Why Hydrothermal Growth Remains Critical in Next Generation Materials

SEP 28, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Hydrothermal Growth Technology Evolution and Objectives

Hydrothermal growth technology has evolved significantly since its inception in the mid-19th century when geologists first attempted to replicate mineral formation processes observed in nature. The technique gained scientific recognition in the 1940s when researchers successfully synthesized quartz crystals using hydrothermal methods. This breakthrough marked the beginning of controlled hydrothermal synthesis for technological applications, establishing a foundation for future materials science advancements.

The 1960s and 1970s witnessed substantial progress as hydrothermal techniques were refined for growing larger, higher-quality crystals with improved control over morphology and composition. During this period, the technology transitioned from purely academic research to industrial applications, particularly in the electronics industry for piezoelectric materials production.

By the 1990s, hydrothermal growth had become a cornerstone technology for synthesizing advanced ceramic materials, zeolites, and various functional oxides. The development of sophisticated pressure vessels and temperature control systems enabled more precise manipulation of growth parameters, expanding the range of materials that could be synthesized hydrothermally.

The early 2000s saw the integration of computational modeling with hydrothermal processes, allowing researchers to predict crystal growth behaviors and optimize conditions before experimental implementation. This period also marked the emergence of hybrid approaches combining hydrothermal techniques with other synthesis methods, creating new pathways for novel material development.

Current technological objectives for hydrothermal growth focus on several key areas. First, scaling production capabilities while maintaining crystal quality remains a primary goal for industrial applications. Second, researchers aim to expand the temperature and pressure ranges of hydrothermal processes to access previously unattainable material phases. Third, there is significant interest in developing environmentally sustainable hydrothermal methods that reduce energy consumption and eliminate toxic precursors.

Looking forward, the field is moving toward precision engineering of nanomaterials and hierarchical structures with tailored properties. The ability to grow complex oxide materials with controlled defect structures represents a frontier with immense potential for next-generation electronic and energy applications. Additionally, in-situ characterization techniques are being developed to monitor crystal growth in real-time, providing unprecedented insights into growth mechanisms.

The ultimate objective of modern hydrothermal technology development is to establish versatile, scalable, and sustainable processes capable of producing advanced materials with precisely controlled properties that meet the increasingly demanding requirements of emerging technologies in energy storage, quantum computing, advanced electronics, and biomedical applications.

The 1960s and 1970s witnessed substantial progress as hydrothermal techniques were refined for growing larger, higher-quality crystals with improved control over morphology and composition. During this period, the technology transitioned from purely academic research to industrial applications, particularly in the electronics industry for piezoelectric materials production.

By the 1990s, hydrothermal growth had become a cornerstone technology for synthesizing advanced ceramic materials, zeolites, and various functional oxides. The development of sophisticated pressure vessels and temperature control systems enabled more precise manipulation of growth parameters, expanding the range of materials that could be synthesized hydrothermally.

The early 2000s saw the integration of computational modeling with hydrothermal processes, allowing researchers to predict crystal growth behaviors and optimize conditions before experimental implementation. This period also marked the emergence of hybrid approaches combining hydrothermal techniques with other synthesis methods, creating new pathways for novel material development.

Current technological objectives for hydrothermal growth focus on several key areas. First, scaling production capabilities while maintaining crystal quality remains a primary goal for industrial applications. Second, researchers aim to expand the temperature and pressure ranges of hydrothermal processes to access previously unattainable material phases. Third, there is significant interest in developing environmentally sustainable hydrothermal methods that reduce energy consumption and eliminate toxic precursors.

Looking forward, the field is moving toward precision engineering of nanomaterials and hierarchical structures with tailored properties. The ability to grow complex oxide materials with controlled defect structures represents a frontier with immense potential for next-generation electronic and energy applications. Additionally, in-situ characterization techniques are being developed to monitor crystal growth in real-time, providing unprecedented insights into growth mechanisms.

