Automated Control Systems for Enhanced Electrolytic Cell Productivity

AUG 1, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Electrolytic Cell Control Evolution and Objectives

Electrolytic cell control systems have undergone significant evolution since their inception in the early 20th century. Initially, these systems relied heavily on manual operation and rudimentary monitoring techniques. As industrial processes became more complex, the need for more sophisticated control mechanisms became apparent. The 1950s and 1960s saw the introduction of analog control systems, which provided basic automation capabilities but were limited in their ability to handle complex variables.

The advent of digital technology in the 1970s marked a turning point in electrolytic cell control. Programmable Logic Controllers (PLCs) and Distributed Control Systems (DCS) began to replace analog systems, offering greater precision and flexibility. This digital revolution allowed for more accurate monitoring of critical parameters such as temperature, current density, and electrolyte composition. The 1980s and 1990s witnessed further advancements with the integration of computer-based control systems, enabling real-time data analysis and more responsive adjustments to process variables.

In recent years, the focus has shifted towards intelligent control systems that leverage artificial intelligence and machine learning algorithms. These advanced systems can predict and optimize cell performance, significantly enhancing productivity and energy efficiency. The current trend is moving towards fully automated, self-adjusting control systems that can adapt to changing conditions without human intervention.

The primary objective of modern electrolytic cell control systems is to maximize productivity while minimizing energy consumption and maintaining product quality. This involves precise control of multiple parameters simultaneously, including current distribution, temperature gradients, and electrolyte flow. Advanced control systems aim to achieve a delicate balance between these factors to optimize overall cell efficiency.

Another key goal is to enhance the longevity of electrolytic cells by preventing degradation and minimizing downtime. This requires sophisticated predictive maintenance capabilities and real-time monitoring of cell health indicators. Additionally, there is a growing emphasis on sustainability, with control systems being designed to reduce environmental impact by optimizing resource utilization and minimizing waste generation.

Looking ahead, the future objectives of electrolytic cell control systems include achieving near-perfect energy efficiency, implementing fully autonomous operation, and seamlessly integrating with broader industrial IoT ecosystems. Research is also focused on developing more robust sensors and actuators capable of withstanding harsh electrolytic environments, as well as advanced data analytics tools for extracting actionable insights from vast amounts of process data.

The advent of digital technology in the 1970s marked a turning point in electrolytic cell control. Programmable Logic Controllers (PLCs) and Distributed Control Systems (DCS) began to replace analog systems, offering greater precision and flexibility. This digital revolution allowed for more accurate monitoring of critical parameters such as temperature, current density, and electrolyte composition. The 1980s and 1990s witnessed further advancements with the integration of computer-based control systems, enabling real-time data analysis and more responsive adjustments to process variables.

In recent years, the focus has shifted towards intelligent control systems that leverage artificial intelligence and machine learning algorithms. These advanced systems can predict and optimize cell performance, significantly enhancing productivity and energy efficiency. The current trend is moving towards fully automated, self-adjusting control systems that can adapt to changing conditions without human intervention.

The primary objective of modern electrolytic cell control systems is to maximize productivity while minimizing energy consumption and maintaining product quality. This involves precise control of multiple parameters simultaneously, including current distribution, temperature gradients, and electrolyte flow. Advanced control systems aim to achieve a delicate balance between these factors to optimize overall cell efficiency.

Another key goal is to enhance the longevity of electrolytic cells by preventing degradation and minimizing downtime. This requires sophisticated predictive maintenance capabilities and real-time monitoring of cell health indicators. Additionally, there is a growing emphasis on sustainability, with control systems being designed to reduce environmental impact by optimizing resource utilization and minimizing waste generation.

Looking ahead, the future objectives of electrolytic cell control systems include achieving near-perfect energy efficiency, implementing fully autonomous operation, and seamlessly integrating with broader industrial IoT ecosystems. Research is also focused on developing more robust sensors and actuators capable of withstanding harsh electrolytic environments, as well as advanced data analytics tools for extracting actionable insights from vast amounts of process data.

Market Demand for Efficient Electrolytic Processes

The market demand for efficient electrolytic processes has been steadily increasing across various industries, driven by the need for improved productivity, cost reduction, and environmental sustainability. Electrolytic processes play a crucial role in numerous applications, including metal production, water treatment, chemical synthesis, and energy storage systems.

In the metal production sector, particularly in aluminum and copper industries, there is a growing demand for advanced electrolytic cell technologies that can enhance productivity while reducing energy consumption. The global aluminum market, for instance, is projected to reach a value of over $250 billion by 2026, with a significant portion of this growth attributed to improved electrolytic processes.

