Advanced Planning Algorithms for Large-Scale Electrolytic Cell Plants

AUG 1, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Electrolytic Cell Planning Evolution and Objectives

The evolution of electrolytic cell planning in large-scale plants has been driven by the increasing demand for efficient and sustainable production processes in industries such as aluminum smelting, chlor-alkali production, and water treatment. Over the past decades, the focus has shifted from manual planning methods to more sophisticated, computer-aided approaches that can handle the complexity of modern electrolytic cell operations.

In the early stages of electrolytic cell planning, the primary objective was to maximize production output while minimizing energy consumption. This led to the development of basic scheduling algorithms that aimed to optimize the timing of cell operations and maintenance activities. As environmental concerns gained prominence, the objectives expanded to include reducing emissions and improving overall sustainability.

The advent of digital technologies and advanced computing capabilities has revolutionized electrolytic cell planning. The integration of real-time data collection and analysis has enabled more dynamic and responsive planning strategies. This shift has allowed for better prediction of cell performance, more accurate forecasting of maintenance needs, and improved overall plant efficiency.

Current objectives in electrolytic cell planning encompass a broader range of factors. These include maximizing cell lifespan, minimizing downtime, optimizing energy efficiency, reducing carbon footprint, and ensuring consistent product quality. Advanced planning algorithms now aim to balance these multiple, often competing, objectives simultaneously.

The development of machine learning and artificial intelligence techniques has opened new avenues for electrolytic cell planning. These technologies offer the potential for predictive maintenance, adaptive control systems, and autonomous decision-making in plant operations. The goal is to create self-optimizing systems that can continuously adjust planning parameters based on changing conditions and historical performance data.

Looking forward, the objectives of electrolytic cell planning are evolving to address emerging challenges in the industry. These include adapting to fluctuating energy prices in a renewable energy-dominated grid, managing the increasing complexity of cell designs, and meeting stricter environmental regulations. Advanced planning algorithms are being developed to incorporate these factors, aiming to create more resilient and adaptable electrolytic cell operations.

As the industry moves towards Industry 4.0 and smart manufacturing concepts, the integration of electrolytic cell planning with broader supply chain and business planning systems is becoming a key objective. This holistic approach aims to optimize not just individual plant operations, but entire production networks, considering factors such as raw material availability, market demand, and logistical constraints.

In the early stages of electrolytic cell planning, the primary objective was to maximize production output while minimizing energy consumption. This led to the development of basic scheduling algorithms that aimed to optimize the timing of cell operations and maintenance activities. As environmental concerns gained prominence, the objectives expanded to include reducing emissions and improving overall sustainability.

The advent of digital technologies and advanced computing capabilities has revolutionized electrolytic cell planning. The integration of real-time data collection and analysis has enabled more dynamic and responsive planning strategies. This shift has allowed for better prediction of cell performance, more accurate forecasting of maintenance needs, and improved overall plant efficiency.

Current objectives in electrolytic cell planning encompass a broader range of factors. These include maximizing cell lifespan, minimizing downtime, optimizing energy efficiency, reducing carbon footprint, and ensuring consistent product quality. Advanced planning algorithms now aim to balance these multiple, often competing, objectives simultaneously.

The development of machine learning and artificial intelligence techniques has opened new avenues for electrolytic cell planning. These technologies offer the potential for predictive maintenance, adaptive control systems, and autonomous decision-making in plant operations. The goal is to create self-optimizing systems that can continuously adjust planning parameters based on changing conditions and historical performance data.

Looking forward, the objectives of electrolytic cell planning are evolving to address emerging challenges in the industry. These include adapting to fluctuating energy prices in a renewable energy-dominated grid, managing the increasing complexity of cell designs, and meeting stricter environmental regulations. Advanced planning algorithms are being developed to incorporate these factors, aiming to create more resilient and adaptable electrolytic cell operations.