The ultimate objective of modern hydrothermal technology development is to establish versatile, scalable, and sustainable processes capable of producing advanced materials with precisely controlled properties that meet the increasingly demanding requirements of emerging technologies in energy storage, quantum computing, advanced electronics, and biomedical applications.

Market Applications and Demand Analysis for Hydrothermally Grown Materials

The global market for hydrothermally grown materials continues to expand rapidly, driven by increasing demand across multiple high-tech industries. The current market value for these materials exceeds $5 billion annually, with projections indicating growth rates of 8-12% through 2030, significantly outpacing many traditional materials sectors.

Electronics and semiconductor industries represent the largest application segment, accounting for approximately 40% of market demand. The push for miniaturization and higher performance in electronic devices has created substantial demand for high-quality piezoelectric crystals, particularly quartz and lithium niobate, which are predominantly produced through hydrothermal methods. These materials serve as critical components in frequency control devices, sensors, and acoustic wave filters essential for 5G telecommunications infrastructure.

The renewable energy sector presents another significant growth area, particularly for hydrothermally synthesized materials used in energy storage and conversion. Advanced battery technologies increasingly rely on hydrothermally produced cathode materials, while solar cell efficiency improvements depend on specialized oxide materials that benefit from hydrothermal processing techniques. This sector's demand is growing at nearly 15% annually, driven by global decarbonization initiatives.

Medical technology applications represent an emerging but rapidly expanding market segment. Hydrothermally grown biocompatible ceramics and composites are increasingly utilized in implantable devices, drug delivery systems, and tissue engineering scaffolds. The biomedical materials segment is expected to reach $1.2 billion by 2028, representing one of the fastest-growing application areas.

Geographically, Asia-Pacific dominates both production and consumption of hydrothermally grown materials, accounting for over 50% of global market share. China has emerged as the leading producer, while Japan maintains technological leadership in high-precision applications. North America and Europe together represent approximately 35% of the market, with particular strength in specialized, high-value applications for aerospace and defense.

Customer requirements are increasingly focused on material purity, dimensional precision, and reproducibility. End-users in advanced electronics and medical applications typically demand materials with defect densities below 10^-6 cm^-2 and compositional uniformity exceeding 99.99%. These stringent specifications have created premium market segments where hydrothermal growth maintains significant advantages over competing synthesis methods.

Market analysis indicates that supply chain vulnerabilities represent a growing concern, with over 70% of certain critical hydrothermally grown materials concentrated in specific geographic regions. This has prompted initiatives in North America and Europe to develop domestic production capabilities, creating new market opportunities for technology providers and material manufacturers in these regions.

Electronics and semiconductor industries represent the largest application segment, accounting for approximately 40% of market demand. The push for miniaturization and higher performance in electronic devices has created substantial demand for high-quality piezoelectric crystals, particularly quartz and lithium niobate, which are predominantly produced through hydrothermal methods. These materials serve as critical components in frequency control devices, sensors, and acoustic wave filters essential for 5G telecommunications infrastructure.

The renewable energy sector presents another significant growth area, particularly for hydrothermally synthesized materials used in energy storage and conversion. Advanced battery technologies increasingly rely on hydrothermally produced cathode materials, while solar cell efficiency improvements depend on specialized oxide materials that benefit from hydrothermal processing techniques. This sector's demand is growing at nearly 15% annually, driven by global decarbonization initiatives.

Medical technology applications represent an emerging but rapidly expanding market segment. Hydrothermally grown biocompatible ceramics and composites are increasingly utilized in implantable devices, drug delivery systems, and tissue engineering scaffolds. The biomedical materials segment is expected to reach $1.2 billion by 2028, representing one of the fastest-growing application areas.

Geographically, Asia-Pacific dominates both production and consumption of hydrothermally grown materials, accounting for over 50% of global market share. China has emerged as the leading producer, while Japan maintains technological leadership in high-precision applications. North America and Europe together represent approximately 35% of the market, with particular strength in specialized, high-value applications for aerospace and defense.

