How Closed-Loop Systems Improve Electrolytic Cell Efficiency

AUG 1, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Electrolytic Efficiency Goals

Electrolytic efficiency goals in closed-loop systems are primarily focused on maximizing the conversion of electrical energy into desired chemical products while minimizing energy losses and resource consumption. These goals are driven by the increasing demand for sustainable and cost-effective industrial processes, particularly in sectors such as chlor-alkali production, metal refining, and water treatment.

One of the key objectives is to reduce the overall energy consumption per unit of product output. This involves optimizing the cell voltage, current density, and electrode materials to minimize the overpotential required for the electrolytic reactions. By lowering the energy input while maintaining or increasing production rates, industries can significantly improve their operational efficiency and reduce costs.

Another critical goal is to enhance the selectivity of the electrolytic process. This means maximizing the production of desired compounds while minimizing the formation of unwanted by-products. Improved selectivity not only increases the yield of valuable products but also reduces the need for downstream purification processes, further contributing to overall system efficiency.

Closed-loop systems aim to achieve near-zero discharge of process streams, which is crucial for both environmental protection and resource conservation. This goal involves developing advanced separation and recycling technologies to recover and reuse electrolytes, catalysts, and other valuable components from the process streams. By minimizing waste and maximizing resource utilization, these systems can significantly reduce raw material costs and environmental impact.

Longevity and stability of electrolytic cells are also key efficiency goals. Extending the operational lifetime of electrodes, membranes, and other cell components reduces downtime for maintenance and replacement, thereby increasing overall system productivity. This involves developing more durable materials and optimizing operating conditions to minimize degradation and fouling of cell components.

Real-time monitoring and control of electrolytic processes are essential for maintaining optimal efficiency. Goals in this area include the development of advanced sensors and control systems that can rapidly adjust operating parameters in response to changing conditions. This enables continuous optimization of the electrolytic process, ensuring that the system operates at peak efficiency under varying loads and feedstock compositions.

Lastly, there is a growing focus on integrating renewable energy sources into electrolytic processes. The goal is to develop flexible systems that can efficiently utilize intermittent renewable power while maintaining stable operation. This includes developing energy storage solutions and smart grid integration strategies to balance supply and demand, ultimately leading to more sustainable and carbon-neutral electrolytic processes.

One of the key objectives is to reduce the overall energy consumption per unit of product output. This involves optimizing the cell voltage, current density, and electrode materials to minimize the overpotential required for the electrolytic reactions. By lowering the energy input while maintaining or increasing production rates, industries can significantly improve their operational efficiency and reduce costs.

Another critical goal is to enhance the selectivity of the electrolytic process. This means maximizing the production of desired compounds while minimizing the formation of unwanted by-products. Improved selectivity not only increases the yield of valuable products but also reduces the need for downstream purification processes, further contributing to overall system efficiency.

Closed-loop systems aim to achieve near-zero discharge of process streams, which is crucial for both environmental protection and resource conservation. This goal involves developing advanced separation and recycling technologies to recover and reuse electrolytes, catalysts, and other valuable components from the process streams. By minimizing waste and maximizing resource utilization, these systems can significantly reduce raw material costs and environmental impact.

Longevity and stability of electrolytic cells are also key efficiency goals. Extending the operational lifetime of electrodes, membranes, and other cell components reduces downtime for maintenance and replacement, thereby increasing overall system productivity. This involves developing more durable materials and optimizing operating conditions to minimize degradation and fouling of cell components.

Real-time monitoring and control of electrolytic processes are essential for maintaining optimal efficiency. Goals in this area include the development of advanced sensors and control systems that can rapidly adjust operating parameters in response to changing conditions. This enables continuous optimization of the electrolytic process, ensuring that the system operates at peak efficiency under varying loads and feedstock compositions.

