Impact of Electrolytic Cell Innovations on the Electronics Industry

AUG 1, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Electrolytic Cell Evolution and Objectives

Electrolytic cells have been a cornerstone of the electronics industry since their inception, playing a crucial role in various manufacturing processes and energy storage applications. The evolution of these cells has been marked by significant milestones, each contributing to the advancement of electronic devices and systems.

The journey of electrolytic cells began in the early 19th century with the pioneering work of scientists like Michael Faraday. Initially used for electroplating and metal purification, these cells quickly found applications in the emerging field of electronics. As the industry progressed, the demand for more efficient and reliable electrolytic cells grew, driving continuous innovation and refinement.

In the mid-20th century, the advent of semiconductor technology revolutionized the electronics industry, creating new challenges and opportunities for electrolytic cell development. The need for precise metal deposition in integrated circuit manufacturing led to the creation of specialized electrolytic cells capable of nanoscale material manipulation. This breakthrough enabled the production of increasingly complex and miniaturized electronic components.

The rise of portable electronics in the late 20th and early 21st centuries further accelerated the evolution of electrolytic cells. The demand for high-capacity, rechargeable batteries spurred research into advanced electrolyte materials and cell designs. This resulted in the development of lithium-ion batteries, which have become ubiquitous in modern electronic devices.

Recent years have seen a focus on sustainability and environmental concerns, driving the exploration of eco-friendly electrolytic cell technologies. Researchers are now investigating novel electrolyte compositions and cell architectures that minimize environmental impact while maximizing performance and longevity.

Looking ahead, the objectives for electrolytic cell innovation in the electronics industry are multifaceted. One primary goal is to enhance energy density and charging speeds in battery applications, enabling longer-lasting and faster-charging electronic devices. Another critical objective is to improve the precision and efficiency of electrolytic processes used in semiconductor manufacturing, supporting the continued miniaturization of electronic components.

Additionally, there is a growing emphasis on developing electrolytic cells that can support emerging technologies such as flexible electronics and wearable devices. This requires the creation of cells that are not only powerful and efficient but also malleable and durable under various conditions.

Ultimately, the ongoing evolution of electrolytic cells aims to address the ever-increasing demands of the electronics industry for higher performance, greater sustainability, and enhanced functionality. As these innovations continue to unfold, they promise to shape the future of electronic devices and systems, enabling new possibilities and pushing the boundaries of what technology can achieve.

The journey of electrolytic cells began in the early 19th century with the pioneering work of scientists like Michael Faraday. Initially used for electroplating and metal purification, these cells quickly found applications in the emerging field of electronics. As the industry progressed, the demand for more efficient and reliable electrolytic cells grew, driving continuous innovation and refinement.

In the mid-20th century, the advent of semiconductor technology revolutionized the electronics industry, creating new challenges and opportunities for electrolytic cell development. The need for precise metal deposition in integrated circuit manufacturing led to the creation of specialized electrolytic cells capable of nanoscale material manipulation. This breakthrough enabled the production of increasingly complex and miniaturized electronic components.

The rise of portable electronics in the late 20th and early 21st centuries further accelerated the evolution of electrolytic cells. The demand for high-capacity, rechargeable batteries spurred research into advanced electrolyte materials and cell designs. This resulted in the development of lithium-ion batteries, which have become ubiquitous in modern electronic devices.

Recent years have seen a focus on sustainability and environmental concerns, driving the exploration of eco-friendly electrolytic cell technologies. Researchers are now investigating novel electrolyte compositions and cell architectures that minimize environmental impact while maximizing performance and longevity.

Looking ahead, the objectives for electrolytic cell innovation in the electronics industry are multifaceted. One primary goal is to enhance energy density and charging speeds in battery applications, enabling longer-lasting and faster-charging electronic devices. Another critical objective is to improve the precision and efficiency of electrolytic processes used in semiconductor manufacturing, supporting the continued miniaturization of electronic components.

