Micro Electrolytic Cell Systems for Laboratory Applications

AUG 1, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Micro Electrolytic Cell Background and Objectives

Micro electrolytic cell systems have emerged as a crucial tool in laboratory applications, revolutionizing the way researchers conduct experiments and analyze samples. These miniaturized electrochemical devices have evolved significantly over the past few decades, driven by advancements in microfabrication techniques and materials science. The development of micro electrolytic cells can be traced back to the late 1990s when the need for more precise and controlled electrochemical analysis at the microscale became apparent.

The evolution of micro electrolytic cell technology has been characterized by a continuous push towards miniaturization, increased sensitivity, and enhanced control over electrochemical processes. Early designs focused on reducing the size of traditional electrochemical cells, while more recent innovations have incorporated microfluidic principles and advanced electrode materials to create highly integrated and efficient systems.

One of the key drivers behind the development of micro electrolytic cell systems has been the growing demand for point-of-care diagnostics and on-site environmental monitoring. These applications require portable, rapid, and sensitive analytical tools that can perform complex electrochemical measurements in resource-limited settings. As a result, researchers have been working towards creating more compact, robust, and user-friendly micro electrolytic cell designs.

The primary objectives of current research in micro electrolytic cell systems for laboratory applications are multifaceted. Firstly, there is a strong focus on improving the sensitivity and selectivity of these devices, enabling the detection of trace amounts of analytes in complex matrices. This is particularly important in fields such as environmental monitoring, where the ability to detect low concentrations of pollutants is crucial.

Secondly, researchers are working on expanding the range of applications for micro electrolytic cells. This includes developing systems capable of performing multiple electrochemical techniques simultaneously, as well as integrating these devices with other analytical methods such as spectroscopy or chromatography. The goal is to create versatile platforms that can provide comprehensive sample analysis in a single, compact device.

Another important objective is to enhance the reproducibility and reliability of micro electrolytic cell measurements. This involves developing standardized fabrication processes, improving electrode stability, and creating robust calibration methods. By addressing these challenges, researchers aim to increase the adoption of micro electrolytic cell systems in regulated industries such as pharmaceuticals and clinical diagnostics.

Looking ahead, the field of micro electrolytic cell systems is poised for further advancements. Emerging trends include the integration of artificial intelligence for data analysis and interpretation, the development of self-calibrating systems, and the exploration of novel electrode materials such as graphene and carbon nanotubes. These innovations are expected to push the boundaries of what is possible with micro electrolytic cell technology, opening up new avenues for research and applications in laboratory settings.

The evolution of micro electrolytic cell technology has been characterized by a continuous push towards miniaturization, increased sensitivity, and enhanced control over electrochemical processes. Early designs focused on reducing the size of traditional electrochemical cells, while more recent innovations have incorporated microfluidic principles and advanced electrode materials to create highly integrated and efficient systems.

One of the key drivers behind the development of micro electrolytic cell systems has been the growing demand for point-of-care diagnostics and on-site environmental monitoring. These applications require portable, rapid, and sensitive analytical tools that can perform complex electrochemical measurements in resource-limited settings. As a result, researchers have been working towards creating more compact, robust, and user-friendly micro electrolytic cell designs.

The primary objectives of current research in micro electrolytic cell systems for laboratory applications are multifaceted. Firstly, there is a strong focus on improving the sensitivity and selectivity of these devices, enabling the detection of trace amounts of analytes in complex matrices. This is particularly important in fields such as environmental monitoring, where the ability to detect low concentrations of pollutants is crucial.

Secondly, researchers are working on expanding the range of applications for micro electrolytic cells. This includes developing systems capable of performing multiple electrochemical techniques simultaneously, as well as integrating these devices with other analytical methods such as spectroscopy or chromatography. The goal is to create versatile platforms that can provide comprehensive sample analysis in a single, compact device.

Another important objective is to enhance the reproducibility and reliability of micro electrolytic cell measurements. This involves developing standardized fabrication processes, improving electrode stability, and creating robust calibration methods. By addressing these challenges, researchers aim to increase the adoption of micro electrolytic cell systems in regulated industries such as pharmaceuticals and clinical diagnostics.

