How Nanostructured Surfaces Benefit Electrolytic Cell Catalysts

AUG 1, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Nanostructured Catalysts: Background and Objectives

Nanostructured catalysts have emerged as a groundbreaking technology in the field of electrolytic cell catalysis, offering unprecedented opportunities for enhancing efficiency and performance. The development of these advanced materials represents a convergence of nanotechnology and electrochemistry, driven by the pressing need for more sustainable and efficient energy conversion processes.

The evolution of nanostructured catalysts can be traced back to the early 2000s when researchers began exploring the unique properties of materials at the nanoscale. As our understanding of nanomaterials grew, so did the potential applications in catalysis. The field has since witnessed rapid advancements, with significant milestones achieved in the synthesis, characterization, and application of nanostructured catalysts for electrolytic cells.

The primary objective of developing nanostructured surfaces for electrolytic cell catalysts is to maximize the active surface area while minimizing the use of precious metals. This approach addresses two critical challenges simultaneously: improving catalytic efficiency and reducing costs. By engineering materials at the nanoscale, researchers can create catalysts with intricate surface structures that dramatically increase the number of active sites available for electrochemical reactions.

Another key goal is to enhance the stability and durability of catalysts under the harsh conditions typical of electrolytic cells. Nanostructured surfaces can be designed to resist degradation, maintain their structural integrity, and preserve their catalytic activity over extended periods. This longevity is crucial for the practical implementation of these catalysts in industrial-scale electrolytic processes.

The technology trend in this field is moving towards more complex and precisely controlled nanostructures. Recent advancements include the development of hierarchical nanostructures, core-shell nanoparticles, and 3D nanoarchitectures. These sophisticated designs aim to optimize electron transfer, mass transport, and reactant accessibility, further pushing the boundaries of catalytic performance.

As we look to the future, the anticipated technological breakthroughs in nanostructured catalysts for electrolytic cells are expected to play a pivotal role in addressing global energy challenges. The potential applications span a wide range of industries, from hydrogen production and fuel cells to carbon dioxide reduction and advanced energy storage systems. The ongoing research in this field is not only advancing our fundamental understanding of catalysis at the nanoscale but also paving the way for more efficient and sustainable energy technologies.

The evolution of nanostructured catalysts can be traced back to the early 2000s when researchers began exploring the unique properties of materials at the nanoscale. As our understanding of nanomaterials grew, so did the potential applications in catalysis. The field has since witnessed rapid advancements, with significant milestones achieved in the synthesis, characterization, and application of nanostructured catalysts for electrolytic cells.

The primary objective of developing nanostructured surfaces for electrolytic cell catalysts is to maximize the active surface area while minimizing the use of precious metals. This approach addresses two critical challenges simultaneously: improving catalytic efficiency and reducing costs. By engineering materials at the nanoscale, researchers can create catalysts with intricate surface structures that dramatically increase the number of active sites available for electrochemical reactions.

Another key goal is to enhance the stability and durability of catalysts under the harsh conditions typical of electrolytic cells. Nanostructured surfaces can be designed to resist degradation, maintain their structural integrity, and preserve their catalytic activity over extended periods. This longevity is crucial for the practical implementation of these catalysts in industrial-scale electrolytic processes.

The technology trend in this field is moving towards more complex and precisely controlled nanostructures. Recent advancements include the development of hierarchical nanostructures, core-shell nanoparticles, and 3D nanoarchitectures. These sophisticated designs aim to optimize electron transfer, mass transport, and reactant accessibility, further pushing the boundaries of catalytic performance.

As we look to the future, the anticipated technological breakthroughs in nanostructured catalysts for electrolytic cells are expected to play a pivotal role in addressing global energy challenges. The potential applications span a wide range of industries, from hydrogen production and fuel cells to carbon dioxide reduction and advanced energy storage systems. The ongoing research in this field is not only advancing our fundamental understanding of catalysis at the nanoscale but also paving the way for more efficient and sustainable energy technologies.

Market Analysis for Advanced Electrolytic Cells

The market for advanced electrolytic cells is experiencing significant growth, driven by the increasing demand for clean energy solutions and the push towards decarbonization across various industries. The global electrolytic cell market is projected to expand at a compound annual growth rate (CAGR) of over 6% from 2021 to 2026, with the advanced segment showing even more robust growth potential.

