How to Enhance Engineering Processes with PTFE?

JUN 27, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

PTFE Technology Evolution

Polytetrafluoroethylene (PTFE) has undergone significant technological evolution since its accidental discovery by Roy Plunkett in 1938. Initially developed as a refrigerant, PTFE's unique properties quickly led to its adoption in various engineering applications. The technology's evolution can be traced through several key phases, each marked by breakthroughs in manufacturing processes and application techniques.

In the 1940s and 1950s, the focus was on developing reliable production methods for PTFE. DuPont's commercialization of Teflon in 1946 marked a significant milestone, leading to the material's widespread use in industrial and consumer products. During this period, researchers worked on improving the polymer's molecular structure and exploring its potential in different forms, such as sheets, tapes, and coatings.

The 1960s and 1970s saw advancements in PTFE's processing techniques. Sintering methods were refined, allowing for the production of more complex shapes and larger components. This era also witnessed the development of modified PTFE materials, such as filled PTFE compounds, which expanded the material's application range and enhanced its mechanical properties.

In the 1980s and 1990s, the focus shifted towards enhancing PTFE's performance in specific applications. Researchers developed techniques to create microporous PTFE membranes, leading to innovations in filtration and breathable fabrics. Concurrently, advancements in surface modification technologies enabled better adhesion of PTFE to other materials, broadening its use in composite structures.

The turn of the millennium brought about nanotechnology-driven innovations in PTFE. Researchers began exploring ways to manipulate PTFE at the molecular level, leading to the development of nanostructured PTFE materials with enhanced properties. This period also saw the emergence of environmentally friendly production methods, addressing concerns about the persistence of fluoropolymers in the environment.

Recent years have witnessed a focus on sustainable PTFE technologies. Efforts are being made to develop bio-based alternatives and improve recycling processes for PTFE products. Additionally, researchers are exploring new applications in emerging fields such as flexible electronics, where PTFE's unique properties can offer significant advantages.

Throughout its evolution, PTFE technology has consistently aimed at enhancing engineering processes. From improving non-stick and low-friction surfaces in manufacturing to providing critical insulation in aerospace applications, PTFE's development has been driven by the need for materials that can withstand extreme conditions while offering superior performance.

In the 1940s and 1950s, the focus was on developing reliable production methods for PTFE. DuPont's commercialization of Teflon in 1946 marked a significant milestone, leading to the material's widespread use in industrial and consumer products. During this period, researchers worked on improving the polymer's molecular structure and exploring its potential in different forms, such as sheets, tapes, and coatings.

The 1960s and 1970s saw advancements in PTFE's processing techniques. Sintering methods were refined, allowing for the production of more complex shapes and larger components. This era also witnessed the development of modified PTFE materials, such as filled PTFE compounds, which expanded the material's application range and enhanced its mechanical properties.

In the 1980s and 1990s, the focus shifted towards enhancing PTFE's performance in specific applications. Researchers developed techniques to create microporous PTFE membranes, leading to innovations in filtration and breathable fabrics. Concurrently, advancements in surface modification technologies enabled better adhesion of PTFE to other materials, broadening its use in composite structures.

The turn of the millennium brought about nanotechnology-driven innovations in PTFE. Researchers began exploring ways to manipulate PTFE at the molecular level, leading to the development of nanostructured PTFE materials with enhanced properties. This period also saw the emergence of environmentally friendly production methods, addressing concerns about the persistence of fluoropolymers in the environment.

Recent years have witnessed a focus on sustainable PTFE technologies. Efforts are being made to develop bio-based alternatives and improve recycling processes for PTFE products. Additionally, researchers are exploring new applications in emerging fields such as flexible electronics, where PTFE's unique properties can offer significant advantages.

Throughout its evolution, PTFE technology has consistently aimed at enhancing engineering processes. From improving non-stick and low-friction surfaces in manufacturing to providing critical insulation in aerospace applications, PTFE's development has been driven by the need for materials that can withstand extreme conditions while offering superior performance.

PTFE Market Demand Analysis

The global market for Polytetrafluoroethylene (PTFE) has been experiencing steady growth, driven by its unique properties and versatile applications across various industries. PTFE's exceptional chemical resistance, low friction coefficient, and high-temperature stability make it a sought-after material in engineering processes.

In the automotive sector, PTFE is increasingly used in gaskets, seals, and bearings, contributing to improved fuel efficiency and reduced emissions. The growing emphasis on electric vehicles has further boosted demand for PTFE in battery components and electrical insulation. This trend is expected to continue as the automotive industry shifts towards more sustainable technologies.