Lastly, there is a growing focus on integrating renewable energy sources into electrolytic processes. The goal is to develop flexible systems that can efficiently utilize intermittent renewable power while maintaining stable operation. This includes developing energy storage solutions and smart grid integration strategies to balance supply and demand, ultimately leading to more sustainable and carbon-neutral electrolytic processes.

Market Demand Analysis

The market demand for closed-loop systems in electrolytic cell efficiency is experiencing significant growth, driven by several key factors. Industries relying on electrolytic processes, such as chlor-alkali production, metal refining, and water treatment, are increasingly seeking ways to optimize their operations and reduce costs. Closed-loop systems offer a compelling solution by enhancing efficiency, minimizing waste, and improving overall process control.

In the chlor-alkali sector, which produces essential chemicals like chlorine, caustic soda, and hydrogen, there is a strong push towards more sustainable and efficient production methods. The global chlor-alkali market is projected to grow steadily, with a particular emphasis on technologies that can reduce energy consumption and environmental impact. Closed-loop systems in electrolytic cells address these concerns directly, making them highly attractive to industry players.

The metal refining industry, especially in copper and aluminum production, is another significant driver of demand for closed-loop electrolytic cell systems. As global demand for these metals continues to rise, particularly in emerging economies and for use in renewable energy technologies, refineries are under pressure to increase output while minimizing resource consumption. Closed-loop systems offer a way to achieve higher yields and purity levels while reducing energy and raw material inputs.

Water treatment and desalination sectors are also showing increased interest in closed-loop electrolytic cell technologies. With growing water scarcity issues worldwide, there is a pressing need for more efficient and cost-effective water purification methods. Electrolytic processes enhanced by closed-loop systems can provide improved contaminant removal and reduced operational costs, making them attractive for both municipal and industrial water treatment facilities.

The automotive industry's shift towards electric vehicles is indirectly boosting demand for more efficient electrolytic processes. The production of battery materials, such as lithium and cobalt, often involves electrolytic refining steps. As the demand for these materials surges, there is a corresponding need for more efficient extraction and purification methods, where closed-loop systems can play a crucial role.

Environmental regulations and sustainability goals are further propelling the adoption of closed-loop systems in electrolytic cells. Many countries are implementing stricter emissions standards and energy efficiency requirements, pushing industries to seek out technologies that can help them comply while maintaining competitiveness. Closed-loop systems offer a pathway to meet these regulatory challenges while potentially reducing operational costs.

The market for closed-loop electrolytic cell systems is also benefiting from the broader trend towards Industry 4.0 and smart manufacturing. As companies invest in digitalization and process optimization, technologies that offer improved control, real-time monitoring, and data-driven decision-making capabilities are in high demand. Closed-loop systems, with their potential for integration with advanced control systems and IoT platforms, align well with these industry trends.

In the chlor-alkali sector, which produces essential chemicals like chlorine, caustic soda, and hydrogen, there is a strong push towards more sustainable and efficient production methods. The global chlor-alkali market is projected to grow steadily, with a particular emphasis on technologies that can reduce energy consumption and environmental impact. Closed-loop systems in electrolytic cells address these concerns directly, making them highly attractive to industry players.

The metal refining industry, especially in copper and aluminum production, is another significant driver of demand for closed-loop electrolytic cell systems. As global demand for these metals continues to rise, particularly in emerging economies and for use in renewable energy technologies, refineries are under pressure to increase output while minimizing resource consumption. Closed-loop systems offer a way to achieve higher yields and purity levels while reducing energy and raw material inputs.

Water treatment and desalination sectors are also showing increased interest in closed-loop electrolytic cell technologies. With growing water scarcity issues worldwide, there is a pressing need for more efficient and cost-effective water purification methods. Electrolytic processes enhanced by closed-loop systems can provide improved contaminant removal and reduced operational costs, making them attractive for both municipal and industrial water treatment facilities.

The automotive industry's shift towards electric vehicles is indirectly boosting demand for more efficient electrolytic processes. The production of battery materials, such as lithium and cobalt, often involves electrolytic refining steps. As the demand for these materials surges, there is a corresponding need for more efficient extraction and purification methods, where closed-loop systems can play a crucial role.