Looking ahead, the field of micro electrolytic cell systems is poised for further advancements. Emerging trends include the integration of artificial intelligence for data analysis and interpretation, the development of self-calibrating systems, and the exploration of novel electrode materials such as graphene and carbon nanotubes. These innovations are expected to push the boundaries of what is possible with micro electrolytic cell technology, opening up new avenues for research and applications in laboratory settings.

Market Analysis for Lab-Scale Electrolysis Systems

The market for lab-scale electrolysis systems is experiencing significant growth, driven by increasing demand for precise and controlled electrolytic processes in research and development settings. This market segment caters to academic institutions, pharmaceutical companies, and industrial research laboratories that require small-scale electrolytic cell systems for various applications, including materials synthesis, electrochemistry studies, and prototype development.

The global laboratory equipment market, which includes micro electrolytic cell systems, is projected to expand at a steady rate over the next five years. This growth is fueled by advancements in research methodologies, increased funding for scientific research, and the rising need for specialized equipment in emerging fields such as nanotechnology and renewable energy research.

Key factors driving the demand for lab-scale electrolysis systems include the growing emphasis on sustainable energy solutions, which has led to increased research in hydrogen production and fuel cell technologies. Additionally, the pharmaceutical industry's focus on electrochemical synthesis for drug discovery and development has created a niche market for specialized electrolytic equipment.

The market is characterized by a mix of established laboratory equipment manufacturers and specialized providers of electrochemistry solutions. Leading companies in this space are continuously innovating to offer more compact, efficient, and user-friendly systems that cater to the evolving needs of researchers and scientists.

Geographically, North America and Europe dominate the market due to their well-established research infrastructure and substantial R&D investments. However, Asia-Pacific is emerging as a rapidly growing market, driven by increasing research activities in countries like China, Japan, and South Korea.

A notable trend in the market is the integration of digital technologies and automation features in lab-scale electrolysis systems. This includes the incorporation of advanced control systems, data logging capabilities, and compatibility with laboratory information management systems (LIMS), enhancing the overall efficiency and reproducibility of experiments.

The competitive landscape is moderately fragmented, with several players offering a range of products from basic electrolytic cells to more sophisticated, integrated systems. Price, performance, and after-sales support are key differentiators in this market, with customers often prioritizing reliability and precision over cost.

Looking ahead, the market for lab-scale electrolysis systems is expected to benefit from the growing interest in green chemistry and sustainable manufacturing processes. This trend is likely to drive further innovations in electrode materials, cell designs, and control systems, opening up new opportunities for market players and researchers alike.

The global laboratory equipment market, which includes micro electrolytic cell systems, is projected to expand at a steady rate over the next five years. This growth is fueled by advancements in research methodologies, increased funding for scientific research, and the rising need for specialized equipment in emerging fields such as nanotechnology and renewable energy research.

Key factors driving the demand for lab-scale electrolysis systems include the growing emphasis on sustainable energy solutions, which has led to increased research in hydrogen production and fuel cell technologies. Additionally, the pharmaceutical industry's focus on electrochemical synthesis for drug discovery and development has created a niche market for specialized electrolytic equipment.

The market is characterized by a mix of established laboratory equipment manufacturers and specialized providers of electrochemistry solutions. Leading companies in this space are continuously innovating to offer more compact, efficient, and user-friendly systems that cater to the evolving needs of researchers and scientists.

Geographically, North America and Europe dominate the market due to their well-established research infrastructure and substantial R&D investments. However, Asia-Pacific is emerging as a rapidly growing market, driven by increasing research activities in countries like China, Japan, and South Korea.

A notable trend in the market is the integration of digital technologies and automation features in lab-scale electrolysis systems. This includes the incorporation of advanced control systems, data logging capabilities, and compatibility with laboratory information management systems (LIMS), enhancing the overall efficiency and reproducibility of experiments.

The competitive landscape is moderately fragmented, with several players offering a range of products from basic electrolytic cells to more sophisticated, integrated systems. Price, performance, and after-sales support are key differentiators in this market, with customers often prioritizing reliability and precision over cost.

