How to Use PTFE for Enhanced Acoustic Solutions?

JUN 27, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

PTFE Acoustics Background

Polytetrafluoroethylene (PTFE), commonly known as Teflon, has been a revolutionary material in various industries since its accidental discovery by Roy Plunkett in 1938. While initially recognized for its non-stick and heat-resistant properties, PTFE has found its way into acoustic applications due to its unique characteristics.

PTFE's acoustic properties stem from its molecular structure, which consists of long chains of carbon atoms fully bonded with fluorine atoms. This structure results in a material with low surface energy, high chemical resistance, and excellent thermal stability. These properties, combined with PTFE's low density and high porosity, make it an ideal candidate for acoustic solutions.

In the realm of acoustics, PTFE has been utilized in various forms, including foams, membranes, and coatings. PTFE foams, in particular, have gained significant attention due to their ability to absorb sound waves across a wide frequency range. The open-cell structure of PTFE foams allows sound waves to penetrate the material, where they are converted into heat energy through friction and viscous losses.

The acoustic performance of PTFE is further enhanced by its hydrophobic nature. Unlike many traditional acoustic materials that can absorb moisture and degrade over time, PTFE remains stable in humid environments. This characteristic makes it particularly suitable for outdoor acoustic applications or in areas with high humidity levels.

PTFE's role in acoustic solutions extends beyond simple sound absorption. Its low coefficient of friction and self-lubricating properties make it an excellent material for reducing mechanical noise in various systems. PTFE coatings and components can significantly decrease friction-induced vibrations and squeaks in mechanical assemblies, contributing to overall noise reduction.

The versatility of PTFE in acoustic applications has led to its adoption in diverse sectors. In the automotive industry, PTFE-based materials are used in engine compartments and vehicle interiors to reduce noise, vibration, and harshness (NVH). The aerospace sector utilizes PTFE in aircraft cabins and engine nacelles for sound insulation. In building acoustics, PTFE membranes and coatings are employed in architectural fabrics and acoustic panels to enhance sound absorption while maintaining aesthetic appeal.

As environmental concerns grow, PTFE's durability and recyclability have become increasingly important. Unlike some acoustic materials that degrade and require frequent replacement, PTFE-based solutions offer long-term performance, reducing waste and the need for frequent maintenance. Additionally, advancements in PTFE recycling technologies are making it possible to repurpose used PTFE materials, further enhancing its sustainability profile in acoustic applications.

PTFE's acoustic properties stem from its molecular structure, which consists of long chains of carbon atoms fully bonded with fluorine atoms. This structure results in a material with low surface energy, high chemical resistance, and excellent thermal stability. These properties, combined with PTFE's low density and high porosity, make it an ideal candidate for acoustic solutions.

In the realm of acoustics, PTFE has been utilized in various forms, including foams, membranes, and coatings. PTFE foams, in particular, have gained significant attention due to their ability to absorb sound waves across a wide frequency range. The open-cell structure of PTFE foams allows sound waves to penetrate the material, where they are converted into heat energy through friction and viscous losses.

The acoustic performance of PTFE is further enhanced by its hydrophobic nature. Unlike many traditional acoustic materials that can absorb moisture and degrade over time, PTFE remains stable in humid environments. This characteristic makes it particularly suitable for outdoor acoustic applications or in areas with high humidity levels.

PTFE's role in acoustic solutions extends beyond simple sound absorption. Its low coefficient of friction and self-lubricating properties make it an excellent material for reducing mechanical noise in various systems. PTFE coatings and components can significantly decrease friction-induced vibrations and squeaks in mechanical assemblies, contributing to overall noise reduction.

The versatility of PTFE in acoustic applications has led to its adoption in diverse sectors. In the automotive industry, PTFE-based materials are used in engine compartments and vehicle interiors to reduce noise, vibration, and harshness (NVH). The aerospace sector utilizes PTFE in aircraft cabins and engine nacelles for sound insulation. In building acoustics, PTFE membranes and coatings are employed in architectural fabrics and acoustic panels to enhance sound absorption while maintaining aesthetic appeal.

As environmental concerns grow, PTFE's durability and recyclability have become increasingly important. Unlike some acoustic materials that degrade and require frequent replacement, PTFE-based solutions offer long-term performance, reducing waste and the need for frequent maintenance. Additionally, advancements in PTFE recycling technologies are making it possible to repurpose used PTFE materials, further enhancing its sustainability profile in acoustic applications.

Acoustic Market Analysis

The acoustic market has experienced significant growth in recent years, driven by increasing demand for noise reduction solutions across various industries. The global acoustic materials market is projected to reach a substantial value by 2027, with a compound annual growth rate (CAGR) exceeding 6% during the forecast period. This growth is primarily attributed to the rising awareness of noise pollution and its adverse effects on human health and well-being.