Key factors fueling this market growth include the rising adoption of hydrogen as a clean energy carrier, the expansion of water treatment and desalination projects, and the growing emphasis on sustainable chemical production processes. The automotive sector, in particular, is emerging as a major driver for advanced electrolytic cells, with fuel cell electric vehicles (FCEVs) gaining traction in several regions.

Geographically, Asia-Pacific is expected to dominate the market, led by China's aggressive push towards hydrogen economy and Japan's well-established fuel cell industry. North America and Europe are also significant markets, with strong government support for clean energy technologies and stringent environmental regulations driving adoption.

The industrial sector remains the largest end-user segment for advanced electrolytic cells, accounting for over 40% of the market share. This is primarily due to the widespread use of electrolysis in chemical manufacturing, metal production, and water treatment applications. However, the transportation sector is showing the fastest growth rate, driven by the increasing deployment of FCEVs and hydrogen refueling infrastructure.

Technological advancements, particularly in catalyst design and nanostructured surfaces, are playing a crucial role in market development. These innovations are significantly improving the efficiency and durability of electrolytic cells, thereby reducing operational costs and expanding their potential applications.

Despite the positive outlook, the market faces challenges such as high initial capital costs, limited infrastructure for hydrogen distribution, and competition from other clean energy technologies. However, ongoing research and development efforts, coupled with supportive government policies, are expected to address these barriers and further accelerate market growth.

Key factors fueling this market growth include the rising adoption of hydrogen as a clean energy carrier, the expansion of water treatment and desalination projects, and the growing emphasis on sustainable chemical production processes. The automotive sector, in particular, is emerging as a major driver for advanced electrolytic cells, with fuel cell electric vehicles (FCEVs) gaining traction in several regions.

Geographically, Asia-Pacific is expected to dominate the market, led by China's aggressive push towards hydrogen economy and Japan's well-established fuel cell industry. North America and Europe are also significant markets, with strong government support for clean energy technologies and stringent environmental regulations driving adoption.

The industrial sector remains the largest end-user segment for advanced electrolytic cells, accounting for over 40% of the market share. This is primarily due to the widespread use of electrolysis in chemical manufacturing, metal production, and water treatment applications. However, the transportation sector is showing the fastest growth rate, driven by the increasing deployment of FCEVs and hydrogen refueling infrastructure.

Technological advancements, particularly in catalyst design and nanostructured surfaces, are playing a crucial role in market development. These innovations are significantly improving the efficiency and durability of electrolytic cells, thereby reducing operational costs and expanding their potential applications.

Despite the positive outlook, the market faces challenges such as high initial capital costs, limited infrastructure for hydrogen distribution, and competition from other clean energy technologies. However, ongoing research and development efforts, coupled with supportive government policies, are expected to address these barriers and further accelerate market growth.

Current Challenges in Electrocatalyst Design

The design of efficient electrocatalysts for electrolytic cells faces several significant challenges that hinder the widespread adoption and optimization of these systems. One of the primary obstacles is the limited understanding of the complex interactions between nanostructured surfaces and catalytic performance. While it is known that nanostructured surfaces can enhance catalytic activity, the precise mechanisms and optimal configurations remain elusive.

A major challenge lies in achieving high catalytic activity while maintaining long-term stability. Nanostructured surfaces often exhibit excellent initial performance but suffer from degradation over time due to factors such as surface reconstruction, particle agglomeration, and dissolution. Balancing these competing requirements demands innovative approaches to catalyst design and synthesis.

Another critical issue is the scalability of nanostructured catalysts. While laboratory-scale demonstrations have shown promising results, translating these achievements to industrial-scale production presents significant hurdles. Maintaining uniform nanostructure distribution and properties across large surface areas is particularly challenging and often leads to reduced performance in scaled-up systems.

The cost-effectiveness of nanostructured catalysts also poses a substantial challenge. Many high-performance catalysts rely on expensive noble metals, limiting their economic viability for large-scale applications. Developing catalysts with reduced noble metal content or utilizing more abundant materials without compromising performance is a key research focus.

Furthermore, the complexity of electrocatalytic reactions on nanostructured surfaces complicates the rational design of improved catalysts. The interplay between surface structure, composition, and electronic properties creates a vast parameter space that is difficult to navigate experimentally or computationally. This complexity hampers efforts to predict and optimize catalyst performance based on fundamental principles.