Looking ahead, the market for lab-scale electrolysis systems is expected to benefit from the growing interest in green chemistry and sustainable manufacturing processes. This trend is likely to drive further innovations in electrode materials, cell designs, and control systems, opening up new opportunities for market players and researchers alike.

Current Challenges in Micro Electrolytic Cell Technology

Micro electrolytic cell systems for laboratory applications face several significant challenges that hinder their widespread adoption and optimal performance. One of the primary issues is the miniaturization of components while maintaining efficiency. As researchers strive to create smaller and more portable devices, they encounter difficulties in scaling down electrodes, membranes, and other critical elements without compromising the system's overall effectiveness.

Another major challenge lies in the precise control of reaction conditions within the micro-scale environment. Maintaining stable pH levels, temperature, and electrolyte concentrations becomes increasingly complex as the cell size decreases. These parameters are crucial for ensuring reproducible and reliable results in laboratory experiments, and their fluctuations can lead to inconsistent outcomes and reduced data quality.

Material selection poses a significant hurdle in micro electrolytic cell development. The materials used must be chemically resistant, electrically conductive, and biocompatible, depending on the specific application. Finding materials that meet all these criteria while also being suitable for microfabrication techniques is an ongoing challenge for researchers and engineers in the field.

The integration of sensing and monitoring capabilities into micro electrolytic cells presents another technical obstacle. Real-time measurement of various parameters, such as current density, voltage, and product formation, is essential for many laboratory applications. However, incorporating these functionalities into a compact design without interfering with the electrolytic process itself requires innovative solutions and advanced manufacturing techniques.

Power management and energy efficiency are also critical concerns in micro electrolytic cell systems. Miniaturization often leads to increased power density requirements, which can result in heat generation and potential damage to sensitive components. Developing efficient power delivery systems and optimizing energy consumption without compromising performance is a delicate balance that researchers must strike.

Lastly, the challenge of scalability and mass production cannot be overlooked. While prototype micro electrolytic cells may demonstrate promising results in laboratory settings, transitioning these designs to large-scale manufacturing processes while maintaining consistency and cost-effectiveness remains a significant hurdle. Addressing these fabrication and scaling issues is crucial for the widespread adoption of micro electrolytic cell technology in various laboratory applications.

Another major challenge lies in the precise control of reaction conditions within the micro-scale environment. Maintaining stable pH levels, temperature, and electrolyte concentrations becomes increasingly complex as the cell size decreases. These parameters are crucial for ensuring reproducible and reliable results in laboratory experiments, and their fluctuations can lead to inconsistent outcomes and reduced data quality.

Material selection poses a significant hurdle in micro electrolytic cell development. The materials used must be chemically resistant, electrically conductive, and biocompatible, depending on the specific application. Finding materials that meet all these criteria while also being suitable for microfabrication techniques is an ongoing challenge for researchers and engineers in the field.

The integration of sensing and monitoring capabilities into micro electrolytic cells presents another technical obstacle. Real-time measurement of various parameters, such as current density, voltage, and product formation, is essential for many laboratory applications. However, incorporating these functionalities into a compact design without interfering with the electrolytic process itself requires innovative solutions and advanced manufacturing techniques.

Power management and energy efficiency are also critical concerns in micro electrolytic cell systems. Miniaturization often leads to increased power density requirements, which can result in heat generation and potential damage to sensitive components. Developing efficient power delivery systems and optimizing energy consumption without compromising performance is a delicate balance that researchers must strike.

Lastly, the challenge of scalability and mass production cannot be overlooked. While prototype micro electrolytic cells may demonstrate promising results in laboratory settings, transitioning these designs to large-scale manufacturing processes while maintaining consistency and cost-effectiveness remains a significant hurdle. Addressing these fabrication and scaling issues is crucial for the widespread adoption of micro electrolytic cell technology in various laboratory applications.