The automotive sector represents a major segment of the acoustic market, as manufacturers strive to enhance the driving experience by reducing cabin noise. The construction industry also contributes significantly to market growth, with a focus on improving sound insulation in residential and commercial buildings. Additionally, the industrial sector is increasingly adopting acoustic solutions to comply with workplace safety regulations and improve worker productivity.

PTFE (Polytetrafluoroethylene) has emerged as a promising material for acoustic applications due to its unique properties. Its low friction coefficient, chemical inertness, and excellent thermal stability make it suitable for a wide range of acoustic solutions. The market for PTFE-based acoustic materials is expected to grow at a faster rate than the overall acoustic market, driven by its superior performance in challenging environments.

The demand for PTFE in acoustic applications is particularly strong in the aerospace and defense industries, where high-performance materials are essential. The material's ability to maintain its properties under extreme conditions makes it ideal for use in aircraft engines, military equipment, and other high-stress environments. Furthermore, the healthcare sector is showing increased interest in PTFE-based acoustic solutions for medical devices and equipment.

Geographically, North America and Europe dominate the acoustic market, with Asia-Pacific emerging as the fastest-growing region. The rapid industrialization and urbanization in countries like China and India are driving the demand for acoustic solutions in these regions. The increasing focus on sustainable and eco-friendly materials is also influencing market trends, with PTFE gaining attention due to its recyclability and long lifespan.

Key players in the acoustic market are investing heavily in research and development to innovate new PTFE-based solutions. These efforts are focused on improving the material's acoustic properties, reducing production costs, and expanding its applications. Collaborations between material manufacturers and end-users are becoming more common, leading to the development of customized acoustic solutions tailored to specific industry needs.

The automotive sector represents a major segment of the acoustic market, as manufacturers strive to enhance the driving experience by reducing cabin noise. The construction industry also contributes significantly to market growth, with a focus on improving sound insulation in residential and commercial buildings. Additionally, the industrial sector is increasingly adopting acoustic solutions to comply with workplace safety regulations and improve worker productivity.

PTFE (Polytetrafluoroethylene) has emerged as a promising material for acoustic applications due to its unique properties. Its low friction coefficient, chemical inertness, and excellent thermal stability make it suitable for a wide range of acoustic solutions. The market for PTFE-based acoustic materials is expected to grow at a faster rate than the overall acoustic market, driven by its superior performance in challenging environments.

The demand for PTFE in acoustic applications is particularly strong in the aerospace and defense industries, where high-performance materials are essential. The material's ability to maintain its properties under extreme conditions makes it ideal for use in aircraft engines, military equipment, and other high-stress environments. Furthermore, the healthcare sector is showing increased interest in PTFE-based acoustic solutions for medical devices and equipment.

Geographically, North America and Europe dominate the acoustic market, with Asia-Pacific emerging as the fastest-growing region. The rapid industrialization and urbanization in countries like China and India are driving the demand for acoustic solutions in these regions. The increasing focus on sustainable and eco-friendly materials is also influencing market trends, with PTFE gaining attention due to its recyclability and long lifespan.

Key players in the acoustic market are investing heavily in research and development to innovate new PTFE-based solutions. These efforts are focused on improving the material's acoustic properties, reducing production costs, and expanding its applications. Collaborations between material manufacturers and end-users are becoming more common, leading to the development of customized acoustic solutions tailored to specific industry needs.

PTFE Acoustic Challenges

Polytetrafluoroethylene (PTFE) has gained significant attention in acoustic applications due to its unique properties. However, the use of PTFE for enhanced acoustic solutions presents several challenges that researchers and engineers must address to fully harness its potential.

One of the primary challenges is optimizing the acoustic performance of PTFE-based materials. While PTFE exhibits excellent sound absorption properties, particularly at high frequencies, its effectiveness across a broader frequency range remains limited. This limitation necessitates the development of composite materials or structural modifications to enhance PTFE's acoustic performance across a wider spectrum.

The integration of PTFE into existing acoustic systems poses another significant challenge. Many current acoustic solutions rely on traditional materials, and incorporating PTFE may require redesigning entire systems or developing new manufacturing processes. This integration challenge extends to ensuring compatibility with other materials used in acoustic applications, as PTFE's non-stick properties can complicate bonding and assembly processes.

Durability and long-term performance of PTFE in acoustic applications present additional concerns. While PTFE is known for its chemical resistance and stability, its behavior under prolonged exposure to various environmental conditions, including temperature fluctuations and humidity, in acoustic settings requires further investigation. Ensuring that PTFE-based acoustic solutions maintain their performance over extended periods is crucial for their widespread adoption.

