Electrolytic Cell Applications in the Textile Industry

AUG 1, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Electrolytic Textile Tech Evolution and Objectives

Electrolytic cell applications in the textile industry have undergone significant evolution over the past decades, driven by the need for more sustainable and efficient production processes. The journey began with basic electrochemical treatments for fabric finishing and has progressed to sophisticated systems for dyeing, wastewater treatment, and even smart textile production.

The primary objective of electrolytic cell technology in textiles is to enhance the quality, durability, and functionality of fabrics while minimizing environmental impact. Early applications focused on improving the colorfastness and wrinkle resistance of fabrics through electrochemical treatments. As environmental concerns grew, the technology evolved to address wastewater treatment, aiming to reduce the industry's water footprint and chemical discharge.

In recent years, the focus has shifted towards developing more advanced applications. These include electrochemical dyeing processes that significantly reduce water and chemical usage compared to traditional methods. Another emerging area is the production of conductive textiles for smart wearables, utilizing electrolytic processes to incorporate conductive materials into fabric structures.

The evolution of this technology has been marked by several key milestones. The introduction of electrolytic desizing in the 1980s marked a significant improvement in fabric preparation. The 1990s saw the development of electrochemical bleaching techniques, which offered a more environmentally friendly alternative to conventional methods. The early 2000s brought about electrolytic dyeing processes, revolutionizing the industry's approach to coloration.

Looking ahead, the objectives for electrolytic cell applications in textiles are multifaceted. There is a strong push towards developing zero-discharge systems, where all chemicals and water are recycled within a closed-loop process. Another goal is to perfect electrochemical finishing techniques that can impart multiple functionalities to fabrics in a single step, such as water repellency, flame resistance, and antimicrobial properties.

Researchers are also exploring the potential of electrolytic cells in creating self-cleaning fabrics and textiles with adaptive properties. These innovations could lead to garments that change color or thermal properties in response to environmental stimuli, opening up new possibilities in fashion and protective clothing.

As the textile industry continues to face pressure to reduce its environmental impact, electrolytic cell technology is expected to play an increasingly crucial role. The ultimate aim is to transform textile manufacturing into a more sustainable, efficient, and innovative process, aligning with global sustainability goals while meeting the ever-evolving demands of consumers for high-performance, eco-friendly textiles.

The primary objective of electrolytic cell technology in textiles is to enhance the quality, durability, and functionality of fabrics while minimizing environmental impact. Early applications focused on improving the colorfastness and wrinkle resistance of fabrics through electrochemical treatments. As environmental concerns grew, the technology evolved to address wastewater treatment, aiming to reduce the industry's water footprint and chemical discharge.

In recent years, the focus has shifted towards developing more advanced applications. These include electrochemical dyeing processes that significantly reduce water and chemical usage compared to traditional methods. Another emerging area is the production of conductive textiles for smart wearables, utilizing electrolytic processes to incorporate conductive materials into fabric structures.

The evolution of this technology has been marked by several key milestones. The introduction of electrolytic desizing in the 1980s marked a significant improvement in fabric preparation. The 1990s saw the development of electrochemical bleaching techniques, which offered a more environmentally friendly alternative to conventional methods. The early 2000s brought about electrolytic dyeing processes, revolutionizing the industry's approach to coloration.

Looking ahead, the objectives for electrolytic cell applications in textiles are multifaceted. There is a strong push towards developing zero-discharge systems, where all chemicals and water are recycled within a closed-loop process. Another goal is to perfect electrochemical finishing techniques that can impart multiple functionalities to fabrics in a single step, such as water repellency, flame resistance, and antimicrobial properties.

Researchers are also exploring the potential of electrolytic cells in creating self-cleaning fabrics and textiles with adaptive properties. These innovations could lead to garments that change color or thermal properties in response to environmental stimuli, opening up new possibilities in fashion and protective clothing.

As the textile industry continues to face pressure to reduce its environmental impact, electrolytic cell technology is expected to play an increasingly crucial role. The ultimate aim is to transform textile manufacturing into a more sustainable, efficient, and innovative process, aligning with global sustainability goals while meeting the ever-evolving demands of consumers for high-performance, eco-friendly textiles.

