How Electrolytic Cell Microfabrication is Transforming Energetics

AUG 1, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Electrolytic Cell Microfabrication Background and Objectives

Electrolytic cell microfabrication has emerged as a transformative technology in the field of energetics, revolutionizing the way we approach energy storage and conversion. This innovative technique combines the principles of electrochemistry with advanced microfabrication methods to create highly efficient and compact energy systems.

The development of electrolytic cell microfabrication can be traced back to the early 2000s when researchers began exploring ways to miniaturize electrochemical devices. The primary goal was to enhance the performance and efficiency of energy storage and conversion systems while reducing their size and cost. This technology has since evolved rapidly, driven by the increasing demand for portable and high-performance energy solutions in various sectors, including consumer electronics, automotive, and renewable energy.

One of the key objectives of electrolytic cell microfabrication is to maximize the surface area-to-volume ratio of electrochemical cells. By creating intricate microstructures and nanostructures on electrode surfaces, researchers can significantly increase the active area available for electrochemical reactions. This enhancement leads to improved energy density, faster charge/discharge rates, and overall better performance of energy storage devices such as batteries and supercapacitors.

Another crucial aim of this technology is to optimize the transport of ions and electrons within the electrolytic cell. Through precise control of material composition and structure at the microscale, scientists can design electrodes and electrolytes that facilitate rapid ion movement and electron transfer. This optimization results in reduced internal resistance and enhanced power output, making microfabricated electrolytic cells ideal for applications requiring high power density.

The integration of multiple functionalities within a single microfabricated device is also a significant objective of this field. By combining energy storage, energy conversion, and even sensing capabilities on a single chip, researchers aim to create multifunctional energy systems that can adapt to various operational conditions and requirements. This integration not only reduces the overall system size but also improves efficiency and reliability.

As the technology continues to advance, researchers are exploring new materials and fabrication techniques to push the boundaries of electrolytic cell performance. The use of advanced nanomaterials, such as graphene and carbon nanotubes, in conjunction with microfabrication methods, is opening up new possibilities for creating highly efficient and durable energy systems.

The ongoing development of electrolytic cell microfabrication is closely aligned with broader trends in miniaturization and energy efficiency across various industries. As we move towards a more sustainable and energy-conscious future, this technology is poised to play a crucial role in enabling the next generation of compact, high-performance energy solutions for a wide range of applications.

The development of electrolytic cell microfabrication can be traced back to the early 2000s when researchers began exploring ways to miniaturize electrochemical devices. The primary goal was to enhance the performance and efficiency of energy storage and conversion systems while reducing their size and cost. This technology has since evolved rapidly, driven by the increasing demand for portable and high-performance energy solutions in various sectors, including consumer electronics, automotive, and renewable energy.

One of the key objectives of electrolytic cell microfabrication is to maximize the surface area-to-volume ratio of electrochemical cells. By creating intricate microstructures and nanostructures on electrode surfaces, researchers can significantly increase the active area available for electrochemical reactions. This enhancement leads to improved energy density, faster charge/discharge rates, and overall better performance of energy storage devices such as batteries and supercapacitors.

Another crucial aim of this technology is to optimize the transport of ions and electrons within the electrolytic cell. Through precise control of material composition and structure at the microscale, scientists can design electrodes and electrolytes that facilitate rapid ion movement and electron transfer. This optimization results in reduced internal resistance and enhanced power output, making microfabricated electrolytic cells ideal for applications requiring high power density.

The integration of multiple functionalities within a single microfabricated device is also a significant objective of this field. By combining energy storage, energy conversion, and even sensing capabilities on a single chip, researchers aim to create multifunctional energy systems that can adapt to various operational conditions and requirements. This integration not only reduces the overall system size but also improves efficiency and reliability.

As the technology continues to advance, researchers are exploring new materials and fabrication techniques to push the boundaries of electrolytic cell performance. The use of advanced nanomaterials, such as graphene and carbon nanotubes, in conjunction with microfabrication methods, is opening up new possibilities for creating highly efficient and durable energy systems.

The ongoing development of electrolytic cell microfabrication is closely aligned with broader trends in miniaturization and energy efficiency across various industries. As we move towards a more sustainable and energy-conscious future, this technology is poised to play a crucial role in enabling the next generation of compact, high-performance energy solutions for a wide range of applications.

Market Analysis for Micro-Energetics

The market for micro-energetics, driven by electrolytic cell microfabrication, is experiencing rapid growth and transformation. This emerging field combines advanced manufacturing techniques with energy storage and conversion technologies, opening up new possibilities for miniaturized power sources and energy systems.