Customer requirements are increasingly focused on material purity, dimensional precision, and reproducibility. End-users in advanced electronics and medical applications typically demand materials with defect densities below 10^-6 cm^-2 and compositional uniformity exceeding 99.99%. These stringent specifications have created premium market segments where hydrothermal growth maintains significant advantages over competing synthesis methods.

Market analysis indicates that supply chain vulnerabilities represent a growing concern, with over 70% of certain critical hydrothermally grown materials concentrated in specific geographic regions. This has prompted initiatives in North America and Europe to develop domestic production capabilities, creating new market opportunities for technology providers and material manufacturers in these regions.

Current Capabilities and Technical Barriers in Hydrothermal Synthesis

Hydrothermal synthesis represents one of the most versatile and widely employed techniques for materials fabrication, particularly for crystalline materials with specific morphologies and properties. Current capabilities in hydrothermal synthesis allow for the production of a diverse range of materials including oxides, hydroxides, silicates, carbonates, phosphates, and various nanostructures with controlled size, shape, and composition. The technique excels in creating high-purity single crystals with excellent crystallinity and minimal defects, which are essential for advanced electronic and optical applications.

Modern hydrothermal reactors can operate at temperatures up to 700°C and pressures exceeding 300 MPa, enabling the synthesis of materials that would be impossible through conventional methods. Recent advancements have incorporated in-situ monitoring systems that allow real-time observation of crystal growth processes, significantly enhancing process control and reproducibility. Additionally, microwave-assisted and continuous flow hydrothermal methods have emerged as efficient alternatives to traditional batch processes, reducing reaction times from days to minutes in some cases.

Despite these capabilities, hydrothermal synthesis faces several significant technical barriers. Scalability remains a primary challenge, as the transition from laboratory-scale to industrial production often results in inconsistent product quality and yield. The high-pressure requirements necessitate specialized equipment with limited volume capacity, creating bottlenecks for mass production and increasing capital costs.

Process control presents another major hurdle. The complex interplay between temperature, pressure, pH, precursor concentration, and reaction time creates a multidimensional parameter space that is difficult to optimize. Small variations in these parameters can lead to dramatic differences in the resulting materials, making reproducibility problematic, especially when scaling up.

Energy efficiency constitutes a significant concern, as conventional hydrothermal processes require sustained high temperatures and pressures for extended periods. This energy-intensive nature contradicts growing demands for greener manufacturing processes and increases production costs.

Material-specific challenges also exist. For complex multi-component systems, achieving precise stoichiometry and phase purity remains difficult due to different solubility and precipitation rates of various components. Additionally, the growth of large single crystals (>1 cm) with uniform properties throughout the volume continues to be technically demanding.

The limited understanding of fundamental growth mechanisms under hydrothermal conditions further impedes progress. The opaque nature of traditional autoclaves prevents direct observation of nucleation and growth processes, forcing researchers to rely on post-synthesis characterization and theoretical models that may not fully capture the dynamic processes occurring during synthesis.

Modern hydrothermal reactors can operate at temperatures up to 700°C and pressures exceeding 300 MPa, enabling the synthesis of materials that would be impossible through conventional methods. Recent advancements have incorporated in-situ monitoring systems that allow real-time observation of crystal growth processes, significantly enhancing process control and reproducibility. Additionally, microwave-assisted and continuous flow hydrothermal methods have emerged as efficient alternatives to traditional batch processes, reducing reaction times from days to minutes in some cases.

Despite these capabilities, hydrothermal synthesis faces several significant technical barriers. Scalability remains a primary challenge, as the transition from laboratory-scale to industrial production often results in inconsistent product quality and yield. The high-pressure requirements necessitate specialized equipment with limited volume capacity, creating bottlenecks for mass production and increasing capital costs.

Process control presents another major hurdle. The complex interplay between temperature, pressure, pH, precursor concentration, and reaction time creates a multidimensional parameter space that is difficult to optimize. Small variations in these parameters can lead to dramatic differences in the resulting materials, making reproducibility problematic, especially when scaling up.