Cost-effectiveness remains a significant hurdle in the widespread implementation of PTFE for acoustic solutions. The material's relatively high cost compared to traditional acoustic materials may limit its application in price-sensitive markets. Developing cost-efficient production methods and demonstrating the long-term value proposition of PTFE-based solutions are essential to overcome this challenge.

Another challenge lies in the customization of PTFE for specific acoustic requirements. Different acoustic applications demand varying levels of sound absorption, reflection, or diffusion. Tailoring PTFE's properties to meet these diverse needs while maintaining its core benefits requires advanced material engineering and processing techniques.

Regulatory compliance and environmental considerations also pose challenges in the use of PTFE for acoustic solutions. Ensuring that PTFE-based acoustic materials meet safety standards, fire resistance requirements, and environmental regulations is crucial. Additionally, addressing concerns about the environmental impact of PTFE production and disposal is necessary for sustainable implementation.

Addressing these challenges requires a multidisciplinary approach, combining expertise in materials science, acoustic engineering, and manufacturing processes. Overcoming these hurdles will pave the way for innovative PTFE-based acoustic solutions that can significantly enhance sound quality and control across various applications.

One of the primary challenges is optimizing the acoustic performance of PTFE-based materials. While PTFE exhibits excellent sound absorption properties, particularly at high frequencies, its effectiveness across a broader frequency range remains limited. This limitation necessitates the development of composite materials or structural modifications to enhance PTFE's acoustic performance across a wider spectrum.

The integration of PTFE into existing acoustic systems poses another significant challenge. Many current acoustic solutions rely on traditional materials, and incorporating PTFE may require redesigning entire systems or developing new manufacturing processes. This integration challenge extends to ensuring compatibility with other materials used in acoustic applications, as PTFE's non-stick properties can complicate bonding and assembly processes.

Durability and long-term performance of PTFE in acoustic applications present additional concerns. While PTFE is known for its chemical resistance and stability, its behavior under prolonged exposure to various environmental conditions, including temperature fluctuations and humidity, in acoustic settings requires further investigation. Ensuring that PTFE-based acoustic solutions maintain their performance over extended periods is crucial for their widespread adoption.

Cost-effectiveness remains a significant hurdle in the widespread implementation of PTFE for acoustic solutions. The material's relatively high cost compared to traditional acoustic materials may limit its application in price-sensitive markets. Developing cost-efficient production methods and demonstrating the long-term value proposition of PTFE-based solutions are essential to overcome this challenge.

Another challenge lies in the customization of PTFE for specific acoustic requirements. Different acoustic applications demand varying levels of sound absorption, reflection, or diffusion. Tailoring PTFE's properties to meet these diverse needs while maintaining its core benefits requires advanced material engineering and processing techniques.

Regulatory compliance and environmental considerations also pose challenges in the use of PTFE for acoustic solutions. Ensuring that PTFE-based acoustic materials meet safety standards, fire resistance requirements, and environmental regulations is crucial. Additionally, addressing concerns about the environmental impact of PTFE production and disposal is necessary for sustainable implementation.

Addressing these challenges requires a multidisciplinary approach, combining expertise in materials science, acoustic engineering, and manufacturing processes. Overcoming these hurdles will pave the way for innovative PTFE-based acoustic solutions that can significantly enhance sound quality and control across various applications.

Current PTFE Solutions

01 PTFE acoustic absorption properties

PTFE exhibits excellent acoustic absorption properties due to its porous structure and high sound absorption coefficient. When used in acoustic applications, PTFE can effectively reduce noise and improve sound quality in various environments.- PTFE acoustic absorption properties: PTFE exhibits excellent acoustic absorption properties due to its porous structure and high surface area. When used in acoustic applications, PTFE can effectively reduce noise and vibrations across a wide frequency range. Its unique molecular structure allows it to absorb sound waves, making it an ideal material for soundproofing and noise reduction in various industries.

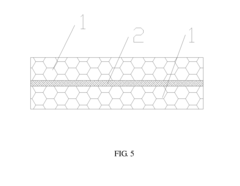

- PTFE-based acoustic composites: Acoustic composites incorporating PTFE demonstrate enhanced sound absorption capabilities. These composites often combine PTFE with other materials such as fibers, foams, or particles to create structures with improved acoustic performance. The synergistic effect of PTFE and other components results in materials with superior sound damping and insulation properties, suitable for use in automotive, aerospace, and construction industries.