Environmental concerns and sustainability requirements add another layer of complexity to electrocatalyst design. Developing catalysts that not only perform well but also minimize environmental impact throughout their lifecycle is increasingly important. This includes considerations such as using eco-friendly synthesis methods, reducing reliance on rare or toxic elements, and ensuring recyclability or recoverability of catalyst materials.

Lastly, the integration of nanostructured catalysts into practical electrolytic cell designs presents its own set of challenges. Issues such as mass transport limitations, bubble formation and release, and uniform current distribution across large electrode surfaces must be addressed to fully leverage the benefits of nanostructured catalysts in real-world applications.

A major challenge lies in achieving high catalytic activity while maintaining long-term stability. Nanostructured surfaces often exhibit excellent initial performance but suffer from degradation over time due to factors such as surface reconstruction, particle agglomeration, and dissolution. Balancing these competing requirements demands innovative approaches to catalyst design and synthesis.

Another critical issue is the scalability of nanostructured catalysts. While laboratory-scale demonstrations have shown promising results, translating these achievements to industrial-scale production presents significant hurdles. Maintaining uniform nanostructure distribution and properties across large surface areas is particularly challenging and often leads to reduced performance in scaled-up systems.

The cost-effectiveness of nanostructured catalysts also poses a substantial challenge. Many high-performance catalysts rely on expensive noble metals, limiting their economic viability for large-scale applications. Developing catalysts with reduced noble metal content or utilizing more abundant materials without compromising performance is a key research focus.

Furthermore, the complexity of electrocatalytic reactions on nanostructured surfaces complicates the rational design of improved catalysts. The interplay between surface structure, composition, and electronic properties creates a vast parameter space that is difficult to navigate experimentally or computationally. This complexity hampers efforts to predict and optimize catalyst performance based on fundamental principles.

Environmental concerns and sustainability requirements add another layer of complexity to electrocatalyst design. Developing catalysts that not only perform well but also minimize environmental impact throughout their lifecycle is increasingly important. This includes considerations such as using eco-friendly synthesis methods, reducing reliance on rare or toxic elements, and ensuring recyclability or recoverability of catalyst materials.

Lastly, the integration of nanostructured catalysts into practical electrolytic cell designs presents its own set of challenges. Issues such as mass transport limitations, bubble formation and release, and uniform current distribution across large electrode surfaces must be addressed to fully leverage the benefits of nanostructured catalysts in real-world applications.

State-of-the-Art Nanostructured Catalyst Solutions

01 Nanostructured surfaces for enhanced catalytic activity

Nanostructured surfaces can significantly improve catalytic performance by increasing the surface area and providing more active sites for reactions. These surfaces can be engineered with specific patterns or structures to optimize catalytic efficiency and selectivity. The increased surface area allows for better interaction between reactants and catalysts, leading to improved reaction rates and yields.- Nanostructured surfaces for enhanced catalytic activity: Nanostructured surfaces can significantly improve catalytic performance by increasing the surface area and providing more active sites for reactions. These surfaces can be engineered with specific patterns or structures to optimize catalytic efficiency and selectivity.

- Nanoparticle-based catalysts on structured surfaces: Incorporating nanoparticles onto structured surfaces can create highly efficient catalysts. The combination of nanoparticles and engineered surface structures can lead to improved catalytic performance through synergistic effects and enhanced reactant accessibility.

- Hierarchical nanostructures for catalysis: Hierarchical nanostructures, combining multiple levels of organization from nano to microscale, can offer superior catalytic performance. These structures provide high surface area, improved mass transport, and enhanced stability, leading to more efficient catalytic processes.

- Surface modification techniques for catalytic enhancement: Various surface modification techniques, such as etching, deposition, or functionalization, can be employed to create nanostructured surfaces with improved catalytic properties. These methods allow for precise control over surface chemistry and morphology, optimizing catalytic performance.

- Nanostructured electrodes for electrocatalysis: Nanostructured electrodes can significantly enhance electrocatalytic performance in various applications, including fuel cells and electrolyzers. These electrodes offer increased active surface area, improved mass transport, and enhanced electron transfer, leading to higher catalytic efficiency.