Energy efficiency constitutes a significant concern, as conventional hydrothermal processes require sustained high temperatures and pressures for extended periods. This energy-intensive nature contradicts growing demands for greener manufacturing processes and increases production costs.

Material-specific challenges also exist. For complex multi-component systems, achieving precise stoichiometry and phase purity remains difficult due to different solubility and precipitation rates of various components. Additionally, the growth of large single crystals (>1 cm) with uniform properties throughout the volume continues to be technically demanding.

The limited understanding of fundamental growth mechanisms under hydrothermal conditions further impedes progress. The opaque nature of traditional autoclaves prevents direct observation of nucleation and growth processes, forcing researchers to rely on post-synthesis characterization and theoretical models that may not fully capture the dynamic processes occurring during synthesis.

Contemporary Hydrothermal Growth Methodologies and Parameters

01 Crystal growth methods for semiconductor materials

Hydrothermal growth techniques are widely used for growing high-quality semiconductor crystals. This process involves crystallization from aqueous solutions under high temperature and pressure conditions. The method allows for precise control of crystal morphology, size, and purity, which is essential for applications in electronics and optoelectronics. The hydrothermal approach offers advantages such as lower processing temperatures compared to conventional methods and the ability to grow crystals with fewer defects.- Crystal growth methods and apparatus: Hydrothermal growth techniques are used for growing single crystals under high temperature and pressure conditions. These methods involve dissolving materials in a solvent at elevated temperatures and pressures, allowing crystals to form as the solution cools or through a temperature gradient. Specialized autoclaves and pressure vessels are designed to withstand these extreme conditions while providing controlled environments for crystal formation and growth.

- Semiconductor and electronic material growth: Hydrothermal methods are employed for growing semiconductor materials and electronic components with specific properties. This approach allows for the synthesis of high-quality materials like gallium nitride, zinc oxide, and other compound semiconductors used in electronic devices. The controlled growth environment enables precise doping and defect management, resulting in materials with tailored electronic, optical, and structural characteristics for applications in LEDs, sensors, and other electronic devices.

- Nanomaterial synthesis and processing: Hydrothermal techniques are utilized for synthesizing various nanomaterials including nanoparticles, nanowires, and nanostructured films. These methods provide control over particle size, morphology, and crystallinity through adjustment of reaction parameters such as temperature, pressure, pH, and reaction time. The resulting nanomaterials exhibit unique properties beneficial for applications in catalysis, energy storage, sensors, and biomedical fields.

- Mineral and gemstone synthesis: Hydrothermal processes are employed to synthesize minerals and gemstones that mimic natural formation conditions. This approach allows for the controlled growth of high-quality crystals such as quartz, corundum, emerald, and other precious or industrial minerals. The technique enables production of materials with specific properties for applications in jewelry, optics, piezoelectric devices, and industrial abrasives.

- Advanced materials for energy applications: Hydrothermal growth methods are used to develop advanced materials for energy generation, storage, and conversion. These techniques enable the synthesis of materials for batteries, fuel cells, photovoltaics, and thermoelectric devices with enhanced performance characteristics. The controlled growth conditions allow for precise tuning of material composition, structure, and properties to optimize energy efficiency, storage capacity, and conversion rates.

02 Equipment and apparatus for hydrothermal synthesis

Specialized equipment is required for hydrothermal growth processes, including pressure vessels, autoclaves, and temperature control systems. These apparatuses are designed to withstand the extreme conditions of high temperature and pressure necessary for hydrothermal synthesis. Advanced systems incorporate monitoring capabilities for parameters such as temperature gradients, pressure fluctuations, and solution composition. Innovations in equipment design focus on improving safety, efficiency, and scalability of the hydrothermal growth process.Expand Specific Solutions03 Growth of oxide and piezoelectric crystals