Textile Industry Demand for Electrolytic Processes

The textile industry has shown a growing demand for electrolytic processes in recent years, driven by the need for more sustainable and efficient production methods. Electrolytic cells have emerged as a promising technology in various textile manufacturing stages, offering significant advantages over traditional chemical processes.

One of the primary areas where electrolytic processes are gaining traction is in textile dyeing and finishing. The conventional dyeing process is known for its high water consumption and chemical usage, leading to environmental concerns. Electrolytic cells provide an alternative approach by generating reactive species in-situ, reducing the need for harmful chemicals and minimizing water usage. This not only addresses environmental issues but also improves the overall efficiency of the dyeing process.

In textile wastewater treatment, electrolytic processes have shown remarkable potential. The textile industry is one of the largest producers of industrial wastewater, often containing complex mixtures of dyes, chemicals, and other pollutants. Electrolytic treatment methods, such as electrocoagulation and electrooxidation, have demonstrated high efficacy in removing color, reducing chemical oxygen demand (COD), and eliminating toxic compounds from textile effluents. These processes offer a more compact and less chemical-intensive alternative to traditional wastewater treatment methods.

The demand for electrolytic processes in textile bleaching is also on the rise. Conventional bleaching methods often rely on harsh chemicals like hydrogen peroxide or chlorine-based compounds. Electrolytic bleaching, on the other hand, generates bleaching agents on-site through the electrolysis of water or salt solutions. This approach not only reduces the transportation and storage of hazardous chemicals but also allows for better control over the bleaching process, resulting in improved fabric quality and reduced environmental impact.

Another area where electrolytic cells are gaining attention is in the production of functional textiles. Electrochemical processes can be used to deposit conductive materials or functional coatings on textile surfaces, enabling the creation of smart textiles with properties such as electrical conductivity, antimicrobial activity, or enhanced durability. This aligns with the growing market demand for high-performance and multifunctional textiles in various applications, including sportswear, medical textiles, and protective clothing.

The increasing focus on circular economy principles in the textile industry has further boosted the demand for electrolytic processes. These technologies offer potential solutions for textile recycling and upcycling, such as the electrochemical separation of blended fabrics or the recovery of valuable materials from textile waste. As sustainability becomes a key driver in the industry, the adoption of electrolytic processes is expected to accelerate, supporting the transition towards more environmentally friendly and resource-efficient textile production.

One of the primary areas where electrolytic processes are gaining traction is in textile dyeing and finishing. The conventional dyeing process is known for its high water consumption and chemical usage, leading to environmental concerns. Electrolytic cells provide an alternative approach by generating reactive species in-situ, reducing the need for harmful chemicals and minimizing water usage. This not only addresses environmental issues but also improves the overall efficiency of the dyeing process.

In textile wastewater treatment, electrolytic processes have shown remarkable potential. The textile industry is one of the largest producers of industrial wastewater, often containing complex mixtures of dyes, chemicals, and other pollutants. Electrolytic treatment methods, such as electrocoagulation and electrooxidation, have demonstrated high efficacy in removing color, reducing chemical oxygen demand (COD), and eliminating toxic compounds from textile effluents. These processes offer a more compact and less chemical-intensive alternative to traditional wastewater treatment methods.

The demand for electrolytic processes in textile bleaching is also on the rise. Conventional bleaching methods often rely on harsh chemicals like hydrogen peroxide or chlorine-based compounds. Electrolytic bleaching, on the other hand, generates bleaching agents on-site through the electrolysis of water or salt solutions. This approach not only reduces the transportation and storage of hazardous chemicals but also allows for better control over the bleaching process, resulting in improved fabric quality and reduced environmental impact.

Another area where electrolytic cells are gaining attention is in the production of functional textiles. Electrochemical processes can be used to deposit conductive materials or functional coatings on textile surfaces, enabling the creation of smart textiles with properties such as electrical conductivity, antimicrobial activity, or enhanced durability. This aligns with the growing market demand for high-performance and multifunctional textiles in various applications, including sportswear, medical textiles, and protective clothing.

