Investigating PTFE thermal barrier coatings for aero‑engine components

PTFE Coating Evolution

The evolution of PTFE thermal barrier coatings for aero-engine components has been a significant area of research and development in the aerospace industry. This journey began in the mid-20th century when the unique properties of polytetrafluoroethylene (PTFE) were first recognized for their potential in high-temperature applications.

In the 1960s, PTFE was primarily used in non-stick cookware and industrial applications. However, aerospace engineers soon realized its potential for thermal insulation in aircraft engines. The initial attempts to use PTFE in aero-engines focused on simple coatings applied to metal substrates, providing a basic level of thermal protection.

The 1970s saw a shift towards more sophisticated PTFE-based composites. Researchers began experimenting with PTFE-matrix materials reinforced with various fillers such as glass fibers, carbon fibers, and ceramic particles. These composites offered improved mechanical properties and thermal stability compared to pure PTFE coatings.

A major breakthrough came in the 1980s with the development of plasma-sprayed PTFE coatings. This technique allowed for the creation of thicker, more uniform coatings with enhanced adhesion to metal substrates. The plasma-sprayed PTFE coatings demonstrated superior thermal barrier properties and improved durability in high-temperature environments.

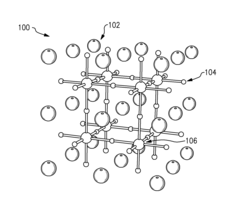

The 1990s marked the beginning of nanomaterial integration into PTFE coatings. Researchers started incorporating nanoparticles such as silica, alumina, and carbon nanotubes into PTFE matrices. These nanocomposite coatings exhibited exceptional thermal resistance and mechanical strength, pushing the boundaries of what was previously achievable with PTFE-based materials.

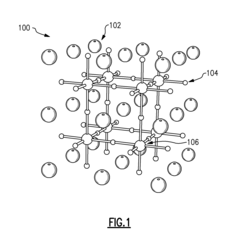

In the early 2000s, the focus shifted towards multi-layer coating systems. Engineers developed complex architectures combining PTFE with other high-performance materials like ceramics and metals. These multi-layer systems provided not only thermal insulation but also enhanced erosion resistance and oxidation protection.

The past decade has seen advancements in smart PTFE coatings. These innovative materials incorporate phase-change materials or shape memory polymers, allowing for adaptive thermal management in response to changing engine conditions. Additionally, researchers have been exploring the potential of graphene-reinforced PTFE coatings, which promise even greater thermal conductivity and mechanical strength.

Recent developments include the use of computational modeling and machine learning algorithms to optimize PTFE coating compositions and structures. These tools enable rapid iteration and testing of new formulations, accelerating the pace of innovation in thermal barrier coatings for aero-engine components.

Aero-Engine Demands

The aerospace industry, particularly the aero-engine sector, has been experiencing a growing demand for advanced thermal barrier coatings (TBCs) to enhance the performance and durability of engine components. This demand is driven by several factors, including the need for increased engine efficiency, reduced fuel consumption, and extended component lifespan.

Aero-engine manufacturers are constantly pushing the boundaries of operating temperatures to achieve higher thrust-to-weight ratios and improved fuel efficiency. This has led to a significant increase in the thermal loads experienced by engine components, especially in the hot sections such as turbine blades and combustion chambers. As a result, there is a pressing need for more effective thermal protection systems.

PTFE (Polytetrafluoroethylene) thermal barrier coatings have emerged as a promising solution to address these challenges. The unique properties of PTFE, including its low thermal conductivity, high temperature resistance, and excellent chemical stability, make it an attractive candidate for aero-engine applications. PTFE coatings can potentially provide superior thermal insulation, reducing the heat transfer to critical engine components and allowing for higher operating temperatures.

The market for PTFE thermal barrier coatings in the aero-engine sector is expected to grow significantly in the coming years. This growth is fueled by the increasing production of commercial and military aircraft, as well as the ongoing efforts to retrofit existing engines with more advanced thermal protection systems. Additionally, the rising focus on sustainable aviation and the need to reduce carbon emissions are driving the adoption of technologies that can improve engine efficiency.

Engine manufacturers are also seeking coatings that can withstand the harsh operating conditions of modern aero-engines, including high temperatures, oxidative environments, and erosive particles. PTFE coatings have shown promise in addressing these requirements, offering potential improvements in durability and resistance to thermal cycling compared to traditional ceramic-based TBCs.