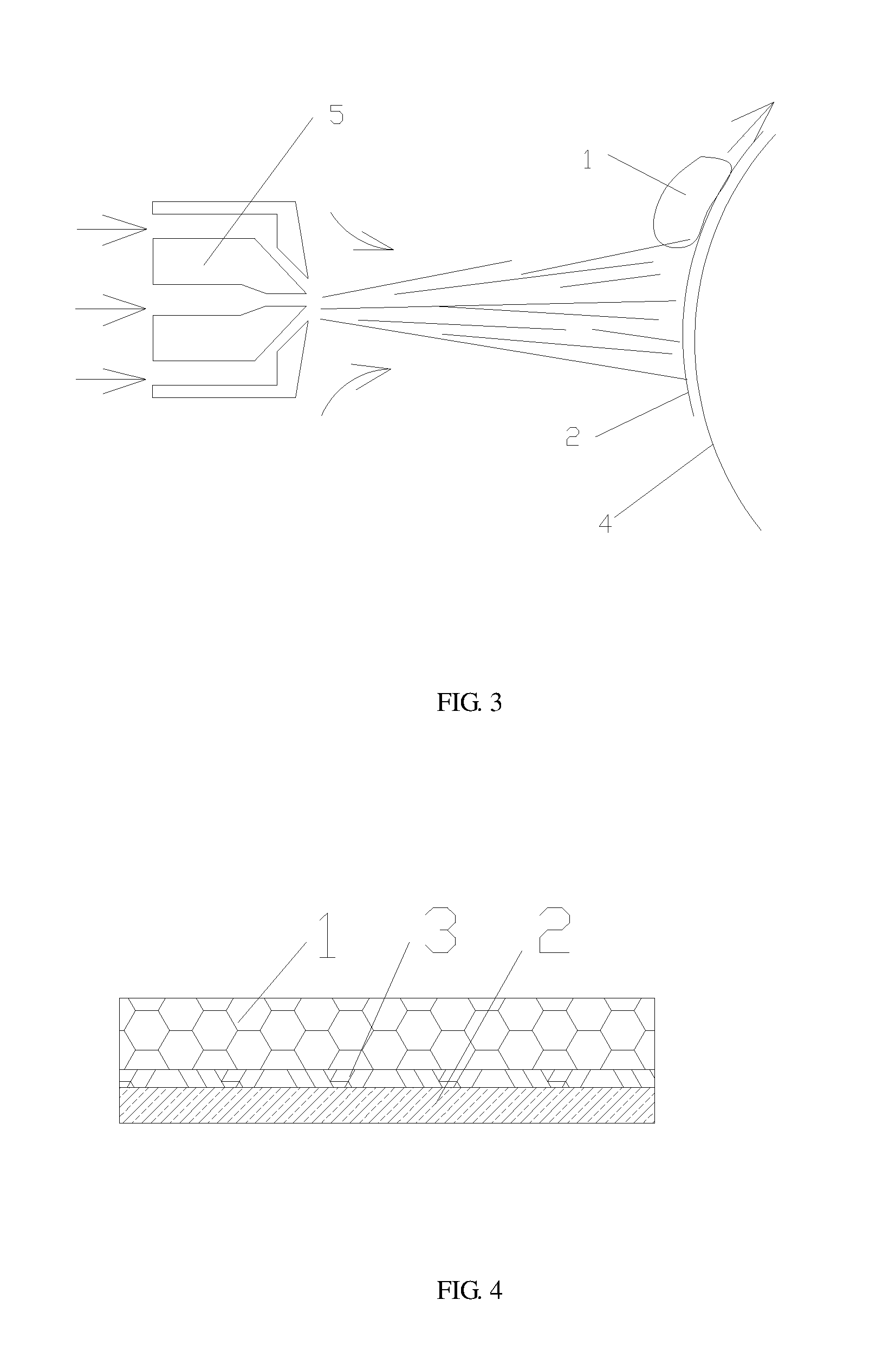

- PTFE membrane acoustic applications: PTFE membranes are utilized in various acoustic applications due to their unique properties. These thin, porous membranes can be designed to selectively allow air flow while blocking water and other contaminants. In acoustic devices, PTFE membranes help protect sensitive components from environmental factors while maintaining sound quality. They are commonly used in speakers, microphones, and hearing aids to improve performance and durability.

- PTFE in acoustic metamaterials: PTFE is increasingly being used in the development of acoustic metamaterials. These engineered structures manipulate sound waves in ways not possible with conventional materials. By incorporating PTFE into carefully designed geometries, researchers can create materials with negative acoustic refractive indices, enhanced sound absorption, or unique wave-guiding properties. Such metamaterials have potential applications in noise control, ultrasonic imaging, and acoustic cloaking.

- PTFE coatings for acoustic applications: PTFE coatings are applied to various surfaces to enhance their acoustic properties. The non-stick and low-friction characteristics of PTFE, combined with its sound-absorbing qualities, make it an excellent choice for coating acoustic panels, ducts, and other noise-sensitive components. These coatings can improve sound attenuation, reduce turbulence-induced noise, and provide additional benefits such as chemical resistance and easy cleaning in challenging environments.