As the industry moves towards Industry 4.0 and smart manufacturing concepts, the integration of electrolytic cell planning with broader supply chain and business planning systems is becoming a key objective. This holistic approach aims to optimize not just individual plant operations, but entire production networks, considering factors such as raw material availability, market demand, and logistical constraints.

Market Demand for Efficient Electrolytic Cell Operations

The market demand for efficient electrolytic cell operations in large-scale plants has been steadily increasing due to the growing emphasis on sustainable energy production and industrial processes. This demand is primarily driven by the aluminum industry, which relies heavily on electrolytic cells for aluminum smelting, as well as the chlor-alkali industry for the production of chlorine and caustic soda.

In the aluminum sector, the global market for primary aluminum is projected to reach 78 million metric tons by 2025, with a compound annual growth rate (CAGR) of 3.8%. This growth is fueled by increasing demand from automotive, construction, and packaging industries. As energy costs constitute a significant portion of aluminum production expenses, there is a strong market pull for advanced planning algorithms that can optimize electrolytic cell operations and reduce energy consumption.

The chlor-alkali industry, another major user of electrolytic cells, is also experiencing substantial growth. The global chlor-alkali market is expected to reach $77 billion by 2027, growing at a CAGR of 5.2%. This growth is driven by the rising demand for PVC, water treatment chemicals, and various industrial applications. Efficient electrolytic cell operations are crucial for maintaining competitiveness in this market.

Environmental regulations and sustainability goals are further intensifying the need for advanced planning algorithms. Many countries have implemented strict emissions targets and energy efficiency standards, compelling industries to adopt more sophisticated technologies for electrolytic cell management. For instance, the European Union's Emissions Trading System (EU ETS) has set a cap on greenhouse gas emissions, incentivizing companies to invest in technologies that can optimize their electrolytic processes.

The market is also witnessing a shift towards digitalization and Industry 4.0 principles. This trend is creating a demand for integrated solutions that combine advanced planning algorithms with real-time monitoring and control systems. Such solutions can provide predictive maintenance, reduce downtime, and enhance overall plant efficiency.

Furthermore, the increasing complexity of large-scale electrolytic cell plants is driving the need for more sophisticated planning tools. As plants grow in size and complexity, traditional planning methods become inadequate, leading to inefficiencies and increased operational costs. Advanced algorithms capable of handling multi-variable optimization problems are becoming essential for maintaining competitiveness in the global market.

In conclusion, the market demand for efficient electrolytic cell operations is robust and growing, driven by industry expansion, environmental regulations, and the need for cost reduction. This demand creates a significant opportunity for the development and implementation of advanced planning algorithms in large-scale electrolytic cell plants across various industries.

In the aluminum sector, the global market for primary aluminum is projected to reach 78 million metric tons by 2025, with a compound annual growth rate (CAGR) of 3.8%. This growth is fueled by increasing demand from automotive, construction, and packaging industries. As energy costs constitute a significant portion of aluminum production expenses, there is a strong market pull for advanced planning algorithms that can optimize electrolytic cell operations and reduce energy consumption.

The chlor-alkali industry, another major user of electrolytic cells, is also experiencing substantial growth. The global chlor-alkali market is expected to reach $77 billion by 2027, growing at a CAGR of 5.2%. This growth is driven by the rising demand for PVC, water treatment chemicals, and various industrial applications. Efficient electrolytic cell operations are crucial for maintaining competitiveness in this market.

Environmental regulations and sustainability goals are further intensifying the need for advanced planning algorithms. Many countries have implemented strict emissions targets and energy efficiency standards, compelling industries to adopt more sophisticated technologies for electrolytic cell management. For instance, the European Union's Emissions Trading System (EU ETS) has set a cap on greenhouse gas emissions, incentivizing companies to invest in technologies that can optimize their electrolytic processes.

The market is also witnessing a shift towards digitalization and Industry 4.0 principles. This trend is creating a demand for integrated solutions that combine advanced planning algorithms with real-time monitoring and control systems. Such solutions can provide predictive maintenance, reduce downtime, and enhance overall plant efficiency.