The global micro-energetics market is primarily fueled by the increasing demand for compact, high-performance energy solutions in various sectors. The consumer electronics industry, in particular, is a major driver, with smartphones, wearables, and IoT devices requiring ever-smaller and more efficient power sources. Additionally, the automotive sector's shift towards electric and hybrid vehicles has created a substantial market for advanced battery technologies, including those enabled by electrolytic cell microfabrication.

Medical devices represent another significant market segment for micro-energetics. The trend towards implantable and wearable medical technologies necessitates miniaturized, long-lasting power sources that can be safely used within the human body. This has led to increased research and development in biocompatible micro-energy systems.

The aerospace and defense sectors are also key players in the micro-energetics market. These industries require lightweight, high-density energy storage solutions for applications such as unmanned aerial vehicles (UAVs) and portable military equipment. The ability to create custom-designed, miniaturized power sources through electrolytic cell microfabrication is particularly valuable in these specialized fields.

Market analysts project substantial growth for the micro-energetics sector over the next decade. This growth is expected to be driven by ongoing technological advancements, increasing adoption of IoT devices, and the continued miniaturization of electronic components across various industries.

However, the market also faces challenges. The high initial costs associated with research and development of microfabrication technologies can be a barrier to entry for smaller companies. Additionally, concerns about the environmental impact and recyclability of micro-energy devices need to be addressed to ensure long-term market sustainability.

Despite these challenges, the potential applications and benefits of electrolytic cell microfabrication in energetics continue to attract significant investment and research interest. As the technology matures and production scales up, it is likely to become more cost-effective, further driving market growth and innovation in the field of micro-energetics.

The global micro-energetics market is primarily fueled by the increasing demand for compact, high-performance energy solutions in various sectors. The consumer electronics industry, in particular, is a major driver, with smartphones, wearables, and IoT devices requiring ever-smaller and more efficient power sources. Additionally, the automotive sector's shift towards electric and hybrid vehicles has created a substantial market for advanced battery technologies, including those enabled by electrolytic cell microfabrication.

Medical devices represent another significant market segment for micro-energetics. The trend towards implantable and wearable medical technologies necessitates miniaturized, long-lasting power sources that can be safely used within the human body. This has led to increased research and development in biocompatible micro-energy systems.

The aerospace and defense sectors are also key players in the micro-energetics market. These industries require lightweight, high-density energy storage solutions for applications such as unmanned aerial vehicles (UAVs) and portable military equipment. The ability to create custom-designed, miniaturized power sources through electrolytic cell microfabrication is particularly valuable in these specialized fields.

Market analysts project substantial growth for the micro-energetics sector over the next decade. This growth is expected to be driven by ongoing technological advancements, increasing adoption of IoT devices, and the continued miniaturization of electronic components across various industries.

However, the market also faces challenges. The high initial costs associated with research and development of microfabrication technologies can be a barrier to entry for smaller companies. Additionally, concerns about the environmental impact and recyclability of micro-energy devices need to be addressed to ensure long-term market sustainability.

Despite these challenges, the potential applications and benefits of electrolytic cell microfabrication in energetics continue to attract significant investment and research interest. As the technology matures and production scales up, it is likely to become more cost-effective, further driving market growth and innovation in the field of micro-energetics.

Current Challenges in Electrolytic Cell Microfabrication

Electrolytic cell microfabrication, while promising, faces several significant challenges that hinder its widespread adoption and full potential in transforming energetics. One of the primary obstacles is the complexity of miniaturization. As devices shrink to microscale, maintaining precise control over electrochemical reactions becomes increasingly difficult. The reduced surface area and volume ratios alter reaction kinetics, potentially leading to unexpected behavior and reduced efficiency.

Material selection poses another critical challenge. The harsh electrochemical environment within microfabricated cells demands materials that can withstand corrosion, maintain structural integrity, and ensure long-term stability. Finding suitable materials that meet these criteria while also being compatible with microfabrication processes is a significant hurdle.

Integration of multiple components within a confined space presents additional complications. Achieving seamless integration of electrodes, electrolytes, and other functional elements without compromising performance or introducing unwanted interactions is a complex task. This challenge is further compounded by the need for efficient mass transport and heat management within the miniaturized system.