The increasing focus on circular economy principles in the textile industry has further boosted the demand for electrolytic processes. These technologies offer potential solutions for textile recycling and upcycling, such as the electrochemical separation of blended fabrics or the recovery of valuable materials from textile waste. As sustainability becomes a key driver in the industry, the adoption of electrolytic processes is expected to accelerate, supporting the transition towards more environmentally friendly and resource-efficient textile production.

Current Electrolytic Cell Challenges in Textiles

The textile industry faces several significant challenges in the application of electrolytic cells, which are crucial for various processes such as dyeing, finishing, and wastewater treatment. One of the primary issues is the high energy consumption associated with electrolytic processes. The electricity required to drive these reactions contributes substantially to operational costs and environmental impact, making it difficult for textile manufacturers to balance efficiency with sustainability goals.

Another major challenge is the complexity of controlling electrolytic reactions in textile applications. The diverse range of fabrics, dyes, and chemicals used in the industry requires precise control over parameters such as current density, electrode materials, and electrolyte composition. Achieving consistent results across different textile substrates and processes remains a significant hurdle for many manufacturers.

Electrode degradation and fouling present ongoing challenges in electrolytic cell applications. The harsh chemical environment in textile processing can lead to rapid deterioration of electrode materials, reducing efficiency and increasing maintenance costs. Additionally, the accumulation of organic and inorganic deposits on electrode surfaces can impair performance and necessitate frequent cleaning or replacement.

The generation of unwanted by-products during electrolytic processes is another concern. In some cases, these by-products can interfere with textile quality or pose environmental risks if not properly managed. For instance, the production of chlorine gas during electrolysis of chloride-containing solutions requires careful handling and safety measures.

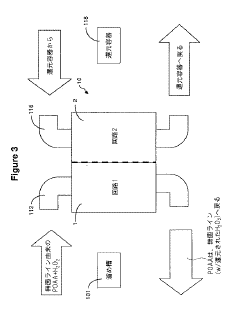

Scale-up and integration of electrolytic cells into existing textile production lines present technical and logistical challenges. Many promising laboratory-scale electrolytic technologies struggle to maintain their effectiveness when scaled to industrial levels. Furthermore, retrofitting existing facilities with new electrolytic systems often requires significant investment and process modifications.

Water and electrolyte management is a critical issue, particularly in water-scarce regions. Electrolytic processes in textiles often require large volumes of water and electrolytes, which must be carefully managed to minimize waste and environmental impact. Developing closed-loop systems for water and electrolyte recycling remains a significant challenge for the industry.

Lastly, the lack of standardization in electrolytic cell technologies for textile applications hinders widespread adoption. The absence of industry-wide best practices and performance benchmarks makes it difficult for manufacturers to evaluate and implement new electrolytic solutions confidently. This challenge is compounded by the rapid pace of technological development in the field, which can lead to uncertainty about long-term investments in specific electrolytic technologies.

Another major challenge is the complexity of controlling electrolytic reactions in textile applications. The diverse range of fabrics, dyes, and chemicals used in the industry requires precise control over parameters such as current density, electrode materials, and electrolyte composition. Achieving consistent results across different textile substrates and processes remains a significant hurdle for many manufacturers.

Electrode degradation and fouling present ongoing challenges in electrolytic cell applications. The harsh chemical environment in textile processing can lead to rapid deterioration of electrode materials, reducing efficiency and increasing maintenance costs. Additionally, the accumulation of organic and inorganic deposits on electrode surfaces can impair performance and necessitate frequent cleaning or replacement.

The generation of unwanted by-products during electrolytic processes is another concern. In some cases, these by-products can interfere with textile quality or pose environmental risks if not properly managed. For instance, the production of chlorine gas during electrolysis of chloride-containing solutions requires careful handling and safety measures.

Scale-up and integration of electrolytic cells into existing textile production lines present technical and logistical challenges. Many promising laboratory-scale electrolytic technologies struggle to maintain their effectiveness when scaled to industrial levels. Furthermore, retrofitting existing facilities with new electrolytic systems often requires significant investment and process modifications.

