Hydrothermal Growth of Single Crystals for Photonic Applications

SEP 28, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Hydrothermal Crystal Growth Background and Objectives

Hydrothermal crystal growth represents one of the most significant methodologies for synthesizing high-quality single crystals, particularly for photonic applications. This technique emerged in the mid-20th century as researchers sought to replicate natural mineral formation processes occurring deep within the Earth's crust. The fundamental principle involves dissolving materials in superheated water under high pressure conditions, followed by controlled crystallization through precise temperature gradients.

The evolution of hydrothermal crystal growth has been marked by several technological breakthroughs, from basic autoclave designs in the 1950s to sophisticated computer-controlled systems in recent decades. Initially developed for quartz crystal production for electronic oscillators, the technology has expanded to encompass a wide range of materials including oxides, phosphates, silicates, and complex multi-component crystals essential for modern photonic applications.

Current technological trends indicate a growing emphasis on scalable production methods, improved crystal quality, and enhanced control over crystal properties. The integration of computational modeling with experimental approaches has accelerated development cycles and enabled more precise prediction of growth parameters. Additionally, there is increasing focus on environmentally sustainable growth processes that minimize resource consumption and hazardous waste generation.

The primary objectives of hydrothermal crystal growth research for photonic applications center on several key areas. First, achieving larger crystal dimensions while maintaining exceptional optical quality remains a persistent challenge. Second, researchers aim to develop more efficient growth processes with higher yield rates and reduced energy consumption. Third, there is significant interest in expanding the range of materials that can be successfully grown using hydrothermal techniques.

For photonic applications specifically, objectives include developing crystals with precisely controlled dopant concentrations, minimizing defect densities that can cause optical scattering, and engineering specific optical properties such as birefringence, nonlinear coefficients, and transmission ranges. The ability to tailor bandgap characteristics and create designer crystals with predetermined properties represents the frontier of current research efforts.

Another critical objective involves reducing the time-to-market for new crystal materials, as traditional development cycles often span several years from initial research to commercial production. This necessitates innovations in growth technology, characterization methods, and process optimization techniques that can accelerate the transition from laboratory to industrial scale.

The ultimate goal is to establish hydrothermal crystal growth as a versatile, reliable, and economically viable method for producing next-generation photonic materials that will enable advances in laser technology, optical communication, quantum computing, and sensing applications.

The evolution of hydrothermal crystal growth has been marked by several technological breakthroughs, from basic autoclave designs in the 1950s to sophisticated computer-controlled systems in recent decades. Initially developed for quartz crystal production for electronic oscillators, the technology has expanded to encompass a wide range of materials including oxides, phosphates, silicates, and complex multi-component crystals essential for modern photonic applications.

Current technological trends indicate a growing emphasis on scalable production methods, improved crystal quality, and enhanced control over crystal properties. The integration of computational modeling with experimental approaches has accelerated development cycles and enabled more precise prediction of growth parameters. Additionally, there is increasing focus on environmentally sustainable growth processes that minimize resource consumption and hazardous waste generation.

The primary objectives of hydrothermal crystal growth research for photonic applications center on several key areas. First, achieving larger crystal dimensions while maintaining exceptional optical quality remains a persistent challenge. Second, researchers aim to develop more efficient growth processes with higher yield rates and reduced energy consumption. Third, there is significant interest in expanding the range of materials that can be successfully grown using hydrothermal techniques.

For photonic applications specifically, objectives include developing crystals with precisely controlled dopant concentrations, minimizing defect densities that can cause optical scattering, and engineering specific optical properties such as birefringence, nonlinear coefficients, and transmission ranges. The ability to tailor bandgap characteristics and create designer crystals with predetermined properties represents the frontier of current research efforts.

Another critical objective involves reducing the time-to-market for new crystal materials, as traditional development cycles often span several years from initial research to commercial production. This necessitates innovations in growth technology, characterization methods, and process optimization techniques that can accelerate the transition from laboratory to industrial scale.

The ultimate goal is to establish hydrothermal crystal growth as a versatile, reliable, and economically viable method for producing next-generation photonic materials that will enable advances in laser technology, optical communication, quantum computing, and sensing applications.