Scaling up production for commercial viability remains a substantial obstacle. While microfabrication techniques are well-established for small-scale prototypes, transitioning to large-scale manufacturing while maintaining consistency and cost-effectiveness is challenging. The intricate nature of these devices often requires specialized equipment and processes, which can be prohibitively expensive for mass production.

Ensuring the long-term reliability and stability of microfabricated electrolytic cells is another significant challenge. The microscale environment is more susceptible to degradation and performance fluctuations over time. Developing robust designs that can maintain consistent performance under various operating conditions and over extended periods is crucial for practical applications.

The interdisciplinary nature of electrolytic cell microfabrication also presents challenges in terms of expertise and collaboration. Successful development requires a synergy of knowledge from electrochemistry, materials science, microfabrication technology, and systems engineering. Bridging these diverse fields and fostering effective collaboration among experts remains a hurdle in advancing the technology.

Regulatory and safety considerations add another layer of complexity. As these microfabricated devices find applications in various fields, including energy storage and biomedical applications, ensuring compliance with relevant regulations and addressing safety concerns become critical challenges that must be overcome for widespread adoption.

Material selection poses another critical challenge. The harsh electrochemical environment within microfabricated cells demands materials that can withstand corrosion, maintain structural integrity, and ensure long-term stability. Finding suitable materials that meet these criteria while also being compatible with microfabrication processes is a significant hurdle.

Integration of multiple components within a confined space presents additional complications. Achieving seamless integration of electrodes, electrolytes, and other functional elements without compromising performance or introducing unwanted interactions is a complex task. This challenge is further compounded by the need for efficient mass transport and heat management within the miniaturized system.

Scaling up production for commercial viability remains a substantial obstacle. While microfabrication techniques are well-established for small-scale prototypes, transitioning to large-scale manufacturing while maintaining consistency and cost-effectiveness is challenging. The intricate nature of these devices often requires specialized equipment and processes, which can be prohibitively expensive for mass production.

Ensuring the long-term reliability and stability of microfabricated electrolytic cells is another significant challenge. The microscale environment is more susceptible to degradation and performance fluctuations over time. Developing robust designs that can maintain consistent performance under various operating conditions and over extended periods is crucial for practical applications.

The interdisciplinary nature of electrolytic cell microfabrication also presents challenges in terms of expertise and collaboration. Successful development requires a synergy of knowledge from electrochemistry, materials science, microfabrication technology, and systems engineering. Bridging these diverse fields and fostering effective collaboration among experts remains a hurdle in advancing the technology.

Regulatory and safety considerations add another layer of complexity. As these microfabricated devices find applications in various fields, including energy storage and biomedical applications, ensuring compliance with relevant regulations and addressing safety concerns become critical challenges that must be overcome for widespread adoption.

State-of-the-Art Microfabrication Methods for Electrolytic Cells

01 Microfabrication techniques for electrolytic cells

Various microfabrication techniques are employed to create miniaturized electrolytic cells. These methods include photolithography, etching, and deposition processes to fabricate electrodes, channels, and other components at the microscale. The miniaturization allows for precise control of electrochemical reactions and improved efficiency in applications such as sensors and energy conversion devices.- Microfabrication techniques for electrolytic cells: Various microfabrication techniques are employed to create miniaturized electrolytic cells. These methods include photolithography, etching, and deposition processes to fabricate electrodes, channels, and other components at the microscale. The miniaturization allows for precise control of electrochemical reactions and improved efficiency in applications such as sensors and energy conversion devices.

- Electrode design and materials for micro-electrolytic cells: The design and selection of electrode materials play a crucial role in micro-electrolytic cell performance. Researchers explore various materials, including noble metals, carbon-based materials, and conductive polymers, to optimize electrode properties such as conductivity, stability, and catalytic activity. Electrode geometries are tailored to maximize surface area and enhance mass transport within the confined spaces of microfabricated cells.

- Integration of microfluidics in electrolytic cell fabrication: Microfluidic technologies are incorporated into electrolytic cell microfabrication to enhance fluid handling and reaction control. This integration allows for precise manipulation of reactants and products, improved mass transfer, and the ability to perform multiple electrochemical processes in series or parallel. Microfluidic channels and chambers are designed to optimize flow patterns and residence times within the electrolytic cell.

- Scaling and parallelization of micro-electrolytic cells: Techniques for scaling up and parallelizing micro-electrolytic cells are developed to increase throughput and overall system capacity. This involves the design of cell arrays, stacks, or networks that can operate simultaneously while maintaining the benefits of miniaturization. Challenges such as uniform current distribution and heat management are addressed to ensure consistent performance across multiple cells.