Existing Micro Electrolytic Cell Designs

01 Design and structure of micro electrolytic cell systems

Micro electrolytic cell systems are designed with specific structures to enhance efficiency and performance. These systems often incorporate innovative electrode configurations, membrane technologies, and miniaturized components to optimize electrochemical reactions at a microscale level. The compact design allows for improved control over reaction conditions and increased surface area-to-volume ratios, leading to enhanced efficiency in various applications.- Design and structure of micro electrolytic cell systems: Micro electrolytic cell systems are designed with specific structures to enhance efficiency and performance. These systems often incorporate innovative electrode configurations, membrane technologies, and miniaturized components to optimize electrochemical reactions at a microscale level. The compact design allows for improved control over reaction conditions and increased surface area-to-volume ratios, leading to enhanced efficiency in various applications.

- Applications of micro electrolytic cell systems: Micro electrolytic cell systems find applications in diverse fields such as water treatment, energy storage, biosensors, and chemical synthesis. These systems are particularly useful in portable devices, environmental monitoring, and point-of-care diagnostics due to their compact size and efficiency. They can be integrated into larger systems or used as standalone units for specific electrochemical processes.

- Control and monitoring of micro electrolytic cells: Advanced control and monitoring systems are crucial for optimizing the performance of micro electrolytic cells. These may include sensors for real-time monitoring of parameters such as pH, temperature, and ion concentrations. Integrated control systems can adjust operating conditions to maintain optimal efficiency and prevent degradation of cell components. Some designs incorporate smart features for remote monitoring and data analysis.

- Materials and coatings for micro electrolytic cells: The choice of materials and coatings plays a critical role in the performance and durability of micro electrolytic cells. Advanced materials such as nanostructured catalysts, conductive polymers, and corrosion-resistant alloys are used to enhance electrochemical reactions and extend the lifespan of cell components. Specialized coatings can improve electrode stability, selectivity, and conductivity in harsh operating environments.

- Integration of micro electrolytic cells with other technologies: Micro electrolytic cell systems are increasingly being integrated with other technologies to create multifunctional devices. This includes combination with microfluidic systems, photovoltaic cells, and wireless communication modules. Such integrations enable new applications in areas like lab-on-a-chip devices, self-powered sensors, and smart water treatment systems. The synergy between micro electrolytic cells and complementary technologies opens up possibilities for innovative solutions in various industries.

02 Applications of micro electrolytic cell systems

Micro electrolytic cell systems find applications in diverse fields such as water treatment, energy storage, biosensors, and chemical synthesis. These systems are particularly useful in scenarios requiring precise control over electrochemical processes, such as in portable water purification devices, miniaturized fuel cells, and lab-on-a-chip devices for analytical chemistry and medical diagnostics.Expand Specific Solutions03 Control and monitoring of micro electrolytic cells

Advanced control and monitoring systems are crucial for optimizing the performance of micro electrolytic cells. These systems often incorporate sensors, microcontrollers, and software algorithms to regulate parameters such as voltage, current, temperature, and electrolyte composition. Real-time monitoring and feedback mechanisms ensure stable operation and allow for rapid adjustments to maintain optimal conditions for the desired electrochemical reactions.Expand Specific Solutions04 Materials and coatings for micro electrolytic cells

The selection of materials and coatings plays a critical role in the performance and durability of micro electrolytic cell systems. Advanced materials, such as nanostructured catalysts, conductive polymers, and corrosion-resistant alloys, are used to enhance electrode efficiency and longevity. Specialized coatings may be applied to improve selectivity, reduce fouling, and extend the operational life of the micro electrolytic cells in various environments.Expand Specific Solutions05 Integration of micro electrolytic cells in larger systems

Micro electrolytic cell systems are often integrated into larger devices or processes to enhance overall functionality. This integration may involve combining multiple micro cells in arrays or stacks, incorporating them into microfluidic systems, or embedding them in smart devices. The seamless integration allows for the development of compact, multifunctional systems that can perform complex electrochemical operations in various industrial, environmental, and biomedical applications.Expand Specific Solutions

Key Players in Lab Electrolysis Equipment Industry

The research on Micro Electrolytic Cell Systems for Laboratory Applications is in a developing stage, with a growing market driven by increasing demand for precise analytical tools in various scientific fields. The market size is expanding, though not yet mature, as more laboratories adopt these systems for diverse applications. Technologically, the field is advancing rapidly, with companies like Abbott Laboratories, Agilent Technologies, and Fraunhofer-Gesellschaft leading innovation. Universities such as Xiamen University and Tokyo Institute of Technology are contributing significantly to research and development, indicating a collaborative ecosystem between industry and academia. The technology's maturity is progressing, but there's still room for substantial improvements in efficiency, miniaturization, and integration with other laboratory systems.

