Comparative Study of Hydrothermal Growth and Vapor Phase Transport

SEP 28, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Crystal Growth Background and Objectives

Crystal growth techniques have evolved significantly over the past century, with hydrothermal growth and vapor phase transport emerging as two critical methodologies for synthesizing high-quality single crystals. The historical development of these techniques traces back to the mid-20th century, with hydrothermal growth gaining prominence in the 1960s for quartz production and vapor phase transport methods evolving from earlier sublimation techniques developed in the 1950s.

The technological evolution of crystal growth methods has been driven by increasing demands for higher purity, larger size, and more precise control over crystal properties across various industries. Hydrothermal growth, mimicking natural geothermal processes, has seen substantial refinements in pressure vessel design, temperature control systems, and nutrient dissolution mechanisms. Meanwhile, vapor phase transport has progressed through innovations in thermal gradient management, carrier gas optimization, and source material purification.

Current industry trends indicate a growing preference for techniques that offer scalability, energy efficiency, and environmental sustainability. The semiconductor industry's push toward larger wafers and higher purity materials has accelerated research in both methodologies, with particular emphasis on defect reduction and crystallographic perfection. Additionally, emerging applications in optoelectronics, quantum computing, and renewable energy have created new requirements for specialized crystal properties.

The primary technical objective of this comparative study is to establish a comprehensive framework for evaluating the relative merits of hydrothermal growth versus vapor phase transport across different material systems and application contexts. Specifically, we aim to quantify differences in crystal quality parameters including defect density, compositional uniformity, and structural perfection. Furthermore, we seek to identify optimal processing windows for each technique based on thermodynamic principles and growth kinetics.

Secondary objectives include developing predictive models for crystal growth rates and quality outcomes based on process parameters, establishing standardized protocols for characterization and quality assessment, and exploring hybrid approaches that might combine advantages of both methodologies. The study will also evaluate economic factors including equipment costs, energy consumption, and scalability to industrial production volumes.

By systematically addressing these objectives, this research aims to provide a decision-making framework for materials scientists and process engineers to select the most appropriate crystal growth technique for specific applications, while also identifying promising directions for future technical innovations in both methodologies. The findings will contribute to the broader understanding of crystal growth science and support continued advancement in materials technology.

The technological evolution of crystal growth methods has been driven by increasing demands for higher purity, larger size, and more precise control over crystal properties across various industries. Hydrothermal growth, mimicking natural geothermal processes, has seen substantial refinements in pressure vessel design, temperature control systems, and nutrient dissolution mechanisms. Meanwhile, vapor phase transport has progressed through innovations in thermal gradient management, carrier gas optimization, and source material purification.

Current industry trends indicate a growing preference for techniques that offer scalability, energy efficiency, and environmental sustainability. The semiconductor industry's push toward larger wafers and higher purity materials has accelerated research in both methodologies, with particular emphasis on defect reduction and crystallographic perfection. Additionally, emerging applications in optoelectronics, quantum computing, and renewable energy have created new requirements for specialized crystal properties.

The primary technical objective of this comparative study is to establish a comprehensive framework for evaluating the relative merits of hydrothermal growth versus vapor phase transport across different material systems and application contexts. Specifically, we aim to quantify differences in crystal quality parameters including defect density, compositional uniformity, and structural perfection. Furthermore, we seek to identify optimal processing windows for each technique based on thermodynamic principles and growth kinetics.

Secondary objectives include developing predictive models for crystal growth rates and quality outcomes based on process parameters, establishing standardized protocols for characterization and quality assessment, and exploring hybrid approaches that might combine advantages of both methodologies. The study will also evaluate economic factors including equipment costs, energy consumption, and scalability to industrial production volumes.

By systematically addressing these objectives, this research aims to provide a decision-making framework for materials scientists and process engineers to select the most appropriate crystal growth technique for specific applications, while also identifying promising directions for future technical innovations in both methodologies. The findings will contribute to the broader understanding of crystal growth science and support continued advancement in materials technology.

Market Applications Analysis

The market for crystal growth technologies, particularly hydrothermal growth and vapor phase transport methods, has experienced significant expansion across multiple industries. These crystal growth techniques are fundamental to producing high-quality single crystals that serve as the foundation for numerous advanced applications.