Additionally, there is a growing emphasis on developing electrolytic cells that can support emerging technologies such as flexible electronics and wearable devices. This requires the creation of cells that are not only powerful and efficient but also malleable and durable under various conditions.

Ultimately, the ongoing evolution of electrolytic cells aims to address the ever-increasing demands of the electronics industry for higher performance, greater sustainability, and enhanced functionality. As these innovations continue to unfold, they promise to shape the future of electronic devices and systems, enabling new possibilities and pushing the boundaries of what technology can achieve.

Electronics Market Demand Analysis

The electronics industry has witnessed a surge in demand for innovative electrolytic cell technologies, driven by the ever-increasing need for more efficient and compact electronic devices. Market analysis reveals a growing appetite for advanced power storage solutions, particularly in consumer electronics, electric vehicles, and renewable energy sectors.

Consumer electronics, including smartphones, laptops, and wearables, continue to be a significant driver of demand for improved electrolytic cells. As these devices become more powerful and feature-rich, they require batteries with higher energy density, faster charging capabilities, and longer lifespans. This has led to a substantial market for next-generation electrolytic cells that can meet these demanding requirements.

The electric vehicle (EV) market has emerged as a major catalyst for electrolytic cell innovations. With global EV sales projected to grow exponentially in the coming years, there is an unprecedented demand for high-performance batteries that can offer extended range, rapid charging, and enhanced safety features. This has spurred significant investment in research and development of advanced electrolytic cell technologies tailored for automotive applications.

Renewable energy storage systems represent another crucial market segment driving the demand for electrolytic cell innovations. As the world transitions towards cleaner energy sources, there is a growing need for efficient and cost-effective energy storage solutions to address the intermittent nature of renewable power generation. This has created opportunities for electrolytic cell technologies that can provide grid-scale energy storage capabilities.

The industrial and medical sectors are also contributing to the market demand for advanced electrolytic cells. Industrial applications require robust and long-lasting power sources for various equipment and machinery, while the medical field seeks compact and reliable energy solutions for implantable devices and portable medical equipment.

Market trends indicate a shift towards more sustainable and environmentally friendly electrolytic cell technologies. Consumers and businesses alike are increasingly prioritizing eco-friendly products, driving demand for cells with reduced environmental impact, improved recyclability, and the use of less toxic materials.

The global market for electrolytic cells is expected to experience substantial growth in the coming years, with Asia-Pacific region leading in terms of both production and consumption. This growth is fueled by the rapid expansion of electronics manufacturing hubs in countries like China, South Korea, and Japan, as well as the increasing adoption of electric vehicles and renewable energy systems in these markets.

In conclusion, the electronics industry's demand for electrolytic cell innovations is multifaceted and robust, spanning various sectors and applications. The market is characterized by a strong push for higher performance, increased energy density, improved sustainability, and enhanced safety features. As technology continues to evolve, the demand for advanced electrolytic cells is expected to intensify, creating significant opportunities for innovation and market growth in the electronics industry.

Consumer electronics, including smartphones, laptops, and wearables, continue to be a significant driver of demand for improved electrolytic cells. As these devices become more powerful and feature-rich, they require batteries with higher energy density, faster charging capabilities, and longer lifespans. This has led to a substantial market for next-generation electrolytic cells that can meet these demanding requirements.

The electric vehicle (EV) market has emerged as a major catalyst for electrolytic cell innovations. With global EV sales projected to grow exponentially in the coming years, there is an unprecedented demand for high-performance batteries that can offer extended range, rapid charging, and enhanced safety features. This has spurred significant investment in research and development of advanced electrolytic cell technologies tailored for automotive applications.

Renewable energy storage systems represent another crucial market segment driving the demand for electrolytic cell innovations. As the world transitions towards cleaner energy sources, there is a growing need for efficient and cost-effective energy storage solutions to address the intermittent nature of renewable power generation. This has created opportunities for electrolytic cell technologies that can provide grid-scale energy storage capabilities.