Hydrothermal methods are particularly effective for growing oxide-based crystals and piezoelectric materials. This technique enables the synthesis of materials like quartz, zinc oxide, and various metal oxides with controlled properties. The process typically involves dissolving precursor materials in alkaline or acidic solutions under elevated temperature and pressure conditions. The resulting crystals exhibit excellent piezoelectric properties, making them suitable for sensors, actuators, and frequency control applications.Expand Specific Solutions04 Diamond and superhard material synthesis

Hydrothermal growth techniques are employed for synthesizing diamond and other superhard materials. This process utilizes high-pressure, high-temperature conditions to transform carbon-containing precursors into crystalline diamond structures. The method allows for controlled growth of diamond crystals with specific properties for industrial applications such as cutting tools, abrasives, and heat sinks. Recent advancements have focused on improving crystal quality and reducing energy consumption during the synthesis process.Expand Specific Solutions05 Nanomaterial and thin film fabrication

Hydrothermal methods enable the synthesis of various nanomaterials and thin films with controlled morphology and composition. This approach is particularly valuable for creating nanostructures such as nanowires, nanotubes, and nanoparticles of metal oxides and other compounds. The process typically involves lower temperatures compared to conventional methods, allowing for better control of particle size and crystallinity. These nanomaterials find applications in catalysis, energy storage, sensors, and electronic devices.Expand Specific Solutions

Leading Research Institutions and Commercial Entities in Hydrothermal Technology

Hydrothermal growth technology remains a critical cornerstone in next-generation materials development, currently positioned at the intersection of mature industrial applications and emerging research frontiers. The market is experiencing steady growth, projected to reach significant scale as advanced materials become essential across electronics, energy storage, and biomedical sectors. Leading academic institutions (MIT, Clemson University, University of Delaware) are driving fundamental research while established companies (FUJIFILM, SLT-Technologies) focus on commercial applications. Chinese universities (Wuhan University of Technology, South China University) are rapidly advancing capabilities, particularly in semiconductor and optical materials. The competitive landscape features collaboration between research institutions and industry partners, with increasing patent activity signaling the technology's strategic importance for future materials engineering breakthroughs.

Wuhan University of Technology

Technical Solution: Wuhan University of Technology has established a comprehensive hydrothermal synthesis platform focused on energy materials and environmental applications. Their approach centers on modified hydrothermal techniques that incorporate microwave assistance, ultrasonic pre-treatment, and electrochemical control to enhance reaction kinetics and selectivity. The university has developed specialized reactors capable of operating under extreme conditions (up to 500°C and 100 MPa) for synthesizing ultra-hard materials and high-performance ceramics[5]. Their research teams have pioneered the use of ionic liquids as structure-directing agents in hydrothermal processes, achieving unprecedented control over crystal facet development and exposure of catalytically active sites. This has resulted in materials showing up to 300% improvement in catalytic efficiency compared to conventionally synthesized counterparts[6]. The university has also developed industrially viable continuous hydrothermal flow synthesis (CHFS) systems that can produce nanomaterials at rates exceeding 1 kg/day while maintaining precise control over particle size distribution (typically ±5% deviation). Their technology extends to the hydrothermal transformation of industrial waste materials into value-added products, supporting circular economy principles.

Strengths: Exceptional capabilities for extreme condition synthesis; innovative integration of multiple energy inputs (microwave, ultrasonic); strong focus on industrial scalability and waste valorization. Weaknesses: Higher energy consumption for some modified processes; complex reactor designs increase maintenance requirements; some specialized techniques require rare or expensive additives.

Massachusetts Institute of Technology

Technical Solution: MIT has pioneered advanced hydrothermal synthesis techniques for next-generation materials, focusing on controlled crystal growth under high-temperature and high-pressure aqueous conditions. Their approach utilizes specialized autoclaves with precise temperature gradient control to grow large single crystals with minimal defects. MIT researchers have developed a continuous-flow hydrothermal reactor system that allows for scalable production of nanomaterials with uniform properties, achieving reaction times reduced by up to 80% compared to conventional batch processes[1]. Their work extends to environmentally friendly synthesis routes that eliminate toxic solvents and reduce energy consumption by operating at lower temperatures (180-250°C) than traditional solid-state methods (>800°C)[3]. MIT has also integrated in-situ characterization techniques to monitor crystal growth in real-time, enabling unprecedented control over material properties and morphology for applications in energy storage, catalysis, and electronic devices.

