How to Implement PTFE for Structural Integrity?

JUN 27, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

PTFE Structural Integrity Background and Objectives

Polytetrafluoroethylene (PTFE), commonly known as Teflon, has been a revolutionary material in various industries since its accidental discovery in 1938. Its unique properties, including high chemical resistance, low friction coefficient, and excellent thermal stability, have made it an invaluable asset in applications ranging from cookware to aerospace engineering. The evolution of PTFE technology has been driven by the increasing demand for materials that can withstand extreme conditions while maintaining structural integrity.

The primary objective of implementing PTFE for structural integrity is to enhance the durability, reliability, and performance of components and systems in challenging environments. This goal encompasses improving the material's mechanical properties, such as tensile strength and impact resistance, while preserving its inherent chemical and thermal advantages. Additionally, researchers and engineers aim to develop innovative manufacturing techniques and composite formulations to expand PTFE's applicability in load-bearing structures and high-stress applications.

The technological trajectory of PTFE has seen significant advancements in recent years, particularly in the development of modified PTFE grades and PTFE-based composites. These innovations have addressed some of the material's limitations, such as poor wear resistance and creep behavior, opening up new possibilities for its use in structural applications. The integration of nanoparticles and the creation of PTFE nanocomposites represent cutting-edge research directions, promising enhanced mechanical properties without compromising the material's unique characteristics.

Market trends indicate a growing demand for PTFE in industries such as automotive, aerospace, and chemical processing, where structural integrity under extreme conditions is paramount. The global PTFE market is projected to expand significantly in the coming years, driven by technological advancements and the material's increasing adoption in emerging applications. This market growth underscores the importance of continued research and development efforts to improve PTFE's structural performance and expand its utility in critical engineering applications.

As we look towards the future, the implementation of PTFE for structural integrity faces several challenges and opportunities. Key areas of focus include improving the material's bonding capabilities with other substances, enhancing its load-bearing capacity, and developing more efficient and cost-effective manufacturing processes. The pursuit of these objectives will likely involve interdisciplinary collaborations, combining expertise in materials science, mechanical engineering, and nanotechnology to push the boundaries of PTFE's capabilities in structural applications.

The primary objective of implementing PTFE for structural integrity is to enhance the durability, reliability, and performance of components and systems in challenging environments. This goal encompasses improving the material's mechanical properties, such as tensile strength and impact resistance, while preserving its inherent chemical and thermal advantages. Additionally, researchers and engineers aim to develop innovative manufacturing techniques and composite formulations to expand PTFE's applicability in load-bearing structures and high-stress applications.

The technological trajectory of PTFE has seen significant advancements in recent years, particularly in the development of modified PTFE grades and PTFE-based composites. These innovations have addressed some of the material's limitations, such as poor wear resistance and creep behavior, opening up new possibilities for its use in structural applications. The integration of nanoparticles and the creation of PTFE nanocomposites represent cutting-edge research directions, promising enhanced mechanical properties without compromising the material's unique characteristics.

Market trends indicate a growing demand for PTFE in industries such as automotive, aerospace, and chemical processing, where structural integrity under extreme conditions is paramount. The global PTFE market is projected to expand significantly in the coming years, driven by technological advancements and the material's increasing adoption in emerging applications. This market growth underscores the importance of continued research and development efforts to improve PTFE's structural performance and expand its utility in critical engineering applications.

As we look towards the future, the implementation of PTFE for structural integrity faces several challenges and opportunities. Key areas of focus include improving the material's bonding capabilities with other substances, enhancing its load-bearing capacity, and developing more efficient and cost-effective manufacturing processes. The pursuit of these objectives will likely involve interdisciplinary collaborations, combining expertise in materials science, mechanical engineering, and nanotechnology to push the boundaries of PTFE's capabilities in structural applications.

Market Analysis for PTFE Structural Applications

The market for PTFE (Polytetrafluoroethylene) in structural applications has been experiencing significant growth due to its unique properties and versatility. PTFE's exceptional chemical resistance, low friction coefficient, and high temperature stability make it an attractive material for various industries seeking to enhance structural integrity.

In the construction sector, PTFE-based materials are increasingly used in architectural membranes, roofing systems, and expansion joints. The demand for lightweight, durable, and weather-resistant structures has driven the adoption of PTFE-coated fabrics and films. These materials offer excellent longevity and reduced maintenance costs, making them particularly appealing for large-scale projects such as stadiums, airports, and commercial buildings.