The aerospace industry represents another significant market for PTFE. Its use in aircraft components, such as hydraulic systems and fuel lines, has been expanding due to its ability to withstand extreme temperatures and harsh chemical environments. As the aerospace sector recovers from the pandemic-induced slowdown, the demand for PTFE in this industry is projected to rise.

In the chemical processing industry, PTFE's corrosion resistance makes it invaluable for lining pipes, valves, and reactors. The increasing focus on safety and efficiency in chemical plants is driving the adoption of PTFE-based solutions. This trend is particularly pronounced in emerging economies where industrial infrastructure is rapidly developing.

The electronics industry is another key driver of PTFE demand. Its excellent dielectric properties make it ideal for high-frequency circuit boards and cable insulation. With the ongoing rollout of 5G networks and the growth of the Internet of Things (IoT), the demand for PTFE in electronic applications is expected to surge.

In the medical field, PTFE's biocompatibility and non-stick properties have led to its widespread use in implants, catheters, and surgical instruments. The aging population in developed countries and improving healthcare access in developing regions are contributing to the growth of PTFE demand in medical applications.

The construction industry is also adopting PTFE-based materials for architectural membranes and coatings. These applications benefit from PTFE's weather resistance, durability, and self-cleaning properties. As sustainable building practices gain traction, the use of PTFE in construction is likely to increase.

Despite its many advantages, the PTFE market faces challenges related to environmental concerns and regulatory pressures. The persistence of fluoropolymers in the environment has led to increased scrutiny and potential restrictions in some regions. This has spurred research into more environmentally friendly alternatives and recycling technologies for PTFE.

In the automotive sector, PTFE is increasingly used in gaskets, seals, and bearings, contributing to improved fuel efficiency and reduced emissions. The growing emphasis on electric vehicles has further boosted demand for PTFE in battery components and electrical insulation. This trend is expected to continue as the automotive industry shifts towards more sustainable technologies.

The aerospace industry represents another significant market for PTFE. Its use in aircraft components, such as hydraulic systems and fuel lines, has been expanding due to its ability to withstand extreme temperatures and harsh chemical environments. As the aerospace sector recovers from the pandemic-induced slowdown, the demand for PTFE in this industry is projected to rise.

In the chemical processing industry, PTFE's corrosion resistance makes it invaluable for lining pipes, valves, and reactors. The increasing focus on safety and efficiency in chemical plants is driving the adoption of PTFE-based solutions. This trend is particularly pronounced in emerging economies where industrial infrastructure is rapidly developing.

The electronics industry is another key driver of PTFE demand. Its excellent dielectric properties make it ideal for high-frequency circuit boards and cable insulation. With the ongoing rollout of 5G networks and the growth of the Internet of Things (IoT), the demand for PTFE in electronic applications is expected to surge.

In the medical field, PTFE's biocompatibility and non-stick properties have led to its widespread use in implants, catheters, and surgical instruments. The aging population in developed countries and improving healthcare access in developing regions are contributing to the growth of PTFE demand in medical applications.

The construction industry is also adopting PTFE-based materials for architectural membranes and coatings. These applications benefit from PTFE's weather resistance, durability, and self-cleaning properties. As sustainable building practices gain traction, the use of PTFE in construction is likely to increase.

Despite its many advantages, the PTFE market faces challenges related to environmental concerns and regulatory pressures. The persistence of fluoropolymers in the environment has led to increased scrutiny and potential restrictions in some regions. This has spurred research into more environmentally friendly alternatives and recycling technologies for PTFE.

PTFE Engineering Challenges

Polytetrafluoroethylene (PTFE) has revolutionized numerous engineering processes, yet its implementation still presents significant challenges. One of the primary obstacles is the material's inherent non-stick properties, which, while beneficial in many applications, can complicate bonding and adhesion processes. Engineers often struggle to create durable connections between PTFE and other materials, limiting its integration in complex assemblies.

The high melting point of PTFE, while advantageous for high-temperature applications, poses difficulties in manufacturing and processing. Traditional molding and shaping techniques are often ineffective, necessitating specialized equipment and expertise. This can lead to increased production costs and longer lead times, potentially hindering widespread adoption in certain industries.

PTFE's low coefficient of friction, while a key advantage in many scenarios, can be problematic in applications requiring controlled friction or grip. Engineers must develop innovative solutions to overcome this challenge, particularly in mechanical systems where precise control is crucial.