The semiconductor industry represents the largest market segment utilizing these crystal growth methods, with an estimated market value exceeding $500 billion globally. Silicon carbide (SiC) and gallium nitride (GaN) crystals grown through these techniques are increasingly replacing traditional silicon in power electronics, particularly in electric vehicles and renewable energy systems. The demand for wide-bandgap semiconductors continues to grow at approximately 25% annually, driven by their superior performance in high-temperature and high-power applications.

Optoelectronics constitutes another substantial market application, where crystals grown through hydrothermal and vapor phase methods are essential for LED manufacturing, laser technologies, and photonic devices. The precision offered by vapor phase transport in producing uniform, defect-free crystals has made it particularly valuable for optical applications requiring exceptional purity and structural perfection.

The medical technology sector has also embraced these crystal growth techniques for specialized applications. Scintillation crystals produced through these methods are crucial components in medical imaging equipment such as PET scanners and radiation detectors. The global medical crystal market segment is growing steadily at 7-8% annually, with increasing demand for higher resolution imaging technologies.

Renewable energy applications represent an emerging market with substantial growth potential. Crystals grown through hydrothermal methods are being developed for next-generation solar cells and energy storage solutions. The superior control over crystal properties offered by these techniques enables the creation of materials with enhanced energy conversion efficiencies.

Industrial applications, including abrasives, cutting tools, and wear-resistant components, constitute a stable market segment for crystals produced through these growth methods. The aerospace and defense sectors also utilize specialized crystals for sensors, communication systems, and advanced electronics, creating a premium market segment where quality requirements justify higher production costs.

The jewelry and luxury goods industry represents a niche but profitable application area, particularly for hydrothermal growth of gemstones like emeralds and quartz. This segment values the ability to produce large, flawless crystals with consistent coloration and optical properties.

The semiconductor industry represents the largest market segment utilizing these crystal growth methods, with an estimated market value exceeding $500 billion globally. Silicon carbide (SiC) and gallium nitride (GaN) crystals grown through these techniques are increasingly replacing traditional silicon in power electronics, particularly in electric vehicles and renewable energy systems. The demand for wide-bandgap semiconductors continues to grow at approximately 25% annually, driven by their superior performance in high-temperature and high-power applications.

Optoelectronics constitutes another substantial market application, where crystals grown through hydrothermal and vapor phase methods are essential for LED manufacturing, laser technologies, and photonic devices. The precision offered by vapor phase transport in producing uniform, defect-free crystals has made it particularly valuable for optical applications requiring exceptional purity and structural perfection.

The medical technology sector has also embraced these crystal growth techniques for specialized applications. Scintillation crystals produced through these methods are crucial components in medical imaging equipment such as PET scanners and radiation detectors. The global medical crystal market segment is growing steadily at 7-8% annually, with increasing demand for higher resolution imaging technologies.

Renewable energy applications represent an emerging market with substantial growth potential. Crystals grown through hydrothermal methods are being developed for next-generation solar cells and energy storage solutions. The superior control over crystal properties offered by these techniques enables the creation of materials with enhanced energy conversion efficiencies.

Industrial applications, including abrasives, cutting tools, and wear-resistant components, constitute a stable market segment for crystals produced through these growth methods. The aerospace and defense sectors also utilize specialized crystals for sensors, communication systems, and advanced electronics, creating a premium market segment where quality requirements justify higher production costs.

The jewelry and luxury goods industry represents a niche but profitable application area, particularly for hydrothermal growth of gemstones like emeralds and quartz. This segment values the ability to produce large, flawless crystals with consistent coloration and optical properties.

Current Status and Technical Challenges

Hydrothermal growth and vapor phase transport represent two significant crystal growth techniques that have been extensively studied and applied in materials science. Currently, these methods are at different stages of technological maturity and face distinct challenges in their implementation and optimization.

The global landscape of hydrothermal growth technology shows considerable advancement, with countries like Japan, the United States, and China leading research efforts. This method has achieved commercial success in growing quartz crystals and has been adapted for various other materials including ZnO, GaN, and complex oxides. The primary technical challenge for hydrothermal growth lies in the extreme conditions required—high pressure (up to 300 MPa) and high temperature (up to 700°C)—necessitating specialized equipment with significant capital investment.

Vapor phase transport, meanwhile, has seen widespread adoption in semiconductor industry applications, particularly for III-V and II-VI compound semiconductors. The technique offers advantages in purity control but struggles with scalability for large-diameter crystals. Recent innovations have focused on modified vapor transport methods that incorporate carrier gases or hybrid approaches combining aspects of different growth techniques.