Furthermore, the increasing complexity of large-scale electrolytic cell plants is driving the need for more sophisticated planning tools. As plants grow in size and complexity, traditional planning methods become inadequate, leading to inefficiencies and increased operational costs. Advanced algorithms capable of handling multi-variable optimization problems are becoming essential for maintaining competitiveness in the global market.

In conclusion, the market demand for efficient electrolytic cell operations is robust and growing, driven by industry expansion, environmental regulations, and the need for cost reduction. This demand creates a significant opportunity for the development and implementation of advanced planning algorithms in large-scale electrolytic cell plants across various industries.

Current Challenges in Large-Scale Plant Planning

Large-scale electrolytic cell plants face numerous challenges in their planning and optimization processes. One of the primary issues is the sheer complexity of these systems, which involve intricate networks of interconnected components and processes. This complexity makes it difficult to develop comprehensive planning algorithms that can account for all variables and constraints simultaneously.

Another significant challenge is the dynamic nature of electrolytic cell operations. Fluctuations in raw material quality, energy prices, and market demands require planning algorithms to be highly adaptable and capable of real-time adjustments. Traditional static planning methods often fall short in addressing these rapidly changing conditions, leading to suboptimal plant performance and resource allocation.

The scale of these plants also presents unique challenges. With hundreds or even thousands of electrolytic cells operating in parallel, the computational requirements for advanced planning algorithms become enormous. This scalability issue often results in a trade-off between solution quality and computational time, forcing planners to compromise on either the accuracy of their models or the responsiveness of their systems.

Energy efficiency is a critical concern in electrolytic cell plants, given their high power consumption. Planning algorithms must optimize energy usage while maintaining production targets, a task complicated by the non-linear relationships between energy input and production output in electrolytic processes. Balancing these factors requires sophisticated modeling techniques that can capture the intricacies of electrochemical reactions and their energy requirements.

Maintenance scheduling poses another significant challenge. Electrolytic cells degrade over time, affecting their efficiency and output quality. Advanced planning algorithms must incorporate predictive maintenance strategies to optimize cell replacement and refurbishment schedules, minimizing downtime while maximizing overall plant productivity.

Environmental regulations and sustainability goals add another layer of complexity to the planning process. Algorithms must now consider factors such as emissions reduction, waste minimization, and resource conservation, often leading to multi-objective optimization problems that are inherently more difficult to solve.

Lastly, the integration of new technologies, such as renewable energy sources and smart grid systems, into existing plant infrastructures presents both opportunities and challenges for planning algorithms. These technologies offer potential for improved efficiency and sustainability but require sophisticated planning approaches to manage their intermittent nature and complex interactions with traditional plant systems.

Another significant challenge is the dynamic nature of electrolytic cell operations. Fluctuations in raw material quality, energy prices, and market demands require planning algorithms to be highly adaptable and capable of real-time adjustments. Traditional static planning methods often fall short in addressing these rapidly changing conditions, leading to suboptimal plant performance and resource allocation.

The scale of these plants also presents unique challenges. With hundreds or even thousands of electrolytic cells operating in parallel, the computational requirements for advanced planning algorithms become enormous. This scalability issue often results in a trade-off between solution quality and computational time, forcing planners to compromise on either the accuracy of their models or the responsiveness of their systems.

Energy efficiency is a critical concern in electrolytic cell plants, given their high power consumption. Planning algorithms must optimize energy usage while maintaining production targets, a task complicated by the non-linear relationships between energy input and production output in electrolytic processes. Balancing these factors requires sophisticated modeling techniques that can capture the intricacies of electrochemical reactions and their energy requirements.

Maintenance scheduling poses another significant challenge. Electrolytic cells degrade over time, affecting their efficiency and output quality. Advanced planning algorithms must incorporate predictive maintenance strategies to optimize cell replacement and refurbishment schedules, minimizing downtime while maximizing overall plant productivity.

