The Potential of Wireless Electrolytic Cells in Industrial Systems

AUG 1, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Wireless Electrolytic Cells: Background and Objectives

Wireless electrolytic cells represent a significant advancement in industrial systems, combining the principles of electrochemistry with wireless technology. This innovative approach has evolved from traditional electrolytic processes, which have been fundamental in various industries for decades. The development of wireless electrolytic cells aims to address the limitations of conventional wired systems, offering enhanced flexibility, efficiency, and scalability in industrial applications.

The historical context of electrolytic cells dates back to the early 19th century, with pioneering work by scientists such as Michael Faraday. These cells have been crucial in processes like electroplating, chlorine production, and metal refining. However, the integration of wireless technology into electrolytic systems is a relatively recent development, driven by the broader trend of Industry 4.0 and the increasing demand for smart, connected industrial solutions.

The primary objective of wireless electrolytic cells is to revolutionize industrial processes by eliminating the need for physical connections between power sources and electrolytic units. This wireless approach offers several potential advantages, including reduced infrastructure costs, improved mobility, and enhanced safety in hazardous environments. Additionally, it aims to facilitate real-time monitoring and control of electrolytic processes, leading to optimized performance and resource utilization.

The technology behind wireless electrolytic cells draws from various fields, including electrochemistry, wireless power transfer, and IoT (Internet of Things). The convergence of these disciplines has opened up new possibilities for industrial applications, ranging from water treatment and metal extraction to energy storage systems. As the technology evolves, it is expected to play a crucial role in advancing sustainable manufacturing practices and circular economy initiatives.

Current research and development efforts in wireless electrolytic cells focus on several key areas. These include improving wireless power transmission efficiency, developing advanced electrode materials, enhancing control systems for precise electrolyte management, and integrating smart sensors for real-time process monitoring. The ultimate goal is to create robust, scalable systems that can operate autonomously in diverse industrial environments.

As industries worldwide seek to modernize their operations and reduce their environmental footprint, wireless electrolytic cells present a promising solution. The technology aligns with global trends towards digitalization, sustainability, and process intensification in industrial systems. By enabling more flexible and efficient electrolytic processes, these wireless systems have the potential to transform various sectors, from chemical manufacturing to renewable energy production.

The historical context of electrolytic cells dates back to the early 19th century, with pioneering work by scientists such as Michael Faraday. These cells have been crucial in processes like electroplating, chlorine production, and metal refining. However, the integration of wireless technology into electrolytic systems is a relatively recent development, driven by the broader trend of Industry 4.0 and the increasing demand for smart, connected industrial solutions.

The primary objective of wireless electrolytic cells is to revolutionize industrial processes by eliminating the need for physical connections between power sources and electrolytic units. This wireless approach offers several potential advantages, including reduced infrastructure costs, improved mobility, and enhanced safety in hazardous environments. Additionally, it aims to facilitate real-time monitoring and control of electrolytic processes, leading to optimized performance and resource utilization.

The technology behind wireless electrolytic cells draws from various fields, including electrochemistry, wireless power transfer, and IoT (Internet of Things). The convergence of these disciplines has opened up new possibilities for industrial applications, ranging from water treatment and metal extraction to energy storage systems. As the technology evolves, it is expected to play a crucial role in advancing sustainable manufacturing practices and circular economy initiatives.

Current research and development efforts in wireless electrolytic cells focus on several key areas. These include improving wireless power transmission efficiency, developing advanced electrode materials, enhancing control systems for precise electrolyte management, and integrating smart sensors for real-time process monitoring. The ultimate goal is to create robust, scalable systems that can operate autonomously in diverse industrial environments.

As industries worldwide seek to modernize their operations and reduce their environmental footprint, wireless electrolytic cells present a promising solution. The technology aligns with global trends towards digitalization, sustainability, and process intensification in industrial systems. By enabling more flexible and efficient electrolytic processes, these wireless systems have the potential to transform various sectors, from chemical manufacturing to renewable energy production.

Industrial Demand for Wireless Electrolytic Solutions

The industrial demand for wireless electrolytic solutions has been steadily growing in recent years, driven by the increasing need for more efficient and flexible manufacturing processes. Wireless electrolytic cells offer significant advantages over traditional wired systems, particularly in industries where mobility and adaptability are crucial.