The aerospace and automotive industries have also recognized the potential of PTFE in structural applications. PTFE-based composites are being utilized in aircraft components, fuel systems, and engine parts to improve fuel efficiency and reduce weight. In the automotive sector, PTFE is finding applications in seals, gaskets, and bearings, contributing to enhanced vehicle performance and durability.

The oil and gas industry represents another significant market for PTFE structural applications. PTFE-lined pipes, valves, and fittings are increasingly used in corrosive environments and high-temperature operations. The material's chemical inertness and low permeability make it ideal for handling aggressive fluids and gases, thereby extending the lifespan of critical infrastructure.

Market analysis indicates that the Asia-Pacific region is expected to witness the highest growth rate in PTFE structural applications. Rapid industrialization, infrastructure development, and increasing investments in advanced materials are driving this trend. North America and Europe remain strong markets, with a focus on innovation and high-performance applications in aerospace and automotive sectors.

The global PTFE market size for structural applications is projected to grow steadily over the next five years. Key factors contributing to this growth include increasing demand for high-performance materials, stringent regulations promoting the use of environmentally friendly substances, and ongoing research and development efforts to expand PTFE's capabilities.

However, challenges such as high production costs and limited recyclability of PTFE products may impact market growth. Manufacturers are investing in research to develop more cost-effective production methods and improve the material's sustainability profile. Additionally, the emergence of alternative fluoropolymers and advanced composites poses potential competition to PTFE in certain structural applications.

Overall, the market analysis for PTFE structural applications reveals a positive outlook, driven by its superior properties and expanding range of applications across multiple industries. As technology advances and new formulations are developed, PTFE is likely to play an increasingly important role in enhancing structural integrity across various sectors.

In the construction sector, PTFE-based materials are increasingly used in architectural membranes, roofing systems, and expansion joints. The demand for lightweight, durable, and weather-resistant structures has driven the adoption of PTFE-coated fabrics and films. These materials offer excellent longevity and reduced maintenance costs, making them particularly appealing for large-scale projects such as stadiums, airports, and commercial buildings.

The aerospace and automotive industries have also recognized the potential of PTFE in structural applications. PTFE-based composites are being utilized in aircraft components, fuel systems, and engine parts to improve fuel efficiency and reduce weight. In the automotive sector, PTFE is finding applications in seals, gaskets, and bearings, contributing to enhanced vehicle performance and durability.

The oil and gas industry represents another significant market for PTFE structural applications. PTFE-lined pipes, valves, and fittings are increasingly used in corrosive environments and high-temperature operations. The material's chemical inertness and low permeability make it ideal for handling aggressive fluids and gases, thereby extending the lifespan of critical infrastructure.

Market analysis indicates that the Asia-Pacific region is expected to witness the highest growth rate in PTFE structural applications. Rapid industrialization, infrastructure development, and increasing investments in advanced materials are driving this trend. North America and Europe remain strong markets, with a focus on innovation and high-performance applications in aerospace and automotive sectors.

The global PTFE market size for structural applications is projected to grow steadily over the next five years. Key factors contributing to this growth include increasing demand for high-performance materials, stringent regulations promoting the use of environmentally friendly substances, and ongoing research and development efforts to expand PTFE's capabilities.

However, challenges such as high production costs and limited recyclability of PTFE products may impact market growth. Manufacturers are investing in research to develop more cost-effective production methods and improve the material's sustainability profile. Additionally, the emergence of alternative fluoropolymers and advanced composites poses potential competition to PTFE in certain structural applications.

Overall, the market analysis for PTFE structural applications reveals a positive outlook, driven by its superior properties and expanding range of applications across multiple industries. As technology advances and new formulations are developed, PTFE is likely to play an increasingly important role in enhancing structural integrity across various sectors.

Current Challenges in PTFE Structural Implementation

Despite the numerous advantages of PTFE in structural applications, several significant challenges persist in its implementation for ensuring structural integrity. One of the primary obstacles is the material's inherent creep behavior under sustained loads. PTFE exhibits a tendency to deform gradually over time, even under relatively low stress levels, which can compromise the long-term stability and reliability of structures incorporating this material.

Another critical challenge lies in the bonding and joining of PTFE components to other materials. The low surface energy of PTFE makes it notoriously difficult to adhere to other substances, limiting its integration into complex structural systems. This issue often necessitates specialized surface treatment techniques or the development of novel bonding methods, which can increase manufacturing complexity and costs.