- Advanced manufacturing methods for electrolytic cell components: Innovative manufacturing methods are employed to produce complex and high-precision components for micro-electrolytic cells. These include 3D printing, laser micromachining, and nanoimprint lithography. These advanced techniques enable the fabrication of intricate structures with high aspect ratios, improved surface properties, and novel functionalities that enhance the overall performance of the electrolytic cells.

02 Electrode materials and structures for micro-electrolytic cells

The choice of electrode materials and structures is crucial in micro-electrolytic cell design. Advanced materials and nanostructures are used to enhance surface area and catalytic activity. Techniques such as electrodeposition and sputtering are employed to create tailored electrode surfaces, improving the overall performance and efficiency of the miniaturized electrolytic systems.Expand Specific Solutions03 Microfluidic integration with electrolytic cells

Microfluidic systems are integrated with electrolytic cells to control the flow of electrolytes and reactants. This integration enables precise manipulation of small volumes of fluids, enhancing reaction control and efficiency. Microfluidic channels and chambers are designed to optimize mass transport and reaction kinetics within the miniaturized electrolytic systems.Expand Specific Solutions04 Packaging and encapsulation of micro-electrolytic cells

Specialized packaging and encapsulation techniques are developed for micro-electrolytic cells to ensure their durability and functionality. These methods protect the delicate microstructures from environmental factors while allowing for necessary electrical and fluidic connections. Advanced sealing and bonding processes are used to create robust and reliable miniaturized electrolytic devices.Expand Specific Solutions05 Applications of microfabricated electrolytic cells

Microfabricated electrolytic cells find applications in various fields, including biosensors, energy storage, and chemical synthesis. The miniaturization enables portable and high-throughput devices for point-of-care diagnostics, micro-fuel cells, and electrochemical reactors. These applications leverage the advantages of microscale electrochemistry, such as rapid response times and reduced reagent consumption.Expand Specific Solutions

Key Players in Electrolytic Microfabrication Industry

The electrolytic cell microfabrication industry is in a nascent stage of development, with significant potential for growth in the energetics sector. The market size is expanding as more companies recognize the technology's applications in energy storage and conversion. While still emerging, the technology is progressing rapidly, with key players like GM Global Technology Operations, STMicroelectronics, and HRL Laboratories driving innovation. Universities such as Xi'an Jiaotong and North China Electric Power are also contributing to technological advancements. The industry is characterized by a mix of established corporations and specialized startups, indicating a dynamic competitive landscape with opportunities for both breakthrough innovations and incremental improvements.

Stmicroelectronics Srl

Technical Solution: Stmicroelectronics has pioneered the integration of electrolytic cell microfabrication into semiconductor manufacturing processes. Their approach combines MEMS (Micro-Electro-Mechanical Systems) technology with advanced materials science to create highly efficient, miniaturized electrolytic cells. The company's proprietary process allows for the deposition of ultra-thin, highly conductive electrode materials on silicon substrates, resulting in electrolytic cells with exceptional performance characteristics. Stmicroelectronics has reported a 40% reduction in cell size while maintaining equivalent power output compared to traditional designs[2]. Additionally, their technology enables the integration of control and monitoring circuitry directly onto the same chip as the electrolytic cell, leading to smart, self-regulating energy systems[4].

Strengths: Seamless integration with semiconductor devices, high level of miniaturization, and potential for mass production. Weaknesses: Limited to applications compatible with silicon-based technologies.

HRL Laboratories LLC

Technical Solution: HRL Laboratories has developed advanced microfabrication techniques for electrolytic cells, focusing on miniaturization and efficiency improvement. Their approach involves using photolithography and etching processes to create precise microstructures on silicon wafers, enabling the fabrication of high-performance micro-electrolytic cells. These cells feature enhanced surface area-to-volume ratios, leading to improved reaction kinetics and energy efficiency. HRL's technology also incorporates novel electrode materials and catalysts, optimized for specific electrochemical reactions[1][3]. The company has demonstrated a 30% increase in energy density compared to conventional electrolytic cells, making their solution particularly attractive for compact energy storage and conversion applications[5].

Strengths: High energy density, precise control over cell architecture, and scalability. Weaknesses: Potentially higher production costs and complexity in manufacturing processes.