In the chemical manufacturing sector, wireless electrolytic cells have gained traction due to their ability to be easily repositioned within production lines. This flexibility allows for rapid reconfiguration of manufacturing processes, reducing downtime and increasing overall productivity. The demand is particularly strong in batch production environments where frequent changes in product specifications require quick adjustments to electrolytic processes.

The oil and gas industry has also shown considerable interest in wireless electrolytic solutions. Offshore platforms and remote drilling sites often face challenges with traditional wired systems due to harsh environmental conditions and the need for frequent equipment relocation. Wireless electrolytic cells provide a more robust and adaptable solution for water treatment and corrosion prevention in these challenging environments.

In the water treatment industry, the demand for wireless electrolytic cells has been driven by the need for more efficient and cost-effective solutions for water purification and desalination. Municipal water treatment plants are increasingly looking to implement these systems to reduce energy consumption and improve the scalability of their operations.

The metal finishing and plating industry has also recognized the potential of wireless electrolytic cells. The ability to precisely control and monitor electroplating processes wirelessly has led to improved quality control and reduced material waste. This has resulted in a growing demand for wireless solutions in both large-scale industrial operations and smaller specialty plating shops.

The electronics manufacturing sector has shown interest in wireless electrolytic cells for applications such as printed circuit board fabrication and semiconductor processing. The demand in this sector is driven by the need for more precise control over electrolytic processes and the ability to integrate these systems into increasingly automated production lines.

As industries continue to embrace Industry 4.0 principles, the demand for wireless electrolytic solutions is expected to grow further. The integration of these systems with IoT platforms and advanced analytics tools is creating new opportunities for process optimization and predictive maintenance, further driving adoption across various industrial sectors.

In the chemical manufacturing sector, wireless electrolytic cells have gained traction due to their ability to be easily repositioned within production lines. This flexibility allows for rapid reconfiguration of manufacturing processes, reducing downtime and increasing overall productivity. The demand is particularly strong in batch production environments where frequent changes in product specifications require quick adjustments to electrolytic processes.

The oil and gas industry has also shown considerable interest in wireless electrolytic solutions. Offshore platforms and remote drilling sites often face challenges with traditional wired systems due to harsh environmental conditions and the need for frequent equipment relocation. Wireless electrolytic cells provide a more robust and adaptable solution for water treatment and corrosion prevention in these challenging environments.

In the water treatment industry, the demand for wireless electrolytic cells has been driven by the need for more efficient and cost-effective solutions for water purification and desalination. Municipal water treatment plants are increasingly looking to implement these systems to reduce energy consumption and improve the scalability of their operations.

The metal finishing and plating industry has also recognized the potential of wireless electrolytic cells. The ability to precisely control and monitor electroplating processes wirelessly has led to improved quality control and reduced material waste. This has resulted in a growing demand for wireless solutions in both large-scale industrial operations and smaller specialty plating shops.

The electronics manufacturing sector has shown interest in wireless electrolytic cells for applications such as printed circuit board fabrication and semiconductor processing. The demand in this sector is driven by the need for more precise control over electrolytic processes and the ability to integrate these systems into increasingly automated production lines.

As industries continue to embrace Industry 4.0 principles, the demand for wireless electrolytic solutions is expected to grow further. The integration of these systems with IoT platforms and advanced analytics tools is creating new opportunities for process optimization and predictive maintenance, further driving adoption across various industrial sectors.

Current State and Challenges in Wireless Electrolytic Technology

Wireless electrolytic technology has made significant strides in recent years, yet it still faces several challenges in its widespread industrial adoption. The current state of this technology is characterized by a mix of promising advancements and persistent obstacles.

One of the primary achievements in wireless electrolytic cells is the development of efficient power transmission systems. Researchers have successfully demonstrated the ability to transfer energy wirelessly to electrolytic cells, eliminating the need for direct electrical connections. This breakthrough has opened up new possibilities for flexible and mobile industrial applications.

However, the efficiency of wireless power transfer remains a significant challenge. While improvements have been made, the energy loss during transmission is still higher compared to traditional wired systems. This inefficiency can lead to increased operational costs and reduced overall system performance, particularly in large-scale industrial applications.

Another area of progress is the miniaturization of wireless electrolytic cells. Compact designs have been developed, allowing for easier integration into existing industrial processes. These smaller cells offer greater versatility and can be deployed in confined spaces where traditional electrolytic systems would be impractical.