Environmental regulations and sustainability goals are further propelling the adoption of closed-loop systems in electrolytic cells. Many countries are implementing stricter emissions standards and energy efficiency requirements, pushing industries to seek out technologies that can help them comply while maintaining competitiveness. Closed-loop systems offer a pathway to meet these regulatory challenges while potentially reducing operational costs.

The market for closed-loop electrolytic cell systems is also benefiting from the broader trend towards Industry 4.0 and smart manufacturing. As companies invest in digitalization and process optimization, technologies that offer improved control, real-time monitoring, and data-driven decision-making capabilities are in high demand. Closed-loop systems, with their potential for integration with advanced control systems and IoT platforms, align well with these industry trends.

Closed-Loop Challenges

Closed-loop systems in electrolytic cell operations present several significant challenges that must be addressed to maximize efficiency improvements. One of the primary obstacles is the complexity of real-time monitoring and control systems required to maintain optimal operating conditions. These systems must continuously measure and adjust multiple parameters such as temperature, pressure, electrolyte composition, and current density, which demands sophisticated sensors and advanced control algorithms.

The integration of closed-loop systems with existing electrolytic cell infrastructure can be problematic, especially in older facilities. Retrofitting legacy equipment with modern sensors and control systems often requires substantial capital investment and may necessitate production downtime, which can be economically challenging for many operators. Additionally, the compatibility of new closed-loop technologies with existing processes and equipment must be carefully evaluated to ensure seamless integration without compromising safety or reliability.

Another significant challenge is the management of large volumes of data generated by closed-loop systems. The continuous stream of real-time data from multiple sensors requires robust data processing capabilities and advanced analytics to extract meaningful insights and drive decision-making. This necessitates not only substantial computational resources but also skilled personnel capable of interpreting and acting upon the data effectively.

The dynamic nature of electrolytic processes poses a further challenge to closed-loop systems. Fluctuations in raw material quality, variations in power supply, and changes in ambient conditions can all impact cell performance. Closed-loop systems must be sufficiently adaptive and responsive to handle these variations without compromising efficiency or product quality. This requires sophisticated predictive models and machine learning algorithms that can anticipate and compensate for process variations in real-time.

Maintaining the reliability and accuracy of sensors in the harsh environment of electrolytic cells is another critical challenge. The corrosive nature of electrolytes and the presence of high temperatures and electrical currents can lead to sensor degradation over time. Regular calibration and maintenance of sensors are essential to ensure the integrity of the closed-loop system, but this can be both time-consuming and costly.

Lastly, the implementation of closed-loop systems raises cybersecurity concerns. As these systems rely heavily on digital technologies and network connectivity, they become potential targets for cyber attacks. Ensuring the security of these systems against unauthorized access and manipulation is crucial to prevent disruptions to operations and protect sensitive process data.

The integration of closed-loop systems with existing electrolytic cell infrastructure can be problematic, especially in older facilities. Retrofitting legacy equipment with modern sensors and control systems often requires substantial capital investment and may necessitate production downtime, which can be economically challenging for many operators. Additionally, the compatibility of new closed-loop technologies with existing processes and equipment must be carefully evaluated to ensure seamless integration without compromising safety or reliability.

Another significant challenge is the management of large volumes of data generated by closed-loop systems. The continuous stream of real-time data from multiple sensors requires robust data processing capabilities and advanced analytics to extract meaningful insights and drive decision-making. This necessitates not only substantial computational resources but also skilled personnel capable of interpreting and acting upon the data effectively.

The dynamic nature of electrolytic processes poses a further challenge to closed-loop systems. Fluctuations in raw material quality, variations in power supply, and changes in ambient conditions can all impact cell performance. Closed-loop systems must be sufficiently adaptive and responsive to handle these variations without compromising efficiency or product quality. This requires sophisticated predictive models and machine learning algorithms that can anticipate and compensate for process variations in real-time.