A critical limitation in both methods is the precise control of growth parameters. For hydrothermal growth, the complex relationship between solution chemistry, temperature gradients, and crystal quality presents significant challenges. Researchers continue to develop in-situ monitoring techniques to better understand and control the growth process, but real-time observation remains difficult due to the opaque nature of pressure vessels.

For vapor phase transport, the main technical hurdles include controlling nucleation sites, managing growth rates, and achieving uniform material properties across larger substrates. The technique also faces challenges in terms of energy efficiency and environmental impact, as traditional methods often require high temperatures maintained over extended periods.

Material-specific challenges exist for both techniques. For example, hydrothermal growth of GaN faces issues with nitrogen solubility and mineralizer selection, while vapor transport of wide-bandgap semiconductors struggles with controlling stoichiometry and defect formation. These challenges have spurred research into hybrid approaches that combine elements of both methods to overcome their respective limitations.

The geographical distribution of research expertise shows concentration in East Asia, North America, and Europe, with emerging contributions from research institutions in India and Brazil. Industrial implementation remains primarily centered in technologically advanced economies, creating potential barriers to technology transfer and global adoption.

The global landscape of hydrothermal growth technology shows considerable advancement, with countries like Japan, the United States, and China leading research efforts. This method has achieved commercial success in growing quartz crystals and has been adapted for various other materials including ZnO, GaN, and complex oxides. The primary technical challenge for hydrothermal growth lies in the extreme conditions required—high pressure (up to 300 MPa) and high temperature (up to 700°C)—necessitating specialized equipment with significant capital investment.

Vapor phase transport, meanwhile, has seen widespread adoption in semiconductor industry applications, particularly for III-V and II-VI compound semiconductors. The technique offers advantages in purity control but struggles with scalability for large-diameter crystals. Recent innovations have focused on modified vapor transport methods that incorporate carrier gases or hybrid approaches combining aspects of different growth techniques.

A critical limitation in both methods is the precise control of growth parameters. For hydrothermal growth, the complex relationship between solution chemistry, temperature gradients, and crystal quality presents significant challenges. Researchers continue to develop in-situ monitoring techniques to better understand and control the growth process, but real-time observation remains difficult due to the opaque nature of pressure vessels.

For vapor phase transport, the main technical hurdles include controlling nucleation sites, managing growth rates, and achieving uniform material properties across larger substrates. The technique also faces challenges in terms of energy efficiency and environmental impact, as traditional methods often require high temperatures maintained over extended periods.

Material-specific challenges exist for both techniques. For example, hydrothermal growth of GaN faces issues with nitrogen solubility and mineralizer selection, while vapor transport of wide-bandgap semiconductors struggles with controlling stoichiometry and defect formation. These challenges have spurred research into hybrid approaches that combine elements of both methods to overcome their respective limitations.

The geographical distribution of research expertise shows concentration in East Asia, North America, and Europe, with emerging contributions from research institutions in India and Brazil. Industrial implementation remains primarily centered in technologically advanced economies, creating potential barriers to technology transfer and global adoption.

Comparative Analysis of Growth Methods

01 Crystal growth methods using hydrothermal techniques

Hydrothermal growth techniques involve the crystallization of materials from high-temperature aqueous solutions under high pressure conditions. This method is particularly effective for growing single crystals with high quality and purity. The process typically uses autoclaves or pressure vessels where precursor materials are dissolved in a solvent at elevated temperatures and pressures, allowing for controlled crystal formation. These techniques are widely used for growing various semiconductor materials, oxide crystals, and other advanced materials with specific electronic or optical properties.- Crystal growth techniques for semiconductor materials: Hydrothermal growth and vapor phase transport are key methods for growing high-quality semiconductor crystals. These techniques involve controlled temperature and pressure conditions to facilitate crystal formation from solution or vapor. The hydrothermal method uses aqueous solutions at elevated temperatures and pressures, while vapor phase transport relies on the sublimation and redeposition of materials in a temperature gradient. These approaches are particularly valuable for growing materials like GaN, SiC, and other compound semiconductors used in electronic and optoelectronic devices.

- Growth of wide bandgap materials and substrates: Specialized hydrothermal and vapor phase transport techniques have been developed for growing wide bandgap materials such as gallium nitride, aluminum nitride, and silicon carbide. These methods enable the production of high-quality single crystals with minimal defects, which serve as substrates for subsequent device fabrication. The processes typically involve precise control of temperature gradients, pressure conditions, and precursor materials to achieve desired crystal properties. These techniques address challenges in producing large-area, low-defect substrates that are critical for high-performance electronic and optoelectronic applications.