Water and electrolyte management is a critical issue, particularly in water-scarce regions. Electrolytic processes in textiles often require large volumes of water and electrolytes, which must be carefully managed to minimize waste and environmental impact. Developing closed-loop systems for water and electrolyte recycling remains a significant challenge for the industry.

Lastly, the lack of standardization in electrolytic cell technologies for textile applications hinders widespread adoption. The absence of industry-wide best practices and performance benchmarks makes it difficult for manufacturers to evaluate and implement new electrolytic solutions confidently. This challenge is compounded by the rapid pace of technological development in the field, which can lead to uncertainty about long-term investments in specific electrolytic technologies.

Current Electrolytic Cell Applications in Textiles

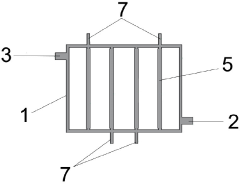

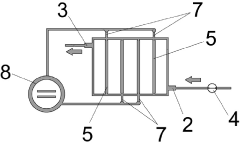

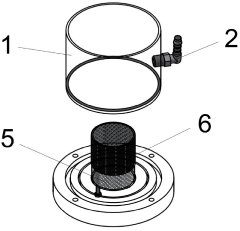

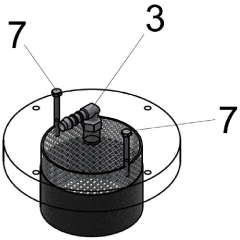

01 Design and structure of electrolytic cells

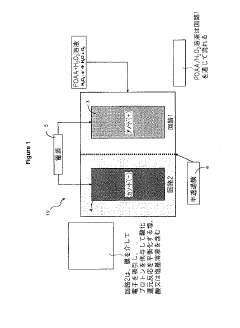

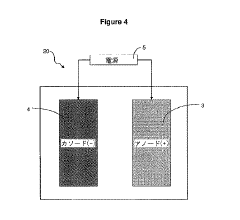

Electrolytic cells are designed with specific structures to facilitate the electrolysis process. These designs may include various components such as electrodes, membranes, and electrolyte chambers. The structure of the cell can significantly impact its efficiency and performance in different applications.- Design and structure of electrolytic cells: Electrolytic cells are designed with specific structures to facilitate efficient electrolysis. This includes the arrangement of electrodes, separation of anode and cathode compartments, and incorporation of membranes or diaphragms. The design aims to optimize the electrochemical process, enhance product yield, and minimize energy consumption.

- Electrode materials and configurations: The choice of electrode materials and their configurations play a crucial role in electrolytic cell performance. Various materials such as metals, alloys, and coated electrodes are used to enhance conductivity, catalytic activity, and durability. Electrode configurations may include planar, mesh, or three-dimensional structures to maximize surface area and reaction efficiency.

- Electrolyte composition and management: The composition of the electrolyte solution is critical for the operation of electrolytic cells. This includes selecting appropriate ionic species, maintaining optimal concentration, and managing pH levels. Electrolyte management systems may involve circulation, purification, and replenishment to ensure consistent cell performance and product quality.

- Control and monitoring systems: Advanced control and monitoring systems are implemented in electrolytic cells to optimize performance and ensure safety. These systems regulate parameters such as current density, voltage, temperature, and electrolyte flow. Real-time monitoring and data analysis enable precise control of the electrolysis process and early detection of potential issues.

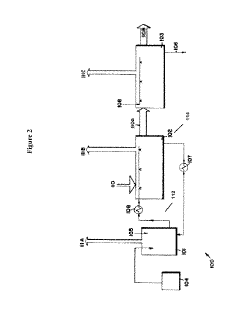

- Applications and specialized electrolytic cells: Electrolytic cells are used in various applications, including water treatment, metal production, and energy storage. Specialized cells are designed for specific processes such as chlor-alkali production, electroplating, and fuel cell technologies. These cells may incorporate unique features to address the requirements of their particular applications.

