Development of Cost-Effective Electrolytic Cell Materials

AUG 1, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Electrolytic Cell Evolution and Objectives

Electrolytic cells have undergone significant evolution since their inception in the early 19th century. The development trajectory has been driven by the need for more efficient, cost-effective, and environmentally friendly materials and designs. Initially, simple two-electrode systems were used, primarily for water electrolysis and metal electroplating. As industrial applications expanded, the focus shifted towards improving electrode materials, cell configurations, and electrolyte compositions.

The mid-20th century saw a surge in research and development, particularly in the chlor-alkali industry, which demanded more durable and efficient electrolytic cells. This period marked the introduction of dimensionally stable anodes (DSA) and membrane cell technology, revolutionizing the field. These advancements significantly reduced energy consumption and improved product quality, setting new standards for industrial electrolysis.

In recent decades, the evolution of electrolytic cells has been largely influenced by environmental concerns and the push for sustainable technologies. This has led to the exploration of novel materials and designs that minimize harmful emissions and reduce the overall carbon footprint of electrolytic processes. Concurrently, the rising interest in hydrogen as a clean energy carrier has reignited research into water electrolysis, driving innovations in electrode materials and cell architectures.

The primary objective in the development of cost-effective electrolytic cell materials is to enhance overall system efficiency while reducing production and operational costs. This involves a multifaceted approach, focusing on several key areas. Firstly, there is a strong emphasis on developing electrode materials with improved catalytic activity, stability, and longevity. This includes exploring nanostructured materials, composite electrodes, and novel alloys that can operate at higher current densities with lower overpotentials.

Another critical objective is the optimization of membrane and separator materials to enhance ion selectivity and reduce electrical resistance. This not only improves energy efficiency but also increases product purity and reduces the need for post-processing. Additionally, there is a growing interest in developing bipolar electrode configurations and modular cell designs that can scale more efficiently and reduce material costs in large-scale applications.

The pursuit of cost-effective materials also extends to the exploration of abundant and easily processable raw materials. This includes investigating earth-abundant catalysts to replace precious metals, and developing synthesis methods that reduce the complexity and energy requirements of material production. Furthermore, there is an increasing focus on designing electrolytic cells that are more adaptable to renewable energy sources, capable of handling intermittent power inputs without compromising performance or lifespan.

The mid-20th century saw a surge in research and development, particularly in the chlor-alkali industry, which demanded more durable and efficient electrolytic cells. This period marked the introduction of dimensionally stable anodes (DSA) and membrane cell technology, revolutionizing the field. These advancements significantly reduced energy consumption and improved product quality, setting new standards for industrial electrolysis.

In recent decades, the evolution of electrolytic cells has been largely influenced by environmental concerns and the push for sustainable technologies. This has led to the exploration of novel materials and designs that minimize harmful emissions and reduce the overall carbon footprint of electrolytic processes. Concurrently, the rising interest in hydrogen as a clean energy carrier has reignited research into water electrolysis, driving innovations in electrode materials and cell architectures.

The primary objective in the development of cost-effective electrolytic cell materials is to enhance overall system efficiency while reducing production and operational costs. This involves a multifaceted approach, focusing on several key areas. Firstly, there is a strong emphasis on developing electrode materials with improved catalytic activity, stability, and longevity. This includes exploring nanostructured materials, composite electrodes, and novel alloys that can operate at higher current densities with lower overpotentials.

Another critical objective is the optimization of membrane and separator materials to enhance ion selectivity and reduce electrical resistance. This not only improves energy efficiency but also increases product purity and reduces the need for post-processing. Additionally, there is a growing interest in developing bipolar electrode configurations and modular cell designs that can scale more efficiently and reduce material costs in large-scale applications.

The pursuit of cost-effective materials also extends to the exploration of abundant and easily processable raw materials. This includes investigating earth-abundant catalysts to replace precious metals, and developing synthesis methods that reduce the complexity and energy requirements of material production. Furthermore, there is an increasing focus on designing electrolytic cells that are more adaptable to renewable energy sources, capable of handling intermittent power inputs without compromising performance or lifespan.