Abbott Laboratories

Technical Solution: Abbott Laboratories has developed advanced micro electrolytic cell systems for laboratory applications, focusing on miniaturization and integration. Their technology utilizes microfluidic channels and electrodes fabricated on silicon or glass substrates, allowing for precise control of electrolyte flow and reaction conditions[1]. The system incorporates multiple sensing elements, including amperometric and potentiometric sensors, enabling real-time monitoring of various analytes[2]. Abbott's micro electrolytic cells are designed for high-throughput screening and point-of-care diagnostics, with applications in drug discovery and personalized medicine[3].

Strengths: Highly integrated and miniaturized design, suitable for point-of-care applications. Weaknesses: May require specialized manufacturing processes, potentially increasing production costs.

Agilent Technologies, Inc.

Technical Solution: Agilent Technologies has developed a micro electrolytic cell system that combines microfluidics with advanced electrochemical detection methods. Their technology features a modular design, allowing for easy customization and integration into existing laboratory workflows[4]. The system utilizes interdigitated microelectrode arrays for enhanced sensitivity and spatial resolution in electrochemical measurements[5]. Agilent's micro electrolytic cells incorporate automated sample handling and precise temperature control, enabling high-throughput analysis for applications such as environmental monitoring and pharmaceutical research[6].

Strengths: Modular design allows for easy customization and integration. Weaknesses: May require specialized expertise for optimal operation and maintenance.

Innovative Electrode Materials and Configurations

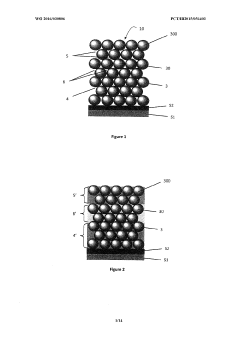

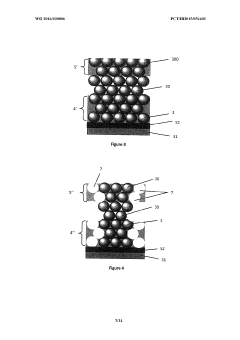

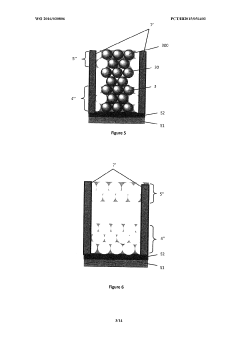

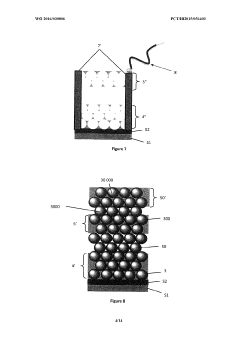

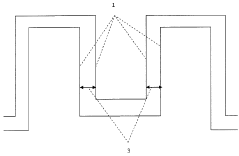

Method for manufacturing a miniaturized electrochemical cell and a miniaturized electrochemical cell

PatentWO2016030806A1

Innovation

- The use of a colloidal template with alternating layers of electron-conducting materials, where the intermediate layer is etched away to create macroporous electrodes with a gap maintained by colloidal particles or insulating materials, allowing for the integration of multiple electrodes in a compact form.

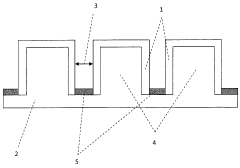

Electrolytic cell equipped with microelectrodes

PatentWO2014072458A1

Innovation

- An electrolytic cell with microelectrodes embedded in a lithographically-patterned substrate, featuring micrometric interelectrodic gaps and extremely smooth surfaces, coated with materials like boron-doped diamond or Pt, Pd, Ir, Ru, and Rh, allowing operation with high-resistivity electrolytes and producing ozone and mixed oxidants without separation and regeneration.