The water treatment industry is another key driver of demand for efficient electrolytic systems. As water scarcity becomes a pressing global issue, there is an increasing need for advanced water purification and desalination technologies. Electrolytic processes, such as electrocoagulation and electrooxidation, are gaining traction due to their effectiveness in removing contaminants and reducing chemical usage.

In the chemical industry, electrolytic processes are becoming increasingly important for the production of various chemicals, including chlorine, sodium hydroxide, and hydrogen. The global chlor-alkali market, which heavily relies on electrolytic processes, is expected to grow at a compound annual growth rate (CAGR) of 5.8% from 2021 to 2028, reaching a market size of $77.4 billion.

The renewable energy sector is also driving demand for efficient electrolytic processes, particularly in the production of green hydrogen. As countries worldwide strive to reduce carbon emissions and transition to clean energy sources, the demand for electrolyzers is surging. The global green hydrogen market is projected to grow at a CAGR of 54.7% from 2021 to 2028, reaching a market value of $89.2 billion by the end of the forecast period.

Furthermore, the automotive industry's shift towards electric vehicles is creating new opportunities for electrolytic processes in battery production and recycling. The global lithium-ion battery market is expected to reach $129.3 billion by 2027, with a CAGR of 18.0% from 2020 to 2027.

As industries continue to prioritize sustainability and efficiency, the demand for automated control systems in electrolytic processes is expected to grow significantly. These systems offer numerous benefits, including improved process control, reduced energy consumption, and enhanced product quality. The global industrial automation market, which includes automated control systems for electrolytic processes, is projected to reach $306.2 billion by 2027, growing at a CAGR of 9.3% from 2020 to 2027.

In the metal production sector, particularly in aluminum and copper industries, there is a growing demand for advanced electrolytic cell technologies that can enhance productivity while reducing energy consumption. The global aluminum market, for instance, is projected to reach a value of over $250 billion by 2026, with a significant portion of this growth attributed to improved electrolytic processes.

The water treatment industry is another key driver of demand for efficient electrolytic systems. As water scarcity becomes a pressing global issue, there is an increasing need for advanced water purification and desalination technologies. Electrolytic processes, such as electrocoagulation and electrooxidation, are gaining traction due to their effectiveness in removing contaminants and reducing chemical usage.

In the chemical industry, electrolytic processes are becoming increasingly important for the production of various chemicals, including chlorine, sodium hydroxide, and hydrogen. The global chlor-alkali market, which heavily relies on electrolytic processes, is expected to grow at a compound annual growth rate (CAGR) of 5.8% from 2021 to 2028, reaching a market size of $77.4 billion.

The renewable energy sector is also driving demand for efficient electrolytic processes, particularly in the production of green hydrogen. As countries worldwide strive to reduce carbon emissions and transition to clean energy sources, the demand for electrolyzers is surging. The global green hydrogen market is projected to grow at a CAGR of 54.7% from 2021 to 2028, reaching a market value of $89.2 billion by the end of the forecast period.

Furthermore, the automotive industry's shift towards electric vehicles is creating new opportunities for electrolytic processes in battery production and recycling. The global lithium-ion battery market is expected to reach $129.3 billion by 2027, with a CAGR of 18.0% from 2020 to 2027.

As industries continue to prioritize sustainability and efficiency, the demand for automated control systems in electrolytic processes is expected to grow significantly. These systems offer numerous benefits, including improved process control, reduced energy consumption, and enhanced product quality. The global industrial automation market, which includes automated control systems for electrolytic processes, is projected to reach $306.2 billion by 2027, growing at a CAGR of 9.3% from 2020 to 2027.

Current Challenges in Automated Electrolytic Control

The automation of electrolytic cell control systems presents several significant challenges that hinder the optimization of productivity in industrial settings. One of the primary obstacles is the complexity of the electrolytic process itself, which involves multiple interdependent variables such as temperature, current density, electrolyte composition, and electrode conditions. These variables interact in non-linear ways, making it difficult to develop accurate predictive models and control algorithms.

Real-time monitoring and data acquisition pose another substantial challenge. The harsh environment within electrolytic cells, characterized by high temperatures and corrosive chemicals, often limits the placement and longevity of sensors. This constraint can result in incomplete or inaccurate data, which in turn affects the precision of automated control systems. Additionally, the sheer volume of data generated in large-scale electrolytic operations can overwhelm traditional processing systems, necessitating advanced data management and analysis techniques.