The material's tendency to creep under load presents another significant engineering hurdle. Over time, PTFE components may deform or lose their dimensional stability, potentially compromising the integrity and performance of engineered systems. This necessitates careful design considerations and regular maintenance protocols to ensure long-term reliability.

Environmental concerns also pose challenges in PTFE engineering. The production process for PTFE historically involved the use of perfluorooctanoic acid (PFOA), a persistent environmental pollutant. While many manufacturers have phased out PFOA, finding equally effective and environmentally friendly alternatives remains an ongoing challenge for the industry.

The high cost of PTFE compared to other polymers can limit its application in cost-sensitive projects. Engineers must carefully weigh the material's benefits against its economic impact, often necessitating complex cost-benefit analyses to justify its use.

Recycling and end-of-life management of PTFE products present additional challenges. The material's chemical stability, while beneficial during use, makes it difficult to break down or recycle effectively. Developing sustainable disposal or recycling methods for PTFE waste is an area requiring significant research and innovation.

As engineering processes continue to evolve, addressing these challenges will be crucial for maximizing the potential of PTFE in various applications. Overcoming these hurdles will require interdisciplinary collaboration, innovative thinking, and continued investment in research and development.

The high melting point of PTFE, while advantageous for high-temperature applications, poses difficulties in manufacturing and processing. Traditional molding and shaping techniques are often ineffective, necessitating specialized equipment and expertise. This can lead to increased production costs and longer lead times, potentially hindering widespread adoption in certain industries.

PTFE's low coefficient of friction, while a key advantage in many scenarios, can be problematic in applications requiring controlled friction or grip. Engineers must develop innovative solutions to overcome this challenge, particularly in mechanical systems where precise control is crucial.

The material's tendency to creep under load presents another significant engineering hurdle. Over time, PTFE components may deform or lose their dimensional stability, potentially compromising the integrity and performance of engineered systems. This necessitates careful design considerations and regular maintenance protocols to ensure long-term reliability.

Environmental concerns also pose challenges in PTFE engineering. The production process for PTFE historically involved the use of perfluorooctanoic acid (PFOA), a persistent environmental pollutant. While many manufacturers have phased out PFOA, finding equally effective and environmentally friendly alternatives remains an ongoing challenge for the industry.

The high cost of PTFE compared to other polymers can limit its application in cost-sensitive projects. Engineers must carefully weigh the material's benefits against its economic impact, often necessitating complex cost-benefit analyses to justify its use.

Recycling and end-of-life management of PTFE products present additional challenges. The material's chemical stability, while beneficial during use, makes it difficult to break down or recycle effectively. Developing sustainable disposal or recycling methods for PTFE waste is an area requiring significant research and innovation.

As engineering processes continue to evolve, addressing these challenges will be crucial for maximizing the potential of PTFE in various applications. Overcoming these hurdles will require interdisciplinary collaboration, innovative thinking, and continued investment in research and development.

Current PTFE Solutions

01 PTFE Extrusion Processes

This category focuses on the extrusion processes for PTFE, including methods for producing PTFE fibers, tubes, and other shapes. The processes involve heating PTFE resin, forcing it through dies, and then cooling or stretching the extruded material to achieve desired properties. Various techniques are employed to control the molecular orientation and crystallinity of the PTFE during extrusion.- PTFE Extrusion Processes: This category focuses on the extrusion processes for PTFE, including methods for producing PTFE fibers, tubes, and other shapes. The processes involve heating PTFE resin, forcing it through dies, and then cooling or further treating the extruded material to achieve desired properties. Various techniques are employed to control the extrusion process and improve the quality of the final product.

- PTFE Sintering and Heat Treatment: Sintering and heat treatment are crucial steps in PTFE engineering processes. These methods involve heating PTFE materials to near or above their melting point to fuse particles together and improve mechanical properties. The processes can be optimized to control crystallinity, density, and other characteristics of the final PTFE product.

- PTFE Surface Modification Techniques: Various techniques are used to modify the surface properties of PTFE materials. These include chemical treatments, plasma treatments, and the application of coatings. Surface modification can enhance adhesion, wettability, or other specific properties of PTFE for different applications.

- PTFE Composite Manufacturing: This category covers processes for creating PTFE composites by combining PTFE with other materials such as fillers, reinforcing fibers, or other polymers. These processes aim to enhance the properties of PTFE or create materials with unique characteristics for specific applications.