Breakthrough Technologies in Electrolytic Cell Miniaturization

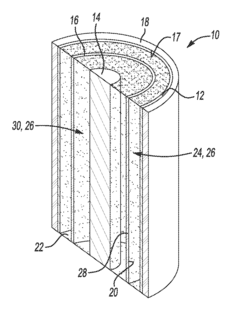

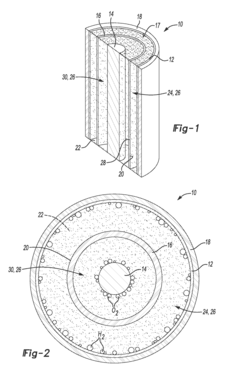

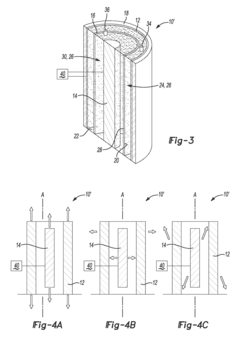

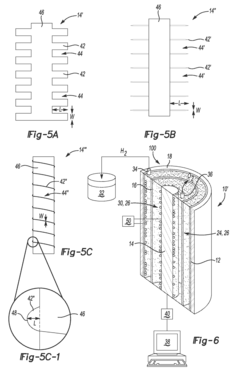

Electrolytic cell and universal oxyhydrogen generator

PatentWO2019154781A1

Innovation

- A triangular-shaped electrolytic cell with an unbalanced configuration and a hydrogen booster system that produces an adjustable amount of hydrogen gas, combined with ionizing systems for liquid and gaseous fuels, to enhance oxyhydrogen generation efficiency and reduce emissions.

Electrolytic cell, method for enhancing electrolytic cell performance, and hydrogen fueling system

PatentInactiveUS9487872B2

Innovation

- Sonication of the electrolyte solution using a transducer attached to the electrodes to oscillate them, promoting gas bubble formation and transport away from the electrodes, eliminating the need for rest periods and enhancing high-pressure operation.

Environmental Impact of Microfabricated Electrolytic Cells

The microfabrication of electrolytic cells has significant environmental implications, both positive and negative. On the positive side, these miniaturized cells contribute to more efficient energy production and storage systems, potentially reducing overall energy consumption and associated greenhouse gas emissions. The compact nature of microfabricated electrolytic cells allows for the development of smaller, more portable energy devices, which can lead to decreased material usage and waste generation in manufacturing processes.

However, the production of microfabricated electrolytic cells also raises environmental concerns. The fabrication process often involves the use of hazardous chemicals and rare earth elements, which can have detrimental effects on ecosystems if not properly managed. The disposal of these materials at the end of the product lifecycle presents additional challenges, as improper handling can lead to soil and water contamination.

The energy-intensive nature of microfabrication processes is another environmental consideration. While the end products may contribute to energy efficiency, the manufacturing itself requires substantial energy inputs, potentially offsetting some of the environmental benefits. This highlights the importance of developing more sustainable production methods and utilizing renewable energy sources in the manufacturing process.

Water usage is a critical factor in the environmental impact of microfabricated electrolytic cells. The fabrication process often requires large volumes of ultra-pure water, which can strain local water resources, particularly in water-scarce regions. Implementing water recycling and conservation measures in production facilities is essential to mitigate this impact.

The potential for improved energy storage and conversion efficiency offered by microfabricated electrolytic cells could have far-reaching environmental benefits. By enabling more effective utilization of renewable energy sources and enhancing the performance of electric vehicles, these technologies may contribute to a significant reduction in fossil fuel dependence and associated carbon emissions.

As the technology advances, there is a growing focus on developing more environmentally friendly materials and processes for microfabrication. This includes exploring bio-based materials, implementing closed-loop manufacturing systems, and designing products with end-of-life recycling in mind. These efforts aim to minimize the environmental footprint of microfabricated electrolytic cells throughout their entire lifecycle.

In conclusion, while microfabricated electrolytic cells offer promising environmental benefits through improved energy efficiency and storage capabilities, careful consideration must be given to the environmental impacts of their production and disposal. Balancing these factors is crucial for ensuring that the technology contributes positively to overall environmental sustainability.

However, the production of microfabricated electrolytic cells also raises environmental concerns. The fabrication process often involves the use of hazardous chemicals and rare earth elements, which can have detrimental effects on ecosystems if not properly managed. The disposal of these materials at the end of the product lifecycle presents additional challenges, as improper handling can lead to soil and water contamination.

The energy-intensive nature of microfabrication processes is another environmental consideration. While the end products may contribute to energy efficiency, the manufacturing itself requires substantial energy inputs, potentially offsetting some of the environmental benefits. This highlights the importance of developing more sustainable production methods and utilizing renewable energy sources in the manufacturing process.