The dynamic nature of electrolytic processes further complicates automated control. Fluctuations in raw material quality, electrode degradation, and changes in operating conditions can rapidly alter the optimal control parameters. Developing adaptive control systems that can respond quickly and accurately to these changes remains a significant technical hurdle. Moreover, the long time constants associated with some aspects of the electrolytic process, such as temperature changes or electrolyte composition adjustments, introduce delays that can destabilize control loops if not properly managed.

Safety considerations add another layer of complexity to automated control systems. The potential for hazardous situations, such as anode effects or cell instabilities, requires robust fail-safe mechanisms and emergency response protocols to be integrated into the control architecture. Balancing these safety requirements with the goal of maximizing productivity often leads to conservative control strategies that may not fully exploit the cell's potential.

Standardization and integration challenges also persist in the industry. Many electrolytic facilities use a mix of legacy equipment and modern control systems, creating compatibility issues and limiting the implementation of fully integrated automation solutions. The lack of standardized protocols for data exchange and control interfaces across different equipment manufacturers further complicates the development of comprehensive automated control systems.

Lastly, the economic constraints of implementing advanced automation technologies present a significant barrier. The high costs associated with retrofitting existing plants with state-of-the-art control systems, coupled with the potential for production disruptions during implementation, often deter companies from adopting new technologies. This reluctance can lead to a widening gap between the theoretical potential of automated control systems and their practical application in industrial settings.

Real-time monitoring and data acquisition pose another substantial challenge. The harsh environment within electrolytic cells, characterized by high temperatures and corrosive chemicals, often limits the placement and longevity of sensors. This constraint can result in incomplete or inaccurate data, which in turn affects the precision of automated control systems. Additionally, the sheer volume of data generated in large-scale electrolytic operations can overwhelm traditional processing systems, necessitating advanced data management and analysis techniques.

The dynamic nature of electrolytic processes further complicates automated control. Fluctuations in raw material quality, electrode degradation, and changes in operating conditions can rapidly alter the optimal control parameters. Developing adaptive control systems that can respond quickly and accurately to these changes remains a significant technical hurdle. Moreover, the long time constants associated with some aspects of the electrolytic process, such as temperature changes or electrolyte composition adjustments, introduce delays that can destabilize control loops if not properly managed.

Safety considerations add another layer of complexity to automated control systems. The potential for hazardous situations, such as anode effects or cell instabilities, requires robust fail-safe mechanisms and emergency response protocols to be integrated into the control architecture. Balancing these safety requirements with the goal of maximizing productivity often leads to conservative control strategies that may not fully exploit the cell's potential.

Standardization and integration challenges also persist in the industry. Many electrolytic facilities use a mix of legacy equipment and modern control systems, creating compatibility issues and limiting the implementation of fully integrated automation solutions. The lack of standardized protocols for data exchange and control interfaces across different equipment manufacturers further complicates the development of comprehensive automated control systems.

Lastly, the economic constraints of implementing advanced automation technologies present a significant barrier. The high costs associated with retrofitting existing plants with state-of-the-art control systems, coupled with the potential for production disruptions during implementation, often deter companies from adopting new technologies. This reluctance can lead to a widening gap between the theoretical potential of automated control systems and their practical application in industrial settings.

Existing Automated Control Solutions

01 Automated control systems for industrial processes

These systems enhance productivity by automating various industrial processes, including manufacturing, assembly, and quality control. They integrate sensors, actuators, and advanced algorithms to optimize operations, reduce human error, and increase efficiency in production environments.- Automated control systems for industrial processes: These systems optimize industrial processes by automating control functions, improving efficiency and productivity. They integrate sensors, actuators, and advanced algorithms to monitor and adjust production parameters in real-time, reducing human error and increasing output quality.

- Machine learning and AI in control systems: Incorporating machine learning and artificial intelligence into automated control systems enhances their ability to adapt to changing conditions and optimize performance. These technologies enable predictive maintenance, process optimization, and continuous improvement of system efficiency.

- Integration of IoT and cloud computing: Internet of Things (IoT) devices and cloud computing are integrated into automated control systems to enable remote monitoring, data analysis, and system management. This integration allows for real-time data collection, centralized control, and improved decision-making across multiple production sites.

- Human-machine interface optimization: Advanced human-machine interfaces are developed to improve operator interaction with automated control systems. These interfaces provide intuitive visualizations, customizable dashboards, and real-time alerts, enabling operators to make informed decisions quickly and efficiently.