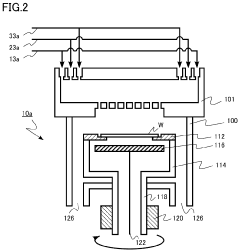

- Equipment and apparatus for crystal growth processes: Specialized equipment and apparatus designs are essential for implementing hydrothermal growth and vapor phase transport processes. These include high-pressure autoclaves for hydrothermal synthesis, specialized furnaces with precise temperature control for vapor transport, and custom-designed reactors that can withstand extreme conditions. The equipment often incorporates monitoring systems to track growth parameters and ensure process stability. Innovations in reactor design focus on improving uniformity, scalability, and reproducibility of crystal growth while maintaining safety under high-temperature and high-pressure conditions.

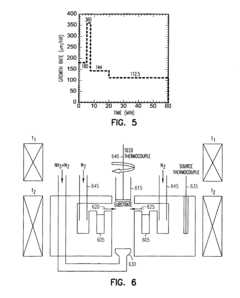

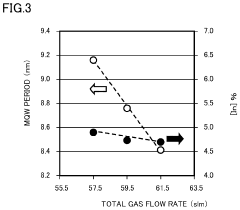

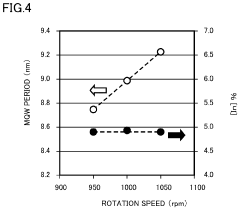

- Growth parameters and process optimization: Successful crystal growth through hydrothermal and vapor phase transport methods depends on careful optimization of multiple process parameters. These include temperature gradients, pressure conditions, growth duration, precursor composition, and transport agent selection. Research focuses on understanding the relationship between these parameters and resulting crystal quality, growth rate, and defect formation. Advanced modeling and in-situ monitoring techniques help in developing optimized growth recipes for specific materials. Process innovations aim to increase crystal size, improve quality, and reduce production costs for commercial applications.

- Novel applications and advanced materials: Hydrothermal growth and vapor phase transport techniques are being applied to develop novel materials and structures beyond traditional semiconductors. These include specialized oxide crystals, two-dimensional materials, nanostructures, and composite materials with unique properties. The methods are also being adapted for growing biocompatible materials for medical applications and specialized optical materials. Research is exploring how these growth techniques can be combined with other fabrication methods to create advanced heterostructures and devices with enhanced functionality for applications in electronics, photonics, energy conversion, and sensing.

02 Vapor phase transport for semiconductor material growth

Vapor phase transport is a crystal growth technique where source materials are vaporized and transported through a gas phase to a cooler region where they condense and form crystals. This method is particularly useful for growing high-purity semiconductor materials and thin films. The process often involves a temperature gradient that drives the transport of vaporized materials from the source to the growth zone. Various carrier gases and transport agents can be used to enhance the efficiency of material transport and control the crystal growth rate and quality.Expand Specific Solutions03 Combined hydrothermal and vapor transport techniques for advanced materials

Hybrid approaches combining elements of both hydrothermal growth and vapor phase transport offer unique advantages for synthesizing complex materials. These combined methods can provide better control over crystal morphology, composition, and defect concentration. The integration of these techniques allows for the growth of materials that may be difficult to synthesize using either method alone. Such hybrid approaches are particularly valuable for developing novel materials with tailored properties for specific applications in electronics, optics, and energy conversion.Expand Specific Solutions04 Equipment and apparatus design for crystal growth processes

Specialized equipment and apparatus designs are crucial for effective implementation of hydrothermal growth and vapor phase transport techniques. These include custom-designed autoclaves, pressure vessels, furnaces with precise temperature control, and specialized reactor chambers. The equipment often incorporates features for monitoring and controlling process parameters such as temperature gradients, pressure, and gas flow rates. Advanced designs may include mechanisms for in-situ observation of crystal growth, automated control systems, and safety features to handle the high-pressure and high-temperature conditions typically required.Expand Specific Solutions05 Applications of crystals grown by hydrothermal and vapor transport methods