Market Analysis for Electrolytic Technologies

The electrolytic technologies market has experienced significant growth in recent years, driven by increasing demand for clean energy solutions and sustainable industrial processes. This market encompasses a wide range of applications, including water treatment, hydrogen production, metal refining, and chemical manufacturing. The global electrolytic technologies market was valued at approximately $20 billion in 2020 and is projected to reach $30 billion by 2025, with a compound annual growth rate (CAGR) of 8.5%.

One of the key drivers of market growth is the rising adoption of hydrogen as a clean energy carrier. Electrolysis is a crucial technology for producing green hydrogen from renewable electricity sources. As countries worldwide commit to reducing carbon emissions and transitioning to cleaner energy systems, the demand for electrolytic hydrogen production is expected to surge. This trend is particularly evident in Europe, where several countries have announced ambitious hydrogen strategies and substantial investments in electrolysis capacity.

The water treatment sector represents another significant market for electrolytic technologies. With growing concerns over water scarcity and pollution, there is an increasing need for advanced water treatment solutions. Electrolytic technologies, such as electrocoagulation and electrooxidation, offer efficient and environmentally friendly methods for removing contaminants from water. The market for electrolytic water treatment systems is expected to grow at a CAGR of 6.8% from 2021 to 2026.

In the industrial sector, electrolytic technologies play a crucial role in metal refining and chemical manufacturing processes. The aluminum industry, in particular, relies heavily on electrolytic cells for the production of primary aluminum. As global demand for aluminum continues to rise, driven by sectors such as automotive and construction, the market for electrolytic cell materials is expected to expand accordingly.

Geographically, Asia-Pacific dominates the electrolytic technologies market, accounting for over 40% of the global market share. This is primarily due to the region's rapid industrialization, growing population, and increasing focus on clean energy solutions. China, in particular, has emerged as a key player in the electrolytic technologies market, with significant investments in hydrogen production and water treatment technologies.

Despite the positive growth outlook, the electrolytic technologies market faces several challenges. The high capital costs associated with electrolytic systems and the need for specialized materials pose barriers to widespread adoption. Additionally, the energy-intensive nature of electrolytic processes raises concerns about overall efficiency and environmental impact. These challenges underscore the importance of developing cost-effective and efficient electrolytic cell materials to drive further market growth and technological advancement.

One of the key drivers of market growth is the rising adoption of hydrogen as a clean energy carrier. Electrolysis is a crucial technology for producing green hydrogen from renewable electricity sources. As countries worldwide commit to reducing carbon emissions and transitioning to cleaner energy systems, the demand for electrolytic hydrogen production is expected to surge. This trend is particularly evident in Europe, where several countries have announced ambitious hydrogen strategies and substantial investments in electrolysis capacity.

The water treatment sector represents another significant market for electrolytic technologies. With growing concerns over water scarcity and pollution, there is an increasing need for advanced water treatment solutions. Electrolytic technologies, such as electrocoagulation and electrooxidation, offer efficient and environmentally friendly methods for removing contaminants from water. The market for electrolytic water treatment systems is expected to grow at a CAGR of 6.8% from 2021 to 2026.

In the industrial sector, electrolytic technologies play a crucial role in metal refining and chemical manufacturing processes. The aluminum industry, in particular, relies heavily on electrolytic cells for the production of primary aluminum. As global demand for aluminum continues to rise, driven by sectors such as automotive and construction, the market for electrolytic cell materials is expected to expand accordingly.

Geographically, Asia-Pacific dominates the electrolytic technologies market, accounting for over 40% of the global market share. This is primarily due to the region's rapid industrialization, growing population, and increasing focus on clean energy solutions. China, in particular, has emerged as a key player in the electrolytic technologies market, with significant investments in hydrogen production and water treatment technologies.

Despite the positive growth outlook, the electrolytic technologies market faces several challenges. The high capital costs associated with electrolytic systems and the need for specialized materials pose barriers to widespread adoption. Additionally, the energy-intensive nature of electrolytic processes raises concerns about overall efficiency and environmental impact. These challenges underscore the importance of developing cost-effective and efficient electrolytic cell materials to drive further market growth and technological advancement.