- Energy management and sustainability in control systems: Automated control systems are designed to optimize energy consumption and promote sustainability in industrial processes. These systems incorporate energy monitoring, load balancing, and intelligent scheduling to reduce waste and improve overall resource efficiency.

02 Machine learning and AI in control systems

Incorporating machine learning and artificial intelligence into automated control systems allows for predictive maintenance, adaptive process optimization, and real-time decision-making. These technologies analyze vast amounts of data to improve system performance and productivity continuously.Expand Specific Solutions03 Integration of IoT and cloud computing

The integration of Internet of Things (IoT) devices and cloud computing in automated control systems enables remote monitoring, data collection, and analysis. This connectivity enhances system flexibility, scalability, and the ability to implement distributed control strategies, leading to improved productivity across multiple locations.Expand Specific Solutions04 Human-machine interface optimization

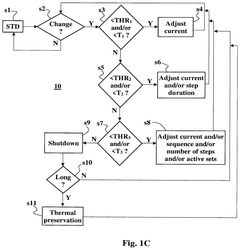

Advanced human-machine interfaces (HMIs) in automated control systems improve operator efficiency and reduce errors. These interfaces utilize intuitive designs, augmented reality, and voice commands to streamline interactions between humans and machines, enhancing overall system productivity.Expand Specific Solutions05 Adaptive and self-optimizing control algorithms

Implementing adaptive and self-optimizing control algorithms allows automated systems to adjust parameters in real-time based on changing conditions. These algorithms use feedback loops and advanced modeling techniques to continuously improve system performance and productivity without human intervention.Expand Specific Solutions

Key Players in Electrolytic Control Systems

The research on automated control systems for enhanced electrolytic cell productivity is in a growth phase, with increasing market size and technological advancements. The global market for these systems is expanding due to the rising demand for efficient aluminum production. Technologically, the field is progressing rapidly, with companies like Aluminum Corp. of China Ltd. and Shenyang Aluminum & Magnesium Engineering & Research Institute leading innovations. Other key players such as Bühler AG and ABB Group are contributing to the development of advanced control systems. The technology's maturity varies, with established firms offering proven solutions while newer entrants like Largo Clean Energy Corp. and GridBeyond Ltd. are introducing novel approaches, particularly in energy efficiency and AI-driven controls.

Aluminum Corp. of China Ltd.

Technical Solution: Aluminum Corp. of China Ltd. (Chalco) has developed an advanced automated control system for electrolytic cells to enhance productivity in aluminum production. The system utilizes real-time data analytics and machine learning algorithms to optimize the electrolysis process[1]. It continuously monitors key parameters such as temperature, voltage, and alumina concentration, making micro-adjustments to maintain optimal operating conditions[2]. The system also incorporates predictive maintenance capabilities, reducing downtime and improving overall efficiency. Chalco's automated control system has reportedly increased production efficiency by up to 15% while reducing energy consumption by 8%[3].

Strengths: Significant improvement in production efficiency and energy savings. Weaknesses: High initial implementation cost and potential dependency on proprietary technology.

Shenyang Aluminum & Magnesium Engineering & Rsch Institute

Technical Solution: Shenyang Aluminum & Magnesium Engineering & Research Institute has developed a specialized Intelligent Control System for Aluminum Electrolysis (ICSAE). This system focuses on the unique challenges of aluminum production, incorporating advanced process models and control algorithms tailored to the electrolytic process. The ICSAE utilizes a multi-level control architecture, combining local cell controllers with a centralized supervisory system[11]. It employs neural network-based soft sensors to estimate difficult-to-measure parameters and uses fuzzy logic control to handle process nonlinearities. The system also includes an expert system module that captures and applies the knowledge of experienced operators. Implementation of the ICSAE has reportedly led to a 5-7% increase in current efficiency and a 3-4% reduction in alumina consumption[12].

Strengths: Highly specialized system designed specifically for aluminum electrolysis. Weaknesses: May have limited applicability outside of aluminum production.