The industrial and medical sectors are also contributing to the market demand for advanced electrolytic cells. Industrial applications require robust and long-lasting power sources for various equipment and machinery, while the medical field seeks compact and reliable energy solutions for implantable devices and portable medical equipment.

Market trends indicate a shift towards more sustainable and environmentally friendly electrolytic cell technologies. Consumers and businesses alike are increasingly prioritizing eco-friendly products, driving demand for cells with reduced environmental impact, improved recyclability, and the use of less toxic materials.

The global market for electrolytic cells is expected to experience substantial growth in the coming years, with Asia-Pacific region leading in terms of both production and consumption. This growth is fueled by the rapid expansion of electronics manufacturing hubs in countries like China, South Korea, and Japan, as well as the increasing adoption of electric vehicles and renewable energy systems in these markets.

In conclusion, the electronics industry's demand for electrolytic cell innovations is multifaceted and robust, spanning various sectors and applications. The market is characterized by a strong push for higher performance, increased energy density, improved sustainability, and enhanced safety features. As technology continues to evolve, the demand for advanced electrolytic cells is expected to intensify, creating significant opportunities for innovation and market growth in the electronics industry.

Electrolytic Cell Tech Status and Challenges

Electrolytic cell technology has made significant strides in recent years, with innovations driving advancements in the electronics industry. The current state of electrolytic cell technology is characterized by improved efficiency, miniaturization, and enhanced performance. However, several challenges persist, hindering further progress in this field.

One of the primary technological advancements in electrolytic cells is the development of novel electrode materials. Researchers have successfully engineered electrodes with increased surface area and improved catalytic properties, leading to higher energy conversion rates and reduced internal resistance. These innovations have resulted in more compact and efficient electrolytic cells, which are crucial for the miniaturization of electronic devices.

Despite these improvements, the electronics industry still faces challenges in scaling up production of advanced electrolytic cells. The manufacturing processes for high-performance electrode materials often involve complex and costly procedures, limiting their widespread adoption. Additionally, ensuring consistent quality and performance across large-scale production remains a significant hurdle.

Another area of progress is the development of electrolytes with enhanced ionic conductivity and stability. These advanced electrolytes enable faster ion transport and improved cell performance. However, issues related to electrolyte degradation and safety concerns, particularly in high-voltage applications, continue to pose challenges for researchers and manufacturers.

The integration of smart monitoring and control systems into electrolytic cells represents a promising trend. These systems allow for real-time monitoring of cell performance, predictive maintenance, and optimization of operating conditions. While this technology shows great potential, its implementation across diverse applications and environments remains a challenge.

Geographical distribution of electrolytic cell technology development shows concentrations in East Asia, North America, and Europe. Countries like Japan, South Korea, and China lead in terms of patent filings and research output, while the United States and Germany maintain strong positions in innovative design and high-end applications.

A significant constraint in the advancement of electrolytic cell technology is the environmental impact of manufacturing processes and materials used. The industry faces increasing pressure to develop more sustainable and eco-friendly solutions, which has led to research into bio-based electrolytes and recyclable electrode materials. However, balancing performance requirements with environmental considerations remains a complex challenge.

In conclusion, while electrolytic cell technology has seen remarkable progress, particularly in terms of efficiency and miniaturization, several obstacles remain. Addressing manufacturing scalability, enhancing safety and stability, and improving sustainability are key areas that require continued focus and innovation to fully realize the potential of electrolytic cells in the electronics industry.

One of the primary technological advancements in electrolytic cells is the development of novel electrode materials. Researchers have successfully engineered electrodes with increased surface area and improved catalytic properties, leading to higher energy conversion rates and reduced internal resistance. These innovations have resulted in more compact and efficient electrolytic cells, which are crucial for the miniaturization of electronic devices.