Despite these advancements, the scalability of wireless electrolytic technology remains a hurdle. While small-scale demonstrations have shown promise, scaling up to industrial levels presents significant engineering challenges. Issues such as maintaining uniform power distribution across large arrays of cells and managing heat dissipation in high-power applications need to be addressed.

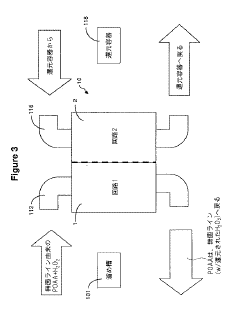

The control and monitoring of wireless electrolytic cells pose another challenge. Without direct electrical connections, traditional methods of monitoring cell performance and controlling electrolysis parameters need to be reimagined. Researchers are exploring advanced sensor technologies and wireless communication protocols to enable real-time monitoring and precise control of these systems.

Material science plays a crucial role in the development of wireless electrolytic cells. The search for more efficient electrode materials and electrolytes that can withstand the unique conditions of wireless operation is ongoing. Innovations in this area could significantly enhance the performance and longevity of these systems.

Regulatory and safety considerations also present challenges to the widespread adoption of wireless electrolytic technology. The use of high-frequency electromagnetic fields for power transmission raises concerns about potential health and environmental impacts. Establishing clear safety guidelines and obtaining regulatory approvals are essential steps for the industry to move forward.

In terms of geographical distribution, research and development in wireless electrolytic technology are primarily concentrated in technologically advanced regions such as North America, Europe, and East Asia. However, there is growing interest from emerging economies looking to leverage this technology for industrial growth and environmental sustainability.

One of the primary achievements in wireless electrolytic cells is the development of efficient power transmission systems. Researchers have successfully demonstrated the ability to transfer energy wirelessly to electrolytic cells, eliminating the need for direct electrical connections. This breakthrough has opened up new possibilities for flexible and mobile industrial applications.

However, the efficiency of wireless power transfer remains a significant challenge. While improvements have been made, the energy loss during transmission is still higher compared to traditional wired systems. This inefficiency can lead to increased operational costs and reduced overall system performance, particularly in large-scale industrial applications.

Another area of progress is the miniaturization of wireless electrolytic cells. Compact designs have been developed, allowing for easier integration into existing industrial processes. These smaller cells offer greater versatility and can be deployed in confined spaces where traditional electrolytic systems would be impractical.

Despite these advancements, the scalability of wireless electrolytic technology remains a hurdle. While small-scale demonstrations have shown promise, scaling up to industrial levels presents significant engineering challenges. Issues such as maintaining uniform power distribution across large arrays of cells and managing heat dissipation in high-power applications need to be addressed.

The control and monitoring of wireless electrolytic cells pose another challenge. Without direct electrical connections, traditional methods of monitoring cell performance and controlling electrolysis parameters need to be reimagined. Researchers are exploring advanced sensor technologies and wireless communication protocols to enable real-time monitoring and precise control of these systems.

Material science plays a crucial role in the development of wireless electrolytic cells. The search for more efficient electrode materials and electrolytes that can withstand the unique conditions of wireless operation is ongoing. Innovations in this area could significantly enhance the performance and longevity of these systems.

Regulatory and safety considerations also present challenges to the widespread adoption of wireless electrolytic technology. The use of high-frequency electromagnetic fields for power transmission raises concerns about potential health and environmental impacts. Establishing clear safety guidelines and obtaining regulatory approvals are essential steps for the industry to move forward.

In terms of geographical distribution, research and development in wireless electrolytic technology are primarily concentrated in technologically advanced regions such as North America, Europe, and East Asia. However, there is growing interest from emerging economies looking to leverage this technology for industrial growth and environmental sustainability.