Environmental regulations and sustainability goals add another layer of complexity to the planning process. Algorithms must now consider factors such as emissions reduction, waste minimization, and resource conservation, often leading to multi-objective optimization problems that are inherently more difficult to solve.

Lastly, the integration of new technologies, such as renewable energy sources and smart grid systems, into existing plant infrastructures presents both opportunities and challenges for planning algorithms. These technologies offer potential for improved efficiency and sustainability but require sophisticated planning approaches to manage their intermittent nature and complex interactions with traditional plant systems.

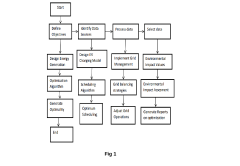

Existing Advanced Planning Methodologies

01 Resource allocation and scheduling optimization

Advanced planning algorithms focus on optimizing resource allocation and scheduling in complex systems. These algorithms consider multiple constraints, priorities, and dependencies to efficiently distribute resources and create optimal schedules. They can be applied in various domains such as manufacturing, logistics, and project management to improve operational efficiency and reduce costs.- Resource allocation and scheduling optimization: Advanced planning algorithms focus on optimizing resource allocation and scheduling in complex systems. These algorithms consider multiple constraints and objectives to efficiently distribute resources and create optimal schedules for various applications, such as manufacturing, logistics, and project management.

- Predictive analytics and forecasting: Advanced planning algorithms incorporate predictive analytics and forecasting techniques to anticipate future trends and demands. These algorithms analyze historical data and external factors to make accurate predictions, enabling proactive decision-making and improved planning processes across various industries.

- Multi-objective optimization: Advanced planning algorithms employ multi-objective optimization techniques to balance conflicting goals and constraints. These algorithms consider multiple criteria simultaneously, allowing for trade-offs between different objectives and generating Pareto-optimal solutions for complex planning problems.

- Machine learning and artificial intelligence integration: Advanced planning algorithms increasingly incorporate machine learning and artificial intelligence techniques to enhance their capabilities. These algorithms can adapt and improve their performance over time, learning from historical data and outcomes to make more intelligent and accurate planning decisions.

- Real-time planning and dynamic optimization: Advanced planning algorithms focus on real-time planning and dynamic optimization to address rapidly changing environments. These algorithms can quickly adjust plans and schedules in response to new information or unexpected events, ensuring optimal performance in dynamic and uncertain situations.

02 Predictive analytics and forecasting

Advanced planning algorithms incorporate predictive analytics and forecasting techniques to anticipate future trends and demands. By analyzing historical data and identifying patterns, these algorithms can generate accurate predictions to support proactive decision-making. This capability is particularly valuable in supply chain management, demand planning, and financial forecasting.Expand Specific Solutions03 Multi-objective optimization

Advanced planning algorithms often employ multi-objective optimization techniques to balance conflicting goals and constraints. These algorithms can simultaneously consider multiple objectives, such as cost minimization, quality maximization, and risk reduction, to find optimal solutions that satisfy diverse requirements. This approach is particularly useful in complex decision-making scenarios across various industries.Expand Specific Solutions04 Machine learning integration

Modern advanced planning algorithms increasingly incorporate machine learning techniques to enhance their capabilities. By leveraging machine learning, these algorithms can adapt to changing conditions, learn from past experiences, and continuously improve their performance. This integration enables more accurate predictions, better decision-making, and increased automation in planning processes.Expand Specific Solutions05 Real-time planning and dynamic optimization

Advanced planning algorithms are designed to handle real-time data and perform dynamic optimization. These algorithms can quickly adjust plans and schedules in response to unexpected events, changes in demand, or resource availability. This capability enables organizations to maintain agility and responsiveness in rapidly changing environments, particularly in industries such as transportation, energy management, and smart manufacturing.Expand Specific Solutions