Despite these improvements, the electronics industry still faces challenges in scaling up production of advanced electrolytic cells. The manufacturing processes for high-performance electrode materials often involve complex and costly procedures, limiting their widespread adoption. Additionally, ensuring consistent quality and performance across large-scale production remains a significant hurdle.

Another area of progress is the development of electrolytes with enhanced ionic conductivity and stability. These advanced electrolytes enable faster ion transport and improved cell performance. However, issues related to electrolyte degradation and safety concerns, particularly in high-voltage applications, continue to pose challenges for researchers and manufacturers.

The integration of smart monitoring and control systems into electrolytic cells represents a promising trend. These systems allow for real-time monitoring of cell performance, predictive maintenance, and optimization of operating conditions. While this technology shows great potential, its implementation across diverse applications and environments remains a challenge.

Geographical distribution of electrolytic cell technology development shows concentrations in East Asia, North America, and Europe. Countries like Japan, South Korea, and China lead in terms of patent filings and research output, while the United States and Germany maintain strong positions in innovative design and high-end applications.

A significant constraint in the advancement of electrolytic cell technology is the environmental impact of manufacturing processes and materials used. The industry faces increasing pressure to develop more sustainable and eco-friendly solutions, which has led to research into bio-based electrolytes and recyclable electrode materials. However, balancing performance requirements with environmental considerations remains a complex challenge.

In conclusion, while electrolytic cell technology has seen remarkable progress, particularly in terms of efficiency and miniaturization, several obstacles remain. Addressing manufacturing scalability, enhancing safety and stability, and improving sustainability are key areas that require continued focus and innovation to fully realize the potential of electrolytic cells in the electronics industry.