Existing Wireless Electrolytic Cell Solutions

01 Wireless power transmission for electrolytic cells

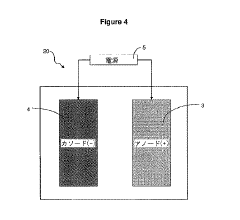

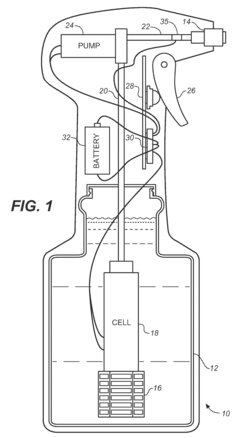

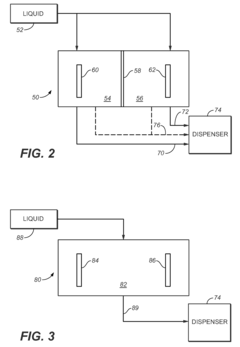

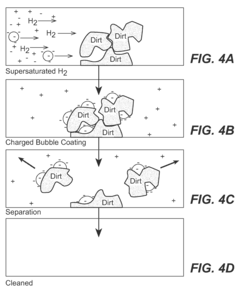

Electrolytic cells can be powered wirelessly using inductive or resonant coupling techniques. This eliminates the need for physical electrical connections, allowing for greater flexibility in cell placement and reducing maintenance issues associated with wired connections. The wireless power transmission system typically consists of a transmitter coil and a receiver coil, with the electrolytic cell connected to the receiver.- Wireless power transmission for electrolytic cells: Electrolytic cells can be powered wirelessly using inductive or resonant coupling techniques. This eliminates the need for physical electrical connections, allowing for greater flexibility in cell placement and reducing maintenance issues associated with wired connections. The wireless power transmission system typically consists of a transmitter coil and a receiver coil, with the electrolytic cell connected to the receiver.

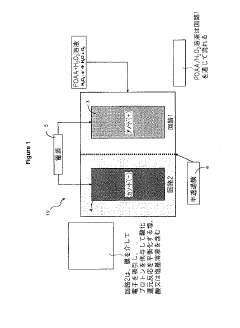

- Remote monitoring and control of wireless electrolytic cells: Wireless communication technologies are integrated into electrolytic cell systems to enable remote monitoring and control. This allows operators to track cell performance, adjust operating parameters, and receive alerts in real-time without being physically present at the cell location. The system may include sensors, microcontrollers, and wireless communication modules to transmit data and receive commands.

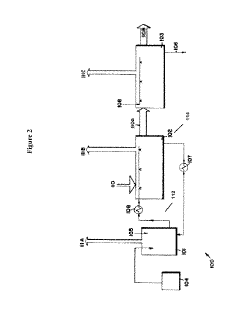

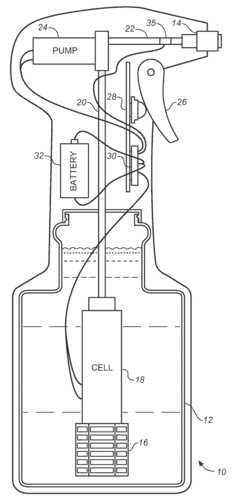

- Portable and modular wireless electrolytic cell designs: Compact and modular electrolytic cell designs incorporate wireless technologies for power and communication. These portable units can be easily deployed in various locations without the need for extensive wiring or infrastructure. The modular nature allows for scalability and easy replacement of components, enhancing overall system flexibility and maintenance.

- Energy harvesting for wireless electrolytic cells: Wireless electrolytic cells can be powered by energy harvesting technologies, such as solar panels, thermoelectric generators, or vibration harvesters. This approach enables the cells to operate autonomously in remote locations without the need for external power sources. The harvested energy is used to drive the electrolysis process and power the wireless communication systems.

- Wireless sensor networks for electrolytic cell arrays: Large-scale electrolytic cell installations can benefit from wireless sensor networks that monitor multiple cells simultaneously. These networks use distributed sensors to collect data on temperature, pressure, electrolyte composition, and other parameters. The data is transmitted wirelessly to a central control system, enabling efficient management of the entire electrolytic process across multiple cells.

