Electrolytic Cell Diagnostics through Advanced Spectral Analysis

AUG 1, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Electrolytic Cell Diagnostics Overview and Objectives

Electrolytic cell diagnostics through advanced spectral analysis has emerged as a critical technology in the field of electrochemistry and industrial process control. This innovative approach combines the principles of electrochemistry with cutting-edge spectroscopic techniques to provide real-time, non-invasive monitoring of electrolytic processes. The evolution of this technology has been driven by the increasing demand for more efficient and sustainable industrial processes, particularly in sectors such as metal production, water treatment, and energy storage.

The primary objective of electrolytic cell diagnostics is to enhance the understanding and control of complex electrochemical reactions occurring within industrial-scale electrolytic cells. By leveraging advanced spectral analysis techniques, researchers and engineers aim to develop more accurate and responsive monitoring systems that can detect subtle changes in electrolyte composition, electrode performance, and overall cell efficiency. This technology seeks to address longstanding challenges in electrolytic processes, including energy inefficiencies, product quality inconsistencies, and equipment degradation.

The development of electrolytic cell diagnostics has been marked by several key milestones. Early efforts focused on adapting existing spectroscopic methods for use in harsh industrial environments. Subsequently, advancements in sensor technology and data processing capabilities have enabled the integration of multiple spectral techniques, providing a more comprehensive view of electrolytic cell dynamics. Recent innovations in machine learning and artificial intelligence have further enhanced the interpretative power of spectral data, allowing for predictive maintenance and optimized process control.

Looking ahead, the field of electrolytic cell diagnostics through advanced spectral analysis is poised for significant growth and innovation. Researchers are exploring the potential of novel spectroscopic methods, such as terahertz spectroscopy and quantum cascade laser-based systems, to probe previously inaccessible aspects of electrolytic processes. Additionally, there is a growing emphasis on developing more robust and miniaturized sensors capable of withstanding extreme conditions while providing high-resolution spectral data.

The ultimate goal of this technology is to revolutionize industrial electrolytic processes by enabling unprecedented levels of control and efficiency. By providing real-time, in-situ analysis of electrolytic cells, advanced spectral diagnostics promise to reduce energy consumption, minimize waste production, and improve product quality across a wide range of industries. As this technology continues to evolve, it is expected to play a crucial role in the development of more sustainable and economically viable electrochemical processes, contributing to broader efforts in industrial decarbonization and resource conservation.

The primary objective of electrolytic cell diagnostics is to enhance the understanding and control of complex electrochemical reactions occurring within industrial-scale electrolytic cells. By leveraging advanced spectral analysis techniques, researchers and engineers aim to develop more accurate and responsive monitoring systems that can detect subtle changes in electrolyte composition, electrode performance, and overall cell efficiency. This technology seeks to address longstanding challenges in electrolytic processes, including energy inefficiencies, product quality inconsistencies, and equipment degradation.

The development of electrolytic cell diagnostics has been marked by several key milestones. Early efforts focused on adapting existing spectroscopic methods for use in harsh industrial environments. Subsequently, advancements in sensor technology and data processing capabilities have enabled the integration of multiple spectral techniques, providing a more comprehensive view of electrolytic cell dynamics. Recent innovations in machine learning and artificial intelligence have further enhanced the interpretative power of spectral data, allowing for predictive maintenance and optimized process control.

Looking ahead, the field of electrolytic cell diagnostics through advanced spectral analysis is poised for significant growth and innovation. Researchers are exploring the potential of novel spectroscopic methods, such as terahertz spectroscopy and quantum cascade laser-based systems, to probe previously inaccessible aspects of electrolytic processes. Additionally, there is a growing emphasis on developing more robust and miniaturized sensors capable of withstanding extreme conditions while providing high-resolution spectral data.

The ultimate goal of this technology is to revolutionize industrial electrolytic processes by enabling unprecedented levels of control and efficiency. By providing real-time, in-situ analysis of electrolytic cells, advanced spectral diagnostics promise to reduce energy consumption, minimize waste production, and improve product quality across a wide range of industries. As this technology continues to evolve, it is expected to play a crucial role in the development of more sustainable and economically viable electrochemical processes, contributing to broader efforts in industrial decarbonization and resource conservation.