Current Challenges in Electrolytic Cell Materials

The development of cost-effective electrolytic cell materials faces several significant challenges in the current technological landscape. One of the primary obstacles is the high cost associated with traditional noble metal catalysts, such as platinum and iridium, which are widely used in electrolytic cells due to their excellent catalytic properties and stability. These materials, while highly effective, are scarce and expensive, limiting their large-scale application in industrial processes.

Another major challenge is the durability and longevity of electrolytic cell materials. The harsh operating conditions, including high temperatures, corrosive electrolytes, and continuous electrochemical reactions, can lead to rapid degradation of materials. This degradation not only reduces the efficiency of the electrolytic process but also increases maintenance costs and downtime, affecting the overall economic viability of electrolytic systems.

The search for alternative materials that can match or surpass the performance of noble metals while being more abundant and cost-effective is ongoing. However, finding materials that exhibit comparable catalytic activity, stability, and conductivity has proven to be a complex task. Many promising candidates, such as transition metal oxides and carbon-based materials, show initial potential but often fall short in long-term stability or overall performance.

Energy efficiency is another critical challenge in the development of electrolytic cell materials. Current materials often require high overpotentials to drive the desired electrochemical reactions, leading to increased energy consumption and operational costs. Improving the energy efficiency of electrolytic processes through the development of advanced materials with lower overpotentials is crucial for making these technologies more economically viable and environmentally sustainable.

The scalability of new material solutions presents an additional hurdle. While some novel materials show promising results in laboratory settings, translating these findings into large-scale industrial applications can be problematic. Issues such as uniformity in material properties, reproducibility of performance, and compatibility with existing manufacturing processes often arise during the scaling-up phase.

Furthermore, the environmental impact of electrolytic cell materials is becoming an increasingly important consideration. There is a growing need for materials that not only perform well and are cost-effective but also have a minimal ecological footprint throughout their lifecycle. This includes considerations for the sourcing of raw materials, the energy intensity of production processes, and the recyclability or disposal of materials at the end of their useful life.

Lastly, the regulatory landscape surrounding new materials for electrolytic cells can pose challenges. Stringent safety and environmental regulations may limit the adoption of certain materials, even if they show promising performance characteristics. Navigating these regulatory requirements while developing innovative solutions adds complexity to the research and development process.

Another major challenge is the durability and longevity of electrolytic cell materials. The harsh operating conditions, including high temperatures, corrosive electrolytes, and continuous electrochemical reactions, can lead to rapid degradation of materials. This degradation not only reduces the efficiency of the electrolytic process but also increases maintenance costs and downtime, affecting the overall economic viability of electrolytic systems.

The search for alternative materials that can match or surpass the performance of noble metals while being more abundant and cost-effective is ongoing. However, finding materials that exhibit comparable catalytic activity, stability, and conductivity has proven to be a complex task. Many promising candidates, such as transition metal oxides and carbon-based materials, show initial potential but often fall short in long-term stability or overall performance.

Energy efficiency is another critical challenge in the development of electrolytic cell materials. Current materials often require high overpotentials to drive the desired electrochemical reactions, leading to increased energy consumption and operational costs. Improving the energy efficiency of electrolytic processes through the development of advanced materials with lower overpotentials is crucial for making these technologies more economically viable and environmentally sustainable.

The scalability of new material solutions presents an additional hurdle. While some novel materials show promising results in laboratory settings, translating these findings into large-scale industrial applications can be problematic. Issues such as uniformity in material properties, reproducibility of performance, and compatibility with existing manufacturing processes often arise during the scaling-up phase.

Furthermore, the environmental impact of electrolytic cell materials is becoming an increasingly important consideration. There is a growing need for materials that not only perform well and are cost-effective but also have a minimal ecological footprint throughout their lifecycle. This includes considerations for the sourcing of raw materials, the energy intensity of production processes, and the recyclability or disposal of materials at the end of their useful life.

Lastly, the regulatory landscape surrounding new materials for electrolytic cells can pose challenges. Stringent safety and environmental regulations may limit the adoption of certain materials, even if they show promising performance characteristics. Navigating these regulatory requirements while developing innovative solutions adds complexity to the research and development process.