Market Analysis for Photonic Crystal Applications

The global market for photonic crystal applications is experiencing robust growth, driven by increasing demand for advanced optical communication systems, sensing technologies, and energy-efficient solutions. Current market valuations place the photonic crystals sector at approximately 10.2 billion USD in 2023, with projections indicating a compound annual growth rate (CAGR) of 8.7% through 2030. This growth trajectory is particularly pronounced in telecommunications, where the need for higher bandwidth and faster data transmission continues to escalate with the ongoing deployment of 5G networks and preparation for 6G technologies.

Regionally, North America and Europe currently dominate the market share, collectively accounting for over 60% of global revenue. However, the Asia-Pacific region is demonstrating the most aggressive growth rates, particularly in countries like China, Japan, and South Korea, where substantial investments in photonic infrastructure and manufacturing capabilities are being made. This regional shift is expected to significantly alter market dynamics over the next decade.

By application segment, telecommunications represents the largest market share at 35%, followed by sensing applications at 25%, and display technologies at 18%. Emerging applications in quantum computing and medical diagnostics, though currently smaller segments, are showing the highest growth potential with annual increases exceeding 12%.

The demand for single crystals grown through hydrothermal methods is particularly strong in the photonics sector due to their superior optical properties, including high transparency, low defect density, and excellent thermal stability. These characteristics make them ideal for applications requiring precise light manipulation and high-performance optical components.

Customer segments show distinct preferences, with research institutions and defense sectors prioritizing performance over cost, while commercial telecommunications and consumer electronics manufacturers seek a balance between performance and economic viability. This dichotomy is creating a two-tiered market structure that influences product development strategies.

Supply chain analysis reveals potential vulnerabilities in raw material sourcing, particularly for rare earth elements used in certain crystal formulations. Geopolitical factors affecting these supply chains could impact market stability and pricing structures in the coming years.

Competitive pricing analysis indicates that while initial costs for hydrothermal-grown single crystals remain higher than alternative manufacturing methods, the total cost of ownership often favors these premium materials due to their longevity, reliability, and superior performance characteristics in demanding photonic applications.

Regionally, North America and Europe currently dominate the market share, collectively accounting for over 60% of global revenue. However, the Asia-Pacific region is demonstrating the most aggressive growth rates, particularly in countries like China, Japan, and South Korea, where substantial investments in photonic infrastructure and manufacturing capabilities are being made. This regional shift is expected to significantly alter market dynamics over the next decade.

By application segment, telecommunications represents the largest market share at 35%, followed by sensing applications at 25%, and display technologies at 18%. Emerging applications in quantum computing and medical diagnostics, though currently smaller segments, are showing the highest growth potential with annual increases exceeding 12%.

The demand for single crystals grown through hydrothermal methods is particularly strong in the photonics sector due to their superior optical properties, including high transparency, low defect density, and excellent thermal stability. These characteristics make them ideal for applications requiring precise light manipulation and high-performance optical components.

Customer segments show distinct preferences, with research institutions and defense sectors prioritizing performance over cost, while commercial telecommunications and consumer electronics manufacturers seek a balance between performance and economic viability. This dichotomy is creating a two-tiered market structure that influences product development strategies.

Supply chain analysis reveals potential vulnerabilities in raw material sourcing, particularly for rare earth elements used in certain crystal formulations. Geopolitical factors affecting these supply chains could impact market stability and pricing structures in the coming years.

Competitive pricing analysis indicates that while initial costs for hydrothermal-grown single crystals remain higher than alternative manufacturing methods, the total cost of ownership often favors these premium materials due to their longevity, reliability, and superior performance characteristics in demanding photonic applications.

Current Hydrothermal Synthesis Challenges

Despite significant advancements in hydrothermal crystal growth techniques, several critical challenges persist in the synthesis of high-quality single crystals for photonic applications. Temperature and pressure control remains one of the most formidable obstacles, as even minor fluctuations can lead to crystal defects, inconsistent growth rates, and compositional inhomogeneities. Current autoclave systems struggle to maintain the precise conditions required for extended periods, particularly when growing larger crystals that may require weeks or months of stable conditions.