Industrial Demand for Spectral Analysis in Electrolysis

The industrial demand for spectral analysis in electrolysis has been steadily growing, driven by the increasing need for more efficient and sustainable production processes in various sectors. Electrolysis plays a crucial role in numerous industries, including chlor-alkali production, metal refining, and water treatment. As these industries face mounting pressure to optimize their operations and reduce environmental impact, the adoption of advanced spectral analysis techniques for electrolytic cell diagnostics has become increasingly important.

In the chlor-alkali industry, which produces essential chemicals like chlorine, sodium hydroxide, and hydrogen, spectral analysis is being employed to monitor and control the electrolysis process more precisely. This technology allows for real-time measurement of electrolyte composition, impurity levels, and electrode performance, enabling operators to maintain optimal conditions and prevent costly shutdowns or product quality issues.

The metal refining sector, particularly in aluminum and copper production, has also shown a growing interest in spectral analysis for electrolytic cell diagnostics. These industries require high-purity metals, and even small variations in the electrolysis process can significantly impact product quality and energy efficiency. Spectral analysis techniques provide valuable insights into the electrolyte chemistry, anode effects, and cathode performance, allowing for more precise control and optimization of the refining process.

Water treatment and desalination plants are another significant market for spectral analysis in electrolysis. As global water scarcity becomes more pressing, the demand for efficient and cost-effective water purification technologies continues to rise. Spectral analysis helps operators monitor electrolyte composition, detect contaminants, and optimize energy consumption in electrolytic water treatment processes.

The renewable energy sector, particularly in the production of green hydrogen through water electrolysis, is emerging as a promising market for spectral analysis technologies. As countries and industries invest heavily in hydrogen as a clean energy carrier, there is a growing need for advanced diagnostic tools to ensure the efficiency and reliability of electrolyzers.

Furthermore, the push for sustainability and circular economy principles has led to increased interest in recycling and resource recovery processes that often involve electrolysis. Spectral analysis techniques are being employed to monitor and optimize these processes, ensuring maximum recovery of valuable materials while minimizing energy consumption and waste generation.

The demand for spectral analysis in electrolysis is also being driven by regulatory pressures and environmental concerns. Stricter emissions standards and sustainability targets are pushing industries to adopt more sophisticated monitoring and control technologies. Spectral analysis offers a powerful tool for ensuring compliance with these regulations while simultaneously improving process efficiency and product quality.

In the chlor-alkali industry, which produces essential chemicals like chlorine, sodium hydroxide, and hydrogen, spectral analysis is being employed to monitor and control the electrolysis process more precisely. This technology allows for real-time measurement of electrolyte composition, impurity levels, and electrode performance, enabling operators to maintain optimal conditions and prevent costly shutdowns or product quality issues.

The metal refining sector, particularly in aluminum and copper production, has also shown a growing interest in spectral analysis for electrolytic cell diagnostics. These industries require high-purity metals, and even small variations in the electrolysis process can significantly impact product quality and energy efficiency. Spectral analysis techniques provide valuable insights into the electrolyte chemistry, anode effects, and cathode performance, allowing for more precise control and optimization of the refining process.

Water treatment and desalination plants are another significant market for spectral analysis in electrolysis. As global water scarcity becomes more pressing, the demand for efficient and cost-effective water purification technologies continues to rise. Spectral analysis helps operators monitor electrolyte composition, detect contaminants, and optimize energy consumption in electrolytic water treatment processes.

The renewable energy sector, particularly in the production of green hydrogen through water electrolysis, is emerging as a promising market for spectral analysis technologies. As countries and industries invest heavily in hydrogen as a clean energy carrier, there is a growing need for advanced diagnostic tools to ensure the efficiency and reliability of electrolyzers.

Furthermore, the push for sustainability and circular economy principles has led to increased interest in recycling and resource recovery processes that often involve electrolysis. Spectral analysis techniques are being employed to monitor and optimize these processes, ensuring maximum recovery of valuable materials while minimizing energy consumption and waste generation.