- PTFE Recycling and Reprocessing: Engineering processes for recycling and reprocessing PTFE materials are becoming increasingly important. These methods involve breaking down used PTFE products, purifying the material, and reprocessing it into new forms. The goal is to reduce waste and create more sustainable manufacturing processes for PTFE products.

02 PTFE Sintering and Heat Treatment

Sintering and heat treatment processes are crucial in PTFE engineering. These methods involve heating PTFE particles to just below their melting point, causing them to fuse together. The sintering process can be optimized to control porosity, density, and mechanical properties of the final PTFE product. Post-sintering heat treatments are also used to modify the crystalline structure and enhance specific characteristics.Expand Specific Solutions03 PTFE Surface Modification Techniques

Various techniques are employed to modify the surface properties of PTFE. These include plasma treatment, chemical etching, and the application of coatings or additives. Surface modification can enhance adhesion, wettability, or introduce specific functionalities to the PTFE surface. These processes are crucial for applications requiring improved bonding or compatibility with other materials.Expand Specific Solutions04 PTFE Composite and Blend Formulations

This category covers the development of PTFE composites and blends. Processes involve incorporating fillers, reinforcing agents, or other polymers into PTFE to enhance its properties or create hybrid materials. Techniques such as powder blending, co-extrusion, or in-situ polymerization are used to produce these advanced PTFE-based materials with tailored characteristics.Expand Specific Solutions05 PTFE Recycling and Reprocessing Methods

Engineering processes for recycling and reprocessing PTFE waste are becoming increasingly important. These methods involve techniques for breaking down used PTFE products, purifying the material, and reprocessing it into new forms. Mechanical, thermal, and chemical processes are employed to recover PTFE from various sources and convert it into reusable raw material or new products.Expand Specific Solutions

Key PTFE Industry Players

The engineering process enhancement with PTFE is in a mature stage, with a significant market size and well-established technological applications. Key players like DAIKIN INDUSTRIES, 3M, and DuPont de Nemours have developed advanced PTFE solutions, indicating high technological maturity. The competitive landscape includes both global corporations and specialized manufacturers, such as Zhejiang Jusheng Fluorochemical and Shandong Huaxia Shenzhou New Materials. Academic institutions like Zhejiang University and Johns Hopkins University contribute to ongoing research and development, ensuring continuous innovation in PTFE applications across various industries.

DAIKIN INDUSTRIES Ltd.

Technical Solution: Daikin has developed innovative PTFE-based solutions to enhance engineering processes across various industries. Their NEOFLON™ PTFE products offer exceptional heat resistance and chemical inertness, making them ideal for use in aggressive chemical environments. In semiconductor manufacturing, Daikin's ultra-high purity PTFE materials help improve process yields and reduce contamination risks[11]. For automotive applications, Daikin has created PTFE-based lubricants and coatings that reduce friction and wear in engine components, improving fuel efficiency and extending part life[12]. In the field of industrial filtration, Daikin's PTFE membrane technologies offer high throughput and excellent particle retention, enhancing process efficiency in industries such as pharmaceuticals and food processing[13].

Strengths: Strong presence in Asian markets, vertically integrated production capabilities, expertise in fluoropolymer chemistry. Weaknesses: Less brand recognition in some global markets compared to competitors, potential regulatory challenges in certain regions.

3M Innovative Properties Co.

Technical Solution: 3M has leveraged PTFE technology to enhance engineering processes across multiple industries. Their Dyneon™ PTFE products offer improved wear resistance and low friction in mechanical applications. In the automotive sector, 3M has developed PTFE-based fuel hose liners that provide excellent chemical resistance and permeation barrier properties, enhancing fuel system efficiency and reducing emissions[5]. For industrial coatings, 3M's PTFE-enhanced formulations offer superior non-stick and anti-corrosion properties, extending equipment life and reducing maintenance costs[6]. In the field of filtration, 3M has pioneered the use of expanded PTFE (ePTFE) membranes, which provide high airflow with excellent particle capture efficiency, improving air quality in various environments[7].

Strengths: Diverse product portfolio, strong focus on innovation, global presence. Weaknesses: Complex organizational structure may slow down decision-making, potential for product cannibalization within the company.

PTFE Innovation Insights

Process for injection moulding of polytetrafluoroethylene

PatentWO1997043102A1

Innovation

- Processing modified suspension PTFE with fillers such as polyether ether ketone (PEEK) and polyphenylene sulfide (PPS) in injection molding, where the fillers remain in the final product and are miscible with PTFE at processing temperatures, allowing for the production of complex components with improved properties.