02 Electrode materials and configurations

The choice of electrode materials and their configurations play a crucial role in electrolytic cells. Different materials and designs can enhance conductivity, catalytic activity, and durability. Innovations in electrode technology focus on improving efficiency and reducing costs in various electrochemical processes.Expand Specific Solutions03 Electrolyte composition and management

The composition and management of electrolytes are essential for optimal cell performance. This includes developing new electrolyte formulations, maintaining electrolyte balance, and managing electrolyte circulation within the cell. Proper electrolyte management can enhance reaction rates and overall cell efficiency.Expand Specific Solutions04 Control systems and monitoring

Advanced control systems and monitoring techniques are employed in electrolytic cells to optimize performance and ensure safety. These may include sensors for measuring various parameters, automated control mechanisms, and data analysis systems for real-time monitoring and adjustment of cell operations.Expand Specific Solutions05 Applications and specialized cell designs

Electrolytic cells are used in a wide range of applications, each requiring specialized designs. This includes cells for water treatment, metal production, energy storage, and chemical synthesis. Specialized designs may incorporate features such as high-pressure operation, temperature control, or integration with other processes.Expand Specific Solutions

Key Players in Textile Electrolytic Solutions

The electrolytic cell applications in the textile industry are in a growth phase, with increasing market size driven by sustainability demands. The technology is moderately mature, with established players like Novozymes A/S and Industrie De Nora SpA leading innovation. Emerging companies such as Ludao Hydrogen Energy and Nantong Sumin New Energy are entering the market, focusing on specialized applications. The competitive landscape is diverse, including chemical manufacturers like Evonik and Covestro, as well as textile-specific firms like Bursali Tekstil. Research institutions and universities are also contributing to technological advancements, indicating ongoing development potential in this field.

Archroma IP GmbH

Technical Solution: Archroma IP GmbH has pioneered the use of electrolytic cell technology in sustainable textile dyeing and finishing processes. Their innovative approach involves electrochemical treatment of textile effluents, significantly reducing water consumption and chemical usage[4]. Archroma's electrolytic cells are designed to generate active species in-situ, which can be used for bleaching, dye fixation, and fabric treatment. This technology allows for the reuse of process water, minimizing environmental impact. The company has also developed electrolytic systems for color removal from textile wastewater, achieving high decolorization rates while reducing sludge production[5]. Archroma's electrolytic cell applications extend to the production of eco-friendly dyes and auxiliaries, contributing to a more sustainable textile industry.

Strengths: Significant reduction in water and chemical usage, improved sustainability in textile processing. Weaknesses: May require specialized training for operators and potential limitations in treating certain types of dyes or fabrics.

Industrie De Nora SpA

Technical Solution: Industrie De Nora SpA has developed advanced electrolytic cell technologies for textile industry applications. Their systems utilize dimensionally stable anodes (DSA) and membrane cell technology to produce chlorine and caustic soda, essential chemicals in textile processing[1]. The company's electrolyzers feature high current efficiency, low energy consumption, and long-lasting electrodes, enabling sustainable textile production. De Nora's electrolytic cells can be integrated into existing textile manufacturing processes, allowing for on-site generation of bleaching agents and other chemicals, reducing transportation costs and environmental impact[2]. The company has also introduced novel electrode coatings that enhance the efficiency of electrolytic processes in textile wastewater treatment, effectively removing dyes and other pollutants[3].

Strengths: High efficiency, reduced energy consumption, and on-site chemical production capabilities. Weaknesses: Initial investment costs may be high, and integration into existing systems can be complex.

Innovative Electrolytic Cell Patents for Textiles

Electrochemical cell for the treatment of wastewater and electrochemical process of surface modification of the textile electrode contained in said electrochemical cell

PatentActiveES2900851A1

Innovation

- An electrochemical cell utilizing surface-modified textile electrodes with electrochemically reduced graphene oxide and metal nanoparticles, which enhance the area/mass and area/volume ratios, allowing for efficient discoloration and organic load reduction with reduced energy consumption.

Electrolytic devices and methods useful in industrial applications

PatentActiveJP2016041270A

Innovation

- The use of electrolytic cells, specifically split cells and single cells, to selectively decompose hydrogen peroxide and peracids in aseptic packaging operations, maintaining optimal ratios of hydrogen peroxide, carboxylic acid, and peracid through electrical means, reducing the need for additional chemicals and monitoring.