Safety Protocols for Laboratory Electrolysis Systems

Safety protocols for laboratory electrolysis systems are crucial for ensuring the well-being of researchers and preventing potential hazards associated with micro electrolytic cell systems. These protocols encompass a wide range of safety measures, from personal protective equipment (PPE) to proper handling of chemicals and electrical components.

Firstly, appropriate PPE is essential when working with electrolytic cell systems. This includes safety goggles, chemical-resistant gloves, and lab coats to protect against splashes or spills of potentially corrosive electrolytes. In cases where volatile gases may be produced, the use of fume hoods or local exhaust ventilation systems is necessary to prevent inhalation of harmful substances.

Proper electrical safety measures are paramount in electrolysis experiments. All electrical connections should be insulated and properly grounded to prevent electric shock. Regular inspection and maintenance of electrical equipment, including power supplies and electrodes, is crucial to identify and address potential hazards before they lead to accidents.

Chemical safety is another critical aspect of laboratory electrolysis systems. Proper storage and handling of electrolytes and other chemicals used in the experiments are essential. This includes using appropriate containers, labeling all chemicals clearly, and maintaining up-to-date safety data sheets (SDS) for quick reference in case of emergencies.

Emergency response procedures should be well-established and communicated to all laboratory personnel. This includes the location and proper use of safety showers, eyewash stations, and fire extinguishers. A clear evacuation plan should be in place in case of severe incidents.

Training and education play a vital role in maintaining safety in laboratory electrolysis systems. All personnel working with these systems should receive comprehensive training on the specific hazards associated with electrolysis, proper use of equipment, and emergency procedures. Regular refresher courses and safety drills can help reinforce these important practices.

Waste management is another crucial aspect of safety protocols. Proper disposal of spent electrolytes and other chemical waste should follow established guidelines to prevent environmental contamination and ensure compliance with regulatory requirements.

Lastly, implementing a robust system for reporting and investigating incidents or near-misses can help identify potential safety issues and prevent future occurrences. This proactive approach to safety management can significantly enhance the overall safety culture in the laboratory environment.

Firstly, appropriate PPE is essential when working with electrolytic cell systems. This includes safety goggles, chemical-resistant gloves, and lab coats to protect against splashes or spills of potentially corrosive electrolytes. In cases where volatile gases may be produced, the use of fume hoods or local exhaust ventilation systems is necessary to prevent inhalation of harmful substances.

Proper electrical safety measures are paramount in electrolysis experiments. All electrical connections should be insulated and properly grounded to prevent electric shock. Regular inspection and maintenance of electrical equipment, including power supplies and electrodes, is crucial to identify and address potential hazards before they lead to accidents.

Chemical safety is another critical aspect of laboratory electrolysis systems. Proper storage and handling of electrolytes and other chemicals used in the experiments are essential. This includes using appropriate containers, labeling all chemicals clearly, and maintaining up-to-date safety data sheets (SDS) for quick reference in case of emergencies.

Emergency response procedures should be well-established and communicated to all laboratory personnel. This includes the location and proper use of safety showers, eyewash stations, and fire extinguishers. A clear evacuation plan should be in place in case of severe incidents.

Training and education play a vital role in maintaining safety in laboratory electrolysis systems. All personnel working with these systems should receive comprehensive training on the specific hazards associated with electrolysis, proper use of equipment, and emergency procedures. Regular refresher courses and safety drills can help reinforce these important practices.

Waste management is another crucial aspect of safety protocols. Proper disposal of spent electrolytes and other chemical waste should follow established guidelines to prevent environmental contamination and ensure compliance with regulatory requirements.

Lastly, implementing a robust system for reporting and investigating incidents or near-misses can help identify potential safety issues and prevent future occurrences. This proactive approach to safety management can significantly enhance the overall safety culture in the laboratory environment.

Environmental Impact of Micro Electrolytic Processes

The environmental impact of micro electrolytic processes in laboratory applications is a crucial aspect to consider when researching and developing micro electrolytic cell systems. These processes, while operating at a small scale, can have significant cumulative effects on the environment if not properly managed.