Scalability presents another significant hurdle, as the transition from laboratory-scale production to industrial volumes introduces complications in maintaining uniform growth conditions throughout larger autoclaves. The geometric constraints of pressure vessels often limit crystal size and quality, creating a bottleneck for applications requiring large-aperture optical components.

Growth rate optimization continues to challenge researchers, with the fundamental trade-off between growth speed and crystal quality remaining unresolved. Rapid growth typically results in higher defect densities and inclusions, while slower growth processes become economically prohibitive due to extended equipment occupation and energy consumption.

Precursor purity and dissolution kinetics significantly impact final crystal quality. Current methods struggle with inconsistent nutrient supply to the growing crystal face, leading to zoning effects and compositional gradients. The development of specialized nutrient delivery systems has shown promise but remains in early experimental stages.

Seed crystal quality and orientation control represent persistent technical barriers. The availability of high-quality seed crystals often limits production capacity, while precise orientation control—critical for exploiting anisotropic optical properties—requires sophisticated mounting techniques that are difficult to standardize across different crystal systems.

Environmental and safety concerns pose increasing challenges as regulations tighten around high-pressure operations and potentially hazardous mineralizers like KOH and NaOH. The corrosive nature of these solutions accelerates autoclave degradation, introducing contamination and raising maintenance costs.

Characterization during growth remains largely underdeveloped, with most quality assessment occurring post-growth. The opacity of autoclave vessels prevents real-time optical monitoring, while the extreme conditions inside make conventional sensing technologies unreliable. Recent attempts at implementing acoustic monitoring and electrical impedance measurements show potential but require significant refinement before becoming standard practice.

These challenges collectively constrain the commercial viability of hydrothermal synthesis for advanced photonic applications, particularly in emerging fields like quantum information processing and integrated photonics where material perfection is paramount.

Scalability presents another significant hurdle, as the transition from laboratory-scale production to industrial volumes introduces complications in maintaining uniform growth conditions throughout larger autoclaves. The geometric constraints of pressure vessels often limit crystal size and quality, creating a bottleneck for applications requiring large-aperture optical components.

Growth rate optimization continues to challenge researchers, with the fundamental trade-off between growth speed and crystal quality remaining unresolved. Rapid growth typically results in higher defect densities and inclusions, while slower growth processes become economically prohibitive due to extended equipment occupation and energy consumption.

Precursor purity and dissolution kinetics significantly impact final crystal quality. Current methods struggle with inconsistent nutrient supply to the growing crystal face, leading to zoning effects and compositional gradients. The development of specialized nutrient delivery systems has shown promise but remains in early experimental stages.

Seed crystal quality and orientation control represent persistent technical barriers. The availability of high-quality seed crystals often limits production capacity, while precise orientation control—critical for exploiting anisotropic optical properties—requires sophisticated mounting techniques that are difficult to standardize across different crystal systems.

Environmental and safety concerns pose increasing challenges as regulations tighten around high-pressure operations and potentially hazardous mineralizers like KOH and NaOH. The corrosive nature of these solutions accelerates autoclave degradation, introducing contamination and raising maintenance costs.

Characterization during growth remains largely underdeveloped, with most quality assessment occurring post-growth. The opacity of autoclave vessels prevents real-time optical monitoring, while the extreme conditions inside make conventional sensing technologies unreliable. Recent attempts at implementing acoustic monitoring and electrical impedance measurements show potential but require significant refinement before becoming standard practice.

These challenges collectively constrain the commercial viability of hydrothermal synthesis for advanced photonic applications, particularly in emerging fields like quantum information processing and integrated photonics where material perfection is paramount.