Maintaining the reliability and accuracy of sensors in the harsh environment of electrolytic cells is another critical challenge. The corrosive nature of electrolytes and the presence of high temperatures and electrical currents can lead to sensor degradation over time. Regular calibration and maintenance of sensors are essential to ensure the integrity of the closed-loop system, but this can be both time-consuming and costly.

Lastly, the implementation of closed-loop systems raises cybersecurity concerns. As these systems rely heavily on digital technologies and network connectivity, they become potential targets for cyber attacks. Ensuring the security of these systems against unauthorized access and manipulation is crucial to prevent disruptions to operations and protect sensitive process data.

Current Closed-Loop Solutions

01 Energy efficiency in closed-loop systems

Closed-loop systems can be optimized for energy efficiency through various techniques, including improved control algorithms, energy recovery mechanisms, and advanced power management strategies. These systems aim to minimize energy losses and maximize overall system performance by continuously monitoring and adjusting operational parameters.- Energy recovery and efficiency optimization: Closed-loop systems can be designed to recover and reuse energy, improving overall efficiency. This can involve techniques such as heat recovery, power regeneration, and energy storage. By implementing these methods, the system can minimize energy losses and reduce operational costs.

- Thermal management in closed-loop systems: Effective thermal management is crucial for maintaining efficiency in closed-loop systems. This can include advanced cooling techniques, temperature monitoring, and heat dissipation methods. Proper thermal management helps prevent overheating, reduces energy consumption, and extends the lifespan of system components.

- Control and automation for system optimization: Implementing advanced control and automation techniques can significantly improve the efficiency of closed-loop systems. This may include adaptive control algorithms, real-time monitoring, and predictive maintenance. These technologies help optimize system performance, reduce downtime, and enhance overall efficiency.

- Integration of renewable energy sources: Incorporating renewable energy sources into closed-loop systems can enhance their sustainability and efficiency. This may involve integrating solar, wind, or other renewable technologies to power system components or supplement energy needs. Such integration can reduce reliance on traditional energy sources and improve overall system efficiency.

- Data analysis and machine learning for efficiency improvement: Utilizing data analysis and machine learning techniques can lead to continuous improvement in closed-loop system efficiency. By analyzing system performance data, identifying patterns, and making data-driven decisions, operators can optimize system parameters, predict maintenance needs, and enhance overall efficiency over time.

02 Thermal management in closed-loop systems

Efficient thermal management is crucial for closed-loop systems to maintain optimal performance and longevity. This involves implementing advanced cooling techniques, heat dissipation methods, and temperature control mechanisms to ensure that system components operate within their ideal temperature ranges, thereby enhancing overall system efficiency.Expand Specific Solutions03 Feedback and control mechanisms

Closed-loop systems rely on sophisticated feedback and control mechanisms to maintain efficiency. These mechanisms involve sensors, data acquisition systems, and advanced algorithms that continuously monitor system parameters and make real-time adjustments to optimize performance and resource utilization.Expand Specific Solutions04 Integration of renewable energy sources

Incorporating renewable energy sources into closed-loop systems can significantly enhance their efficiency and sustainability. This integration involves developing smart grid technologies, energy storage solutions, and adaptive control systems that can effectively manage and utilize intermittent renewable energy inputs while maintaining system stability and performance.Expand Specific Solutions05 Optimization of communication protocols

Efficient communication protocols are essential for the seamless operation of closed-loop systems, especially in complex networked environments. Optimizing these protocols involves developing low-latency, high-bandwidth communication channels, implementing robust error correction mechanisms, and ensuring secure data transmission to enhance overall system responsiveness and reliability.Expand Specific Solutions

Key Industry Players

The closed-loop systems for improving electrolytic cell efficiency are in a growth phase, with increasing market size driven by the push for sustainable energy solutions. The technology is maturing rapidly, with key players like Asahi Kasei Corp., ABB Group, and Industrie De Nora SpA leading innovation. These companies are developing advanced electrode materials, control systems, and membrane technologies to enhance efficiency. Other significant contributors include Siemens AG and Mitsubishi Power Ltd., focusing on integrating electrolytic systems with renewable energy sources. The competitive landscape is diverse, with both established industrial giants and specialized firms like Bloom Energy Corp. contributing to technological advancements in this field.