Existing Cost-Effective Material Solutions

01 Cost-effective electrode materials

Developing and utilizing cost-effective electrode materials is crucial for improving the economic viability of electrolytic cells. This includes exploring alternative materials that offer similar performance to traditional expensive electrodes but at a lower cost. Research focuses on materials that balance durability, conductivity, and catalytic activity while remaining economically feasible for large-scale production.- Cost-effective electrode materials: Developing and utilizing cost-effective electrode materials is crucial for improving the economic viability of electrolytic cells. This includes exploring alternative materials that offer similar performance to traditional expensive options, such as using carbon-based electrodes or metal alloys that balance cost and efficiency. The selection of these materials can significantly impact the overall cost-effectiveness of the electrolytic process.

- Optimization of electrolyte composition: Optimizing the electrolyte composition can enhance the efficiency and cost-effectiveness of electrolytic cells. This involves finding the right balance of ionic species, additives, and pH levels to maximize conductivity and minimize side reactions. Improved electrolyte formulations can lead to reduced energy consumption and increased product yield, thereby improving the overall economics of the process.

- Advanced cell design and manufacturing techniques: Implementing advanced cell designs and manufacturing techniques can significantly improve the cost-effectiveness of electrolytic cells. This includes innovations in cell geometry, membrane technology, and assembly methods that enhance performance while reducing material and production costs. Modular designs and scalable manufacturing processes can also contribute to improved economic efficiency.

- Energy efficiency and power management: Improving energy efficiency and implementing smart power management systems are key factors in enhancing the cost-effectiveness of electrolytic cells. This involves optimizing operating parameters, such as current density and temperature, as well as integrating renewable energy sources and energy recovery systems. Advanced control systems can help maintain optimal performance while minimizing energy consumption.

- Life cycle analysis and maintenance strategies: Conducting comprehensive life cycle analyses and developing effective maintenance strategies can significantly impact the long-term cost-effectiveness of electrolytic cells. This includes assessing the durability of materials, implementing predictive maintenance techniques, and optimizing replacement schedules. By extending the operational life of cell components and reducing downtime, overall costs can be minimized.

02 Optimization of electrolyte composition

Optimizing the electrolyte composition can significantly impact the cost-effectiveness of electrolytic cells. This involves finding the right balance of ionic conductivity, stability, and cost. Researchers are exploring various electrolyte formulations to enhance performance while reducing overall material costs, including the use of less expensive or more abundant chemical components.Expand Specific Solutions03 Improved cell design for efficiency

Enhancing the design of electrolytic cells can lead to improved efficiency and cost-effectiveness. This includes optimizing cell geometry, electrode spacing, and flow dynamics to maximize reaction rates and minimize energy consumption. Advanced designs may incorporate features that reduce material waste and extend the operational lifespan of cell components.Expand Specific Solutions04 Recycling and reuse of materials

Implementing strategies for recycling and reusing materials in electrolytic cells can significantly reduce overall costs. This approach involves developing processes to recover and refurbish expensive components, such as catalysts or electrodes, at the end of their initial life cycle. It also includes designing cells with easily separable and recyclable parts.Expand Specific Solutions05 Process control and automation

Implementing advanced process control and automation systems can enhance the cost-effectiveness of electrolytic cell operations. This includes using sensors, data analytics, and artificial intelligence to optimize operating conditions in real-time, reducing energy consumption and extending the lifespan of materials. Automation can also minimize human error and labor costs associated with cell maintenance and operation.Expand Specific Solutions

Key Players in Electrolytic Cell Industry

The development of cost-effective electrolytic cell materials is currently in a growth phase, with significant market potential driven by the increasing demand for clean energy solutions. The global market size for electrolyzers is projected to expand rapidly, fueled by the push for green hydrogen production. Technologically, the field is advancing, with companies like Siemens AG, Robert Bosch GmbH, and Toyota Motor Corp. leading innovation. Research institutions such as Fraunhofer-Gesellschaft and the National University of Singapore are contributing to technological advancements. However, the technology is not yet fully mature, with ongoing efforts to improve efficiency and reduce costs, as evidenced by the involvement of startups like Hysata Pty Ltd. and established players like Industrie De Nora SpA.