Current Hydrothermal Growth Techniques

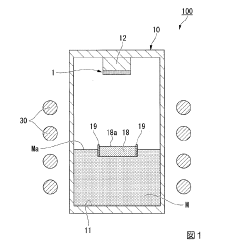

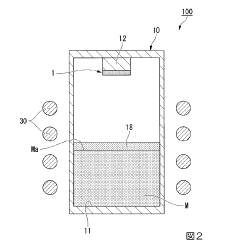

01 Hydrothermal growth apparatus and reactors

Specialized equipment and reactors are essential for the hydrothermal growth of single crystals. These systems typically include pressure vessels, autoclaves, or specialized chambers designed to withstand high temperatures and pressures required for crystal formation. The apparatus often features temperature control mechanisms, pressure monitoring systems, and corrosion-resistant materials to maintain optimal growth conditions. Advanced designs may incorporate seed crystal holders, nutrient compartments, and baffles to control solution flow and temperature gradients.- Hydrothermal growth methods for semiconductor crystals: Hydrothermal methods are used for growing high-quality semiconductor single crystals such as GaN, ZnO, and other III-V compounds. These processes typically involve dissolving source materials in supercritical water or mineralizers under high temperature and pressure conditions, followed by controlled crystallization. The method allows for precise control of crystal growth parameters, resulting in crystals with fewer defects and improved electronic properties for applications in optoelectronics and power devices.

- Equipment and apparatus for hydrothermal crystal growth: Specialized equipment is essential for hydrothermal crystal growth, including autoclaves, pressure vessels, and temperature control systems. These apparatuses must withstand extreme conditions of high temperature and pressure while providing precise control over growth parameters. Advanced designs incorporate features such as corrosion-resistant liners, temperature gradient control mechanisms, and monitoring systems to ensure optimal crystal growth conditions and safety during the hydrothermal process.

- Growth of oxide and piezoelectric crystals: Hydrothermal techniques are particularly effective for growing oxide-based single crystals such as quartz, lithium niobate, and other piezoelectric materials. The process typically uses alkaline mineralizers like KOH or NaOH to dissolve feedstock material and precipitate it onto seed crystals under controlled temperature gradients. This method produces high-quality crystals with excellent piezoelectric properties for applications in frequency control, sensors, and acoustic wave devices.

- Nutrient solutions and mineralizers for crystal growth: The composition of nutrient solutions and mineralizers plays a crucial role in hydrothermal crystal growth. Various additives, solvents, and pH modifiers are used to enhance solubility of source materials and control growth kinetics. Optimizing these solutions involves careful selection of mineralizers (such as hydroxides, carbonates, or halides) and understanding their interaction with growth parameters to achieve desired crystal morphology, size, and purity while minimizing defects and impurities.

- Temperature and pressure control techniques: Precise control of temperature gradients and pressure conditions is fundamental to successful hydrothermal crystal growth. Techniques include establishing controlled temperature differences between dissolution and growth zones, maintaining stable pressure environments, and implementing slow cooling or heating rates. Advanced methods utilize computerized control systems to create optimal supersaturation conditions and manage nucleation and growth rates, resulting in larger, higher-quality single crystals with fewer dislocations and improved uniformity.

02 Growth of semiconductor and electronic material crystals

Hydrothermal methods are particularly valuable for growing high-quality semiconductor and electronic material crystals. This approach enables the synthesis of materials like gallium nitride, zinc oxide, and silicon carbide with controlled properties for electronic applications. The process typically involves dissolving source materials in supercritical water or mineralizers under high pressure and temperature conditions, followed by controlled crystallization on seed crystals. These techniques allow for the production of crystals with fewer defects and higher purity compared to other growth methods.Expand Specific Solutions03 Growth parameters and conditions optimization

Successful hydrothermal crystal growth requires careful optimization of various parameters including temperature, pressure, pH, mineralizer concentration, and growth duration. Temperature gradients between the nutrient and crystallization zones drive the mass transport necessary for crystal formation. The selection of appropriate mineralizers (such as alkali hydroxides, carbonates, or chlorides) enhances the solubility of precursor materials. Controlling supersaturation levels and growth rates is crucial for obtaining high-quality crystals with minimal defects and desired morphology.Expand Specific Solutions04 Growth of oxide and piezoelectric crystals

Hydrothermal methods excel in the growth of oxide and piezoelectric single crystals such as quartz, lithium niobate, and various metal oxides. The technique allows for controlled growth at relatively low temperatures compared to melt-based methods, resulting in crystals with fewer thermal defects. For piezoelectric materials, hydrothermal growth can produce crystals with superior electromechanical properties and fewer compositional variations. The process typically employs alkaline solutions under high pressure and moderate temperatures to dissolve nutrient materials and precipitate them onto seed crystals.Expand Specific Solutions05 Novel materials and specialized crystal growth techniques