Furthermore, the aerospace industry's shift towards more electric and hybrid-electric propulsion systems has created new thermal management challenges. PTFE thermal barrier coatings could play a crucial role in protecting sensitive electronic components and managing heat distribution in these advanced propulsion systems.

As environmental regulations become more stringent, there is an increasing demand for coatings that can contribute to noise reduction in aero-engines. PTFE's inherent damping properties make it an attractive option for acoustic insulation applications, potentially addressing both thermal and noise reduction requirements simultaneously.

PTFE Coating Challenges

The application of PTFE (polytetrafluoroethylene) thermal barrier coatings for aero-engine components presents several significant challenges that researchers and engineers must address. One of the primary obstacles is the inherent low thermal stability of PTFE at elevated temperatures. While PTFE exhibits excellent non-stick and low friction properties, its performance begins to degrade at temperatures above 260°C (500°F), which is well below the operating temperatures of many aero-engine components.

Another critical challenge is achieving adequate adhesion between the PTFE coating and the substrate material of the engine components. The non-stick nature of PTFE, which makes it desirable for many applications, also makes it difficult to bond securely to metal surfaces. This poor adhesion can lead to coating delamination or flaking during the extreme thermal cycling and mechanical stresses experienced in aero-engine environments.

The thickness control of PTFE coatings poses another significant hurdle. Thermal barrier coatings require precise thickness to provide optimal insulation without compromising the aerodynamic properties of engine components. However, achieving uniform and controlled thickness with PTFE coatings, especially on complex geometries typical in aero-engines, remains a technical challenge.

Durability and wear resistance of PTFE coatings in the harsh aero-engine environment is another area of concern. The coating must withstand not only high temperatures but also erosive particles, oxidative atmospheres, and potential chemical interactions with combustion products. The soft nature of PTFE makes it susceptible to wear and erosion, potentially limiting its long-term effectiveness as a thermal barrier.

Furthermore, the thermal conductivity of PTFE, while lower than many metals, is still higher than traditional ceramic thermal barrier coatings. This necessitates the development of composite or multi-layer coating systems to achieve the desired thermal insulation properties, adding complexity to the coating process and potentially increasing costs.

The integration of PTFE coatings into existing manufacturing processes for aero-engine components presents additional challenges. Adapting current production lines to incorporate PTFE coating application without compromising efficiency or increasing production time significantly is a considerable task for manufacturers.

Lastly, the environmental and health concerns associated with the production and application of PTFE coatings must be addressed. The potential release of harmful fluoropolymer fumes during high-temperature application or in the event of coating failure during engine operation raises safety and regulatory compliance issues that need careful consideration and mitigation strategies.

PTFE Application Methods

01 PTFE-based thermal barrier coatings

PTFE (polytetrafluoroethylene) is used as a base material for thermal barrier coatings due to its excellent heat resistance and low thermal conductivity. These coatings can be applied to various surfaces to provide thermal insulation and protection against high temperatures.- PTFE-based thermal barrier coatings: PTFE (polytetrafluoroethylene) is used as a base material for thermal barrier coatings due to its excellent heat resistance and low thermal conductivity. These coatings can be applied to various substrates to provide thermal insulation and protection against high temperatures. The PTFE-based coatings can be enhanced with additional components to improve their performance and durability.

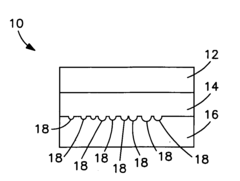

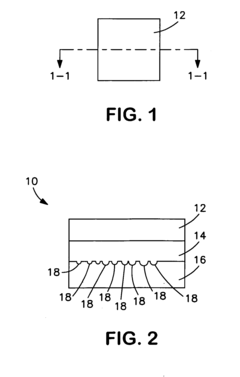

- Multilayer thermal barrier coating systems: Thermal barrier coatings can be designed as multilayer systems to enhance their effectiveness. These systems typically consist of a bond coat, a ceramic top coat, and sometimes intermediate layers. The multilayer structure helps improve adhesion, thermal insulation, and overall coating performance. Different materials and application techniques can be used for each layer to optimize the coating's properties.

- Ceramic-based thermal barrier coatings: Ceramic materials are widely used in thermal barrier coatings due to their high temperature resistance and low thermal conductivity. Common ceramic materials include yttria-stabilized zirconia (YSZ) and other oxide ceramics. These coatings can be applied using various methods such as plasma spraying or electron beam physical vapor deposition (EB-PVD) to create a protective layer against high temperatures.