Crystals grown using hydrothermal and vapor transport methods find applications across various technological fields. These include semiconductor devices, optoelectronic components, piezoelectric materials, and substrates for epitaxial growth. The high-quality single crystals produced by these methods are essential for advanced electronic devices, sensors, lasers, and other photonic applications. The controlled growth conditions allow for tailoring material properties to meet specific requirements for emerging technologies in communications, computing, medical devices, and renewable energy systems.Expand Specific Solutions

Key Industry Players and Research Groups

The hydrothermal growth and vapor phase transport technology landscape is currently in a growth phase, with increasing market adoption across semiconductor, electronics, and materials science sectors. The global market is expanding rapidly, driven by demand for high-quality crystals in advanced applications. Technologically, the field shows varying maturity levels, with established players like Shin-Etsu Handotai, NuFlare Technology, and Mitsubishi Electric demonstrating commercial-scale production capabilities, while research institutions such as Beihang University, Central South University, and Wuhan University are advancing fundamental innovations. Academic-industrial collaborations between companies like EPISTAR Corp. and Sony Group with research institutions are accelerating development, particularly in wide-bandgap semiconductors and novel crystal growth techniques, positioning this technology for significant expansion in next-generation electronic applications.

NuFlare Technology, Inc.

Technical Solution: NuFlare Technology has developed advanced hydrothermal growth systems for producing high-quality single crystals, particularly focusing on piezoelectric materials like LiNbO3 and LiTaO3. Their proprietary autoclave design incorporates precise temperature control mechanisms that maintain stable temperature gradients (±0.1°C) throughout the growth process. The company's hydrothermal growth technology utilizes specialized mineralizers and optimized pressure conditions (100-200 MPa) to achieve growth rates of approximately 0.5-1 mm/day while minimizing defect formation. NuFlare has also pioneered hybrid approaches that combine aspects of hydrothermal growth with vapor phase transport for specialized applications requiring both high purity and controlled doping profiles.

Strengths: Superior crystal quality with extremely low dislocation density (<10^3 cm^-2); excellent compositional uniformity; ability to grow large crystals (>4 inches). Weaknesses: Relatively slow growth rates compared to other methods; high equipment costs; process requires specialized high-pressure vessels with significant safety considerations.

Shin-Etsu Handotai Co., Ltd.

Technical Solution: Shin-Etsu Handotai has developed sophisticated vapor phase transport (VPT) systems for semiconductor materials, particularly focusing on SiC and GaN crystal growth. Their technology utilizes a modified physical vapor transport (PVT) method with precisely controlled temperature gradients (typically 2200-2400°C at source, 50-100°C lower at substrate) and carrier gas compositions to achieve high-quality crystal growth. The company's proprietary reactor designs incorporate specialized graphite crucibles with optimized geometry to enhance mass transport efficiency and reduce parasitic nucleation. Shin-Etsu's VPT process achieves growth rates of 0.5-1 mm/hour while maintaining low defect densities. Their technology also includes post-growth annealing processes to further reduce dislocations and improve crystal quality.

Strengths: High growth rates compared to hydrothermal methods; excellent scalability for industrial production; ability to produce ultra-high purity crystals with controlled doping. Weaknesses: Higher energy consumption due to elevated process temperatures; challenges in maintaining uniform growth conditions across large diameter substrates; limited to materials with suitable vapor pressure characteristics.

Critical Patents and Scientific Literature

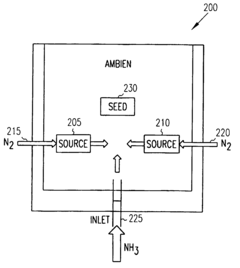

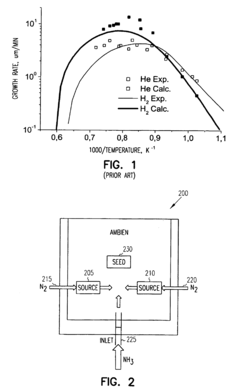

GaN bulk growth by Ga vapor transport

PatentActiveUS7867335B2

Innovation

- The method involves creating a high supersaturated Ga vapor using GaN powder and an inert gas, injecting it with a nitride source like ammonia, allowing for stable and high growth rates of thick GaN films or boules by separating the Ga vapor generation from the growth site, enabling control over Ga vapor concentration and substrate temperature.