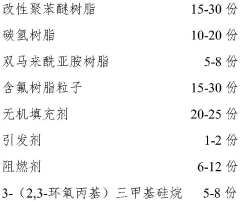

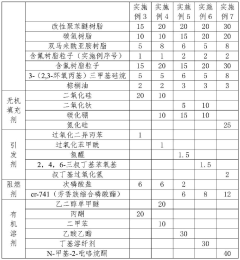

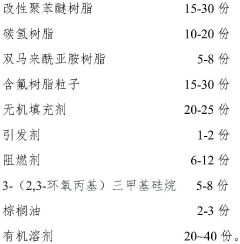

Resin composition with excellent compatibility as well as preparation method and application thereof

PatentActiveCN116656111A

Innovation

- Using modified polyphenylene ether, hydrocarbon resin and bismaleimide combined with modified fluorine-containing resin particles, PTFE is modified through sodium naphthalene solution chemical treatment to increase its surface energy, and the modified PTFE particles are polymerized with The compounding of matrix polymer improves compatibility and processing performance.

PTFE Environmental Impact

The environmental impact of PTFE (Polytetrafluoroethylene) is a critical consideration in its application to enhance engineering processes. While PTFE offers numerous benefits in terms of performance and durability, its production and disposal raise significant environmental concerns.

PTFE manufacturing involves the use of perfluorooctanoic acid (PFOA), a persistent organic pollutant. PFOA has been linked to various health issues and environmental contamination. It can persist in the environment for extended periods, potentially accumulating in living organisms and ecosystems. This has led to increased scrutiny and regulatory pressure on PTFE production methods.

In response to these concerns, many manufacturers have developed alternative production processes that reduce or eliminate the use of PFOA. These "PFOA-free" methods aim to mitigate the environmental impact of PTFE production while maintaining its desirable properties. However, the long-term effects of these alternative processes and materials are still being studied.

The disposal of PTFE products also presents environmental challenges. PTFE is not biodegradable and can persist in landfills for centuries. Incineration of PTFE can release harmful substances, including hydrogen fluoride and other toxic gases. This necessitates careful consideration of end-of-life management for PTFE-enhanced engineering products.

Recycling PTFE is technically possible but economically challenging due to its high melting point and chemical stability. Some specialized recycling processes have been developed, but they are not widely available or economically viable for all applications. This limitation in recyclability contributes to the overall environmental footprint of PTFE use in engineering processes.

Despite these challenges, PTFE's unique properties often lead to environmental benefits in specific applications. Its non-stick and low-friction characteristics can reduce energy consumption in machinery and increase the lifespan of components, potentially offsetting some of its negative environmental impacts through improved efficiency and reduced material consumption over time.

The use of PTFE in seals and gaskets can prevent leaks of hazardous materials, contributing to environmental protection in industrial settings. Additionally, PTFE's chemical resistance makes it valuable in pollution control equipment and environmental monitoring devices, indirectly supporting environmental conservation efforts.

As engineering processes continue to evolve, balancing the performance benefits of PTFE with its environmental impact remains a key challenge. Ongoing research into more sustainable production methods, improved recycling techniques, and the development of environmentally friendly alternatives will be crucial in addressing these concerns and ensuring the responsible use of PTFE in engineering applications.

PTFE manufacturing involves the use of perfluorooctanoic acid (PFOA), a persistent organic pollutant. PFOA has been linked to various health issues and environmental contamination. It can persist in the environment for extended periods, potentially accumulating in living organisms and ecosystems. This has led to increased scrutiny and regulatory pressure on PTFE production methods.

In response to these concerns, many manufacturers have developed alternative production processes that reduce or eliminate the use of PFOA. These "PFOA-free" methods aim to mitigate the environmental impact of PTFE production while maintaining its desirable properties. However, the long-term effects of these alternative processes and materials are still being studied.

The disposal of PTFE products also presents environmental challenges. PTFE is not biodegradable and can persist in landfills for centuries. Incineration of PTFE can release harmful substances, including hydrogen fluoride and other toxic gases. This necessitates careful consideration of end-of-life management for PTFE-enhanced engineering products.

Recycling PTFE is technically possible but economically challenging due to its high melting point and chemical stability. Some specialized recycling processes have been developed, but they are not widely available or economically viable for all applications. This limitation in recyclability contributes to the overall environmental footprint of PTFE use in engineering processes.

Despite these challenges, PTFE's unique properties often lead to environmental benefits in specific applications. Its non-stick and low-friction characteristics can reduce energy consumption in machinery and increase the lifespan of components, potentially offsetting some of its negative environmental impacts through improved efficiency and reduced material consumption over time.