The thermal expansion characteristics of PTFE also present significant engineering hurdles. Its high coefficient of thermal expansion can lead to dimensional instability in structures exposed to temperature fluctuations, potentially causing misalignments, gaps, or excessive stress in composite structures. This property requires careful consideration in design and material selection processes, particularly for applications in environments with wide temperature ranges.

Furthermore, the relatively low mechanical strength of PTFE compared to traditional structural materials like metals or high-performance polymers limits its use in load-bearing applications. While PTFE offers excellent chemical resistance and low friction properties, its inability to withstand high stresses without deformation restricts its structural applications to specific, low-load scenarios.

The manufacturing of complex PTFE structures also presents challenges. Traditional fabrication methods for polymers, such as injection molding, are often not suitable for PTFE due to its high melting point and unique flow characteristics. This necessitates specialized processing techniques, which can be costly and limit the geometric complexity of PTFE components.

Lastly, the long-term durability and aging behavior of PTFE in structural applications remain areas of concern. While PTFE is known for its chemical inertness, prolonged exposure to certain environmental conditions, such as UV radiation or extreme temperatures, can potentially degrade its properties over time. Understanding and mitigating these long-term effects are crucial for ensuring the structural integrity of PTFE-based components throughout their intended service life.

Another critical challenge lies in the bonding and joining of PTFE components to other materials. The low surface energy of PTFE makes it notoriously difficult to adhere to other substances, limiting its integration into complex structural systems. This issue often necessitates specialized surface treatment techniques or the development of novel bonding methods, which can increase manufacturing complexity and costs.

The thermal expansion characteristics of PTFE also present significant engineering hurdles. Its high coefficient of thermal expansion can lead to dimensional instability in structures exposed to temperature fluctuations, potentially causing misalignments, gaps, or excessive stress in composite structures. This property requires careful consideration in design and material selection processes, particularly for applications in environments with wide temperature ranges.

Furthermore, the relatively low mechanical strength of PTFE compared to traditional structural materials like metals or high-performance polymers limits its use in load-bearing applications. While PTFE offers excellent chemical resistance and low friction properties, its inability to withstand high stresses without deformation restricts its structural applications to specific, low-load scenarios.

The manufacturing of complex PTFE structures also presents challenges. Traditional fabrication methods for polymers, such as injection molding, are often not suitable for PTFE due to its high melting point and unique flow characteristics. This necessitates specialized processing techniques, which can be costly and limit the geometric complexity of PTFE components.

Lastly, the long-term durability and aging behavior of PTFE in structural applications remain areas of concern. While PTFE is known for its chemical inertness, prolonged exposure to certain environmental conditions, such as UV radiation or extreme temperatures, can potentially degrade its properties over time. Understanding and mitigating these long-term effects are crucial for ensuring the structural integrity of PTFE-based components throughout their intended service life.

Existing PTFE Structural Integration Methods

01 PTFE composite materials for enhanced structural integrity

PTFE can be combined with other materials to create composites with improved structural integrity. These composites often incorporate reinforcing agents or fillers to enhance mechanical properties, such as strength and durability, while maintaining PTFE's desirable characteristics like low friction and chemical resistance.- PTFE composite materials for enhanced structural integrity: PTFE can be combined with other materials to create composites with improved structural integrity. These composites often incorporate reinforcing agents or fillers to enhance mechanical properties, such as strength and durability, while maintaining PTFE's desirable characteristics like chemical resistance and low friction.

- Manufacturing processes to improve PTFE structural integrity: Various manufacturing techniques can be employed to enhance the structural integrity of PTFE products. These may include specialized molding processes, sintering methods, or post-processing treatments that optimize the material's physical properties and performance characteristics.

- PTFE modifications for specific applications: PTFE can be modified or formulated to meet specific application requirements that demand enhanced structural integrity. This may involve the addition of specific additives, surface treatments, or the development of specialized PTFE grades tailored for particular use cases, such as in high-stress environments or extreme temperatures.

- Testing and analysis methods for PTFE structural integrity: Various testing and analysis techniques are employed to evaluate and ensure the structural integrity of PTFE components. These may include mechanical testing, microscopic analysis, thermal analysis, and accelerated aging tests to assess the material's performance and durability under different conditions.

- PTFE in composite structures for industrial applications: PTFE is utilized in composite structures for various industrial applications where structural integrity is crucial. These composites may incorporate PTFE as a key component in multi-layer structures, coatings, or as part of complex assemblies designed to withstand challenging operational conditions in sectors such as aerospace, oil and gas, or chemical processing.