Current Electrolytic Cell Solutions

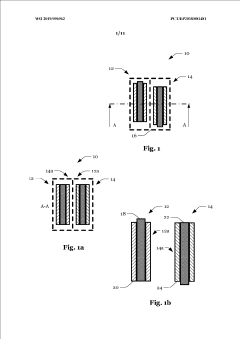

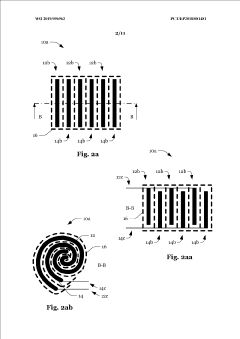

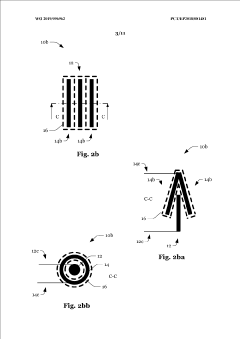

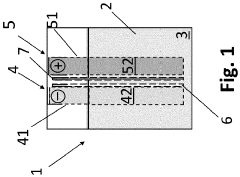

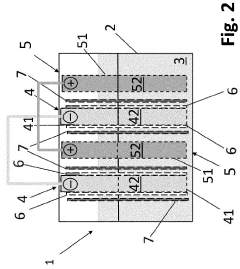

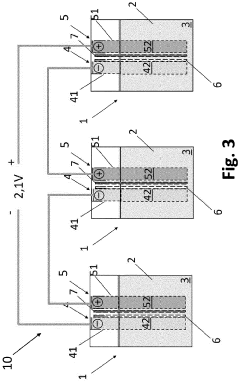

01 Electrolytic cell design and components

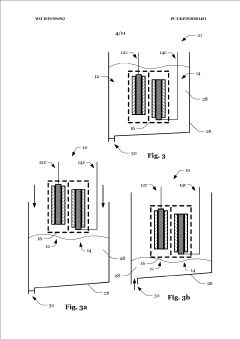

Electrolytic cells are designed with specific components to facilitate electrochemical reactions. These components typically include electrodes (anode and cathode), an electrolyte, and a separator. The design of the cell can be optimized for various applications, such as water electrolysis, metal production, or energy storage. Factors like electrode material, electrolyte composition, and cell geometry play crucial roles in determining the efficiency and performance of the electrolytic cell.- Electrolytic cell design and components: Electrolytic cells are designed with specific components to facilitate electrochemical reactions. These components typically include electrodes (anode and cathode), an electrolyte solution, and a separator. The design of the cell can be optimized for various applications, such as water electrolysis, metal production, or energy storage. Factors like electrode material, cell geometry, and membrane selection play crucial roles in the efficiency and performance of the electrolytic cell.

- Electrolyte composition and properties: The electrolyte is a key component in electrolytic cells, serving as the medium for ion transport between electrodes. The composition and properties of the electrolyte significantly influence the cell's performance. Researchers focus on developing electrolytes with high ionic conductivity, stability, and compatibility with electrode materials. Additives may be incorporated to enhance specific properties or prevent unwanted side reactions. The choice of electrolyte depends on the intended application and operating conditions of the cell.

- Electrode materials and coatings: The selection of electrode materials is crucial for the efficiency and durability of electrolytic cells. Researchers investigate various materials and coatings to improve electrode performance, including catalytic activity, corrosion resistance, and longevity. Novel electrode materials may include advanced alloys, nanostructured surfaces, or composite materials. Coatings can be applied to enhance specific properties or protect the underlying electrode material from degradation during operation.

- Membrane and separator technology: Membranes and separators play a vital role in electrolytic cells by preventing direct contact between the anode and cathode while allowing selective ion transport. Advancements in membrane technology focus on improving ion selectivity, conductivity, and mechanical stability. Novel membrane materials and structures are developed to enhance cell performance, reduce energy consumption, and extend operational lifetimes. The choice of membrane or separator depends on the specific requirements of the electrolytic process and the operating conditions.

- Process control and optimization: Efficient operation of electrolytic cells requires precise control and optimization of various process parameters. This includes monitoring and adjusting factors such as temperature, pressure, current density, and electrolyte flow rates. Advanced control systems and algorithms are developed to maintain optimal operating conditions and maximize cell efficiency. Researchers also focus on developing sensors and monitoring techniques to provide real-time data on cell performance and detect potential issues before they lead to system failures.

02 Electrolyte composition and properties

The electrolyte is a key component in electrolytic cells, serving as the medium for ion transport between electrodes. Electrolyte composition can be tailored to enhance conductivity, stability, and reaction kinetics. Various types of electrolytes, including aqueous solutions, molten salts, and solid electrolytes, are used depending on the specific application. Additives may be incorporated to improve electrolyte performance or address issues such as corrosion or side reactions.Expand Specific Solutions03 Electrode materials and configurations

The choice of electrode materials and their configurations significantly impact the performance of electrolytic cells. Electrodes can be made from various materials, including metals, alloys, and advanced composites, each offering specific advantages in terms of conductivity, catalytic activity, and durability. Electrode surface modifications, such as coatings or nanostructures, can enhance reactivity and efficiency. The geometry and arrangement of electrodes within the cell also influence current distribution and overall cell performance.Expand Specific Solutions04 Membrane and separator technology

Membranes and separators play a crucial role in electrolytic cells by preventing direct contact between the anode and cathode while allowing selective ion transport. Advanced membrane materials, such as ion-exchange membranes or ceramic separators, can improve cell efficiency and selectivity. The development of novel membrane technologies focuses on enhancing ion conductivity, chemical stability, and mechanical strength to address challenges in various electrolytic processes.Expand Specific Solutions05 Process control and optimization

Optimizing the performance of electrolytic cells involves careful control of operating parameters such as temperature, pressure, current density, and electrolyte flow. Advanced process control systems, including sensors and feedback mechanisms, can be implemented to maintain optimal conditions and improve efficiency. Modeling and simulation techniques are often employed to predict cell behavior and optimize design parameters. Additionally, strategies for heat management, gas evolution control, and impurity removal are crucial for maintaining long-term cell performance and product quality.Expand Specific Solutions