The use of PTFE in seals and gaskets can prevent leaks of hazardous materials, contributing to environmental protection in industrial settings. Additionally, PTFE's chemical resistance makes it valuable in pollution control equipment and environmental monitoring devices, indirectly supporting environmental conservation efforts.

As engineering processes continue to evolve, balancing the performance benefits of PTFE with its environmental impact remains a key challenge. Ongoing research into more sustainable production methods, improved recycling techniques, and the development of environmentally friendly alternatives will be crucial in addressing these concerns and ensuring the responsible use of PTFE in engineering applications.

PTFE Safety Regulations

The implementation of PTFE in engineering processes necessitates strict adherence to safety regulations to ensure the protection of workers, the environment, and the integrity of the final products. Regulatory bodies such as the Occupational Safety and Health Administration (OSHA) and the Environmental Protection Agency (EPA) have established guidelines for the safe handling and use of PTFE in industrial settings.

One of the primary safety concerns when working with PTFE is the potential release of harmful fumes during high-temperature processing. When heated above 260°C (500°F), PTFE can decompose and release toxic gases, including perfluoroisobutene (PFIB) and hydrogen fluoride (HF). To mitigate this risk, engineering facilities must implement robust ventilation systems and ensure that processing temperatures remain below the decomposition threshold.

Personal protective equipment (PPE) is crucial when handling PTFE materials. Workers should wear appropriate gloves, eye protection, and respiratory equipment to prevent skin contact and inhalation of PTFE particles. Additionally, proper training on the safe handling and disposal of PTFE materials is essential for all personnel involved in the engineering processes.

Storage and transportation of PTFE materials also require careful consideration. PTFE should be stored in cool, dry areas away from direct sunlight and heat sources. During transportation, containers must be properly sealed and labeled to prevent contamination and ensure safe handling throughout the supply chain.

Waste management is another critical aspect of PTFE safety regulations. Proper disposal methods must be employed to prevent environmental contamination. Recycling programs for PTFE materials should be implemented where possible, and any non-recyclable waste must be disposed of in accordance with local and national regulations.

Regular safety audits and inspections are necessary to ensure ongoing compliance with PTFE safety regulations. These audits should assess the effectiveness of safety measures, identify potential hazards, and implement corrective actions as needed. Documentation of safety procedures, incident reports, and employee training records should be maintained and regularly updated.

In the context of enhancing engineering processes with PTFE, it is crucial to integrate safety considerations into the design phase. This proactive approach can help identify potential risks early on and implement appropriate safety measures before production begins. By prioritizing safety in PTFE-related engineering processes, companies can not only protect their workforce and the environment but also improve overall efficiency and product quality.

One of the primary safety concerns when working with PTFE is the potential release of harmful fumes during high-temperature processing. When heated above 260°C (500°F), PTFE can decompose and release toxic gases, including perfluoroisobutene (PFIB) and hydrogen fluoride (HF). To mitigate this risk, engineering facilities must implement robust ventilation systems and ensure that processing temperatures remain below the decomposition threshold.

Personal protective equipment (PPE) is crucial when handling PTFE materials. Workers should wear appropriate gloves, eye protection, and respiratory equipment to prevent skin contact and inhalation of PTFE particles. Additionally, proper training on the safe handling and disposal of PTFE materials is essential for all personnel involved in the engineering processes.

Storage and transportation of PTFE materials also require careful consideration. PTFE should be stored in cool, dry areas away from direct sunlight and heat sources. During transportation, containers must be properly sealed and labeled to prevent contamination and ensure safe handling throughout the supply chain.

Waste management is another critical aspect of PTFE safety regulations. Proper disposal methods must be employed to prevent environmental contamination. Recycling programs for PTFE materials should be implemented where possible, and any non-recyclable waste must be disposed of in accordance with local and national regulations.

Regular safety audits and inspections are necessary to ensure ongoing compliance with PTFE safety regulations. These audits should assess the effectiveness of safety measures, identify potential hazards, and implement corrective actions as needed. Documentation of safety procedures, incident reports, and employee training records should be maintained and regularly updated.

In the context of enhancing engineering processes with PTFE, it is crucial to integrate safety considerations into the design phase. This proactive approach can help identify potential risks early on and implement appropriate safety measures before production begins. By prioritizing safety in PTFE-related engineering processes, companies can not only protect their workforce and the environment but also improve overall efficiency and product quality.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!