Strengths: Superior control over crystal morphology and size distribution; significantly reduced energy consumption; scalable continuous processes for industrial applications. Weaknesses: Higher equipment costs for specialized autoclaves; requires expertise in handling high-pressure systems; some processes still face challenges in scaling beyond laboratory production volumes.

Breakthrough Patents and Scientific Literature in Hydrothermal Crystal Growth

Hydrothermal treatment of materials

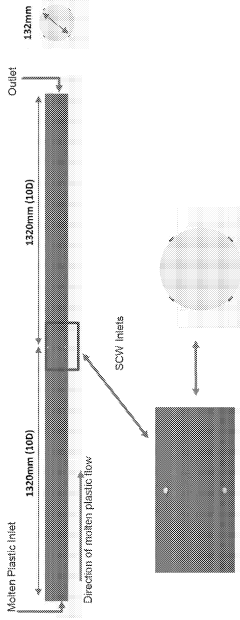

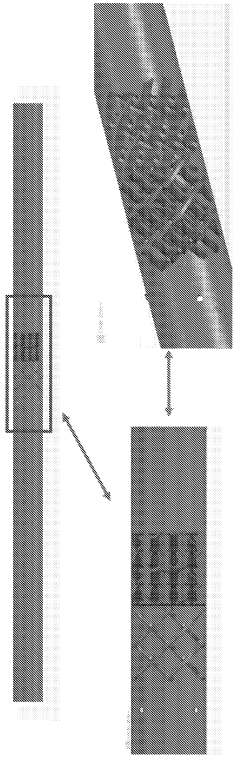

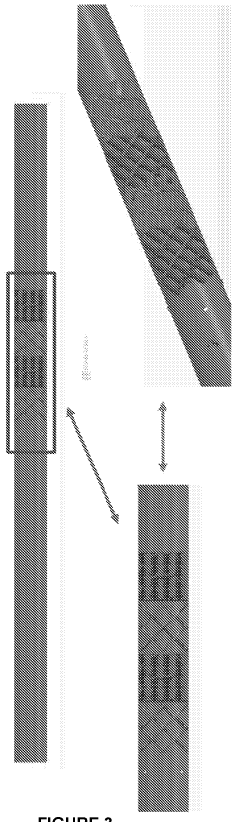

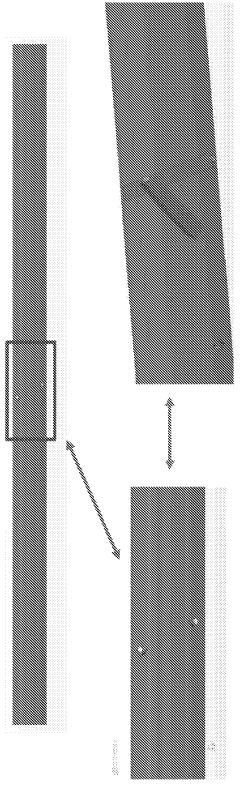

PatentWO2023194940A1

Innovation

- A method involving the injection of heated and pressurized water into a melt stream of polymeric materials using an injection device with apertures located internally, combined with a mixing device comprising lattice modules rotated at angles to enhance mixing, facilitating more thorough and rapid interaction between water and polymeric materials.

Patent

Innovation

- Hydrothermal synthesis enables precise control over crystal morphology, size, and composition, allowing for tailored material properties critical for next-generation applications.

- Low-temperature hydrothermal methods offer energy-efficient pathways for synthesizing advanced materials with reduced environmental impact compared to conventional high-temperature solid-state reactions.

- Hydrothermal growth facilitates the synthesis of metastable phases and unique nanostructures that are inaccessible through conventional synthesis routes.