Key Players in Electrolytic Cell Industry

The electrolytic cell innovation landscape in the electronics industry is characterized by intense competition and rapid technological advancements. The market is in a growth phase, driven by increasing demand for energy storage solutions and sustainable technologies. Major players like Sony, LG Energy Solution, and Samsung Electronics are investing heavily in R&D to improve energy density and efficiency. Emerging companies such as Sila Nanotechnologies and BroadBit Batteries are disrupting the field with novel materials and chemistries. The technology is maturing, with established firms like Siemens Energy and ThyssenKrupp Uhde Chlorine Engineers commercializing advanced electrolytic solutions, while research institutions like Caltech and EPFL continue to push the boundaries of innovation.

Industrie De Nora SpA

Technical Solution: Industrie De Nora SpA has developed advanced electrode technologies for electrolytic cells, focusing on improving efficiency and reducing energy consumption in industrial processes. Their innovations include the use of dimensionally stable anodes (DSA) with specialized coatings that enhance conductivity and durability[1]. These electrodes are designed to operate at higher current densities while maintaining long-term stability, which is crucial for applications in chlor-alkali production and water treatment[2]. The company has also made significant strides in membrane cell technology, developing thin-film composite membranes that allow for better ion selectivity and reduced electrical resistance[3].

Strengths: Highly efficient electrodes, reduced energy consumption, and improved durability. Weaknesses: High initial investment costs and potential limitations in scaling up for certain applications.

Dalian Institute of Chemical Physics Chinese Academy of Sci

Technical Solution: The Dalian Institute of Chemical Physics has made significant contributions to electrolytic cell innovations, particularly in the field of fuel cells and electrolyzers. Their research focuses on developing novel catalysts and electrode materials to enhance the efficiency of electrochemical processes. One of their key innovations is the development of non-precious metal catalysts for oxygen reduction reactions in fuel cells, which could significantly reduce costs while maintaining high performance[4]. They have also made advancements in high-temperature solid oxide electrolysis cells (SOECs) for hydrogen production, improving electrode microstructures to increase durability and efficiency[5].

Strengths: Cutting-edge research in catalyst development and cost-effective solutions. Weaknesses: Potential challenges in translating laboratory research to large-scale industrial applications.

Core Electrolytic Cell Innovations

Process and apparatus for manufacturing an electrochemical cell

PatentWO2019096962A1

Innovation

- The process involves immersing the electrode assembly in an electrolyte bath with a surplus of electrolyte solution for even saturation and degassing, followed by removing excess solvent and electrolyte, allowing for increased active material loading and energy density without premature termination due to electrolyte depletion, and encasing the assembly after wetting and formation.

Improved electrolytic cell

PatentInactiveEP4362165A1

Innovation

- An electrolytic cell design featuring a copper oxide or metallic copper negative electrode, a nickel hydroxide-based positive electrode, and a semi-permeable polymer membrane that allows OH- and H+ ions to pass through, preventing copper hydroxide leakage and using a stable alkaline electrolyte solution with additives like lithium hydroxide and borate to enhance performance.

Environmental Impact Assessment

The environmental impact of electrolytic cell innovations in the electronics industry is a critical consideration as these technologies continue to evolve. The production and use of electrolytic cells have both positive and negative effects on the environment, which must be carefully assessed and managed.

One of the primary environmental benefits of advanced electrolytic cells is their potential to improve energy efficiency in electronic devices. As these cells become more efficient, they can reduce overall energy consumption, leading to decreased greenhouse gas emissions associated with power generation. This is particularly significant in portable electronics, where improved battery life can reduce the frequency of charging and, consequently, the energy demand from the grid.