Environmental Impact of Textile Electrolytic Processes

The environmental impact of textile electrolytic processes is a critical consideration in the adoption and implementation of these technologies within the textile industry. Electrolytic processes, while offering significant benefits in terms of efficiency and product quality, can also pose potential risks to the environment if not properly managed.

One of the primary environmental concerns associated with textile electrolytic processes is water pollution. These processes often involve the use of various chemicals and electrolytes, which can result in the discharge of contaminated wastewater. The effluents may contain heavy metals, dyes, and other pollutants that can harm aquatic ecosystems if released untreated into water bodies. To mitigate this issue, many textile manufacturers have implemented advanced wastewater treatment systems, including membrane filtration and chemical precipitation techniques, to remove harmful substances before discharge.

Energy consumption is another significant environmental factor to consider. Electrolytic processes typically require substantial amounts of electricity, contributing to increased carbon emissions if the energy source is not renewable. However, advancements in electrode materials and cell designs have led to improved energy efficiency in recent years, reducing the overall environmental footprint of these processes.

The generation of gaseous emissions during electrolytic processes is also a concern. Depending on the specific application, these emissions may include chlorine, hydrogen, or other potentially harmful gases. Proper ventilation systems and gas capture technologies are essential to minimize the release of these substances into the atmosphere and ensure worker safety.

Solid waste management is an additional environmental challenge associated with textile electrolytic processes. The disposal of spent electrodes, membranes, and other process-related materials requires careful consideration to prevent soil contamination and reduce landfill usage. Many companies are now exploring recycling and regeneration techniques for these materials to promote a more circular economy approach.

Despite these challenges, electrolytic processes in the textile industry also offer potential environmental benefits. For instance, they can reduce the need for certain chemical treatments, leading to a decrease in overall chemical consumption and associated environmental impacts. Additionally, electrolytic technologies often enable more precise control over dyeing and finishing processes, resulting in reduced water and energy usage compared to traditional methods.

As the textile industry continues to evolve, there is a growing focus on developing more sustainable electrolytic processes. Research efforts are underway to explore bio-based electrolytes, advanced electrode materials, and innovative cell designs that minimize environmental impact while maintaining or improving process efficiency. These developments, coupled with stricter environmental regulations and increased consumer demand for sustainable products, are driving the industry towards more environmentally friendly electrolytic solutions.

One of the primary environmental concerns associated with textile electrolytic processes is water pollution. These processes often involve the use of various chemicals and electrolytes, which can result in the discharge of contaminated wastewater. The effluents may contain heavy metals, dyes, and other pollutants that can harm aquatic ecosystems if released untreated into water bodies. To mitigate this issue, many textile manufacturers have implemented advanced wastewater treatment systems, including membrane filtration and chemical precipitation techniques, to remove harmful substances before discharge.

Energy consumption is another significant environmental factor to consider. Electrolytic processes typically require substantial amounts of electricity, contributing to increased carbon emissions if the energy source is not renewable. However, advancements in electrode materials and cell designs have led to improved energy efficiency in recent years, reducing the overall environmental footprint of these processes.

The generation of gaseous emissions during electrolytic processes is also a concern. Depending on the specific application, these emissions may include chlorine, hydrogen, or other potentially harmful gases. Proper ventilation systems and gas capture technologies are essential to minimize the release of these substances into the atmosphere and ensure worker safety.

Solid waste management is an additional environmental challenge associated with textile electrolytic processes. The disposal of spent electrodes, membranes, and other process-related materials requires careful consideration to prevent soil contamination and reduce landfill usage. Many companies are now exploring recycling and regeneration techniques for these materials to promote a more circular economy approach.

Despite these challenges, electrolytic processes in the textile industry also offer potential environmental benefits. For instance, they can reduce the need for certain chemical treatments, leading to a decrease in overall chemical consumption and associated environmental impacts. Additionally, electrolytic technologies often enable more precise control over dyeing and finishing processes, resulting in reduced water and energy usage compared to traditional methods.