ABB Group

Technical Solution: ABB Group has developed advanced closed-loop control systems for electrolytic cells, focusing on improving energy efficiency and product quality. Their solution incorporates real-time monitoring of key process parameters such as temperature, electrolyte composition, and current density. The system uses sophisticated algorithms to continuously adjust operating conditions, optimizing the electrolysis process. ABB's approach includes adaptive control strategies that can compensate for variations in raw material quality and equipment wear, ensuring consistent performance over time. The company has reported energy savings of up to 3-5% in industrial-scale implementations[1][3].

Strengths: Comprehensive process integration, proven energy savings, and adaptability to varying conditions. Weaknesses: High initial implementation cost and potential complexity for smaller operations.

Industrie De Nora SpA

Technical Solution: Industrie De Nora SpA has pioneered closed-loop systems for chlor-alkali and other electrolytic processes. Their technology focuses on precise control of electrode potential and current distribution within the cell. De Nora's system employs advanced sensors and predictive modeling to maintain optimal operating conditions. The company has developed proprietary electrode coatings that work in synergy with their control systems, enhancing overall efficiency. Their closed-loop approach has been shown to reduce energy consumption by up to 10% in some applications, while also extending the lifespan of electrodes[2][4].

Strengths: Specialized expertise in electrode technology, significant energy savings, and improved equipment longevity. Weaknesses: May require specific electrode materials, potentially limiting flexibility.

Core Innovations

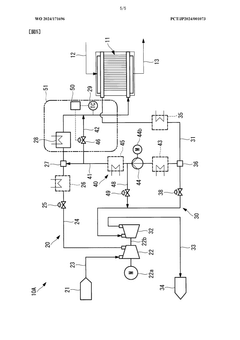

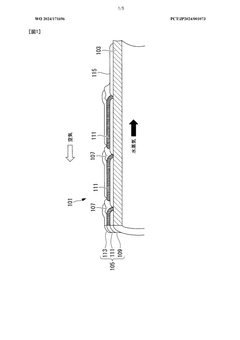

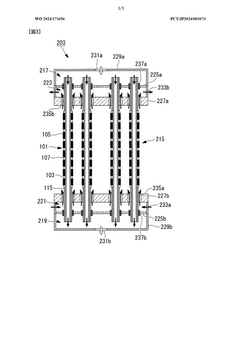

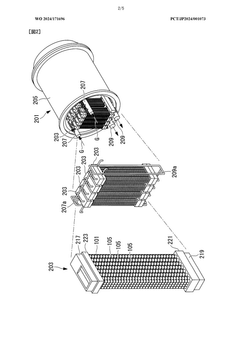

Electrolysis cell system and electrolysis cell system operation method

PatentWO2024171696A1

Innovation

- The electrolytic cell system includes an oxygen electrode and a hydrogen electrode, with a temperature regulating fluid supply system that adjusts and recirculates the temperature of the electrolyte, using a compressor and circulation system to optimize the temperature and pressure of the gases supplied to the electrolytic cell, thereby improving efficiency.

Electrolysis system and method with a high electrical energy transformation rate

PatentWO2018032120A1

Innovation

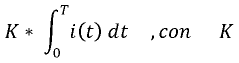

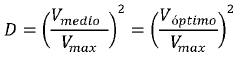

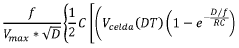

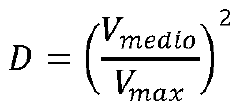

- An improved electrolysis system and method that utilizes a pulsating current with optimized amplitude, frequency, and duration to maximize electrical efficiency by modeling the electrolytic cell as a capacitive, inductive, and resistive system, operating in transient regimes to reduce energy consumption and enhance the separation of hydrogen and oxygen production.