However, the manufacturing process of electrolytic cells can have substantial environmental implications. The extraction and processing of raw materials, such as lithium, cobalt, and rare earth elements, often involve energy-intensive operations and can lead to habitat destruction, water pollution, and soil contamination in mining areas. As demand for these materials increases with the growth of the electronics industry, responsible sourcing and sustainable mining practices become increasingly important.

The disposal and recycling of electrolytic cells present another environmental challenge. Many electronic devices containing these cells end up in landfills, where they can leach harmful chemicals into the soil and groundwater. Improper disposal can release toxic substances, including heavy metals, into the environment. To mitigate these risks, the electronics industry must focus on developing more efficient recycling processes and implementing robust take-back programs for end-of-life devices.

Innovations in electrolytic cell technology also offer opportunities for environmental improvement. Research into alternative materials and manufacturing processes aims to reduce the reliance on scarce or environmentally problematic resources. For instance, the development of sodium-ion batteries could decrease the demand for lithium, potentially alleviating some of the environmental pressures associated with lithium mining.

Furthermore, advancements in electrolytic cells are enabling the broader adoption of renewable energy technologies. Improved energy storage capabilities facilitate the integration of intermittent renewable sources like solar and wind into the power grid, supporting the transition to cleaner energy systems. This indirect environmental benefit could have far-reaching positive impacts on global efforts to combat climate change.

As the electronics industry continues to innovate in electrolytic cell technology, it is crucial to conduct comprehensive life cycle assessments. These assessments should consider the environmental impacts from raw material extraction through manufacturing, use, and end-of-life disposal or recycling. By taking a holistic approach, the industry can identify areas for improvement and develop strategies to minimize negative environmental effects while maximizing the benefits of these technological advancements.

One of the primary environmental benefits of advanced electrolytic cells is their potential to improve energy efficiency in electronic devices. As these cells become more efficient, they can reduce overall energy consumption, leading to decreased greenhouse gas emissions associated with power generation. This is particularly significant in portable electronics, where improved battery life can reduce the frequency of charging and, consequently, the energy demand from the grid.

However, the manufacturing process of electrolytic cells can have substantial environmental implications. The extraction and processing of raw materials, such as lithium, cobalt, and rare earth elements, often involve energy-intensive operations and can lead to habitat destruction, water pollution, and soil contamination in mining areas. As demand for these materials increases with the growth of the electronics industry, responsible sourcing and sustainable mining practices become increasingly important.

The disposal and recycling of electrolytic cells present another environmental challenge. Many electronic devices containing these cells end up in landfills, where they can leach harmful chemicals into the soil and groundwater. Improper disposal can release toxic substances, including heavy metals, into the environment. To mitigate these risks, the electronics industry must focus on developing more efficient recycling processes and implementing robust take-back programs for end-of-life devices.

Innovations in electrolytic cell technology also offer opportunities for environmental improvement. Research into alternative materials and manufacturing processes aims to reduce the reliance on scarce or environmentally problematic resources. For instance, the development of sodium-ion batteries could decrease the demand for lithium, potentially alleviating some of the environmental pressures associated with lithium mining.

Furthermore, advancements in electrolytic cells are enabling the broader adoption of renewable energy technologies. Improved energy storage capabilities facilitate the integration of intermittent renewable sources like solar and wind into the power grid, supporting the transition to cleaner energy systems. This indirect environmental benefit could have far-reaching positive impacts on global efforts to combat climate change.

As the electronics industry continues to innovate in electrolytic cell technology, it is crucial to conduct comprehensive life cycle assessments. These assessments should consider the environmental impacts from raw material extraction through manufacturing, use, and end-of-life disposal or recycling. By taking a holistic approach, the industry can identify areas for improvement and develop strategies to minimize negative environmental effects while maximizing the benefits of these technological advancements.