Key Players in Advanced Industrial Planning Solutions

The advanced planning algorithms for large-scale electrolytic cell plants represent a mature technology in a well-established industry. The market for these algorithms is substantial, driven by the growing demand for efficient and sustainable production processes in the chemical and metallurgical sectors. Key players in this field include BASF, ABB Group, and Guiyang Aluminium Magnesium Design & Research Institute. These companies, along with academic institutions like Central South University, are continuously refining algorithms to optimize plant operations, reduce energy consumption, and improve product quality. The competitive landscape is characterized by a mix of global chemical giants, specialized engineering firms, and research institutions, each contributing to the ongoing evolution of planning algorithms for electrolytic cell plants.

Guiyang Aluminium Magnesium Design & Research Inst. Co. Ltd.

Technical Solution: Guiyang Aluminium Magnesium Design & Research Institute has developed advanced planning algorithms for large-scale electrolytic cell plants, focusing on optimizing the production process of aluminum and magnesium. Their approach integrates machine learning and predictive modeling to enhance operational efficiency. The institute has implemented a digital twin system that simulates the entire electrolytic process, allowing for real-time adjustments and predictive maintenance[1]. This system incorporates data from multiple sensors throughout the plant, enabling precise control of electrolyte composition, temperature, and current density. The algorithm also optimizes energy consumption by dynamically adjusting the power input based on production demands and electricity pricing[3].

Strengths: Specialized expertise in aluminum and magnesium production; integration of digital twin technology for real-time optimization. Weaknesses: May be limited to specific metal production processes; potential high implementation costs for smaller plants.

ABB Group

Technical Solution: ABB Group has developed a comprehensive suite of advanced planning algorithms for large-scale electrolytic cell plants, focusing on their ABB Ability™ platform. This solution incorporates AI and machine learning to optimize plant operations across multiple parameters. The system utilizes predictive analytics to forecast production rates, energy consumption, and maintenance needs. ABB's algorithms integrate real-time data from electrolytic cells, power systems, and auxiliary equipment to create a holistic view of plant operations[2]. The platform employs adaptive control strategies that continuously adjust process parameters to maintain optimal performance under varying conditions. Additionally, ABB has implemented a hierarchical optimization approach that considers both local cell-level optimizations and global plant-wide efficiency[4].

Strengths: Comprehensive solution covering multiple aspects of plant operations; strong integration capabilities with existing industrial systems. Weaknesses: May require significant investment for full implementation; potential complexity in adapting to highly specialized electrolytic processes.

Innovative Algorithms for Electrolytic Cell Optimization

Advanced optimization model for coupling power plant to PV-wind-electric vehicles

PatentPendingIN202341063717A

Innovation

- An advanced optimization model that integrates data analytics, predictive algorithms, and real-time control mechanisms to dynamically manage the interplay between power plants, PV, wind energy, and electric vehicle charging systems, optimizing renewable energy utilization, grid stability, and EV charging schedules.

Environmental Impact of Optimized Electrolytic Processes

The optimization of electrolytic processes in large-scale cell plants through advanced planning algorithms has significant environmental implications. These optimized processes can lead to substantial reductions in energy consumption, which is a critical factor in minimizing the carbon footprint of electrolytic operations. By improving the efficiency of resource utilization, these algorithms contribute to the conservation of raw materials and reduction of waste generation.

One of the primary environmental benefits of optimized electrolytic processes is the decrease in greenhouse gas emissions. Advanced planning algorithms enable more precise control over the electrolysis process, resulting in lower electricity consumption per unit of product. This reduction in energy demand translates directly into decreased carbon dioxide emissions from power generation, particularly in regions where fossil fuels remain a significant part of the energy mix.

Water management is another area where optimized processes can yield environmental advantages. Advanced algorithms can help in predicting and controlling water usage more accurately, leading to reduced water consumption and minimized wastewater generation. This is particularly crucial in water-stressed regions where electrolytic plants operate, as it helps in preserving local water resources and reducing the environmental impact on aquatic ecosystems.