Water usage is a critical factor in the environmental impact of microfabricated electrolytic cells. The fabrication process often requires large volumes of ultra-pure water, which can strain local water resources, particularly in water-scarce regions. Implementing water recycling and conservation measures in production facilities is essential to mitigate this impact.

The potential for improved energy storage and conversion efficiency offered by microfabricated electrolytic cells could have far-reaching environmental benefits. By enabling more effective utilization of renewable energy sources and enhancing the performance of electric vehicles, these technologies may contribute to a significant reduction in fossil fuel dependence and associated carbon emissions.

As the technology advances, there is a growing focus on developing more environmentally friendly materials and processes for microfabrication. This includes exploring bio-based materials, implementing closed-loop manufacturing systems, and designing products with end-of-life recycling in mind. These efforts aim to minimize the environmental footprint of microfabricated electrolytic cells throughout their entire lifecycle.

In conclusion, while microfabricated electrolytic cells offer promising environmental benefits through improved energy efficiency and storage capabilities, careful consideration must be given to the environmental impacts of their production and disposal. Balancing these factors is crucial for ensuring that the technology contributes positively to overall environmental sustainability.

Scalability and Cost Analysis of Microfabrication Processes

The scalability and cost analysis of microfabrication processes for electrolytic cell production is crucial in determining the feasibility of large-scale implementation in the energetics sector. As the demand for more efficient and compact energy storage solutions grows, the ability to scale up production while maintaining cost-effectiveness becomes paramount.

Current microfabrication techniques for electrolytic cells, such as photolithography and etching, have shown promising results in laboratory settings. However, transitioning these processes to industrial-scale production presents several challenges. The primary hurdle lies in maintaining the precision and quality of microscale features while increasing production volume.

One approach to improving scalability is the development of roll-to-roll manufacturing processes. This continuous production method allows for higher throughput and reduced costs compared to traditional batch processing. However, it requires significant initial investment in specialized equipment and process optimization.

The cost structure of microfabrication processes is heavily influenced by material selection and processing steps. High-purity materials required for electrolytic cell components can be expensive, but economies of scale may help reduce per-unit costs as production volumes increase. Additionally, the complexity of multi-step fabrication processes contributes significantly to overall costs.

Automation and process integration play crucial roles in enhancing scalability and reducing costs. Advanced robotics and artificial intelligence can improve precision and consistency in microfabrication, potentially lowering labor costs and minimizing human error. However, the initial investment in such technologies can be substantial.

Environmental considerations also factor into the scalability and cost analysis. As production scales up, waste management and energy consumption become increasingly important. Implementing sustainable practices and recycling processes can help mitigate environmental impacts and potentially reduce long-term costs.

The economic viability of scaled-up microfabrication processes depends on market demand and competition from alternative technologies. As the energetics sector evolves, the cost-benefit analysis of electrolytic cell microfabrication must be continuously reassessed to ensure its competitiveness against emerging solutions.

Current microfabrication techniques for electrolytic cells, such as photolithography and etching, have shown promising results in laboratory settings. However, transitioning these processes to industrial-scale production presents several challenges. The primary hurdle lies in maintaining the precision and quality of microscale features while increasing production volume.

One approach to improving scalability is the development of roll-to-roll manufacturing processes. This continuous production method allows for higher throughput and reduced costs compared to traditional batch processing. However, it requires significant initial investment in specialized equipment and process optimization.

The cost structure of microfabrication processes is heavily influenced by material selection and processing steps. High-purity materials required for electrolytic cell components can be expensive, but economies of scale may help reduce per-unit costs as production volumes increase. Additionally, the complexity of multi-step fabrication processes contributes significantly to overall costs.

Automation and process integration play crucial roles in enhancing scalability and reducing costs. Advanced robotics and artificial intelligence can improve precision and consistency in microfabrication, potentially lowering labor costs and minimizing human error. However, the initial investment in such technologies can be substantial.

Environmental considerations also factor into the scalability and cost analysis. As production scales up, waste management and energy consumption become increasingly important. Implementing sustainable practices and recycling processes can help mitigate environmental impacts and potentially reduce long-term costs.

The economic viability of scaled-up microfabrication processes depends on market demand and competition from alternative technologies. As the energetics sector evolves, the cost-benefit analysis of electrolytic cell microfabrication must be continuously reassessed to ensure its competitiveness against emerging solutions.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!