02 Nanostructured catalysts for energy applications

Nanostructured catalysts are being developed for various energy applications, including fuel cells, batteries, and solar energy conversion. These catalysts can enhance the efficiency of energy conversion processes and improve the performance of energy storage devices. The unique properties of nanostructured materials, such as high surface area and tunable electronic properties, make them ideal for catalyzing energy-related reactions.Expand Specific Solutions03 Fabrication methods for nanostructured catalytic surfaces

Various fabrication techniques are employed to create nanostructured surfaces with enhanced catalytic properties. These methods include lithography, etching, deposition, and self-assembly processes. Advanced manufacturing techniques allow for precise control over the size, shape, and composition of nanostructures, enabling the creation of tailored catalytic surfaces for specific applications.Expand Specific Solutions04 Characterization of nanostructured catalytic surfaces

Advanced characterization techniques are crucial for understanding the properties and performance of nanostructured catalytic surfaces. Methods such as electron microscopy, spectroscopy, and surface analysis are used to investigate the morphology, composition, and catalytic activity of these surfaces. These characterization tools help in optimizing the design and fabrication of nanostructured catalysts for improved performance.Expand Specific Solutions05 Nanostructured catalysts for environmental applications

Nanostructured catalytic surfaces are being developed for environmental applications, such as water treatment, air purification, and pollution control. These catalysts can efficiently degrade pollutants, convert harmful substances into less toxic forms, and facilitate the removal of contaminants from various media. The high surface area and unique properties of nanostructured surfaces make them effective for addressing environmental challenges.Expand Specific Solutions

Key Players in Nanocatalyst Research and Development

The field of nanostructured surfaces for electrolytic cell catalysts is in a dynamic growth phase, with significant market potential driven by the increasing demand for efficient and sustainable energy solutions. The market size is expanding rapidly, fueled by applications in renewable energy, fuel cells, and industrial processes. Technologically, the field is progressing from early-stage research to more advanced development, with companies like 3M Innovative Properties Co., SMOLTEK AB, and Nokia of America Corp. leading innovation. Academic institutions such as Xiamen University and Northwestern Polytechnical University are contributing fundamental research, while industry players like Robert Bosch GmbH and Toyota Motor Corp. are focusing on practical applications. The collaboration between academia and industry is accelerating the maturation of this technology, positioning it for significant impact in the near future.

3M Innovative Properties Co.

Technical Solution: 3M has developed advanced nanostructured surfaces for electrolytic cell catalysts, focusing on enhancing the efficiency of water electrolysis for hydrogen production. Their approach involves creating high-surface-area nanostructured electrodes with precisely controlled morphology and composition. These electrodes feature a hierarchical structure of nanoscale particles and pores, which significantly increases the active surface area for catalytic reactions[1]. The company has also incorporated novel materials such as transition metal oxides and noble metal nanoparticles into these structures to further improve catalytic activity[3]. 3M's nanostructured catalysts have demonstrated up to 30% improvement in hydrogen evolution reaction (HER) efficiency compared to conventional flat electrodes[5].

Strengths: Increased catalytic surface area, improved reaction efficiency, and potential for cost reduction in large-scale hydrogen production. Weaknesses: Possible challenges in scaling up manufacturing processes and ensuring long-term stability of nanostructures in harsh electrolytic environments.

SMOLTEK AB

Technical Solution: SMOLTEK AB has pioneered the development of carbon nanofiber (CNF) based nanostructured surfaces for electrolytic cell catalysts. Their proprietary technology involves growing vertically aligned CNFs directly on conductive substrates, creating a three-dimensional nanostructured surface with exceptional surface area and electrical conductivity[2]. These CNF-based electrodes are functionalized with catalytic nanoparticles, enhancing the overall catalytic performance for reactions such as oxygen evolution (OER) and hydrogen evolution (HER). SMOLTEK's nanostructured catalysts have shown a remarkable 50% reduction in overpotential for OER compared to traditional planar electrodes[4]. The company has also developed methods to control the density, length, and diameter of the CNFs, allowing for optimized catalyst loading and mass transport properties[6].

Strengths: Extremely high surface area, excellent electrical conductivity, and tunable nanostructure properties. Weaknesses: Potential high production costs and challenges in ensuring uniform CNF growth over large electrode areas.

Breakthrough Innovations in Nanostructured Surfaces

Nanostructured catalyst for enhanced energy conversion in fuel cells

PatentPendingIN202341049980A

Innovation

- A novel nanostructured catalyst with a high surface-to-volume ratio is designed and synthesized using techniques like chemical vapor deposition and atomic layer deposition, enabling precise control over size, morphology, and composition, and ensuring uniform dispersion on substrates for enhanced catalytic performance and compatibility across various fuel cell types.