02 Remote monitoring and control of wireless electrolytic cells

Wireless communication technologies are integrated into electrolytic cell systems to enable remote monitoring and control. This allows operators to track cell performance, adjust parameters, and respond to issues in real-time without being physically present at the cell location. Sensors collect data on various cell parameters, which is then transmitted wirelessly to a central control system.Expand Specific Solutions03 Portable and modular wireless electrolytic cell designs

Wireless electrolytic cells are designed to be portable and modular, allowing for easy deployment in various settings. These designs often incorporate compact power sources, such as batteries or small fuel cells, along with wireless communication modules. The modular nature enables quick assembly, disassembly, and reconfiguration of electrolytic cell arrays for different applications.Expand Specific Solutions04 Energy harvesting for wireless electrolytic cells

To enhance the autonomy of wireless electrolytic cells, energy harvesting technologies are integrated into the system. These may include solar panels, thermoelectric generators, or piezoelectric devices that capture ambient energy to power the cell or recharge its batteries. This approach reduces or eliminates the need for external power sources, making the cells more self-sufficient and suitable for remote operations.Expand Specific Solutions05 Advanced electrode materials for wireless electrolytic cells

Specialized electrode materials are developed to improve the efficiency and performance of wireless electrolytic cells. These materials may have enhanced conductivity, catalytic properties, or durability to withstand the unique operating conditions of wireless cells. Some electrodes are designed to be more responsive to wireless power transmission, ensuring optimal energy transfer and utilization within the cell.Expand Specific Solutions

Key Players in Wireless Electrolytic Cell Industry

The wireless electrolytic cell technology in industrial systems is in an early development stage, with significant potential for growth. The market size is expanding as industries seek more efficient and flexible electrochemical solutions. While the technology is not yet fully mature, several key players are driving innovation. Companies like Industrie De Nora SpA, Sunfire GmbH, and Primus Power Corp. are at the forefront, developing advanced electrode technologies and energy storage solutions. Academic institutions such as the California Institute of Technology and Fudan University are contributing to fundamental research. The competitive landscape is diverse, with established industrial giants like Ecolab USA, Inc. and Danfoss A/S also exploring applications, indicating growing interest across various sectors.

Asahi Kasei Corp.

Technical Solution: Asahi Kasei Corporation has been actively developing wireless electrolytic cell technology for industrial systems, with a focus on chlor-alkali production and hydrogen generation. Their approach leverages their expertise in membrane technology and electrochemistry to create more efficient and flexible electrolytic systems. Asahi Kasei has developed advanced ion-exchange membranes that can significantly improve the performance of electrolytic cells, reducing energy consumption and increasing product purity[1]. In recent years, the company has been exploring the integration of wireless power transmission techniques with their electrolytic cell designs to enhance operational flexibility and reduce maintenance requirements in industrial settings[2]. Asahi Kasei's research also extends to the development of novel electrode materials and catalysts that can improve the efficiency and durability of wireless electrolytic cells, particularly for applications in water electrolysis and fuel cell technologies[3].

Strengths: Strong expertise in membrane technology and electrochemistry, potential for significant improvements in efficiency and product quality. Weaknesses: May face challenges in adapting existing industrial infrastructure to wireless systems.

Industrie De Nora SpA

Technical Solution: Industrie De Nora SpA has made significant strides in wireless electrolytic cell technology for industrial systems, particularly in the field of chlor-alkali production and water treatment. Their approach focuses on developing advanced electrode materials and coatings that enhance the efficiency and durability of electrolytic cells. De Nora's DSA (Dimensionally Stable Anode) technology has been a game-changer in the industry, offering improved performance and longer lifespan for electrolytic processes[1]. In recent years, the company has been exploring wireless power transmission techniques to further optimize their electrolytic cell designs, potentially reducing maintenance costs and improving operational flexibility in industrial settings[2]. De Nora's research also extends to the development of novel membrane technologies that can be integrated with wireless electrolytic cells to improve selectivity and reduce energy consumption in various industrial applications[3].

Strengths: Extensive experience in electrode technology, potential for significant improvements in efficiency and durability. Weaknesses: May face challenges in adapting existing industrial infrastructure to wireless systems.

Core Innovations in Wireless Electrolytic Cell Design

Electrolytic devices and methods useful in industrial applications

PatentActiveJP2016041270A

Innovation

- The use of electrolytic cells, specifically split cells and single cells, to selectively decompose hydrogen peroxide and peracids in aseptic packaging operations, maintaining optimal ratios of hydrogen peroxide, carboxylic acid, and peracid through electrical means, reducing the need for additional chemicals and monitoring.