02 PTFE-based acoustic composites

Composite materials incorporating PTFE with other materials, such as fibers or foams, can enhance acoustic performance. These composites combine the beneficial properties of PTFE with complementary materials to create structures with improved sound absorption and insulation characteristics.Expand Specific Solutions03 PTFE membrane acoustic applications

PTFE membranes are utilized in acoustic applications due to their unique properties. These thin, porous membranes can be designed to selectively allow air flow while blocking water and other contaminants, making them ideal for use in acoustic vents and protective covers for speakers and microphones.Expand Specific Solutions04 PTFE acoustic foam

PTFE-based acoustic foams offer excellent sound absorption properties while maintaining the material's inherent chemical resistance and durability. These foams can be engineered with specific pore sizes and densities to target particular frequency ranges for optimal acoustic performance in various applications.Expand Specific Solutions05 PTFE in acoustic transducers

PTFE is used in the construction of acoustic transducers, such as speakers and microphones, due to its low friction, high temperature resistance, and excellent dielectric properties. The material can be incorporated into diaphragms, surrounds, or other components to improve the overall performance and durability of acoustic devices.Expand Specific Solutions

Key PTFE Acoustic Players

The use of PTFE for enhanced acoustic solutions is in a growth phase, with increasing market size and technological advancements. The industry is characterized by a mix of established players and innovative newcomers, reflecting a competitive landscape. Companies like W. L. Gore & Associates and DAIKIN INDUSTRIES Ltd. are leveraging their expertise in PTFE to develop cutting-edge acoustic solutions. Meanwhile, research institutions such as Zhejiang University and Nanjing University are contributing to technological progress. The market is seeing a convergence of material science and acoustic engineering, with firms like Zhenjiang Best New Materials Co. Ltd. and Guangdong Zhengtong Boya Decoration Engineering Co., Ltd. focusing on specialized applications. As the technology matures, we can expect further innovations and market expansion in this sector.

W. L. Gore & Associates, Inc.

Technical Solution: W. L. Gore & Associates has developed advanced PTFE-based acoustic solutions for enhanced sound absorption and noise reduction. Their technology utilizes expanded PTFE (ePTFE) membranes with a unique microporous structure that effectively traps sound waves[1]. The company's GORE Acoustic Vents combine ePTFE membranes with protective materials to create thin, lightweight acoustic barriers that offer high sound transmission loss while maintaining air and liquid permeability[2]. This allows for excellent acoustic performance in various applications, including automotive, consumer electronics, and industrial equipment. Gore's acoustic solutions also feature hydrophobic and oleophobic properties, ensuring long-lasting performance in challenging environments[3].

Strengths: Superior sound absorption, thin and lightweight design, water and oil resistance, versatile applications. Weaknesses: Potentially higher cost compared to traditional materials, may require specialized manufacturing processes.

DAIKIN INDUSTRIES Ltd.

Technical Solution: DAIKIN has developed innovative PTFE-based acoustic solutions leveraging their expertise in fluoropolymer technologies. Their approach involves creating multi-layered structures combining PTFE with other materials to optimize sound absorption and insulation properties[4]. DAIKIN's acoustic PTFE foams feature a unique cellular structure that effectively traps sound waves across a wide frequency range[5]. The company has also developed PTFE-based acoustic membranes with precisely controlled pore sizes and distributions, allowing for tailored acoustic performance in different applications[6]. These solutions are particularly effective in high-temperature and chemically aggressive environments where traditional acoustic materials may fail.

Strengths: High-temperature resistance, chemical inertness, customizable acoustic properties. Weaknesses: Potentially higher production costs, limited biodegradability.