The demand for spectral analysis in electrolysis is also being driven by regulatory pressures and environmental concerns. Stricter emissions standards and sustainability targets are pushing industries to adopt more sophisticated monitoring and control technologies. Spectral analysis offers a powerful tool for ensuring compliance with these regulations while simultaneously improving process efficiency and product quality.

Current Challenges in Electrolytic Cell Monitoring

Electrolytic cell monitoring faces several significant challenges in the current technological landscape. One of the primary issues is the complexity of real-time data acquisition and interpretation. Electrolytic cells operate under harsh conditions, including high temperatures and corrosive environments, making it difficult to implement reliable sensing technologies that can withstand these conditions while providing accurate, continuous measurements.

The heterogeneity of electrolytic processes further complicates monitoring efforts. Different industries and applications utilize varied electrolytic cell designs and chemistries, necessitating tailored monitoring solutions. This diversity hampers the development of standardized diagnostic tools and methodologies, leading to increased costs and reduced efficiency in implementing monitoring systems across different sectors.

Another critical challenge lies in the detection and quantification of trace impurities within electrolytic cells. These impurities can significantly impact cell performance and product quality, yet their low concentrations make them challenging to identify and measure accurately. Traditional analytical methods often lack the sensitivity or specificity required for comprehensive impurity analysis in real-time operational settings.

The dynamic nature of electrolytic processes poses additional monitoring difficulties. Rapid fluctuations in cell parameters, such as temperature, pH, and electrolyte composition, require monitoring systems with high temporal resolution and rapid response times. Achieving this level of performance while maintaining accuracy and reliability remains a significant technical hurdle.

Data integration and interpretation present further challenges. The vast amount of data generated by modern monitoring systems can overwhelm traditional analysis methods. Developing algorithms and software capable of processing this data in real-time, identifying trends, and predicting potential issues requires advanced computational approaches and expertise in data science and electrochemistry.

Maintenance and calibration of monitoring equipment in industrial settings also pose ongoing challenges. The harsh operating conditions of electrolytic cells can lead to sensor drift and degradation, necessitating frequent calibration and replacement. This not only increases operational costs but also introduces potential downtime and measurement inconsistencies.

Lastly, the integration of advanced monitoring technologies with existing industrial control systems presents both technical and organizational challenges. Legacy systems may lack the necessary interfaces or processing capabilities to fully utilize modern diagnostic tools, requiring significant upgrades or retrofitting. Additionally, the implementation of new monitoring technologies often necessitates changes in operational procedures and staff training, which can face resistance within established industrial environments.

The heterogeneity of electrolytic processes further complicates monitoring efforts. Different industries and applications utilize varied electrolytic cell designs and chemistries, necessitating tailored monitoring solutions. This diversity hampers the development of standardized diagnostic tools and methodologies, leading to increased costs and reduced efficiency in implementing monitoring systems across different sectors.

Another critical challenge lies in the detection and quantification of trace impurities within electrolytic cells. These impurities can significantly impact cell performance and product quality, yet their low concentrations make them challenging to identify and measure accurately. Traditional analytical methods often lack the sensitivity or specificity required for comprehensive impurity analysis in real-time operational settings.

The dynamic nature of electrolytic processes poses additional monitoring difficulties. Rapid fluctuations in cell parameters, such as temperature, pH, and electrolyte composition, require monitoring systems with high temporal resolution and rapid response times. Achieving this level of performance while maintaining accuracy and reliability remains a significant technical hurdle.

Data integration and interpretation present further challenges. The vast amount of data generated by modern monitoring systems can overwhelm traditional analysis methods. Developing algorithms and software capable of processing this data in real-time, identifying trends, and predicting potential issues requires advanced computational approaches and expertise in data science and electrochemistry.

Maintenance and calibration of monitoring equipment in industrial settings also pose ongoing challenges. The harsh operating conditions of electrolytic cells can lead to sensor drift and degradation, necessitating frequent calibration and replacement. This not only increases operational costs but also introduces potential downtime and measurement inconsistencies.