Advanced hydrothermal techniques have been developed for growing novel materials and specialized crystals with unique properties. These include methods for growing nanocrystals, hierarchical structures, and composite materials. Innovations such as microwave-assisted hydrothermal growth, continuous flow systems, and template-directed growth enable precise control over crystal morphology and composition. Specialized additives and growth modifiers can be used to control crystal habit, incorporate dopants, or create functional interfaces, expanding the range of materials that can be synthesized hydrothermally.Expand Specific Solutions

Leading Companies in Photonic Crystal Production

The hydrothermal growth of single crystals for photonic applications is currently in a transitional phase from emerging to growth stage, with the global market estimated at $1.2-1.5 billion and projected to expand at 8-10% CAGR through 2028. The competitive landscape features academic institutions (Clemson University, Shandong University) conducting foundational research alongside established industrial players (Shin-Etsu Handotai, SCHOTT AG, Corning) with mature manufacturing capabilities. Asian companies, particularly from China and Japan (JA Solar, Mitsubishi Gas Chemical, RESONAC), are rapidly gaining market share through cost-effective production methods. Technical maturity varies significantly across applications, with telecommunications and semiconductor applications reaching higher maturity levels than emerging quantum photonics applications, where companies like Kromek and Fairfield Crystal Technology are developing specialized solutions.

Shin-Etsu Handotai Co., Ltd.

Technical Solution: Shin-Etsu Handotai has developed a sophisticated hydrothermal crystal growth technology specifically for photonic applications, focusing on materials like lithium tantalate, lithium niobate, and quartz derivatives. Their process employs custom-engineered autoclaves with multi-zone heating systems capable of maintaining temperature gradients with precision better than ±0.05°C across growth chambers. The company utilizes proprietary mineralizer compositions that enhance growth kinetics while minimizing impurity incorporation, achieving growth rates of 0.7-1.3 mm/day without compromising crystal quality. Shin-Etsu's technology incorporates real-time monitoring of solution parameters including pH, conductivity, and supersaturation to dynamically adjust growth conditions. Their crystals exhibit exceptional optical homogeneity with refractive index variations less than 10⁻⁶ across apertures exceeding 50 mm, and defect densities below 10³ cm⁻². These properties make their crystals particularly suitable for advanced photonic applications including high-power laser systems, electro-optic modulators, and integrated photonic circuits where precise control of optical properties is essential.

Strengths: Exceptional control over crystal stoichiometry and composition; ability to produce crystals with very low OH content; excellent reproducibility between growth runs. Weaknesses: High capital and operational costs; limited throughput due to long growth cycles; technical complexity requiring specialized expertise for process optimization.

CRYSTAL SYSTEMS CORP.

Technical Solution: Crystal Systems Corp. has developed an innovative hydrothermal growth technology specifically optimized for photonic-grade single crystals. Their approach utilizes specialized high-pressure vessels constructed from corrosion-resistant superalloys capable of operating at temperatures up to 700°C and pressures exceeding 200 MPa. The company employs computer-controlled temperature profiles with stability better than ±0.1°C to establish precise supersaturation conditions that promote defect-free crystal growth. Their proprietary mineralizer formulations, typically based on alkali hydroxides with specific additives, enable growth rates of 0.8-1.2 mm/day while maintaining exceptional crystal quality. Crystal Systems specializes in producing large-aperture quartz, zinc oxide, and lithium niobate crystals with dimensions exceeding 75×75×25 mm. Their crystals feature dislocation densities below 10² cm⁻² and optical homogeneity better than 10⁻⁶ across the entire volume, making them ideal for advanced photonic applications including optical isolators, modulators, and frequency conversion devices.

Strengths: Ability to grow exceptionally large single crystals; excellent control over stoichiometry and dopant incorporation; consistent crystal quality between production batches. Weaknesses: Energy-intensive process with high operational costs; long production cycles limiting throughput; technical challenges in scaling to industrial volumes.