PTFE Acoustic Innovations

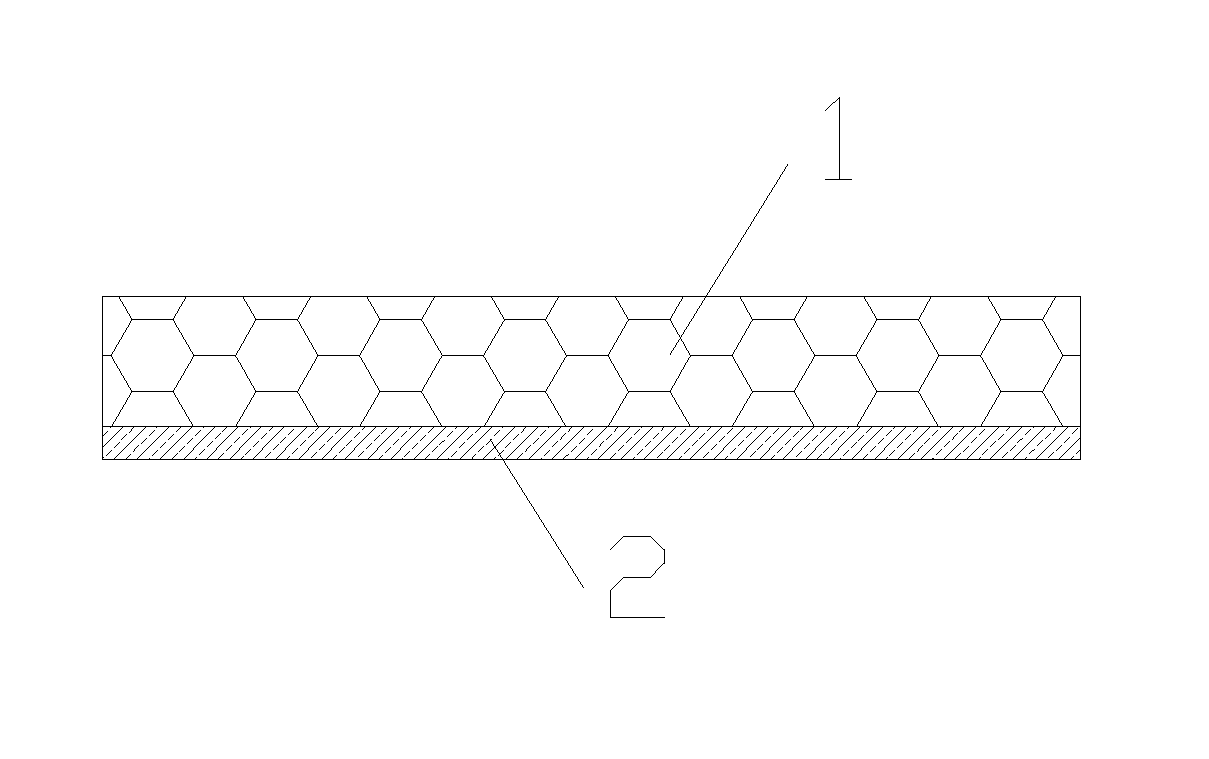

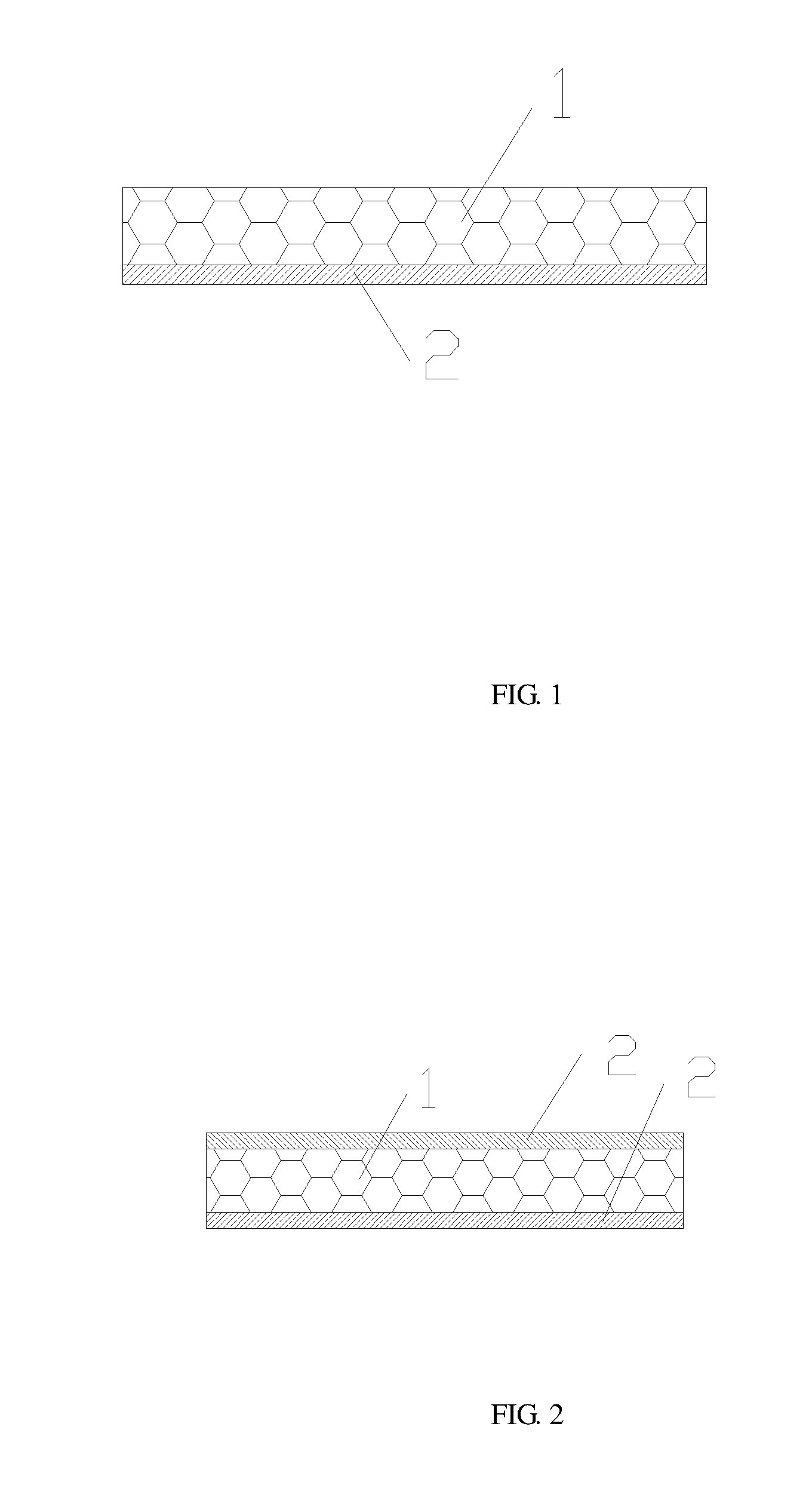

High Sound Absorption Coefficient Expanded PTFE Composite Fiber Cotton

PatentActiveUS20160121588A1

Innovation

- A high sound absorption coefficient expanded PTFE composite fiber cotton is developed, comprising a melt-blown high polymer fibrous layer and an expanded PTFE film layer, combined through heating, ultrasonic welding, or an adhesive, to create a material with enhanced sound attenuation capabilities.

Improved ultrasonic attenuation material

PatentInactiveJP2013223733A

Innovation

- The use of acoustic attenuation materials comprising a first component with porosity and a second component that partially fills the voids, along with layers of porous polymers and reinforcing materials, to enhance sound damping while reducing the overall size and weight of the ultrasound probe.

PTFE Manufacturing Process

The manufacturing process of PTFE (Polytetrafluoroethylene) for enhanced acoustic solutions involves several key steps, each contributing to the material's unique properties that make it suitable for acoustic applications. The process begins with the polymerization of tetrafluoroethylene (TFE) monomer, typically using free-radical polymerization techniques. This reaction is carried out under carefully controlled conditions, including temperature, pressure, and the presence of specific initiators and regulators.

Once the PTFE polymer is formed, it undergoes a series of processing steps to achieve the desired form and characteristics for acoustic applications. One common method is paste extrusion, where PTFE resin is mixed with a lubricant to form a paste. This paste is then extruded through a die to create various shapes, such as sheets, rods, or tubes, which can be further processed into acoustic components.

Another important manufacturing technique is sintering, where PTFE particles are heated above their melting point and then cooled to form a cohesive mass. This process is crucial for enhancing the material's mechanical properties and reducing its porosity, which is essential for certain acoustic applications. Sintering can be followed by compression molding to create specific shapes or components.