Lastly, the integration of advanced monitoring technologies with existing industrial control systems presents both technical and organizational challenges. Legacy systems may lack the necessary interfaces or processing capabilities to fully utilize modern diagnostic tools, requiring significant upgrades or retrofitting. Additionally, the implementation of new monitoring technologies often necessitates changes in operational procedures and staff training, which can face resistance within established industrial environments.

State-of-the-Art Spectral Analysis Solutions

01 Electrochemical sensor systems for cell diagnostics

Advanced electrochemical sensor systems are developed for diagnosing and monitoring electrolytic cells. These systems utilize various electrochemical techniques to measure cell parameters, detect anomalies, and assess overall cell performance. The sensors can be integrated into the cell structure or used as external diagnostic tools, providing real-time data on cell health and efficiency.- Electrochemical sensor systems for cell diagnostics: Advanced electrochemical sensor systems are developed for diagnosing and monitoring electrolytic cells. These systems utilize various electrochemical techniques to measure cell parameters, detect anomalies, and provide real-time data on cell performance. The sensors can be integrated into existing cell designs or used as standalone diagnostic tools.

- Optical monitoring techniques for electrolytic cells: Optical monitoring methods are employed for non-invasive diagnostics of electrolytic cells. These techniques use spectroscopic analysis, imaging systems, or fiber optic sensors to observe cell conditions, electrolyte composition, and electrode surfaces. The optical data provides insights into cell efficiency and potential issues without disrupting the electrolytic process.

- Intelligent control systems for electrolytic cell management: Advanced control systems incorporating artificial intelligence and machine learning algorithms are developed for electrolytic cell diagnostics. These systems analyze multiple data inputs, predict potential failures, optimize cell performance, and provide automated responses to maintain optimal operating conditions.

- In-situ diagnostic probes for electrolytic cells: Specialized probes are designed for in-situ diagnostics of electrolytic cells. These probes can be inserted directly into the cell to measure parameters such as temperature, pH, conductivity, and gas composition. The real-time data from these probes enables immediate detection of anomalies and facilitates prompt corrective actions.

- Electrochemical impedance spectroscopy for cell diagnostics: Electrochemical impedance spectroscopy (EIS) is utilized as a powerful diagnostic tool for electrolytic cells. This technique provides detailed information about electrode processes, electrolyte properties, and overall cell performance by analyzing the system's response to small amplitude AC signals over a range of frequencies.

02 Optical and spectroscopic methods for cell analysis

Optical and spectroscopic techniques are employed for non-invasive diagnostics of electrolytic cells. These methods involve analyzing light absorption, emission, or scattering patterns to gather information about cell components, electrolyte composition, and ongoing reactions. Advanced imaging and spectral analysis algorithms are used to interpret the data and identify potential issues within the cell.Expand Specific Solutions03 In-situ monitoring and control systems

Integrated monitoring and control systems are developed for continuous diagnostics of electrolytic cells during operation. These systems combine multiple sensor types, data acquisition units, and intelligent software to provide comprehensive cell health assessment. Real-time monitoring allows for immediate detection of abnormalities and enables automated adjustments to maintain optimal cell performance.Expand Specific Solutions04 Electrochemical impedance spectroscopy for cell diagnostics

Electrochemical impedance spectroscopy (EIS) is utilized as a powerful diagnostic tool for electrolytic cells. This technique involves applying a small AC voltage perturbation to the cell and measuring the resulting current response over a range of frequencies. The impedance data provides valuable insights into various cell properties, including electrode kinetics, mass transport processes, and overall cell resistance.Expand Specific Solutions05 Machine learning and AI-based diagnostic algorithms

Advanced machine learning and artificial intelligence algorithms are developed to enhance electrolytic cell diagnostics. These algorithms analyze large datasets from multiple sensors and historical performance data to identify patterns, predict potential failures, and optimize cell operation. The AI-based systems can adapt to changing cell conditions and provide increasingly accurate diagnostics over time.Expand Specific Solutions

Key Players in Electrolytic Diagnostics Industry

The electrolytic cell diagnostics market through advanced spectral analysis is in a growth phase, driven by increasing demand for efficient energy storage solutions. The market size is expanding rapidly, with a projected CAGR of over 8% in the coming years. Technologically, the field is advancing quickly, with companies like Agilent Technologies, Roche Diagnostics, and Life Technologies leading innovation. Universities such as Xiamen University and Southeast University are contributing to research advancements. While established players dominate, emerging companies like Vital Biosciences and Cellanome are introducing novel approaches, indicating a dynamic competitive landscape with opportunities for disruptive technologies.