Dalian Institute of Chemical Physics Chinese Academy of Sci

Technical Solution: The Dalian Institute of Chemical Physics (DICP) has developed innovative electrocatalysts for water electrolysis, focusing on non-precious metal-based materials to reduce costs. Their approach involves using transition metal phosphides and nitrides as efficient catalysts for both hydrogen and oxygen evolution reactions. DICP has successfully synthesized nanostructured nickel phosphide (Ni2P) catalysts that exhibit high activity and stability in alkaline electrolytes[1]. Additionally, they have explored the use of carbon-supported cobalt nitrides (CoNx/C) as bifunctional catalysts for overall water splitting[2]. These materials have shown promising performance comparable to precious metal catalysts but at a fraction of the cost.

Strengths: Cost-effective alternatives to precious metals, high catalytic activity, and stability in alkaline conditions. Weaknesses: Potential scalability issues and long-term durability concerns in industrial applications.

Siemens AG

Technical Solution: Siemens AG has made significant strides in developing cost-effective electrolytic cell materials for green hydrogen production. Their focus has been on improving the efficiency and durability of proton exchange membrane (PEM) electrolyzers. Siemens has developed advanced membrane electrode assemblies (MEAs) using novel catalyst layers and membrane materials that reduce the overall platinum group metal (PGM) loading while maintaining high performance[3]. They have also implemented innovative cell designs that optimize fluid flow and reduce ohmic losses, resulting in increased efficiency. Siemens' electrolyzers have achieved electricity-to-hydrogen conversion efficiencies of up to 75%[4], with a target to reach 80% in the near future. Additionally, they have explored the use of anion exchange membranes (AEMs) as a potential low-cost alternative to PEM technology.

Strengths: High efficiency, reduced PGM loading, and advanced cell designs. Weaknesses: Still reliant on some precious metals, and AEM technology is not yet fully mature for large-scale applications.

Innovative Electrolytic Cell Material Patents

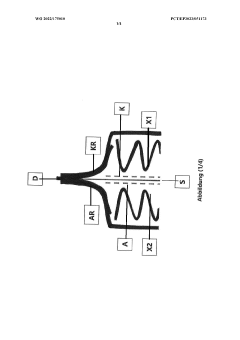

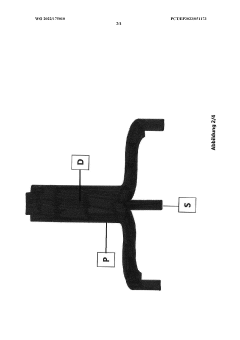

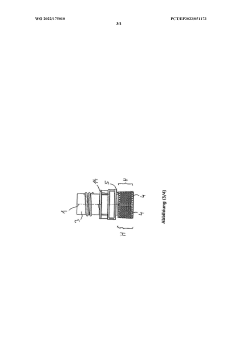

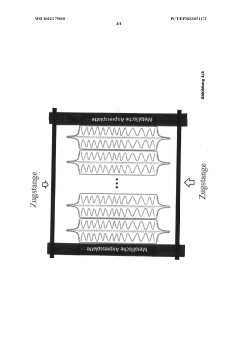

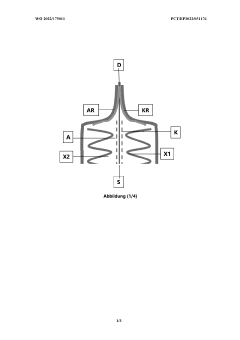

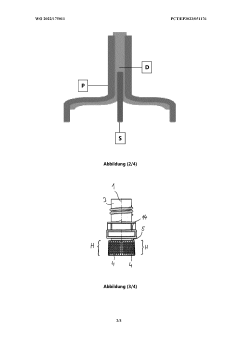

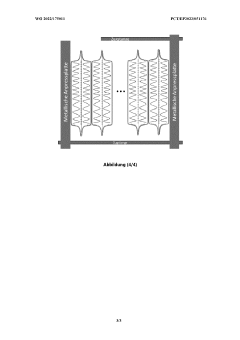

Process for producing an electrolysis cell and a corresponding electrolysis stack

PatentWO2022175010A1

Innovation

- A continuous process using thin metal foils (0.05 to 0.15 mm thick) for electrolytic cells with elastic spacers and a roll-to-sheet process for precise assembly, combined with vacuum stiffening and electrically insulating plastics for sealing, allowing for lightweight, flexible, and chemically resistant cell production.