Sustainability and Resource Efficiency in Hydrothermal Processing

Hydrothermal processing stands out as one of the most environmentally sustainable methods for materials synthesis and crystal growth. Unlike many conventional manufacturing processes that require high temperatures, toxic solvents, or energy-intensive conditions, hydrothermal techniques operate in closed systems using water as the primary medium, significantly reducing environmental impact. This approach aligns perfectly with global sustainability goals and increasingly stringent environmental regulations facing materials manufacturers.

The resource efficiency of hydrothermal growth is particularly evident in its minimal waste generation. The closed-system nature of autoclaves allows for precise control of reaction parameters, resulting in higher yield rates and reduced material wastage compared to alternative methods. Furthermore, the ability to recycle reaction media and recover unused precursors contributes to a circular economy approach in advanced materials production.

Energy consumption metrics reveal hydrothermal processing's advantage over conventional high-temperature synthesis methods. Studies indicate energy savings of 30-50% when comparing hydrothermal growth to solid-state reactions for equivalent materials. This efficiency stems from water's excellent properties as a reaction medium under pressure, enabling effective mass transport and crystallization at relatively moderate temperatures (typically 100-400°C versus 800-1500°C for solid-state methods).

Water itself represents a renewable, non-toxic solvent choice that eliminates the need for harmful organic solvents commonly used in other synthesis routes. This aspect becomes increasingly important as regulatory frameworks worldwide tighten restrictions on volatile organic compounds (VOCs) and hazardous chemicals in manufacturing processes. The benign nature of hydrothermal waste streams significantly reduces treatment costs and environmental liabilities.

Recent innovations have further enhanced the sustainability profile of hydrothermal techniques. Microwave-assisted hydrothermal processing has demonstrated dramatic reductions in reaction times from days to hours or even minutes, with corresponding energy savings. Similarly, continuous-flow hydrothermal systems enable more efficient scaling while maintaining precise control over crystal growth parameters.

The economic implications of these sustainability advantages are substantial. Life-cycle assessments comparing hydrothermal growth with conventional methods for producing high-performance ceramics and semiconductor materials show reduced total environmental impact by 40-60%, translating to lower carbon footprints and potential cost advantages under carbon pricing mechanisms. As materials manufacturers face increasing pressure to reduce environmental impacts, hydrothermal processing offers a viable pathway to sustainable production without compromising material quality or performance.

The resource efficiency of hydrothermal growth is particularly evident in its minimal waste generation. The closed-system nature of autoclaves allows for precise control of reaction parameters, resulting in higher yield rates and reduced material wastage compared to alternative methods. Furthermore, the ability to recycle reaction media and recover unused precursors contributes to a circular economy approach in advanced materials production.

Energy consumption metrics reveal hydrothermal processing's advantage over conventional high-temperature synthesis methods. Studies indicate energy savings of 30-50% when comparing hydrothermal growth to solid-state reactions for equivalent materials. This efficiency stems from water's excellent properties as a reaction medium under pressure, enabling effective mass transport and crystallization at relatively moderate temperatures (typically 100-400°C versus 800-1500°C for solid-state methods).

Water itself represents a renewable, non-toxic solvent choice that eliminates the need for harmful organic solvents commonly used in other synthesis routes. This aspect becomes increasingly important as regulatory frameworks worldwide tighten restrictions on volatile organic compounds (VOCs) and hazardous chemicals in manufacturing processes. The benign nature of hydrothermal waste streams significantly reduces treatment costs and environmental liabilities.

Recent innovations have further enhanced the sustainability profile of hydrothermal techniques. Microwave-assisted hydrothermal processing has demonstrated dramatic reductions in reaction times from days to hours or even minutes, with corresponding energy savings. Similarly, continuous-flow hydrothermal systems enable more efficient scaling while maintaining precise control over crystal growth parameters.