Innovative Control Algorithms for Electrolysis

Electrolysis system and operation method thereof

PatentPendingUS20250215591A1

Innovation

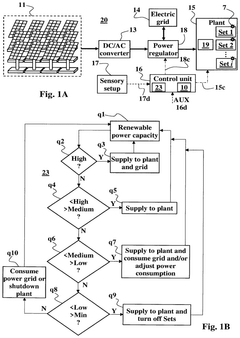

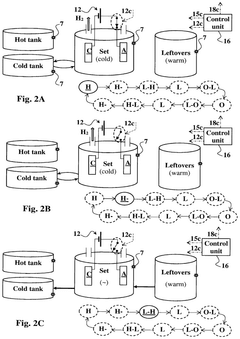

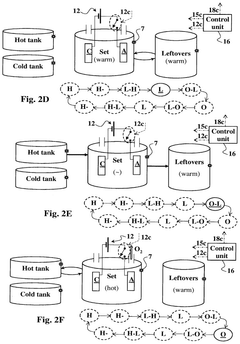

- A control system for electrolysis systems that adjusts power management and phase-shifted electrolysis processes to optimize operation with fluctuating renewable power, including activating/deactivating reactors, adjusting power supply, and managing electrolyte phases to maintain efficiency and safety.

Operation support device, operation support method and operation support program

PatentWO2024014438A1

Innovation

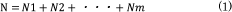

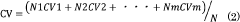

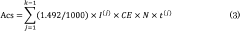

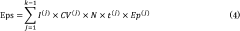

- A driving support device and method that calculates and adjusts the current values for each electrolytic cell based on production amount, impurity concentration, and temperature, identifying underperforming cells to optimize power usage and adjust operating conditions to ensure target production is met with minimized energy expenditure.

Energy Efficiency in Electrolytic Processes

Energy efficiency in electrolytic processes is a critical aspect of automated control systems for enhanced electrolytic cell productivity. The optimization of energy consumption in these processes not only reduces operational costs but also contributes to environmental sustainability. In electrolytic cells, energy is primarily consumed in the form of electricity to drive the electrochemical reactions. The efficiency of this energy conversion is influenced by various factors, including cell design, electrode materials, electrolyte composition, and operating conditions.

One of the key strategies for improving energy efficiency is the implementation of advanced process control systems. These systems utilize real-time monitoring and data analysis to optimize the operating parameters of electrolytic cells. By maintaining optimal current densities, temperature profiles, and electrolyte concentrations, the energy input can be more effectively converted into desired product output. Additionally, the use of high-performance electrode materials and optimized cell geometries can significantly reduce energy losses due to overpotentials and resistive heating.

Another important aspect of energy efficiency in electrolytic processes is the recovery and utilization of waste heat. Electrolytic cells generate substantial amounts of heat as a byproduct of the electrochemical reactions. Implementing heat recovery systems can capture this thermal energy for use in preheating feedstocks, maintaining optimal cell temperatures, or generating electricity through thermoelectric devices. This approach not only improves overall energy efficiency but also reduces the cooling requirements of the electrolytic system.

The integration of renewable energy sources into electrolytic processes presents a promising avenue for enhancing energy efficiency and sustainability. Intermittent renewable energy, such as solar or wind power, can be effectively utilized in electrolytic systems through smart grid technologies and energy storage solutions. This integration allows for the dynamic adjustment of production rates based on energy availability, potentially reducing reliance on fossil fuel-based electricity and lowering the carbon footprint of the electrolytic process.

Advancements in materials science and nanotechnology are also contributing to improved energy efficiency in electrolytic cells. Novel electrode materials with enhanced catalytic properties and increased surface areas can reduce the overpotentials required for electrochemical reactions, thereby lowering the overall energy input. Similarly, the development of ion-selective membranes and advanced separator materials can minimize energy losses associated with ion transport and side reactions within the cell.

One of the key strategies for improving energy efficiency is the implementation of advanced process control systems. These systems utilize real-time monitoring and data analysis to optimize the operating parameters of electrolytic cells. By maintaining optimal current densities, temperature profiles, and electrolyte concentrations, the energy input can be more effectively converted into desired product output. Additionally, the use of high-performance electrode materials and optimized cell geometries can significantly reduce energy losses due to overpotentials and resistive heating.

Another important aspect of energy efficiency in electrolytic processes is the recovery and utilization of waste heat. Electrolytic cells generate substantial amounts of heat as a byproduct of the electrochemical reactions. Implementing heat recovery systems can capture this thermal energy for use in preheating feedstocks, maintaining optimal cell temperatures, or generating electricity through thermoelectric devices. This approach not only improves overall energy efficiency but also reduces the cooling requirements of the electrolytic system.

The integration of renewable energy sources into electrolytic processes presents a promising avenue for enhancing energy efficiency and sustainability. Intermittent renewable energy, such as solar or wind power, can be effectively utilized in electrolytic systems through smart grid technologies and energy storage solutions. This integration allows for the dynamic adjustment of production rates based on energy availability, potentially reducing reliance on fossil fuel-based electricity and lowering the carbon footprint of the electrolytic process.