02 Manufacturing processes to improve PTFE structural integrity

Various manufacturing techniques can be employed to enhance the structural integrity of PTFE products. These may include specialized molding processes, sintering methods, or post-processing treatments that optimize the material's physical properties and performance characteristics.Expand Specific Solutions03 PTFE modifications for specific applications

PTFE can be modified or formulated to meet specific structural requirements in various applications. This may involve the addition of specific additives, surface treatments, or the development of unique PTFE grades tailored to enhance structural integrity in particular use cases.Expand Specific Solutions04 Testing and analysis methods for PTFE structural integrity

Various testing and analysis techniques are used to evaluate and ensure the structural integrity of PTFE components. These may include mechanical testing, microscopic analysis, and simulation methods to assess factors such as strength, wear resistance, and long-term performance under different conditions.Expand Specific Solutions05 PTFE in multi-layer structures for improved integrity

PTFE can be incorporated into multi-layer structures or coatings to enhance overall structural integrity. These designs may combine PTFE with other materials in strategic configurations to leverage the unique properties of each component, resulting in improved performance and durability.Expand Specific Solutions

Key Players in PTFE Structural Materials

The implementation of PTFE for structural integrity is in a mature stage of development, with a significant market size and established technological applications. The competitive landscape is characterized by a mix of academic institutions, multinational corporations, and specialized manufacturers. Companies like DAIKIN INDUSTRIES Ltd., AGC, Inc., and Sumitomo Electric Industries Ltd. are leading players with advanced R&D capabilities. Emerging players such as Shandong Dongyue Polymer Material Co. Ltd. and Jiangsu Yihao Plastic Industry Co Ltd. are also making strides in PTFE applications. The technology's maturity is evident from its widespread use across industries, including aerospace, automotive, and medical devices, as seen in the involvement of companies like Medtronic Vascular, Inc. and Boston Scientific Scimed, Inc.

DAIKIN INDUSTRIES Ltd.

Technical Solution: Daikin has developed advanced PTFE (polytetrafluoroethylene) technologies for structural integrity applications. Their approach involves creating modified PTFE materials with enhanced mechanical properties. They use a unique polymerization process that results in a more uniform molecular structure, leading to improved tensile strength and elongation[1]. Daikin has also developed PTFE composites by incorporating fillers such as glass fibers or carbon nanotubes, which significantly enhance the material's load-bearing capacity and resistance to deformation under stress[3]. Additionally, they have implemented surface modification techniques to improve PTFE's adhesion to other materials, crucial for its use in composite structures[5].

Strengths: Superior chemical resistance, excellent thermal stability, and low friction properties. Weaknesses: Higher cost compared to conventional plastics, limited load-bearing capacity in pure form.

Shandong Dongyue Polymer Material Co. Ltd.

Technical Solution: Shandong Dongyue has developed a proprietary process for producing high-performance PTFE materials tailored for structural applications. Their method involves a controlled polymerization process that results in a more uniform molecular weight distribution, leading to improved mechanical properties[2]. They have also implemented a unique sintering process that enhances the material's crystallinity, resulting in better dimensional stability and reduced creep under load[4]. Furthermore, Dongyue has developed PTFE nanocomposites by incorporating nanoscale fillers, which significantly improve the material's compressive strength and wear resistance without compromising its chemical inertness[6].

Strengths: Excellent chemical resistance, good electrical insulation properties, and enhanced mechanical strength. Weaknesses: Relatively high production costs, limited high-temperature load-bearing capacity.

Innovative PTFE Structural Enhancement Techniques

Microporous polytetrafluoroethylene (PTFE) bodies with filler

PatentWO1997020881A1

Innovation

- Incorporating inorganic filler particles in the nanometer range (5-500 nm) into stretched polytetrafluoroethylene (ePTFE) to form a microporous PTFE body, where the nanoparticles are integrated into the structure without disrupting the fibril structure, thereby retaining the original properties of ePTFE.