Method and apparatus for applying electrical charge through a fluid with a sinusoidal waveform having at step discontinuity

PatentInactiveUS20110121110A1

Innovation

- An apparatus and method that includes an electrode without a corresponding return electrode, generating a sinusoidal voltage waveform with local peaks to create an alternating electric field, and a liquid flow path with an electrolysis cell to produce electrochemically-activated liquids, which are enhanced by an electroporation electrode to apply an additional electrical potential, thereby increasing the sanitization effectiveness.

Energy Efficiency and Sustainability Considerations

The integration of wireless electrolytic cells in industrial systems presents significant opportunities for enhancing energy efficiency and promoting sustainability. These innovative devices offer a range of benefits that align with the growing global emphasis on reducing carbon footprints and optimizing resource utilization in industrial processes.

One of the primary advantages of wireless electrolytic cells is their potential to minimize energy losses associated with traditional wired systems. By eliminating the need for physical connections, these cells can reduce resistance and improve overall energy transfer efficiency. This translates to lower power consumption and decreased operational costs for industrial facilities, contributing to both economic and environmental sustainability.

Furthermore, wireless electrolytic cells enable more flexible and adaptable industrial setups. The absence of wired connections allows for easier reconfiguration of production lines and equipment, reducing downtime and enhancing overall system efficiency. This flexibility also facilitates the integration of renewable energy sources, as wireless cells can be more readily connected to intermittent power supplies such as solar or wind energy.

The implementation of wireless electrolytic cells can lead to significant reductions in material waste. Traditional wired systems often require extensive cabling and connectors, which not only consume resources during production but also contribute to electronic waste at the end of their lifecycle. Wireless solutions minimize these material requirements, aligning with circular economy principles and reducing the environmental impact of industrial operations.

In terms of maintenance and longevity, wireless electrolytic cells offer advantages that contribute to sustainability. The elimination of physical connections reduces wear and tear, potentially extending the lifespan of equipment and decreasing the frequency of replacements. This not only conserves resources but also minimizes the environmental impact associated with manufacturing and disposing of industrial components.

The potential for improved process control and monitoring through wireless electrolytic cells can lead to optimized resource utilization. Real-time data transmission and analysis enable more precise adjustments to industrial processes, reducing waste and improving overall efficiency. This data-driven approach supports the development of smarter, more sustainable industrial practices.

As industries strive to meet increasingly stringent environmental regulations and sustainability targets, the adoption of wireless electrolytic cells represents a promising avenue for progress. By enhancing energy efficiency, reducing material waste, and enabling more flexible and optimized operations, these innovative devices align closely with the principles of sustainable industrial development and the global transition towards cleaner, more efficient production methods.

One of the primary advantages of wireless electrolytic cells is their potential to minimize energy losses associated with traditional wired systems. By eliminating the need for physical connections, these cells can reduce resistance and improve overall energy transfer efficiency. This translates to lower power consumption and decreased operational costs for industrial facilities, contributing to both economic and environmental sustainability.

Furthermore, wireless electrolytic cells enable more flexible and adaptable industrial setups. The absence of wired connections allows for easier reconfiguration of production lines and equipment, reducing downtime and enhancing overall system efficiency. This flexibility also facilitates the integration of renewable energy sources, as wireless cells can be more readily connected to intermittent power supplies such as solar or wind energy.

The implementation of wireless electrolytic cells can lead to significant reductions in material waste. Traditional wired systems often require extensive cabling and connectors, which not only consume resources during production but also contribute to electronic waste at the end of their lifecycle. Wireless solutions minimize these material requirements, aligning with circular economy principles and reducing the environmental impact of industrial operations.

In terms of maintenance and longevity, wireless electrolytic cells offer advantages that contribute to sustainability. The elimination of physical connections reduces wear and tear, potentially extending the lifespan of equipment and decreasing the frequency of replacements. This not only conserves resources but also minimizes the environmental impact associated with manufacturing and disposing of industrial components.

The potential for improved process control and monitoring through wireless electrolytic cells can lead to optimized resource utilization. Real-time data transmission and analysis enable more precise adjustments to industrial processes, reducing waste and improving overall efficiency. This data-driven approach supports the development of smarter, more sustainable industrial practices.

As industries strive to meet increasingly stringent environmental regulations and sustainability targets, the adoption of wireless electrolytic cells represents a promising avenue for progress. By enhancing energy efficiency, reducing material waste, and enabling more flexible and optimized operations, these innovative devices align closely with the principles of sustainable industrial development and the global transition towards cleaner, more efficient production methods.