As the textile industry continues to evolve, there is a growing focus on developing more sustainable electrolytic processes. Research efforts are underway to explore bio-based electrolytes, advanced electrode materials, and innovative cell designs that minimize environmental impact while maintaining or improving process efficiency. These developments, coupled with stricter environmental regulations and increased consumer demand for sustainable products, are driving the industry towards more environmentally friendly electrolytic solutions.

Regulatory Framework for Textile Electrolytic Tech

The regulatory framework for electrolytic cell applications in the textile industry is complex and multifaceted, encompassing environmental, safety, and quality standards. At the international level, organizations such as the International Organization for Standardization (ISO) and the World Trade Organization (WTO) play crucial roles in setting global standards and facilitating trade in textile products.

Environmental regulations are particularly stringent for electrolytic processes in textiles due to their potential impact on water resources. The European Union's REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) regulation is a prime example, requiring manufacturers to register and assess the safety of chemicals used in their processes, including those in electrolytic treatments. Similarly, the United States Environmental Protection Agency (EPA) enforces the Clean Water Act, which regulates the discharge of pollutants from textile facilities, including those using electrolytic technologies.

Occupational health and safety regulations also significantly impact the implementation of electrolytic cell applications in textiles. The Occupational Safety and Health Administration (OSHA) in the United States and the European Agency for Safety and Health at Work (EU-OSHA) mandate strict safety protocols for workers handling electrolytic processes, including proper ventilation, personal protective equipment, and emergency response procedures.

Quality standards for textile products treated with electrolytic processes are governed by various national and international bodies. The American Association of Textile Chemists and Colorists (AATCC) and the European Committee for Standardization (CEN) provide specific test methods and quality benchmarks for electrolytically treated textiles, ensuring consistency and reliability in the final products.

Emerging regulations are focusing on sustainability and circular economy principles. The EU's Circular Economy Action Plan, for instance, is pushing for more sustainable textile production methods, which may influence the adoption and development of electrolytic technologies that reduce water and chemical usage. Additionally, countries like China, a major textile producer, have implemented stricter environmental regulations through their Five-Year Plans, directly impacting the use of electrolytic processes in textile manufacturing.

As the industry evolves, regulatory bodies are increasingly emphasizing the need for transparency and traceability in textile supply chains. This trend is likely to affect how electrolytic cell applications are documented and reported throughout the production process, potentially leading to new compliance requirements for manufacturers utilizing these technologies.

Environmental regulations are particularly stringent for electrolytic processes in textiles due to their potential impact on water resources. The European Union's REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) regulation is a prime example, requiring manufacturers to register and assess the safety of chemicals used in their processes, including those in electrolytic treatments. Similarly, the United States Environmental Protection Agency (EPA) enforces the Clean Water Act, which regulates the discharge of pollutants from textile facilities, including those using electrolytic technologies.

Occupational health and safety regulations also significantly impact the implementation of electrolytic cell applications in textiles. The Occupational Safety and Health Administration (OSHA) in the United States and the European Agency for Safety and Health at Work (EU-OSHA) mandate strict safety protocols for workers handling electrolytic processes, including proper ventilation, personal protective equipment, and emergency response procedures.

Quality standards for textile products treated with electrolytic processes are governed by various national and international bodies. The American Association of Textile Chemists and Colorists (AATCC) and the European Committee for Standardization (CEN) provide specific test methods and quality benchmarks for electrolytically treated textiles, ensuring consistency and reliability in the final products.

Emerging regulations are focusing on sustainability and circular economy principles. The EU's Circular Economy Action Plan, for instance, is pushing for more sustainable textile production methods, which may influence the adoption and development of electrolytic technologies that reduce water and chemical usage. Additionally, countries like China, a major textile producer, have implemented stricter environmental regulations through their Five-Year Plans, directly impacting the use of electrolytic processes in textile manufacturing.

As the industry evolves, regulatory bodies are increasingly emphasizing the need for transparency and traceability in textile supply chains. This trend is likely to affect how electrolytic cell applications are documented and reported throughout the production process, potentially leading to new compliance requirements for manufacturers utilizing these technologies.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!