Electrolytic cell

PatentWO2022175011A1

Innovation

- The use of thin metal foils (0.05 to 0.15 mm thick) for electrolytic cells with elastic spacers and a vacuum-stiffened design to ensure flat electrode contact and pressure resistance, combined with a sealing compound for electrical isolation and a method to connect cells in series using pressure plates and tie rods.

Environmental Impact Assessment

The development of cost-effective electrolytic cell materials has significant environmental implications that must be carefully assessed. These materials play a crucial role in various industrial processes, including water treatment, chemical production, and energy storage. As such, their environmental impact extends across multiple domains.

One of the primary environmental considerations is the reduction of energy consumption in electrolytic processes. More efficient and cost-effective materials can lead to lower energy requirements, thereby reducing greenhouse gas emissions associated with power generation. This is particularly important in industries that rely heavily on electrolysis, such as chlor-alkali production and hydrogen generation.

The durability and longevity of electrolytic cell materials also contribute to their environmental profile. Materials that exhibit enhanced resistance to corrosion and degradation can significantly extend the operational lifespan of electrolytic cells. This, in turn, reduces the frequency of replacements and maintenance, minimizing waste generation and resource consumption associated with manufacturing new components.

Another critical aspect is the potential for these materials to enable more environmentally friendly production processes. For instance, in water treatment applications, advanced electrolytic cell materials can improve the efficiency of contaminant removal, reducing the need for chemical additives and minimizing the generation of harmful by-products.

The raw materials used in the production of electrolytic cell components also warrant consideration. The shift towards more abundant and less environmentally impactful materials can reduce the ecological footprint associated with mining and processing rare or toxic elements. This aligns with broader sustainability goals and circular economy principles.

Furthermore, the end-of-life management of electrolytic cell materials is an important environmental factor. Developing materials that are easier to recycle or repurpose can significantly reduce waste and promote resource conservation. This aspect is particularly relevant given the increasing focus on lifecycle assessments and extended producer responsibility in industrial sectors.

The potential for these materials to enable or enhance green technologies should also be evaluated. For example, more efficient electrolytic cells could accelerate the adoption of hydrogen as a clean energy carrier or improve the performance of flow batteries for renewable energy storage.

In conclusion, the environmental impact assessment of cost-effective electrolytic cell materials must consider a wide range of factors, from energy efficiency and resource consumption to waste reduction and enabling green technologies. A comprehensive evaluation of these aspects is essential to ensure that advancements in this field contribute positively to overall environmental sustainability.

One of the primary environmental considerations is the reduction of energy consumption in electrolytic processes. More efficient and cost-effective materials can lead to lower energy requirements, thereby reducing greenhouse gas emissions associated with power generation. This is particularly important in industries that rely heavily on electrolysis, such as chlor-alkali production and hydrogen generation.

The durability and longevity of electrolytic cell materials also contribute to their environmental profile. Materials that exhibit enhanced resistance to corrosion and degradation can significantly extend the operational lifespan of electrolytic cells. This, in turn, reduces the frequency of replacements and maintenance, minimizing waste generation and resource consumption associated with manufacturing new components.

Another critical aspect is the potential for these materials to enable more environmentally friendly production processes. For instance, in water treatment applications, advanced electrolytic cell materials can improve the efficiency of contaminant removal, reducing the need for chemical additives and minimizing the generation of harmful by-products.

The raw materials used in the production of electrolytic cell components also warrant consideration. The shift towards more abundant and less environmentally impactful materials can reduce the ecological footprint associated with mining and processing rare or toxic elements. This aligns with broader sustainability goals and circular economy principles.

Furthermore, the end-of-life management of electrolytic cell materials is an important environmental factor. Developing materials that are easier to recycle or repurpose can significantly reduce waste and promote resource conservation. This aspect is particularly relevant given the increasing focus on lifecycle assessments and extended producer responsibility in industrial sectors.

The potential for these materials to enable or enhance green technologies should also be evaluated. For example, more efficient electrolytic cells could accelerate the adoption of hydrogen as a clean energy carrier or improve the performance of flow batteries for renewable energy storage.