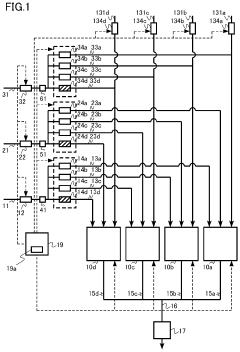

Vapor phase growth apparatus and vapor phase growth method

PatentActiveUS11124894B2

Innovation

- A vapor phase growth apparatus and method that utilize multiple reactors with independent control of process gas flow rates and parameters, including group-III and group-V elements, rotation speed, and temperature, allowing for simultaneous film growth with adjusted characteristics across multiple substrates.

Material Properties and Characterization

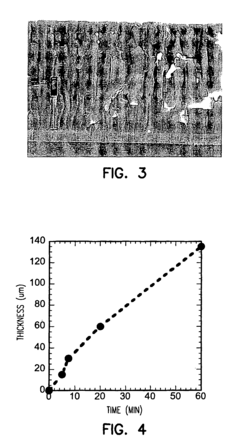

The comparative analysis of materials produced through hydrothermal growth and vapor phase transport reveals significant differences in their structural, optical, and electrical properties. Crystals grown via hydrothermal methods typically exhibit higher purity levels with fewer point defects, particularly oxygen vacancies, compared to their vapor transport counterparts. X-ray diffraction (XRD) analyses demonstrate that hydrothermally grown crystals often possess superior crystallinity with lattice parameters closer to theoretical values, indicating reduced internal strain.

Scanning electron microscopy (SEM) examinations show distinct morphological characteristics between the two growth methods. Hydrothermal crystals frequently display well-defined facets and smoother surfaces, while vapor transport crystals may exhibit terraced structures and higher density of surface irregularities. These morphological differences directly impact the material's surface-to-volume ratio and consequently affect their performance in various applications.

Photoluminescence (PL) spectroscopy reveals that the optical properties vary significantly between the two growth techniques. Hydrothermally grown materials generally demonstrate narrower emission peaks with reduced deep-level emissions, suggesting fewer defect states within the bandgap. Conversely, vapor transport materials often show broader emission spectra with additional peaks attributed to native defects and impurities incorporated during the growth process.

Electrical characterization through Hall effect measurements indicates that carrier mobility and concentration differ substantially between the two growth methods. Hydrothermally grown crystals typically exhibit more uniform carrier distribution and higher mobility values due to reduced scattering from defects. The resistivity profiles across samples also show greater consistency in hydrothermal materials, whereas vapor transport samples often display position-dependent electrical properties.

Thermal conductivity measurements reveal that hydrothermally grown crystals generally possess higher thermal conductivity values, attributed to their lower concentration of phonon-scattering defects. This property is particularly crucial for high-power electronic applications where efficient heat dissipation is essential for device reliability and performance.

Mechanical testing demonstrates that hydrothermal crystals often exhibit higher hardness values and fracture toughness compared to vapor transport materials. These enhanced mechanical properties can be attributed to the more uniform microstructure and lower concentration of extended defects such as dislocations and grain boundaries in hydrothermally grown materials.

Scanning electron microscopy (SEM) examinations show distinct morphological characteristics between the two growth methods. Hydrothermal crystals frequently display well-defined facets and smoother surfaces, while vapor transport crystals may exhibit terraced structures and higher density of surface irregularities. These morphological differences directly impact the material's surface-to-volume ratio and consequently affect their performance in various applications.

Photoluminescence (PL) spectroscopy reveals that the optical properties vary significantly between the two growth techniques. Hydrothermally grown materials generally demonstrate narrower emission peaks with reduced deep-level emissions, suggesting fewer defect states within the bandgap. Conversely, vapor transport materials often show broader emission spectra with additional peaks attributed to native defects and impurities incorporated during the growth process.

Electrical characterization through Hall effect measurements indicates that carrier mobility and concentration differ substantially between the two growth methods. Hydrothermally grown crystals typically exhibit more uniform carrier distribution and higher mobility values due to reduced scattering from defects. The resistivity profiles across samples also show greater consistency in hydrothermal materials, whereas vapor transport samples often display position-dependent electrical properties.

Thermal conductivity measurements reveal that hydrothermally grown crystals generally possess higher thermal conductivity values, attributed to their lower concentration of phonon-scattering defects. This property is particularly crucial for high-power electronic applications where efficient heat dissipation is essential for device reliability and performance.

Mechanical testing demonstrates that hydrothermal crystals often exhibit higher hardness values and fracture toughness compared to vapor transport materials. These enhanced mechanical properties can be attributed to the more uniform microstructure and lower concentration of extended defects such as dislocations and grain boundaries in hydrothermally grown materials.