Key Patents in Hydrothermal Crystal Synthesis

Single crystal growth method

PatentActiveJP2020040843A

Innovation

- A single crystal growth method that involves using a crucible with a metal carbide coating on the raw material surface to suppress the recrystallization of the sublimated raw material gas, employing tantalum carbide powder to prevent the formation of nuclei and subsequent polymorphs.

Material Sustainability and Resource Efficiency

The hydrothermal growth of single crystals for photonic applications presents significant opportunities for enhancing material sustainability and resource efficiency in the optoelectronics industry. Traditional crystal growth methods often involve energy-intensive processes and utilize hazardous chemicals, creating substantial environmental concerns. In contrast, hydrothermal techniques operate at relatively lower temperatures (typically 300-600°C) compared to melt-based methods (often >1000°C), resulting in considerably reduced energy consumption.

The closed-system nature of hydrothermal growth vessels enables efficient material recycling and minimizes waste generation. Precursor solutions can be reused across multiple growth cycles, with recovery rates reaching 85-95% for many valuable materials such as lithium niobate and quartz. This circular approach significantly reduces the demand for raw material extraction, particularly important for rare earth elements and other critical materials used in photonic applications.

Water serves as the primary solvent in hydrothermal processes, replacing toxic organic solvents commonly employed in alternative methods. This substitution eliminates hazardous waste streams and reduces environmental remediation costs. Recent advancements in mineralizer chemistry have further improved dissolution efficiency while utilizing more environmentally benign compounds, moving away from traditional highly alkaline or acidic solutions.

Energy efficiency in hydrothermal growth has seen remarkable improvements through process optimization. Modern autoclave designs incorporate advanced insulation materials and precise temperature control systems, reducing energy requirements by 30-40% compared to earlier generations. Additionally, the development of continuous-flow hydrothermal systems enables more efficient heat recovery and transfer, further decreasing the carbon footprint of crystal production.

The scalability of hydrothermal processes presents another sustainability advantage. Industrial-scale production can maintain quality while achieving economies of scale that reduce per-unit resource consumption. Recent innovations in autoclave design have increased batch sizes without compromising crystal quality, enabling more efficient production cycles and reducing equipment redundancy.

Life cycle assessments of hydrothermally grown crystals for photonic applications demonstrate 40-60% lower environmental impact compared to conventional methods across multiple indicators, including carbon emissions, water usage, and waste generation. This favorable sustainability profile positions hydrothermal growth as an increasingly attractive option as environmental regulations tighten globally and consumers demand greener technology solutions.

The closed-system nature of hydrothermal growth vessels enables efficient material recycling and minimizes waste generation. Precursor solutions can be reused across multiple growth cycles, with recovery rates reaching 85-95% for many valuable materials such as lithium niobate and quartz. This circular approach significantly reduces the demand for raw material extraction, particularly important for rare earth elements and other critical materials used in photonic applications.

Water serves as the primary solvent in hydrothermal processes, replacing toxic organic solvents commonly employed in alternative methods. This substitution eliminates hazardous waste streams and reduces environmental remediation costs. Recent advancements in mineralizer chemistry have further improved dissolution efficiency while utilizing more environmentally benign compounds, moving away from traditional highly alkaline or acidic solutions.

Energy efficiency in hydrothermal growth has seen remarkable improvements through process optimization. Modern autoclave designs incorporate advanced insulation materials and precise temperature control systems, reducing energy requirements by 30-40% compared to earlier generations. Additionally, the development of continuous-flow hydrothermal systems enables more efficient heat recovery and transfer, further decreasing the carbon footprint of crystal production.

The scalability of hydrothermal processes presents another sustainability advantage. Industrial-scale production can maintain quality while achieving economies of scale that reduce per-unit resource consumption. Recent innovations in autoclave design have increased batch sizes without compromising crystal quality, enabling more efficient production cycles and reducing equipment redundancy.

Life cycle assessments of hydrothermally grown crystals for photonic applications demonstrate 40-60% lower environmental impact compared to conventional methods across multiple indicators, including carbon emissions, water usage, and waste generation. This favorable sustainability profile positions hydrothermal growth as an increasingly attractive option as environmental regulations tighten globally and consumers demand greener technology solutions.