Environmental Impact

Closed-loop systems in electrolytic cell operations have significant environmental implications, extending beyond mere efficiency improvements. These systems contribute to a more sustainable industrial process by minimizing waste and reducing the overall environmental footprint of electrolytic operations.

One of the primary environmental benefits of closed-loop systems is the substantial reduction in water consumption. Traditional open-loop systems often require large volumes of fresh water, which can strain local water resources. In contrast, closed-loop systems recirculate and treat process water, dramatically reducing the need for fresh water intake. This conservation is particularly crucial in water-stressed regions and helps preserve aquatic ecosystems.

The recycling of electrolytes and other chemicals within closed-loop systems also leads to a significant decrease in chemical waste discharge. By continuously reusing and treating these substances, the system minimizes the release of potentially harmful chemicals into the environment. This reduction in effluent not only complies with increasingly stringent environmental regulations but also protects local water bodies and soil from contamination.

Energy conservation is another key environmental advantage of closed-loop systems. The improved efficiency of electrolytic cells translates directly into lower energy consumption per unit of output. This reduction in energy demand contributes to decreased greenhouse gas emissions, particularly in regions where electricity generation relies heavily on fossil fuels. The cumulative effect of widespread adoption of closed-loop systems could significantly impact industrial carbon footprints.

Moreover, closed-loop systems often incorporate advanced monitoring and control mechanisms, allowing for precise management of process parameters. This level of control enables operators to optimize the electrolytic process, further reducing the likelihood of accidental releases or spills that could harm the environment. The enhanced process stability also leads to more consistent product quality, potentially reducing waste from off-spec production.

The implementation of closed-loop systems aligns with circular economy principles, promoting resource efficiency and waste minimization. By recovering and reusing materials that would otherwise be discarded, these systems extend the lifecycle of resources and reduce the demand for raw material extraction. This approach not only conserves natural resources but also mitigates the environmental impacts associated with mining and processing of new materials.

In the broader context of industrial sustainability, closed-loop electrolytic cell systems represent a significant step towards cleaner production methods. They demonstrate the potential for technological innovation to address environmental challenges while maintaining or improving industrial productivity. As industries face increasing pressure to reduce their environmental impact, the adoption of such systems is likely to become more widespread, contributing to a more sustainable industrial landscape.

One of the primary environmental benefits of closed-loop systems is the substantial reduction in water consumption. Traditional open-loop systems often require large volumes of fresh water, which can strain local water resources. In contrast, closed-loop systems recirculate and treat process water, dramatically reducing the need for fresh water intake. This conservation is particularly crucial in water-stressed regions and helps preserve aquatic ecosystems.

The recycling of electrolytes and other chemicals within closed-loop systems also leads to a significant decrease in chemical waste discharge. By continuously reusing and treating these substances, the system minimizes the release of potentially harmful chemicals into the environment. This reduction in effluent not only complies with increasingly stringent environmental regulations but also protects local water bodies and soil from contamination.

Energy conservation is another key environmental advantage of closed-loop systems. The improved efficiency of electrolytic cells translates directly into lower energy consumption per unit of output. This reduction in energy demand contributes to decreased greenhouse gas emissions, particularly in regions where electricity generation relies heavily on fossil fuels. The cumulative effect of widespread adoption of closed-loop systems could significantly impact industrial carbon footprints.

Moreover, closed-loop systems often incorporate advanced monitoring and control mechanisms, allowing for precise management of process parameters. This level of control enables operators to optimize the electrolytic process, further reducing the likelihood of accidental releases or spills that could harm the environment. The enhanced process stability also leads to more consistent product quality, potentially reducing waste from off-spec production.