Safety and Regulatory Compliance for Industrial Implementation

The implementation of wireless electrolytic cells in industrial systems necessitates a comprehensive approach to safety and regulatory compliance. As this technology advances, it is crucial to address potential risks and ensure adherence to established standards and regulations.

One of the primary safety concerns in wireless electrolytic cells is the management of electromagnetic radiation. Industrial systems must comply with electromagnetic compatibility (EMC) standards to prevent interference with other equipment and ensure worker safety. This includes adherence to guidelines set by organizations such as the International Electrotechnical Commission (IEC) and the Federal Communications Commission (FCC).

Chemical safety is another critical aspect, particularly in industries dealing with hazardous materials. The wireless nature of these cells may introduce new challenges in containing and monitoring electrolytes. Compliance with regulations such as REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) in the European Union and OSHA (Occupational Safety and Health Administration) standards in the United States is essential.

Explosion protection is a significant consideration, especially in industries where flammable gases or dust may be present. Wireless electrolytic cells must be designed and implemented in accordance with ATEX directives in the EU or equivalent standards in other regions to prevent potential ignition sources.

Data security and privacy regulations also play a crucial role in the implementation of wireless electrolytic cells. As these systems often involve the transmission of sensitive industrial data, compliance with regulations such as GDPR (General Data Protection Regulation) in the EU or industry-specific standards like NIST (National Institute of Standards and Technology) guidelines is necessary to protect against cyber threats and data breaches.

Environmental regulations must be considered, particularly regarding the disposal of electrolytes and other materials used in these systems. Compliance with waste management regulations and environmental protection standards, such as those set by the Environmental Protection Agency (EPA) in the United States, is crucial for sustainable implementation.

To ensure ongoing compliance and safety, regular risk assessments and audits should be conducted. This includes evaluating the potential impact of wireless electrolytic cells on existing safety systems and updating emergency response protocols accordingly. Training programs for personnel working with or around these systems should be developed and implemented to maintain a high level of safety awareness and regulatory compliance.

As the technology evolves, it is important to stay abreast of changes in regulations and standards. Participation in industry working groups and collaboration with regulatory bodies can help shape future guidelines and ensure that safety and compliance measures keep pace with technological advancements in wireless electrolytic cells for industrial applications.

One of the primary safety concerns in wireless electrolytic cells is the management of electromagnetic radiation. Industrial systems must comply with electromagnetic compatibility (EMC) standards to prevent interference with other equipment and ensure worker safety. This includes adherence to guidelines set by organizations such as the International Electrotechnical Commission (IEC) and the Federal Communications Commission (FCC).

Chemical safety is another critical aspect, particularly in industries dealing with hazardous materials. The wireless nature of these cells may introduce new challenges in containing and monitoring electrolytes. Compliance with regulations such as REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) in the European Union and OSHA (Occupational Safety and Health Administration) standards in the United States is essential.

Explosion protection is a significant consideration, especially in industries where flammable gases or dust may be present. Wireless electrolytic cells must be designed and implemented in accordance with ATEX directives in the EU or equivalent standards in other regions to prevent potential ignition sources.

Data security and privacy regulations also play a crucial role in the implementation of wireless electrolytic cells. As these systems often involve the transmission of sensitive industrial data, compliance with regulations such as GDPR (General Data Protection Regulation) in the EU or industry-specific standards like NIST (National Institute of Standards and Technology) guidelines is necessary to protect against cyber threats and data breaches.

Environmental regulations must be considered, particularly regarding the disposal of electrolytes and other materials used in these systems. Compliance with waste management regulations and environmental protection standards, such as those set by the Environmental Protection Agency (EPA) in the United States, is crucial for sustainable implementation.

To ensure ongoing compliance and safety, regular risk assessments and audits should be conducted. This includes evaluating the potential impact of wireless electrolytic cells on existing safety systems and updating emergency response protocols accordingly. Training programs for personnel working with or around these systems should be developed and implemented to maintain a high level of safety awareness and regulatory compliance.

As the technology evolves, it is important to stay abreast of changes in regulations and standards. Participation in industry working groups and collaboration with regulatory bodies can help shape future guidelines and ensure that safety and compliance measures keep pace with technological advancements in wireless electrolytic cells for industrial applications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!