In conclusion, the environmental impact assessment of cost-effective electrolytic cell materials must consider a wide range of factors, from energy efficiency and resource consumption to waste reduction and enabling green technologies. A comprehensive evaluation of these aspects is essential to ensure that advancements in this field contribute positively to overall environmental sustainability.

Economic Feasibility Analysis

The economic feasibility of developing cost-effective electrolytic cell materials is a critical factor in determining the viability of large-scale implementation. This analysis considers various aspects, including production costs, market potential, and long-term economic benefits.

Production costs for electrolytic cell materials have historically been a significant barrier to widespread adoption. However, recent advancements in material science and manufacturing processes have shown promising results in reducing these costs. For instance, the development of novel catalysts and electrode materials has led to improved efficiency and durability, potentially lowering the overall cost of electrolytic cells.

Market potential for cost-effective electrolytic cell materials is substantial, particularly in the renewable energy sector. As the global push for clean energy intensifies, the demand for efficient and affordable electrolysis technologies is expected to grow significantly. This increased demand could drive economies of scale, further reducing production costs and improving economic viability.

Long-term economic benefits of investing in cost-effective electrolytic cell materials extend beyond immediate market opportunities. The development of these materials could lead to more efficient hydrogen production, which has implications for various industries, including transportation, industrial processes, and energy storage. This could result in substantial cost savings and environmental benefits over time.

A cost-benefit analysis reveals that while initial research and development costs may be high, the potential returns on investment are considerable. As production scales up and technology matures, the cost per unit is expected to decrease, making electrolytic cells more accessible to a broader range of applications and markets.

Comparative analysis with existing technologies shows that cost-effective electrolytic cell materials have the potential to outperform current alternatives in terms of efficiency and long-term cost-effectiveness. This could lead to a shift in the energy landscape, with electrolysis becoming a more viable option for various applications.

Government incentives and policies supporting clean energy technologies could further enhance the economic feasibility of developing these materials. Subsidies, tax breaks, and research grants can help offset initial costs and accelerate the commercialization process, making the development of cost-effective electrolytic cell materials more attractive to investors and industry stakeholders.

In conclusion, the economic feasibility of developing cost-effective electrolytic cell materials appears promising. While challenges remain, the potential benefits in terms of market growth, long-term cost savings, and environmental impact make this an attractive area for investment and further research.

Production costs for electrolytic cell materials have historically been a significant barrier to widespread adoption. However, recent advancements in material science and manufacturing processes have shown promising results in reducing these costs. For instance, the development of novel catalysts and electrode materials has led to improved efficiency and durability, potentially lowering the overall cost of electrolytic cells.

Market potential for cost-effective electrolytic cell materials is substantial, particularly in the renewable energy sector. As the global push for clean energy intensifies, the demand for efficient and affordable electrolysis technologies is expected to grow significantly. This increased demand could drive economies of scale, further reducing production costs and improving economic viability.

Long-term economic benefits of investing in cost-effective electrolytic cell materials extend beyond immediate market opportunities. The development of these materials could lead to more efficient hydrogen production, which has implications for various industries, including transportation, industrial processes, and energy storage. This could result in substantial cost savings and environmental benefits over time.

A cost-benefit analysis reveals that while initial research and development costs may be high, the potential returns on investment are considerable. As production scales up and technology matures, the cost per unit is expected to decrease, making electrolytic cells more accessible to a broader range of applications and markets.

Comparative analysis with existing technologies shows that cost-effective electrolytic cell materials have the potential to outperform current alternatives in terms of efficiency and long-term cost-effectiveness. This could lead to a shift in the energy landscape, with electrolysis becoming a more viable option for various applications.

Government incentives and policies supporting clean energy technologies could further enhance the economic feasibility of developing these materials. Subsidies, tax breaks, and research grants can help offset initial costs and accelerate the commercialization process, making the development of cost-effective electrolytic cell materials more attractive to investors and industry stakeholders.

In conclusion, the economic feasibility of developing cost-effective electrolytic cell materials appears promising. While challenges remain, the potential benefits in terms of market growth, long-term cost savings, and environmental impact make this an attractive area for investment and further research.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!