The optimization of chemical usage in electrolytic processes also contributes to environmental protection. By precisely calculating and controlling the input of chemicals, advanced planning algorithms can minimize excess use, thereby reducing the potential for chemical spills or releases into the environment. This not only lowers the risk of soil and water contamination but also decreases the overall chemical footprint of the operation.

Furthermore, these optimized processes can lead to improvements in product quality and consistency. This, in turn, can reduce the occurrence of off-spec products and the need for reprocessing, which often involves additional energy consumption and resource use. By minimizing rework and waste, the overall environmental impact of the production process is further reduced.

The implementation of advanced planning algorithms also enables better predictive maintenance schedules for electrolytic cells. This proactive approach to equipment maintenance can extend the lifespan of critical components, reducing the frequency of replacements and the associated environmental costs of manufacturing and disposing of industrial equipment.

Lastly, the data-driven nature of these advanced algorithms provides valuable insights for continuous improvement in environmental performance. By analyzing operational data, plant managers can identify trends and opportunities for further optimization, leading to ongoing reductions in environmental impact over time. This data-centric approach aligns well with environmental management systems and supports compliance with increasingly stringent environmental regulations.

One of the primary environmental benefits of optimized electrolytic processes is the decrease in greenhouse gas emissions. Advanced planning algorithms enable more precise control over the electrolysis process, resulting in lower electricity consumption per unit of product. This reduction in energy demand translates directly into decreased carbon dioxide emissions from power generation, particularly in regions where fossil fuels remain a significant part of the energy mix.

Water management is another area where optimized processes can yield environmental advantages. Advanced algorithms can help in predicting and controlling water usage more accurately, leading to reduced water consumption and minimized wastewater generation. This is particularly crucial in water-stressed regions where electrolytic plants operate, as it helps in preserving local water resources and reducing the environmental impact on aquatic ecosystems.

The optimization of chemical usage in electrolytic processes also contributes to environmental protection. By precisely calculating and controlling the input of chemicals, advanced planning algorithms can minimize excess use, thereby reducing the potential for chemical spills or releases into the environment. This not only lowers the risk of soil and water contamination but also decreases the overall chemical footprint of the operation.

Furthermore, these optimized processes can lead to improvements in product quality and consistency. This, in turn, can reduce the occurrence of off-spec products and the need for reprocessing, which often involves additional energy consumption and resource use. By minimizing rework and waste, the overall environmental impact of the production process is further reduced.

The implementation of advanced planning algorithms also enables better predictive maintenance schedules for electrolytic cells. This proactive approach to equipment maintenance can extend the lifespan of critical components, reducing the frequency of replacements and the associated environmental costs of manufacturing and disposing of industrial equipment.

Lastly, the data-driven nature of these advanced algorithms provides valuable insights for continuous improvement in environmental performance. By analyzing operational data, plant managers can identify trends and opportunities for further optimization, leading to ongoing reductions in environmental impact over time. This data-centric approach aligns well with environmental management systems and supports compliance with increasingly stringent environmental regulations.

Regulatory Framework for Industrial Planning Systems

The regulatory framework for industrial planning systems in the context of advanced planning algorithms for large-scale electrolytic cell plants encompasses a complex set of guidelines and standards. These regulations are designed to ensure the safe, efficient, and environmentally responsible operation of such facilities while promoting innovation and technological advancement.

At the international level, organizations such as the International Electrotechnical Commission (IEC) and the International Organization for Standardization (ISO) play crucial roles in setting global standards for industrial planning systems. These standards often focus on safety protocols, performance metrics, and interoperability requirements for planning algorithms and control systems used in electrolytic cell plants.

National regulatory bodies, such as the Environmental Protection Agency (EPA) in the United States or the European Chemicals Agency (ECHA) in the European Union, establish specific regulations governing the planning and operation of large-scale industrial facilities. These regulations typically address environmental impact assessments, emissions control, waste management, and resource efficiency.