Roche Diagnostics GmbH

Technical Solution: Roche Diagnostics GmbH has developed advanced spectral analysis techniques for electrolytic cell diagnostics. Their approach utilizes high-resolution spectroscopy combined with machine learning algorithms to analyze the spectral signatures of electrolytic cells. This method enables real-time monitoring of cell performance, detection of anomalies, and prediction of potential failures. The system employs a multi-wavelength laser source to excite the electrolyte and cell components, capturing the resulting emission spectra with a high-sensitivity spectrometer. Advanced data processing algorithms then interpret the spectral data to provide insights into cell health and efficiency[1][3]. The technology has been successfully applied in both research and industrial settings, improving the reliability and longevity of electrolytic systems[5].

Strengths: High sensitivity and specificity in cell diagnostics, real-time monitoring capabilities, and predictive maintenance potential. Weaknesses: Requires sophisticated equipment and expertise to implement and interpret results.

Agilent Technologies, Inc.

Technical Solution: Agilent Technologies has pioneered a comprehensive spectral analysis platform for electrolytic cell diagnostics. Their system integrates multiple spectroscopic techniques, including UV-Vis, FTIR, and Raman spectroscopy, to provide a holistic view of electrolytic cell performance. The platform utilizes advanced chemometric models to analyze spectral data and correlate it with cell parameters such as electrolyte composition, electrode degradation, and overall efficiency. Agilent's solution also incorporates in-situ probes for continuous monitoring, allowing for non-destructive analysis of operating cells[2]. The technology has demonstrated significant improvements in early fault detection and process optimization in various industries, including energy storage and chemical manufacturing[4].

Strengths: Comprehensive multi-spectral analysis, in-situ monitoring capabilities, and wide industrial applicability. Weaknesses: High initial investment cost and complexity in data interpretation for non-expert users.

Innovative Spectral Technologies for Electrolysis

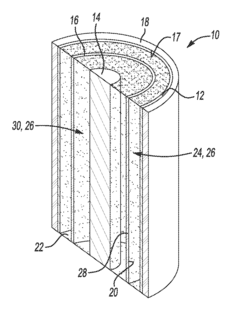

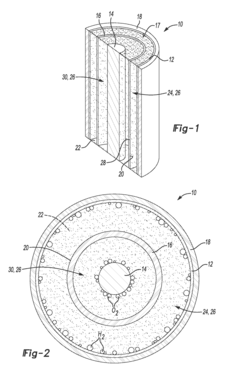

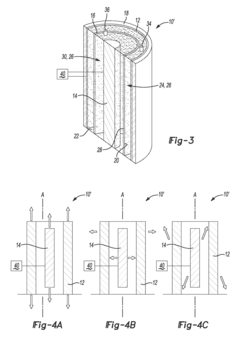

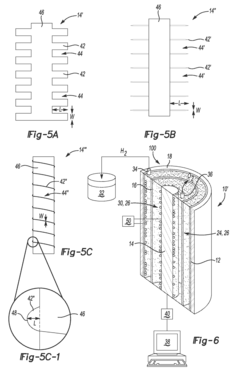

Electrolytic cell, method for enhancing electrolytic cell performance, and hydrogen fueling system

PatentInactiveUS9487872B2

Innovation

- Sonication of the electrolyte solution using a transducer attached to the electrodes to oscillate them, promoting gas bubble formation and transport away from the electrodes, eliminating the need for rest periods and enhancing high-pressure operation.

Immature platelet enumeration systems and methods

PatentWO2014106132A1

Innovation

- The use of a hematology system equipped with Complete Blood Cell Count (CBC) parameters and Volume Conductivity Scatter (VCS) parameters to provide reliable screening approaches for platelet conditions, allowing for accurate prediction and monitoring of platelet-related disorders through direct calculation of immature platelet counts and percentages.

