advantages and challenges from an environmental perspective. While PTFE's chemical inertness and durability contribute to the longevity of devices, potentially reducing waste, these same properties make PTFE difficult to recycle or biodegrade. The disposal of PTFE-containing lab-on-chip devices often results in incineration or landfilling, both of which can lead to the release of harmful fluorinated compounds into the environment.

The potential for PTFE microparticle shedding during device operation is another environmental concern. These particles can enter aquatic ecosystems, potentially impacting marine life and entering the food chain. The bioaccumulation of PTFE-derived compounds in organisms is an area of ongoing research, with implications for both environmental and human health.

Efforts to mitigate the environmental impact of PTFE in lab-on-chip devices include the development of alternative materials and surface treatments. Researchers are exploring bio-based hydrophobic coatings and environmentally friendly manufacturing processes to reduce the reliance on fluoropolymers. Additionally, advancements in PTFE recycling technologies and the implementation of closed-loop manufacturing systems offer promising avenues for reducing the environmental footprint of PTFE-based microfluidic devices.

As the field of lab-on-chip technology continues to evolve, balancing the performance benefits of PTFE with environmental sustainability remains a key challenge. Future developments in this area will likely focus on green chemistry approaches, lifecycle assessments, and the integration of environmental considerations into the design and manufacturing processes of microfluidic devices.

PTFE manufacturing involves the use of perfluorooctanoic acid (PFOA), a persistent organic pollutant. Although efforts have been made to phase out PFOA, the environmental legacy of its production remains. The synthesis of PTFE also requires substantial energy inputs, contributing to greenhouse gas emissions. Moreover, the fluoropolymer industry's reliance on fluorine-based raw materials raises questions about resource depletion and the long-term sustainability of PTFE production.

In lab-on-chip applications, the use of PTFE coatings or components presents both advantages and challenges from an environmental perspective. While PTFE's chemical inertness and durability contribute to the longevity of devices, potentially reducing waste, these same properties make PTFE difficult to recycle or biodegrade. The disposal of PTFE-containing lab-on-chip devices often results in incineration or landfilling, both of which can lead to the release of harmful fluorinated compounds into the environment.

The potential for PTFE microparticle shedding during device operation is another environmental concern. These particles can enter aquatic ecosystems, potentially impacting marine life and entering the food chain. The bioaccumulation of PTFE-derived compounds in organisms is an area of ongoing research, with implications for both environmental and human health.

Efforts to mitigate the environmental impact of PTFE in lab-on-chip devices include the development of alternative materials and surface treatments. Researchers are exploring bio-based hydrophobic coatings and environmentally friendly manufacturing processes to reduce the reliance on fluoropolymers. Additionally, advancements in PTFE recycling technologies and the implementation of closed-loop manufacturing systems offer promising avenues for reducing the environmental footprint of PTFE-based microfluidic devices.

As the field of lab-on-chip technology continues to evolve, balancing the performance benefits of PTFE with environmental sustainability remains a key challenge. Future developments in this area will likely focus on green chemistry approaches, lifecycle assessments, and the integration of environmental considerations into the design and manufacturing processes of microfluidic devices.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!