Advancements in materials science and nanotechnology are also contributing to improved energy efficiency in electrolytic cells. Novel electrode materials with enhanced catalytic properties and increased surface areas can reduce the overpotentials required for electrochemical reactions, thereby lowering the overall energy input. Similarly, the development of ion-selective membranes and advanced separator materials can minimize energy losses associated with ion transport and side reactions within the cell.

Environmental Impact of Advanced Electrolytic Systems

The implementation of advanced electrolytic systems, particularly those with automated control mechanisms for enhanced productivity, has significant environmental implications that warrant careful consideration. These systems, while designed to improve efficiency and output, can have both positive and negative impacts on the environment.

One of the primary environmental benefits of advanced electrolytic systems is their potential for increased energy efficiency. By optimizing the electrolytic process through automated control, these systems can reduce overall energy consumption per unit of output. This reduction in energy usage translates directly to lower greenhouse gas emissions, particularly in regions where electricity generation relies heavily on fossil fuels. Moreover, the precise control afforded by these systems can minimize waste production and improve resource utilization, further reducing the environmental footprint of industrial processes.

However, the environmental impact of these systems extends beyond energy efficiency. The materials used in the construction and operation of advanced electrolytic cells, including rare earth elements and specialized alloys, may have significant upstream environmental costs associated with their extraction and processing. The increased reliance on complex electronic components for automation also introduces concerns regarding electronic waste and the need for responsible disposal or recycling of these components at the end of their lifecycle.

Water usage and wastewater management are critical environmental considerations for electrolytic processes. Advanced systems may offer improvements in water efficiency through better process control and recycling capabilities. However, the potential for increased production capacity could lead to greater overall water demand, particularly in water-stressed regions. Additionally, the composition of wastewater from these systems may be more complex due to the use of advanced materials and chemicals, necessitating sophisticated treatment processes to prevent environmental contamination.

The environmental impact of these systems also extends to air quality. While improved process control can reduce emissions of volatile compounds and particulates, the potential for increased production capacity may offset these gains if not properly managed. Fugitive emissions from larger or more numerous electrolytic cells could contribute to local air quality issues, necessitating robust monitoring and control measures.

Lastly, the lifecycle environmental impact of advanced electrolytic systems must be considered. This includes the environmental costs of research and development, manufacturing, transportation, installation, operation, maintenance, and eventual decommissioning. While these systems may offer environmental benefits during operation, a comprehensive assessment must account for the full lifecycle to determine their net environmental impact.

One of the primary environmental benefits of advanced electrolytic systems is their potential for increased energy efficiency. By optimizing the electrolytic process through automated control, these systems can reduce overall energy consumption per unit of output. This reduction in energy usage translates directly to lower greenhouse gas emissions, particularly in regions where electricity generation relies heavily on fossil fuels. Moreover, the precise control afforded by these systems can minimize waste production and improve resource utilization, further reducing the environmental footprint of industrial processes.

However, the environmental impact of these systems extends beyond energy efficiency. The materials used in the construction and operation of advanced electrolytic cells, including rare earth elements and specialized alloys, may have significant upstream environmental costs associated with their extraction and processing. The increased reliance on complex electronic components for automation also introduces concerns regarding electronic waste and the need for responsible disposal or recycling of these components at the end of their lifecycle.

Water usage and wastewater management are critical environmental considerations for electrolytic processes. Advanced systems may offer improvements in water efficiency through better process control and recycling capabilities. However, the potential for increased production capacity could lead to greater overall water demand, particularly in water-stressed regions. Additionally, the composition of wastewater from these systems may be more complex due to the use of advanced materials and chemicals, necessitating sophisticated treatment processes to prevent environmental contamination.

The environmental impact of these systems also extends to air quality. While improved process control can reduce emissions of volatile compounds and particulates, the potential for increased production capacity may offset these gains if not properly managed. Fugitive emissions from larger or more numerous electrolytic cells could contribute to local air quality issues, necessitating robust monitoring and control measures.

Lastly, the lifecycle environmental impact of advanced electrolytic systems must be considered. This includes the environmental costs of research and development, manufacturing, transportation, installation, operation, maintenance, and eventual decommissioning. While these systems may offer environmental benefits during operation, a comprehensive assessment must account for the full lifecycle to determine their net environmental impact.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!