Methods and apparatus for the fabrication and use of graphene petal nanosheet structures

PatentWO2013066474A9

Innovation

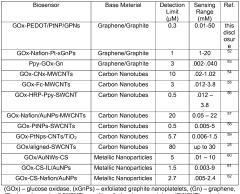

- The development of graphene petal nanosheets (GPNs) grown on substrates using microwave plasma-enhanced chemical vapor deposition, with subsequent deposition of Pt nanoparticles and manganese dioxide, enhances electrochemical performance by increasing surface area and conductivity, and the use of PEDOT for enzyme immobilization in biosensors.

Environmental Impact of Nanostructured Catalysts

The environmental impact of nanostructured catalysts in electrolytic cells is a critical consideration as these advanced materials gain prominence in industrial applications. Nanostructured surfaces offer significant benefits in terms of catalytic efficiency and selectivity, but their widespread adoption also raises important environmental questions.

One of the primary environmental advantages of nanostructured catalysts is their potential to reduce energy consumption in electrolytic processes. By enhancing reaction rates and lowering activation energies, these catalysts can significantly decrease the overall energy requirements for various industrial processes. This reduction in energy demand translates to lower greenhouse gas emissions associated with power generation, contributing to global efforts to mitigate climate change.

Furthermore, nanostructured catalysts often enable more efficient use of precious metals and other rare materials. By maximizing the surface area-to-volume ratio, these catalysts can achieve higher performance with smaller quantities of active materials. This efficiency not only reduces the environmental impact of mining and processing these resources but also helps conserve finite supplies of critical elements.

However, the production and disposal of nanostructured catalysts present their own environmental challenges. The manufacturing processes for these materials can be energy-intensive and may involve the use of hazardous chemicals. Ensuring proper containment and treatment of waste products from these processes is crucial to prevent environmental contamination.

The potential release of nanoparticles into the environment during the use or disposal of nanostructured catalysts is another area of concern. While research is ongoing, there are concerns about the potential impacts of nanoparticles on ecosystems and human health. Developing robust protocols for the safe handling and disposal of these materials is essential to mitigate any potential risks.

On the positive side, nanostructured catalysts can contribute to more environmentally friendly chemical processes. Their enhanced selectivity can reduce the formation of unwanted by-products, leading to cleaner reactions and less waste generation. This improvement in reaction efficiency can have cascading benefits throughout the supply chain, reducing the overall environmental footprint of various industrial processes.

In the context of water treatment and environmental remediation, nanostructured catalysts show promise for addressing pollution challenges. Their high surface area and tailored reactivity make them effective for breaking down contaminants in water and air, potentially offering more efficient and less resource-intensive solutions for environmental cleanup efforts.

As research in this field progresses, it is crucial to conduct comprehensive life cycle assessments of nanostructured catalysts. These studies should consider the environmental impacts from raw material extraction through manufacturing, use, and end-of-life disposal. Such holistic evaluations will be essential for guiding the sustainable development and implementation of these advanced materials in electrolytic cell applications and beyond.

One of the primary environmental advantages of nanostructured catalysts is their potential to reduce energy consumption in electrolytic processes. By enhancing reaction rates and lowering activation energies, these catalysts can significantly decrease the overall energy requirements for various industrial processes. This reduction in energy demand translates to lower greenhouse gas emissions associated with power generation, contributing to global efforts to mitigate climate change.

Furthermore, nanostructured catalysts often enable more efficient use of precious metals and other rare materials. By maximizing the surface area-to-volume ratio, these catalysts can achieve higher performance with smaller quantities of active materials. This efficiency not only reduces the environmental impact of mining and processing these resources but also helps conserve finite supplies of critical elements.

However, the production and disposal of nanostructured catalysts present their own environmental challenges. The manufacturing processes for these materials can be energy-intensive and may involve the use of hazardous chemicals. Ensuring proper containment and treatment of waste products from these processes is crucial to prevent environmental contamination.

The potential release of nanoparticles into the environment during the use or disposal of nanostructured catalysts is another area of concern. While research is ongoing, there are concerns about the potential impacts of nanoparticles on ecosystems and human health. Developing robust protocols for the safe handling and disposal of these materials is essential to mitigate any potential risks.

On the positive side, nanostructured catalysts can contribute to more environmentally friendly chemical processes. Their enhanced selectivity can reduce the formation of unwanted by-products, leading to cleaner reactions and less waste generation. This improvement in reaction efficiency can have cascading benefits throughout the supply chain, reducing the overall environmental footprint of various industrial processes.