In the realm of advanced planning algorithms, regulatory frameworks often emphasize the importance of transparency and explainability. As these algorithms become more sophisticated, there is a growing demand for clear documentation of decision-making processes and the ability to audit algorithmic outputs. This is particularly crucial in industries dealing with hazardous materials or processes, such as electrolytic cell plants.

Cybersecurity regulations also play a significant role in the regulatory landscape for industrial planning systems. Given the critical nature of large-scale electrolytic cell plants, robust cybersecurity measures are mandated to protect against potential threats to operational technology (OT) systems and prevent unauthorized access to sensitive planning data.

Regulatory frameworks are increasingly addressing the integration of artificial intelligence (AI) and machine learning (ML) techniques in industrial planning systems. As these technologies become more prevalent in optimizing plant operations, regulators are developing guidelines to ensure their responsible and ethical implementation. This includes considerations for data privacy, algorithmic bias, and the potential impact on human workforce roles.

Energy efficiency and sustainability regulations are also shaping the development of advanced planning algorithms for electrolytic cell plants. Many jurisdictions now require industrial facilities to implement energy management systems and continuously improve their energy performance. Planning algorithms must therefore incorporate these regulatory requirements into their optimization strategies.

As the field of advanced planning algorithms continues to evolve, regulatory frameworks are likely to adapt and expand. Future regulations may focus on areas such as real-time monitoring and reporting capabilities, integration with smart grid systems, and the use of digital twins for predictive maintenance and optimization. The ongoing challenge for regulators and industry stakeholders will be to strike a balance between fostering innovation and ensuring the safe, responsible operation of large-scale electrolytic cell plants.

At the international level, organizations such as the International Electrotechnical Commission (IEC) and the International Organization for Standardization (ISO) play crucial roles in setting global standards for industrial planning systems. These standards often focus on safety protocols, performance metrics, and interoperability requirements for planning algorithms and control systems used in electrolytic cell plants.

National regulatory bodies, such as the Environmental Protection Agency (EPA) in the United States or the European Chemicals Agency (ECHA) in the European Union, establish specific regulations governing the planning and operation of large-scale industrial facilities. These regulations typically address environmental impact assessments, emissions control, waste management, and resource efficiency.

In the realm of advanced planning algorithms, regulatory frameworks often emphasize the importance of transparency and explainability. As these algorithms become more sophisticated, there is a growing demand for clear documentation of decision-making processes and the ability to audit algorithmic outputs. This is particularly crucial in industries dealing with hazardous materials or processes, such as electrolytic cell plants.

Cybersecurity regulations also play a significant role in the regulatory landscape for industrial planning systems. Given the critical nature of large-scale electrolytic cell plants, robust cybersecurity measures are mandated to protect against potential threats to operational technology (OT) systems and prevent unauthorized access to sensitive planning data.

Regulatory frameworks are increasingly addressing the integration of artificial intelligence (AI) and machine learning (ML) techniques in industrial planning systems. As these technologies become more prevalent in optimizing plant operations, regulators are developing guidelines to ensure their responsible and ethical implementation. This includes considerations for data privacy, algorithmic bias, and the potential impact on human workforce roles.

Energy efficiency and sustainability regulations are also shaping the development of advanced planning algorithms for electrolytic cell plants. Many jurisdictions now require industrial facilities to implement energy management systems and continuously improve their energy performance. Planning algorithms must therefore incorporate these regulatory requirements into their optimization strategies.

As the field of advanced planning algorithms continues to evolve, regulatory frameworks are likely to adapt and expand. Future regulations may focus on areas such as real-time monitoring and reporting capabilities, integration with smart grid systems, and the use of digital twins for predictive maintenance and optimization. The ongoing challenge for regulators and industry stakeholders will be to strike a balance between fostering innovation and ensuring the safe, responsible operation of large-scale electrolytic cell plants.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!