For applications requiring porous PTFE structures, which can be beneficial for sound absorption, manufacturers may employ techniques such as expanded PTFE (ePTFE) production. This involves stretching PTFE under specific conditions to create a microporous structure with excellent acoustic properties.

Surface modification techniques are often applied to PTFE products to enhance their acoustic performance further. These may include plasma treatment, chemical etching, or the application of specialized coatings to improve sound absorption or reflection characteristics.

Quality control is a critical aspect of the PTFE manufacturing process for acoustic solutions. This involves rigorous testing of the material's physical, chemical, and acoustic properties to ensure consistency and performance. Manufacturers often use advanced testing equipment to measure parameters such as sound absorption coefficients, transmission loss, and impedance.

The final stages of manufacturing may involve cutting, shaping, or assembling PTFE components into specific acoustic products. This can include the creation of acoustic panels, baffles, or liners designed for various applications, from architectural acoustics to industrial noise control.

Once the PTFE polymer is formed, it undergoes a series of processing steps to achieve the desired form and characteristics for acoustic applications. One common method is paste extrusion, where PTFE resin is mixed with a lubricant to form a paste. This paste is then extruded through a die to create various shapes, such as sheets, rods, or tubes, which can be further processed into acoustic components.

Another important manufacturing technique is sintering, where PTFE particles are heated above their melting point and then cooled to form a cohesive mass. This process is crucial for enhancing the material's mechanical properties and reducing its porosity, which is essential for certain acoustic applications. Sintering can be followed by compression molding to create specific shapes or components.