In the context of water treatment and environmental remediation, nanostructured catalysts show promise for addressing pollution challenges. Their high surface area and tailored reactivity make them effective for breaking down contaminants in water and air, potentially offering more efficient and less resource-intensive solutions for environmental cleanup efforts.

As research in this field progresses, it is crucial to conduct comprehensive life cycle assessments of nanostructured catalysts. These studies should consider the environmental impacts from raw material extraction through manufacturing, use, and end-of-life disposal. Such holistic evaluations will be essential for guiding the sustainable development and implementation of these advanced materials in electrolytic cell applications and beyond.

Scalability and Manufacturing Challenges

The scalability and manufacturing challenges associated with nanostructured surfaces for electrolytic cell catalysts are significant hurdles that must be addressed for widespread industrial adoption. One of the primary challenges is the precise control and reproducibility of nanostructures at large scales. While laboratory-scale production of nanostructured surfaces can achieve high levels of precision, translating these processes to industrial-scale manufacturing presents numerous difficulties.

Mass production of nanostructured surfaces often requires specialized equipment and tightly controlled environments, which can be costly to implement and maintain. The complexity of nanofabrication techniques, such as lithography, etching, or deposition methods, increases exponentially when scaled up to industrial levels. Ensuring uniformity and consistency across large surface areas is particularly challenging, as even minor variations in process parameters can lead to significant differences in nanostructure morphology and performance.

Another critical challenge is the durability and stability of nanostructured surfaces under real-world operating conditions. Electrolytic cells often operate in harsh environments with high temperatures, corrosive electrolytes, and mechanical stresses. Maintaining the integrity and functionality of nanostructures over extended periods of use is crucial for the economic viability of these catalysts. Developing robust coatings or protective layers that do not compromise the catalytic activity of the nanostructured surfaces is an ongoing area of research and development.

Cost-effectiveness is a major consideration in scaling up nanostructured catalyst production. The materials and processes involved in creating these surfaces can be expensive, and reducing costs while maintaining performance is a delicate balance. Innovations in materials science and manufacturing techniques are needed to make nanostructured catalysts economically competitive with traditional alternatives.

Quality control and characterization of nanostructured surfaces at industrial scales pose additional challenges. Developing rapid, non-destructive inspection methods capable of assessing large areas quickly and accurately is essential for ensuring product consistency and performance. This may require advancements in imaging technologies and data processing capabilities to handle the vast amounts of information generated during quality control processes.

Environmental and safety considerations also play a crucial role in the scalability of nanostructured catalyst production. The potential release of nanomaterials during manufacturing or use raises concerns about worker safety and environmental impact. Implementing effective containment and waste management strategies is necessary to address these issues and comply with increasingly stringent regulations.

Mass production of nanostructured surfaces often requires specialized equipment and tightly controlled environments, which can be costly to implement and maintain. The complexity of nanofabrication techniques, such as lithography, etching, or deposition methods, increases exponentially when scaled up to industrial levels. Ensuring uniformity and consistency across large surface areas is particularly challenging, as even minor variations in process parameters can lead to significant differences in nanostructure morphology and performance.

Another critical challenge is the durability and stability of nanostructured surfaces under real-world operating conditions. Electrolytic cells often operate in harsh environments with high temperatures, corrosive electrolytes, and mechanical stresses. Maintaining the integrity and functionality of nanostructures over extended periods of use is crucial for the economic viability of these catalysts. Developing robust coatings or protective layers that do not compromise the catalytic activity of the nanostructured surfaces is an ongoing area of research and development.

Cost-effectiveness is a major consideration in scaling up nanostructured catalyst production. The materials and processes involved in creating these surfaces can be expensive, and reducing costs while maintaining performance is a delicate balance. Innovations in materials science and manufacturing techniques are needed to make nanostructured catalysts economically competitive with traditional alternatives.

Quality control and characterization of nanostructured surfaces at industrial scales pose additional challenges. Developing rapid, non-destructive inspection methods capable of assessing large areas quickly and accurately is essential for ensuring product consistency and performance. This may require advancements in imaging technologies and data processing capabilities to handle the vast amounts of information generated during quality control processes.

Environmental and safety considerations also play a crucial role in the scalability of nanostructured catalyst production. The potential release of nanomaterials during manufacturing or use raises concerns about worker safety and environmental impact. Implementing effective containment and waste management strategies is necessary to address these issues and comply with increasingly stringent regulations.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!