- Nanostructured thermal barrier coatings: Nanostructured materials are being incorporated into thermal barrier coatings to enhance their performance. These coatings utilize nanoscale features or nanoparticles to improve thermal insulation, mechanical properties, and durability. Nanostructured coatings can offer advantages such as increased strain tolerance and reduced thermal conductivity compared to conventional coatings.

- Environmental barrier coatings for thermal protection: Environmental barrier coatings (EBCs) are developed to provide both thermal protection and resistance to environmental degradation. These coatings are designed to protect underlying materials from high temperatures, oxidation, and corrosion in harsh environments. EBCs often incorporate multiple layers of different materials to achieve the desired protective properties.

02 Multi-layer thermal barrier coating systems

Thermal barrier coatings often consist of multiple layers, including a bond coat, a ceramic top coat, and sometimes intermediate layers. This multi-layer structure enhances the overall performance and durability of the coating system, providing better thermal insulation and protection against thermal cycling.Expand Specific Solutions03 Application methods for PTFE thermal barrier coatings

Various application methods are used for depositing PTFE thermal barrier coatings, including spray coating, plasma spraying, and chemical vapor deposition. These techniques allow for precise control of coating thickness and composition, ensuring optimal thermal barrier performance.Expand Specific Solutions04 Additives and fillers for enhanced thermal barrier properties

Incorporating additives and fillers into PTFE-based thermal barrier coatings can significantly improve their performance. These additives may include ceramic particles, metal oxides, or other heat-resistant materials that enhance the coating's thermal insulation properties and mechanical strength.Expand Specific Solutions05 Surface preparation and coating adhesion

Proper surface preparation is crucial for ensuring strong adhesion of PTFE thermal barrier coatings to the substrate. Techniques such as grit blasting, chemical etching, or plasma treatment are employed to improve the surface characteristics and promote better bonding between the coating and the substrate material.Expand Specific Solutions

Aerospace Coating Firms

The investigation of PTFE thermal barrier coatings for aero-engine components is in a mature development stage, with significant market potential in the aerospace industry. The global market for thermal barrier coatings is expected to grow substantially, driven by increasing demand for fuel-efficient and high-performance aircraft engines. Key players in this field include United Technologies Corp., Pratt & Whitney, and General Electric Company, who are investing heavily in research and development to enhance coating performance and durability. Universities like Beihang University and Xi'an Jiaotong University are also contributing to advancements in this technology. The competition is intense, with companies focusing on developing innovative coating materials and application techniques to gain a competitive edge in this high-value market.

Honeywell International Technologies Ltd.

Mitsubishi Hitachi Power Systems

PTFE Coating Innovations

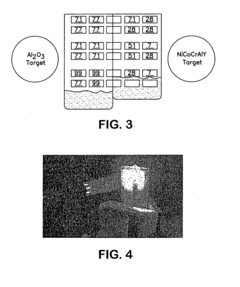

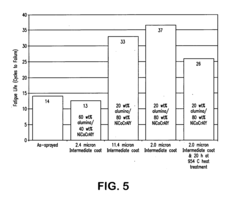

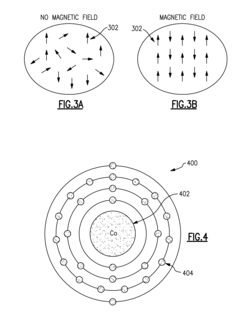

- Development of a nanocomposite coating with an intermediate thermal expansion coefficient (TCE) that fills the valleys of the rough bond coat, reducing interfacial stresses by matching the thermal expansion properties of the metallic bond coat and ceramic top coat, and incorporating nanoparticles to enhance thermal insulation and reduce thermal conductivity.

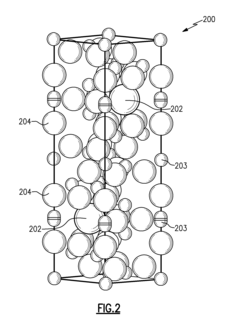

- A dual-function thermal barrier and RF absorber coating composition, comprising a Lanthanide-Aluminum-Iron-Oxygen system with magnetic properties, applied as a single layer to provide both heat insulation and RF scattering, featuring strain tolerance and thermal expansion matching that of aircraft engine components, allowing plasma spraying and compatibility with superalloys.

Environmental Impact

The environmental impact of PTFE thermal barrier coatings for aero-engine components is a critical consideration in their development and application. These coatings play a significant role in improving engine efficiency and reducing fuel consumption, which indirectly contributes to lower greenhouse gas emissions from aircraft operations.