For applications requiring porous PTFE structures, which can be beneficial for sound absorption, manufacturers may employ techniques such as expanded PTFE (ePTFE) production. This involves stretching PTFE under specific conditions to create a microporous structure with excellent acoustic properties.

Surface modification techniques are often applied to PTFE products to enhance their acoustic performance further. These may include plasma treatment, chemical etching, or the application of specialized coatings to improve sound absorption or reflection characteristics.

Quality control is a critical aspect of the PTFE manufacturing process for acoustic solutions. This involves rigorous testing of the material's physical, chemical, and acoustic properties to ensure consistency and performance. Manufacturers often use advanced testing equipment to measure parameters such as sound absorption coefficients, transmission loss, and impedance.

The final stages of manufacturing may involve cutting, shaping, or assembling PTFE components into specific acoustic products. This can include the creation of acoustic panels, baffles, or liners designed for various applications, from architectural acoustics to industrial noise control.

Environmental Impact

The use of PTFE (Polytetrafluoroethylene) in acoustic solutions presents both advantages and challenges from an environmental perspective. PTFE's exceptional durability and resistance to degradation contribute to its long-lasting performance in acoustic applications, potentially reducing the need for frequent replacements and minimizing waste generation over time. This longevity aligns with sustainable product design principles and supports the reduction of overall material consumption.

However, the production process of PTFE raises environmental concerns. The manufacturing of PTFE involves the use of fluoropolymers, which can lead to the emission of greenhouse gases and other pollutants. Perfluorooctanoic acid (PFOA), a chemical historically used in PTFE production, has been linked to environmental contamination and potential health risks. In response to these concerns, many manufacturers have transitioned to alternative production methods that eliminate or significantly reduce PFOA use.

The end-of-life management of PTFE-based acoustic solutions also presents environmental challenges. While PTFE is theoretically recyclable, the practical implementation of recycling processes for PTFE-containing products remains limited due to the complexity of separating PTFE from other materials in composite acoustic solutions. This limitation can lead to increased landfill waste or the need for specialized disposal methods.

On the positive side, the application of PTFE in acoustic solutions can contribute to energy efficiency in buildings and vehicles. By enhancing sound insulation and absorption, PTFE-based materials can reduce the energy required for heating, ventilation, and air conditioning systems, thereby lowering overall energy consumption and associated carbon emissions.

Recent advancements in PTFE technology have focused on improving its environmental profile. Research into bio-based alternatives and more sustainable production methods aims to address the environmental impacts associated with traditional PTFE manufacturing. Additionally, efforts to develop more effective recycling techniques for PTFE-containing products are ongoing, with the potential to significantly improve the material's lifecycle sustainability.

As environmental regulations become increasingly stringent, the acoustic industry is likely to see further innovations in PTFE applications that prioritize eco-friendly production, enhanced recyclability, and reduced environmental footprint. The challenge lies in balancing the superior acoustic properties of PTFE with the growing demand for environmentally responsible materials and processes in acoustic solutions.

However, the production process of PTFE raises environmental concerns. The manufacturing of PTFE involves the use of fluoropolymers, which can lead to the emission of greenhouse gases and other pollutants. Perfluorooctanoic acid (PFOA), a chemical historically used in PTFE production, has been linked to environmental contamination and potential health risks. In response to these concerns, many manufacturers have transitioned to alternative production methods that eliminate or significantly reduce PFOA use.

The end-of-life management of PTFE-based acoustic solutions also presents environmental challenges. While PTFE is theoretically recyclable, the practical implementation of recycling processes for PTFE-containing products remains limited due to the complexity of separating PTFE from other materials in composite acoustic solutions. This limitation can lead to increased landfill waste or the need for specialized disposal methods.

On the positive side, the application of PTFE in acoustic solutions can contribute to energy efficiency in buildings and vehicles. By enhancing sound insulation and absorption, PTFE-based materials can reduce the energy required for heating, ventilation, and air conditioning systems, thereby lowering overall energy consumption and associated carbon emissions.

Recent advancements in PTFE technology have focused on improving its environmental profile. Research into bio-based alternatives and more sustainable production methods aims to address the environmental impacts associated with traditional PTFE manufacturing. Additionally, efforts to develop more effective recycling techniques for PTFE-containing products are ongoing, with the potential to significantly improve the material's lifecycle sustainability.

As environmental regulations become increasingly stringent, the acoustic industry is likely to see further innovations in PTFE applications that prioritize eco-friendly production, enhanced recyclability, and reduced environmental footprint. The challenge lies in balancing the superior acoustic properties of PTFE with the growing demand for environmentally responsible materials and processes in acoustic solutions.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!