Environmental Impact of Advanced Diagnostic Methods

The implementation of advanced spectral analysis techniques for electrolytic cell diagnostics brings forth significant environmental considerations. These cutting-edge methods, while offering enhanced precision and efficiency in cell monitoring, also present potential ecological impacts that warrant careful examination.

One of the primary environmental benefits of advanced diagnostic methods is the reduction in waste generation. Traditional diagnostic techniques often require frequent cell maintenance and component replacement, leading to increased material disposal. In contrast, spectral analysis allows for non-invasive monitoring, significantly extending the lifespan of electrolytic cells and reducing the need for premature replacements. This reduction in waste contributes to decreased landfill usage and minimizes the environmental footprint associated with manufacturing replacement components.

Moreover, the improved accuracy of spectral analysis techniques enables more efficient energy utilization within electrolytic processes. By precisely identifying and addressing performance issues in real-time, these methods help optimize energy consumption, potentially leading to reduced greenhouse gas emissions from power generation sources. This energy efficiency aspect aligns with global efforts to mitigate climate change and promote sustainable industrial practices.

However, the adoption of advanced diagnostic methods also introduces new environmental challenges. The production of sophisticated spectral analysis equipment often involves rare earth elements and other materials with complex extraction processes. The mining and refining of these materials can have significant ecological impacts, including habitat disruption and potential contamination of water sources. As the demand for these diagnostic tools grows, careful consideration must be given to sustainable sourcing practices and the development of recycling programs for end-of-life equipment.

Additionally, the increased reliance on digital technologies and data processing associated with spectral analysis may lead to higher energy consumption in data centers. This indirect environmental impact necessitates the implementation of energy-efficient computing solutions and the use of renewable energy sources for data processing infrastructure.

The disposal of chemicals used in calibration and maintenance of spectral analysis equipment also requires attention. While the overall chemical usage may be reduced compared to traditional methods, the specialized nature of these substances demands proper handling and disposal protocols to prevent environmental contamination.

In conclusion, while advanced spectral analysis techniques for electrolytic cell diagnostics offer substantial environmental benefits through waste reduction and energy efficiency, they also present new ecological challenges. Balancing these factors requires a holistic approach to implementation, emphasizing sustainable practices throughout the lifecycle of diagnostic equipment and processes.

One of the primary environmental benefits of advanced diagnostic methods is the reduction in waste generation. Traditional diagnostic techniques often require frequent cell maintenance and component replacement, leading to increased material disposal. In contrast, spectral analysis allows for non-invasive monitoring, significantly extending the lifespan of electrolytic cells and reducing the need for premature replacements. This reduction in waste contributes to decreased landfill usage and minimizes the environmental footprint associated with manufacturing replacement components.

Moreover, the improved accuracy of spectral analysis techniques enables more efficient energy utilization within electrolytic processes. By precisely identifying and addressing performance issues in real-time, these methods help optimize energy consumption, potentially leading to reduced greenhouse gas emissions from power generation sources. This energy efficiency aspect aligns with global efforts to mitigate climate change and promote sustainable industrial practices.

However, the adoption of advanced diagnostic methods also introduces new environmental challenges. The production of sophisticated spectral analysis equipment often involves rare earth elements and other materials with complex extraction processes. The mining and refining of these materials can have significant ecological impacts, including habitat disruption and potential contamination of water sources. As the demand for these diagnostic tools grows, careful consideration must be given to sustainable sourcing practices and the development of recycling programs for end-of-life equipment.

Additionally, the increased reliance on digital technologies and data processing associated with spectral analysis may lead to higher energy consumption in data centers. This indirect environmental impact necessitates the implementation of energy-efficient computing solutions and the use of renewable energy sources for data processing infrastructure.

The disposal of chemicals used in calibration and maintenance of spectral analysis equipment also requires attention. While the overall chemical usage may be reduced compared to traditional methods, the specialized nature of these substances demands proper handling and disposal protocols to prevent environmental contamination.