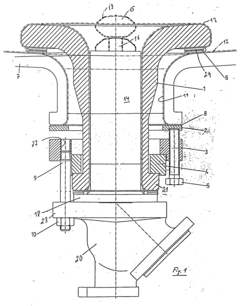

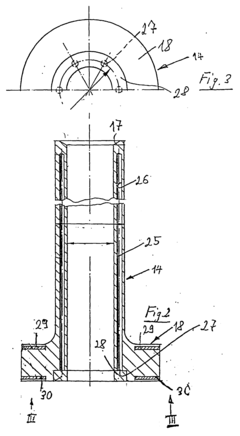

Tubular article used as a valve seat

PatentInactiveEP0908656A1

Innovation

- Integration of reinforcement inserts with matching thermophysical properties, such as glass, steel, or heat-resistant plastics, within the tubular fitting's wall, along with a radially projecting annular flange for fluid-tight mounting, eliminates the need for separate sealing rings and ensures stability at high temperatures.

Environmental Impact of PTFE in Structures

The implementation of Polytetrafluoroethylene (PTFE) in structural applications has raised significant environmental concerns due to its persistence and potential ecological impacts. PTFE, while offering excellent structural integrity benefits, is a synthetic fluoropolymer that does not naturally degrade in the environment. When used in buildings and infrastructure, PTFE can contribute to long-term environmental issues if not properly managed throughout its lifecycle.

One of the primary environmental concerns associated with PTFE in structures is its production process. The manufacture of PTFE involves the use of perfluorooctanoic acid (PFOA), a persistent organic pollutant that has been linked to various health and environmental issues. Although many manufacturers have phased out PFOA, the alternatives used may still pose environmental risks that require further study and mitigation strategies.

During the use phase, PTFE-based structural components generally have minimal direct environmental impact due to their inert nature. However, the material's resistance to degradation becomes problematic at the end of its life cycle. PTFE does not biodegrade and can persist in the environment for centuries, potentially accumulating in ecosystems and food chains if not properly disposed of or recycled.

The disposal and recycling of PTFE-containing structures present significant challenges. Incineration of PTFE can release harmful fluorine-containing compounds, including hydrofluoric acid and perfluoroisobutylene, which are toxic and contribute to air pollution. Landfilling is not an ideal solution either, as it does not address the material's persistence and may lead to soil and water contamination over time.

Efforts to mitigate the environmental impact of PTFE in structures focus on several areas. Improved production techniques aim to reduce or eliminate the use of harmful substances like PFOA. Additionally, research into alternative materials that offer similar structural benefits with reduced environmental impact is ongoing. The development of effective recycling methods for PTFE-containing building materials is crucial for minimizing waste and promoting a circular economy approach in construction.

Furthermore, the implementation of lifecycle assessments for PTFE-based structural components is becoming increasingly important. These assessments help quantify the environmental impacts from production to disposal, enabling more informed decision-making in material selection and end-of-life management. As awareness of PTFE's environmental implications grows, there is a push towards designing structures with easier disassembly and material recovery in mind, facilitating more efficient recycling and reducing the overall environmental footprint of PTFE use in construction.

One of the primary environmental concerns associated with PTFE in structures is its production process. The manufacture of PTFE involves the use of perfluorooctanoic acid (PFOA), a persistent organic pollutant that has been linked to various health and environmental issues. Although many manufacturers have phased out PFOA, the alternatives used may still pose environmental risks that require further study and mitigation strategies.

During the use phase, PTFE-based structural components generally have minimal direct environmental impact due to their inert nature. However, the material's resistance to degradation becomes problematic at the end of its life cycle. PTFE does not biodegrade and can persist in the environment for centuries, potentially accumulating in ecosystems and food chains if not properly disposed of or recycled.

The disposal and recycling of PTFE-containing structures present significant challenges. Incineration of PTFE can release harmful fluorine-containing compounds, including hydrofluoric acid and perfluoroisobutylene, which are toxic and contribute to air pollution. Landfilling is not an ideal solution either, as it does not address the material's persistence and may lead to soil and water contamination over time.

Efforts to mitigate the environmental impact of PTFE in structures focus on several areas. Improved production techniques aim to reduce or eliminate the use of harmful substances like PFOA. Additionally, research into alternative materials that offer similar structural benefits with reduced environmental impact is ongoing. The development of effective recycling methods for PTFE-containing building materials is crucial for minimizing waste and promoting a circular economy approach in construction.

Furthermore, the implementation of lifecycle assessments for PTFE-based structural components is becoming increasingly important. These assessments help quantify the environmental impacts from production to disposal, enabling more informed decision-making in material selection and end-of-life management. As awareness of PTFE's environmental implications grows, there is a push towards designing structures with easier disassembly and material recovery in mind, facilitating more efficient recycling and reducing the overall environmental footprint of PTFE use in construction.