The economic implications of these sustainability advantages are substantial. Life-cycle assessments comparing hydrothermal growth with conventional methods for producing high-performance ceramics and semiconductor materials show reduced total environmental impact by 40-60%, translating to lower carbon footprints and potential cost advantages under carbon pricing mechanisms. As materials manufacturers face increasing pressure to reduce environmental impacts, hydrothermal processing offers a viable pathway to sustainable production without compromising material quality or performance.

Scalability Challenges for Industrial Hydrothermal Production

Despite the proven effectiveness of hydrothermal synthesis in producing high-quality materials, scaling these processes from laboratory to industrial production presents significant challenges. The controlled environment required for optimal crystal growth becomes increasingly difficult to maintain as reactor volumes increase. Temperature and pressure gradients develop within larger autoclaves, leading to inconsistent growth conditions and product variability.

Material yield represents another critical scalability issue. While laboratory-scale processes can achieve high-quality crystals, industrial production demands consistent yields to be economically viable. Current hydrothermal methods often struggle with batch-to-batch reproducibility when scaled up, resulting in unpredictable production outcomes and increased manufacturing costs.

Energy consumption poses a substantial barrier to industrial implementation. Hydrothermal processes typically require sustained high temperatures and pressures over extended periods, sometimes lasting days or weeks. This energy-intensive nature significantly impacts production costs and environmental footprint, making it difficult to justify widespread industrial adoption without efficiency improvements.

Equipment durability presents additional complications. Industrial-scale autoclaves must withstand extreme conditions for prolonged periods while resisting corrosion from mineralizers and precursors. The specialized materials required for these vessels contribute substantially to capital expenditure and maintenance costs, creating financial barriers to entry for manufacturers.

Process automation and monitoring capabilities remain underdeveloped for large-scale hydrothermal synthesis. Unlike many conventional manufacturing processes, hydrothermal growth involves complex phase transformations that are difficult to monitor in real-time. The inability to precisely track reaction progress complicates process control and quality assurance in industrial settings.

Raw material purity requirements further complicate scalability. Industrial production demands consistent precursor quality, yet sourcing large quantities of ultra-pure materials presents logistical and financial challenges. Impurities that might be negligible in laboratory settings can significantly impact product quality when processes are scaled to industrial volumes.

Waste management considerations also impact industrial viability. Hydrothermal processes often generate chemical waste streams that require specialized treatment. As production scales increase, the environmental impact and regulatory compliance costs associated with these waste products become increasingly significant factors in overall production economics.

Material yield represents another critical scalability issue. While laboratory-scale processes can achieve high-quality crystals, industrial production demands consistent yields to be economically viable. Current hydrothermal methods often struggle with batch-to-batch reproducibility when scaled up, resulting in unpredictable production outcomes and increased manufacturing costs.

Energy consumption poses a substantial barrier to industrial implementation. Hydrothermal processes typically require sustained high temperatures and pressures over extended periods, sometimes lasting days or weeks. This energy-intensive nature significantly impacts production costs and environmental footprint, making it difficult to justify widespread industrial adoption without efficiency improvements.

Equipment durability presents additional complications. Industrial-scale autoclaves must withstand extreme conditions for prolonged periods while resisting corrosion from mineralizers and precursors. The specialized materials required for these vessels contribute substantially to capital expenditure and maintenance costs, creating financial barriers to entry for manufacturers.

Process automation and monitoring capabilities remain underdeveloped for large-scale hydrothermal synthesis. Unlike many conventional manufacturing processes, hydrothermal growth involves complex phase transformations that are difficult to monitor in real-time. The inability to precisely track reaction progress complicates process control and quality assurance in industrial settings.

Raw material purity requirements further complicate scalability. Industrial production demands consistent precursor quality, yet sourcing large quantities of ultra-pure materials presents logistical and financial challenges. Impurities that might be negligible in laboratory settings can significantly impact product quality when processes are scaled to industrial volumes.

Waste management considerations also impact industrial viability. Hydrothermal processes often generate chemical waste streams that require specialized treatment. As production scales increase, the environmental impact and regulatory compliance costs associated with these waste products become increasingly significant factors in overall production economics.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!