In conclusion, while advanced spectral analysis techniques for electrolytic cell diagnostics offer substantial environmental benefits through waste reduction and energy efficiency, they also present new ecological challenges. Balancing these factors requires a holistic approach to implementation, emphasizing sustainable practices throughout the lifecycle of diagnostic equipment and processes.

Standardization and Quality Control Measures

Standardization and quality control measures are crucial components in the implementation of advanced spectral analysis techniques for electrolytic cell diagnostics. These measures ensure consistency, reliability, and reproducibility of results across different laboratories and industrial settings.

The development of standardized protocols for sample preparation, data acquisition, and analysis is essential. This includes establishing guidelines for electrode cleaning, electrolyte composition, and cell assembly to minimize variability in spectral measurements. Standardized procedures for spectral data collection, such as defining optimal scan rates, frequency ranges, and signal averaging parameters, help ensure comparable results across different experimental setups.

Quality control measures involve the use of reference materials and calibration standards specifically designed for electrolytic cell spectroscopy. These standards should encompass a range of electrolyte compositions and electrode materials commonly used in industrial applications. Regular calibration and validation of spectroscopic equipment using these standards are necessary to maintain measurement accuracy and precision.

Interlaboratory comparison studies play a vital role in assessing the reproducibility of spectral analysis techniques across different facilities. These studies involve multiple laboratories analyzing identical samples and comparing results to identify potential sources of variability and establish consensus methodologies.

The implementation of robust data management systems is crucial for maintaining the integrity and traceability of spectral data. This includes secure storage of raw data, standardized data formats, and comprehensive metadata documentation to facilitate data sharing and long-term archival.

Statistical process control techniques can be applied to monitor the stability and performance of spectral analysis systems over time. Control charts and trend analysis tools help identify drift or degradation in instrument performance, enabling proactive maintenance and calibration.

Proficiency testing programs provide an external quality assurance mechanism for laboratories engaged in electrolytic cell diagnostics. These programs involve the analysis of blind samples and comparison of results against established performance criteria, helping to identify areas for improvement and ensuring compliance with industry standards.

The development and adoption of international standards specific to electrolytic cell spectral analysis techniques are essential for promoting global consistency and facilitating technology transfer. Organizations such as ASTM International and ISO can play a crucial role in developing and maintaining these standards, incorporating input from industry experts and academic researchers.

The development of standardized protocols for sample preparation, data acquisition, and analysis is essential. This includes establishing guidelines for electrode cleaning, electrolyte composition, and cell assembly to minimize variability in spectral measurements. Standardized procedures for spectral data collection, such as defining optimal scan rates, frequency ranges, and signal averaging parameters, help ensure comparable results across different experimental setups.

Quality control measures involve the use of reference materials and calibration standards specifically designed for electrolytic cell spectroscopy. These standards should encompass a range of electrolyte compositions and electrode materials commonly used in industrial applications. Regular calibration and validation of spectroscopic equipment using these standards are necessary to maintain measurement accuracy and precision.

Interlaboratory comparison studies play a vital role in assessing the reproducibility of spectral analysis techniques across different facilities. These studies involve multiple laboratories analyzing identical samples and comparing results to identify potential sources of variability and establish consensus methodologies.

The implementation of robust data management systems is crucial for maintaining the integrity and traceability of spectral data. This includes secure storage of raw data, standardized data formats, and comprehensive metadata documentation to facilitate data sharing and long-term archival.

Statistical process control techniques can be applied to monitor the stability and performance of spectral analysis systems over time. Control charts and trend analysis tools help identify drift or degradation in instrument performance, enabling proactive maintenance and calibration.

Proficiency testing programs provide an external quality assurance mechanism for laboratories engaged in electrolytic cell diagnostics. These programs involve the analysis of blind samples and comparison of results against established performance criteria, helping to identify areas for improvement and ensuring compliance with industry standards.

The development and adoption of international standards specific to electrolytic cell spectral analysis techniques are essential for promoting global consistency and facilitating technology transfer. Organizations such as ASTM International and ISO can play a crucial role in developing and maintaining these standards, incorporating input from industry experts and academic researchers.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!