One of the primary environmental concerns associated with micro electrolytic processes is the generation of potentially harmful byproducts. Depending on the specific electrolytic reactions involved, these systems may produce gases, ions, or other chemical species that could be detrimental to the environment if released. For instance, the electrolysis of water can generate hydrogen and oxygen gases, which, if not properly contained, may pose safety risks or contribute to atmospheric changes.

The use of electrolytes and electrode materials in micro electrolytic cells also raises environmental considerations. Some electrolytes may contain toxic or corrosive substances that require careful handling and disposal. Similarly, electrode materials may include rare or precious metals, the mining and processing of which can have substantial environmental impacts. Proper recycling and recovery of these materials are essential to minimize resource depletion and reduce the overall environmental footprint of micro electrolytic systems.

Energy consumption is another critical factor in assessing the environmental impact of micro electrolytic processes. While individual cells may have low power requirements, the cumulative energy demand of multiple cells or prolonged operation can be significant. Researchers must focus on optimizing energy efficiency and exploring the integration of renewable energy sources to power these systems, thereby reducing their carbon footprint and aligning with sustainable laboratory practices.

Water usage and wastewater management are additional environmental concerns associated with micro electrolytic processes. Some applications may require continuous flow or frequent replacement of electrolyte solutions, leading to increased water consumption and the generation of wastewater that may contain dissolved metals or other contaminants. Implementing water recycling systems and developing efficient purification methods for spent electrolytes can help mitigate these impacts.

The lifecycle assessment of micro electrolytic cell systems is crucial for understanding their overall environmental impact. This includes considering the environmental costs of manufacturing, transportation, operation, and eventual disposal or recycling of the components. By adopting a cradle-to-grave approach, researchers can identify opportunities for improving the sustainability of these systems throughout their lifecycle.

Lastly, the potential for scaling up micro electrolytic processes from laboratory to industrial applications must be evaluated from an environmental perspective. While the environmental impact of a single micro electrolytic cell may be minimal, the cumulative effect of widespread adoption could be substantial. Therefore, it is essential to anticipate and address potential environmental challenges early in the research and development phase to ensure the sustainable implementation of this technology on a larger scale.

One of the primary environmental concerns associated with micro electrolytic processes is the generation of potentially harmful byproducts. Depending on the specific electrolytic reactions involved, these systems may produce gases, ions, or other chemical species that could be detrimental to the environment if released. For instance, the electrolysis of water can generate hydrogen and oxygen gases, which, if not properly contained, may pose safety risks or contribute to atmospheric changes.

The use of electrolytes and electrode materials in micro electrolytic cells also raises environmental considerations. Some electrolytes may contain toxic or corrosive substances that require careful handling and disposal. Similarly, electrode materials may include rare or precious metals, the mining and processing of which can have substantial environmental impacts. Proper recycling and recovery of these materials are essential to minimize resource depletion and reduce the overall environmental footprint of micro electrolytic systems.

Energy consumption is another critical factor in assessing the environmental impact of micro electrolytic processes. While individual cells may have low power requirements, the cumulative energy demand of multiple cells or prolonged operation can be significant. Researchers must focus on optimizing energy efficiency and exploring the integration of renewable energy sources to power these systems, thereby reducing their carbon footprint and aligning with sustainable laboratory practices.

Water usage and wastewater management are additional environmental concerns associated with micro electrolytic processes. Some applications may require continuous flow or frequent replacement of electrolyte solutions, leading to increased water consumption and the generation of wastewater that may contain dissolved metals or other contaminants. Implementing water recycling systems and developing efficient purification methods for spent electrolytes can help mitigate these impacts.

The lifecycle assessment of micro electrolytic cell systems is crucial for understanding their overall environmental impact. This includes considering the environmental costs of manufacturing, transportation, operation, and eventual disposal or recycling of the components. By adopting a cradle-to-grave approach, researchers can identify opportunities for improving the sustainability of these systems throughout their lifecycle.

Lastly, the potential for scaling up micro electrolytic processes from laboratory to industrial applications must be evaluated from an environmental perspective. While the environmental impact of a single micro electrolytic cell may be minimal, the cumulative effect of widespread adoption could be substantial. Therefore, it is essential to anticipate and address potential environmental challenges early in the research and development phase to ensure the sustainable implementation of this technology on a larger scale.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!