Supply Chain Implications

The innovations in electrolytic cell technology are poised to significantly impact the supply chain dynamics of the electronics industry. As these advancements gain traction, they are likely to reshape the sourcing, production, and distribution processes across the sector.

One of the primary implications is the potential for localized production of critical electronic components. Improved electrolytic cell efficiency may enable smaller-scale, decentralized manufacturing facilities. This shift could reduce dependency on centralized production hubs, leading to more resilient and flexible supply chains. Companies may be able to establish production closer to end markets, potentially reducing transportation costs and lead times.

The adoption of advanced electrolytic cell technologies may also influence raw material sourcing strategies. As new materials and processes are developed, suppliers may need to adapt their offerings to meet evolving specifications. This could lead to the emergence of new suppliers and the transformation of existing ones, potentially altering long-standing supply relationships within the industry.

Furthermore, these innovations may impact inventory management practices. Enhanced production efficiency and quality control through improved electrolytic processes could lead to more predictable output and reduced defect rates. This, in turn, may allow for leaner inventory practices and just-in-time manufacturing approaches, potentially reducing costs and improving cash flow for electronics manufacturers.

The integration of electrolytic cell innovations into the supply chain may also necessitate changes in logistics and distribution networks. As production becomes more distributed and customized, there may be a need for more agile and responsive logistics solutions. This could drive investments in advanced tracking and monitoring systems, as well as the development of new distribution models tailored to the evolving production landscape.

Additionally, these technological advancements may influence supplier selection criteria and supply chain partnerships. Electronics companies may prioritize suppliers who can demonstrate proficiency in implementing and leveraging electrolytic cell innovations. This could lead to a reconfiguration of supplier networks and the formation of new strategic alliances focused on technological collaboration and knowledge sharing.

Lastly, the adoption of electrolytic cell innovations may have implications for supply chain sustainability efforts. Improved efficiency and reduced waste in production processes could contribute to lower environmental impacts and support companies in meeting increasingly stringent sustainability targets. This may become a key differentiator in supplier selection and could drive further innovation in eco-friendly manufacturing practices throughout the supply chain.

One of the primary implications is the potential for localized production of critical electronic components. Improved electrolytic cell efficiency may enable smaller-scale, decentralized manufacturing facilities. This shift could reduce dependency on centralized production hubs, leading to more resilient and flexible supply chains. Companies may be able to establish production closer to end markets, potentially reducing transportation costs and lead times.

The adoption of advanced electrolytic cell technologies may also influence raw material sourcing strategies. As new materials and processes are developed, suppliers may need to adapt their offerings to meet evolving specifications. This could lead to the emergence of new suppliers and the transformation of existing ones, potentially altering long-standing supply relationships within the industry.

Furthermore, these innovations may impact inventory management practices. Enhanced production efficiency and quality control through improved electrolytic processes could lead to more predictable output and reduced defect rates. This, in turn, may allow for leaner inventory practices and just-in-time manufacturing approaches, potentially reducing costs and improving cash flow for electronics manufacturers.

The integration of electrolytic cell innovations into the supply chain may also necessitate changes in logistics and distribution networks. As production becomes more distributed and customized, there may be a need for more agile and responsive logistics solutions. This could drive investments in advanced tracking and monitoring systems, as well as the development of new distribution models tailored to the evolving production landscape.

Additionally, these technological advancements may influence supplier selection criteria and supply chain partnerships. Electronics companies may prioritize suppliers who can demonstrate proficiency in implementing and leveraging electrolytic cell innovations. This could lead to a reconfiguration of supplier networks and the formation of new strategic alliances focused on technological collaboration and knowledge sharing.

Lastly, the adoption of electrolytic cell innovations may have implications for supply chain sustainability efforts. Improved efficiency and reduced waste in production processes could contribute to lower environmental impacts and support companies in meeting increasingly stringent sustainability targets. This may become a key differentiator in supplier selection and could drive further innovation in eco-friendly manufacturing practices throughout the supply chain.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!