PTFE thermal barrier coatings help to maintain optimal operating temperatures within the engine, allowing for more efficient combustion processes. This increased efficiency translates to reduced fuel consumption, which in turn leads to decreased carbon dioxide emissions per flight. The potential for fuel savings can be substantial, with estimates suggesting that advanced thermal barrier coatings could contribute to a 1-2% reduction in overall fuel consumption for commercial aircraft.

However, the production and application of PTFE coatings also have environmental implications that must be carefully evaluated. The manufacturing process of PTFE involves the use of fluoropolymers, which can have negative environmental impacts if not properly managed. Emissions of perfluorooctanoic acid (PFOA) and other perfluorinated compounds during production have been a concern, prompting industry efforts to develop alternative manufacturing methods with reduced environmental footprints.

The durability and longevity of PTFE thermal barrier coatings also factor into their environmental impact assessment. Coatings that can withstand high temperatures and harsh operating conditions for extended periods reduce the frequency of engine maintenance and component replacement. This longevity not only improves the overall lifecycle efficiency of aero-engines but also minimizes waste generation and resource consumption associated with frequent part replacements.

End-of-life considerations for PTFE-coated components present another environmental challenge. The disposal or recycling of these materials requires specialized processes to prevent the release of harmful substances into the environment. Research into environmentally friendly disposal methods and potential recycling techniques for PTFE coatings is ongoing, aiming to close the loop in the material's lifecycle and minimize its long-term environmental impact.

Advancements in PTFE coating technologies are also focusing on reducing the thickness of the coatings while maintaining their thermal barrier properties. Thinner coatings not only improve engine performance but also decrease the amount of material used, further reducing the environmental footprint of their production and application.

As the aviation industry continues to prioritize sustainability, the development of PTFE thermal barrier coatings must balance performance improvements with environmental considerations. This includes exploring bio-based alternatives, optimizing production processes to minimize emissions, and investing in research to enhance the recyclability of coated components at the end of their service life.

Certification Standards

Certification standards play a crucial role in ensuring the safety, reliability, and performance of PTFE thermal barrier coatings for aero-engine components. These standards are established by regulatory bodies and industry organizations to maintain consistency and quality across the aerospace sector.

The Federal Aviation Administration (FAA) in the United States and the European Union Aviation Safety Agency (EASA) are the primary regulatory bodies responsible for setting certification standards for aerospace components. These agencies work closely with industry stakeholders to develop and update standards that address the unique challenges posed by PTFE thermal barrier coatings.

One of the key certification standards for PTFE thermal barrier coatings is the SAE Aerospace Material Specification (AMS) 2432. This specification outlines the requirements for the application of polytetrafluoroethylene (PTFE) coatings on metallic substrates used in aerospace applications. It covers aspects such as surface preparation, coating thickness, adhesion, and thermal cycling resistance.

The ISO 9001 quality management system standard is also relevant for manufacturers of PTFE thermal barrier coatings. This standard ensures that companies have robust processes in place for consistent product quality and continuous improvement. Additionally, the AS9100 standard, which is specific to the aerospace industry, builds upon ISO 9001 and addresses the unique requirements of aerospace manufacturers and suppliers.

Thermal performance testing is a critical aspect of certification for PTFE thermal barrier coatings. Standards such as ASTM E903 and ASTM C1371 are used to measure solar reflectance and emittance, respectively. These properties are essential for evaluating the coating's ability to reflect heat and maintain thermal efficiency in aero-engine components.

Durability and environmental resistance are also key factors in certification. Standards like ASTM G154 for accelerated weathering and ASTM B117 for salt spray resistance are employed to assess the coating's long-term performance under various environmental conditions. These tests help ensure that the PTFE thermal barrier coatings can withstand the harsh operating conditions experienced by aero-engine components.

Certification standards also address the environmental and health aspects of PTFE thermal barrier coatings. The Registration, Evaluation, Authorisation and Restriction of Chemicals (REACH) regulation in the European Union sets guidelines for the use of chemicals in manufacturing processes, including those used in PTFE coatings. Compliance with REACH ensures that the coatings meet stringent environmental and safety requirements.

As technology advances and new materials are developed, certification standards for PTFE thermal barrier coatings continue to evolve. Industry organizations such as SAE International and the Aerospace Industries Association (AIA) work collaboratively with regulatory bodies to update existing standards and develop new ones that address emerging technologies and challenges in the field of thermal barrier coatings for aero-engine components.