PTFE Structural Standards and Regulations

The implementation of PTFE (Polytetrafluoroethylene) for structural integrity is governed by a comprehensive set of standards and regulations. These guidelines ensure the safe and effective use of PTFE in various structural applications, particularly in industries such as aerospace, chemical processing, and construction.

ASTM International, formerly known as the American Society for Testing and Materials, has developed several standards specifically for PTFE materials. ASTM D4894 and ASTM D4895 are key standards that outline the specifications for molded and ram extruded PTFE materials, respectively. These standards define the physical, mechanical, and thermal properties that PTFE must meet for structural applications.

The International Organization for Standardization (ISO) also provides relevant standards for PTFE in structural contexts. ISO 13000-1 and ISO 13000-2 cover the classification and specifications of PTFE sheets, rods, and tubes. These standards are crucial for ensuring consistency and quality in PTFE products used in structural components.

In the aerospace industry, the Federal Aviation Administration (FAA) and the European Aviation Safety Agency (EASA) have established regulations that impact the use of PTFE in aircraft structures. These regulations often reference military specifications such as MIL-P-22241, which details the requirements for PTFE in aerospace applications.

For chemical processing and industrial applications, the American Society of Mechanical Engineers (ASME) provides guidelines in its Boiler and Pressure Vessel Code. Section VIII of this code addresses the use of non-metallic materials, including PTFE, in pressure vessels and piping systems.

The Food and Drug Administration (FDA) in the United States regulates the use of PTFE in food contact applications, which can include certain structural components in food processing equipment. FDA 21 CFR 177.1550 outlines the specific requirements for PTFE used in these contexts.

Building codes and construction standards also play a role in regulating PTFE use in architectural applications. The International Building Code (IBC) and standards from organizations like the American Architectural Manufacturers Association (AAMA) provide guidelines for the use of PTFE-based materials in building envelopes and structures.

Environmental regulations, such as those set by the Environmental Protection Agency (EPA) in the United States and the European Chemicals Agency (ECHA) in the EU, also impact the use of PTFE in structural applications. These regulations focus on the environmental impact and potential health effects of PTFE and its manufacturing processes.

Compliance with these standards and regulations is essential for ensuring the structural integrity, safety, and performance of PTFE in various applications. Engineers and manufacturers must carefully consider these guidelines when implementing PTFE in structural designs to meet legal requirements and industry best practices.

ASTM International, formerly known as the American Society for Testing and Materials, has developed several standards specifically for PTFE materials. ASTM D4894 and ASTM D4895 are key standards that outline the specifications for molded and ram extruded PTFE materials, respectively. These standards define the physical, mechanical, and thermal properties that PTFE must meet for structural applications.

The International Organization for Standardization (ISO) also provides relevant standards for PTFE in structural contexts. ISO 13000-1 and ISO 13000-2 cover the classification and specifications of PTFE sheets, rods, and tubes. These standards are crucial for ensuring consistency and quality in PTFE products used in structural components.

In the aerospace industry, the Federal Aviation Administration (FAA) and the European Aviation Safety Agency (EASA) have established regulations that impact the use of PTFE in aircraft structures. These regulations often reference military specifications such as MIL-P-22241, which details the requirements for PTFE in aerospace applications.

For chemical processing and industrial applications, the American Society of Mechanical Engineers (ASME) provides guidelines in its Boiler and Pressure Vessel Code. Section VIII of this code addresses the use of non-metallic materials, including PTFE, in pressure vessels and piping systems.

The Food and Drug Administration (FDA) in the United States regulates the use of PTFE in food contact applications, which can include certain structural components in food processing equipment. FDA 21 CFR 177.1550 outlines the specific requirements for PTFE used in these contexts.

Building codes and construction standards also play a role in regulating PTFE use in architectural applications. The International Building Code (IBC) and standards from organizations like the American Architectural Manufacturers Association (AAMA) provide guidelines for the use of PTFE-based materials in building envelopes and structures.

Environmental regulations, such as those set by the Environmental Protection Agency (EPA) in the United States and the European Chemicals Agency (ECHA) in the EU, also impact the use of PTFE in structural applications. These regulations focus on the environmental impact and potential health effects of PTFE and its manufacturing processes.

Compliance with these standards and regulations is essential for ensuring the structural integrity, safety, and performance of PTFE in various applications. Engineers and manufacturers must carefully consider these guidelines when implementing PTFE in structural designs to meet legal requirements and industry best practices.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!