The implementation of closed-loop systems aligns with circular economy principles, promoting resource efficiency and waste minimization. By recovering and reusing materials that would otherwise be discarded, these systems extend the lifecycle of resources and reduce the demand for raw material extraction. This approach not only conserves natural resources but also mitigates the environmental impacts associated with mining and processing of new materials.

In the broader context of industrial sustainability, closed-loop electrolytic cell systems represent a significant step towards cleaner production methods. They demonstrate the potential for technological innovation to address environmental challenges while maintaining or improving industrial productivity. As industries face increasing pressure to reduce their environmental impact, the adoption of such systems is likely to become more widespread, contributing to a more sustainable industrial landscape.

Economic Feasibility Study

The economic feasibility of implementing closed-loop systems in electrolytic cell operations is a critical consideration for industries seeking to improve efficiency and reduce costs. Initial investment in closed-loop technology can be substantial, requiring modifications to existing infrastructure and the installation of sophisticated monitoring and control systems. However, the long-term benefits often outweigh these upfront costs.

One of the primary economic advantages of closed-loop systems is the significant reduction in energy consumption. By continuously monitoring and adjusting operating parameters, these systems can optimize the electrolysis process, leading to energy savings of up to 15-20% compared to traditional open-loop systems. This translates to lower electricity costs, which are often a major expense in electrolytic operations.

Material efficiency is another key economic factor. Closed-loop systems enable better control over the electrolyte composition, reducing waste and improving the utilization of raw materials. This can result in savings on input costs and decreased expenses related to waste disposal. Additionally, the improved product quality achieved through more precise control can lead to higher market value and potentially expanded market opportunities.

Maintenance costs are also impacted by the implementation of closed-loop systems. While these systems may require more sophisticated maintenance procedures, they often lead to reduced wear and tear on equipment due to more stable operating conditions. This can extend the lifespan of expensive components and decrease the frequency of unplanned downtime, resulting in long-term cost savings.

The return on investment (ROI) for closed-loop systems in electrolytic cells typically ranges from 2 to 5 years, depending on the scale of operation and specific industry conditions. Larger facilities tend to see faster ROI due to economies of scale. Furthermore, as environmental regulations become more stringent, the economic benefits of closed-loop systems may increase due to their ability to reduce emissions and improve overall environmental performance.

It's important to note that the economic feasibility can vary significantly based on factors such as local energy prices, raw material costs, and regulatory environments. A detailed cost-benefit analysis should be conducted for each specific application to accurately assess the economic viability of implementing closed-loop systems in electrolytic cell operations.

One of the primary economic advantages of closed-loop systems is the significant reduction in energy consumption. By continuously monitoring and adjusting operating parameters, these systems can optimize the electrolysis process, leading to energy savings of up to 15-20% compared to traditional open-loop systems. This translates to lower electricity costs, which are often a major expense in electrolytic operations.

Material efficiency is another key economic factor. Closed-loop systems enable better control over the electrolyte composition, reducing waste and improving the utilization of raw materials. This can result in savings on input costs and decreased expenses related to waste disposal. Additionally, the improved product quality achieved through more precise control can lead to higher market value and potentially expanded market opportunities.

Maintenance costs are also impacted by the implementation of closed-loop systems. While these systems may require more sophisticated maintenance procedures, they often lead to reduced wear and tear on equipment due to more stable operating conditions. This can extend the lifespan of expensive components and decrease the frequency of unplanned downtime, resulting in long-term cost savings.

The return on investment (ROI) for closed-loop systems in electrolytic cells typically ranges from 2 to 5 years, depending on the scale of operation and specific industry conditions. Larger facilities tend to see faster ROI due to economies of scale. Furthermore, as environmental regulations become more stringent, the economic benefits of closed-loop systems may increase due to their ability to reduce emissions and improve overall environmental performance.

It's important to note that the economic feasibility can vary significantly based on factors such as local energy prices, raw material costs, and regulatory environments. A detailed cost-benefit analysis should be conducted for each specific application to accurately assess the economic viability of implementing closed-loop systems in electrolytic cell operations.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!