Quality Control and Characterization Methods

Quality control and characterization methods are critical components in the hydrothermal growth of single crystals for photonic applications. The precision required for photonic devices demands rigorous assessment protocols throughout the crystal growth process. X-ray diffraction (XRD) serves as a primary technique for evaluating crystal structure, orientation, and lattice parameters, providing essential information about crystallographic quality and phase purity. High-resolution XRD can detect subtle lattice distortions and defects that might compromise optical performance.

Optical characterization techniques form another crucial aspect of quality assessment. Transmission and absorption spectroscopy reveal the optical transparency windows and absorption edges, directly correlating to the crystal's suitability for specific photonic applications. Birefringence measurements are particularly important for crystals intended for polarization-dependent devices, while refractive index determination across various wavelengths enables precise optical design calculations.

Surface morphology analysis employs scanning electron microscopy (SEM) and atomic force microscopy (AFM) to quantify surface roughness and identify microscopic defects. These techniques can detect growth striations, inclusions, and other imperfections that might cause light scattering or wavefront distortion in photonic devices. For more detailed defect analysis, transmission electron microscopy (TEM) provides atomic-level resolution to characterize dislocations and point defects.

Chemical composition verification using energy-dispersive X-ray spectroscopy (EDX), inductively coupled plasma mass spectrometry (ICP-MS), or secondary ion mass spectrometry (SIMS) ensures stoichiometric accuracy and identifies potential impurities that could affect optical properties. Trace element contamination can significantly impact optical transmission and luminescence characteristics, making these analyses essential for high-performance photonic applications.

In-process monitoring has evolved significantly with the integration of real-time characterization tools. Temperature and pressure sensors with feedback control systems maintain growth conditions within optimal parameters. Some advanced hydrothermal systems incorporate in-situ optical probes that monitor crystal growth rates and detect early signs of defect formation, allowing for immediate process adjustments to improve yield and quality.

Statistical process control methodologies have been increasingly adopted to establish correlations between growth parameters and final crystal quality. This approach enables systematic optimization of growth conditions and provides quantitative metrics for quality assurance. The development of standardized testing protocols specific to photonic applications ensures consistency across production batches and facilitates meaningful comparisons between different growth techniques and manufacturers.

Optical characterization techniques form another crucial aspect of quality assessment. Transmission and absorption spectroscopy reveal the optical transparency windows and absorption edges, directly correlating to the crystal's suitability for specific photonic applications. Birefringence measurements are particularly important for crystals intended for polarization-dependent devices, while refractive index determination across various wavelengths enables precise optical design calculations.

Surface morphology analysis employs scanning electron microscopy (SEM) and atomic force microscopy (AFM) to quantify surface roughness and identify microscopic defects. These techniques can detect growth striations, inclusions, and other imperfections that might cause light scattering or wavefront distortion in photonic devices. For more detailed defect analysis, transmission electron microscopy (TEM) provides atomic-level resolution to characterize dislocations and point defects.

Chemical composition verification using energy-dispersive X-ray spectroscopy (EDX), inductively coupled plasma mass spectrometry (ICP-MS), or secondary ion mass spectrometry (SIMS) ensures stoichiometric accuracy and identifies potential impurities that could affect optical properties. Trace element contamination can significantly impact optical transmission and luminescence characteristics, making these analyses essential for high-performance photonic applications.

In-process monitoring has evolved significantly with the integration of real-time characterization tools. Temperature and pressure sensors with feedback control systems maintain growth conditions within optimal parameters. Some advanced hydrothermal systems incorporate in-situ optical probes that monitor crystal growth rates and detect early signs of defect formation, allowing for immediate process adjustments to improve yield and quality.

Statistical process control methodologies have been increasingly adopted to establish correlations between growth parameters and final crystal quality. This approach enables systematic optimization of growth conditions and provides quantitative metrics for quality assurance. The development of standardized testing protocols specific to photonic applications ensures consistency across production batches and facilitates meaningful comparisons between different growth techniques and manufacturers.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!