Environmental Impact and Sustainability

The environmental footprint of crystal growth methods has become increasingly important as sustainability concerns rise across industries. Hydrothermal growth and vapor phase transport (VPT) methods present distinctly different environmental profiles that warrant careful consideration for future technological implementations.

Hydrothermal growth processes typically operate in closed systems using water as the primary solvent, which inherently reduces volatile emissions compared to other methods. However, these systems require significant energy input to maintain high temperatures and pressures over extended periods, often ranging from 400-600°C and 100-400 MPa. The energy intensity translates to considerable carbon emissions when powered by non-renewable sources. Additionally, hydrothermal methods frequently employ mineralizers such as NaOH, KOH, or Na2CO3 that require proper neutralization and disposal to prevent environmental contamination.

Vapor phase transport, by contrast, generally operates at higher temperatures (800-1200°C) but often at lower pressures, creating a different energy consumption profile. VPT methods typically use transport agents like halogens or metal halides that can pose significant environmental and health risks if released. The gaseous byproducts require sophisticated scrubbing and treatment systems to prevent atmospheric pollution.

Water consumption represents another critical difference between these techniques. Hydrothermal growth, as its name suggests, requires substantial quantities of ultrapure water, placing pressure on water resources. VPT methods generally consume less water but may require more specialized gases and chemicals that have their own extraction and production footprints.

Raw material efficiency also differs significantly between these approaches. Hydrothermal methods often achieve higher yield rates and can utilize lower-grade precursors due to the solvent properties of supercritical water. VPT techniques typically require higher-purity starting materials but can achieve exceptional crystal quality with less material waste in optimized systems.

The recyclability of process components presents another sustainability consideration. Hydrothermal autoclaves can be reused for thousands of growth cycles, though the corrosive conditions gradually degrade equipment. VPT systems generally experience less corrosion but may require more frequent replacement of certain components due to deposition on reactor walls.

Recent innovations in both methods have focused on reducing environmental impact through energy recovery systems, closed-loop chemical recycling, and process optimization. Some manufacturers have implemented renewable energy sources specifically for crystal growth operations, significantly reducing the carbon footprint of both techniques. As regulatory pressures increase globally, further advancements in sustainable crystal growth technologies will likely accelerate, potentially altering the comparative environmental profiles of these important manufacturing processes.

Hydrothermal growth processes typically operate in closed systems using water as the primary solvent, which inherently reduces volatile emissions compared to other methods. However, these systems require significant energy input to maintain high temperatures and pressures over extended periods, often ranging from 400-600°C and 100-400 MPa. The energy intensity translates to considerable carbon emissions when powered by non-renewable sources. Additionally, hydrothermal methods frequently employ mineralizers such as NaOH, KOH, or Na2CO3 that require proper neutralization and disposal to prevent environmental contamination.

Vapor phase transport, by contrast, generally operates at higher temperatures (800-1200°C) but often at lower pressures, creating a different energy consumption profile. VPT methods typically use transport agents like halogens or metal halides that can pose significant environmental and health risks if released. The gaseous byproducts require sophisticated scrubbing and treatment systems to prevent atmospheric pollution.

Water consumption represents another critical difference between these techniques. Hydrothermal growth, as its name suggests, requires substantial quantities of ultrapure water, placing pressure on water resources. VPT methods generally consume less water but may require more specialized gases and chemicals that have their own extraction and production footprints.

Raw material efficiency also differs significantly between these approaches. Hydrothermal methods often achieve higher yield rates and can utilize lower-grade precursors due to the solvent properties of supercritical water. VPT techniques typically require higher-purity starting materials but can achieve exceptional crystal quality with less material waste in optimized systems.

The recyclability of process components presents another sustainability consideration. Hydrothermal autoclaves can be reused for thousands of growth cycles, though the corrosive conditions gradually degrade equipment. VPT systems generally experience less corrosion but may require more frequent replacement of certain components due to deposition on reactor walls.

Recent innovations in both methods have focused on reducing environmental impact through energy recovery systems, closed-loop chemical recycling, and process optimization. Some manufacturers have implemented renewable energy sources specifically for crystal growth operations, significantly reducing the carbon footprint of both techniques. As regulatory pressures increase globally, further advancements in sustainable crystal growth technologies will likely accelerate, potentially altering the comparative environmental profiles of these important manufacturing processes.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!