Integration of Electrolytic Cells in Smart Factory Systems

AUG 1, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Electrolytic Cells in Smart Factories: Background and Objectives

Electrolytic cells have been a cornerstone of industrial processes for over a century, primarily used in the production of chemicals, metals, and other materials. As we enter the era of smart manufacturing, the integration of these traditional electrochemical systems into modern, digitally-driven factory environments presents both significant opportunities and challenges. This technological convergence aims to enhance efficiency, reduce waste, and optimize resource utilization in industries ranging from metal refining to chemical production.

The evolution of electrolytic cell technology has been marked by incremental improvements in electrode materials, cell design, and process control. However, the advent of Industry 4.0 and the concept of smart factories have opened new avenues for revolutionary advancements. The integration of electrolytic cells into smart factory systems represents a paradigm shift in how these fundamental industrial processes are managed and optimized.

The primary objective of this integration is to create a seamless, data-driven ecosystem where electrolytic processes are not isolated operations but integral components of a larger, interconnected manufacturing network. This involves the implementation of advanced sensors, real-time monitoring systems, and predictive analytics to enhance the performance and reliability of electrolytic cells. By doing so, manufacturers aim to achieve unprecedented levels of process control, energy efficiency, and product quality.

Another key goal is to leverage the power of artificial intelligence and machine learning algorithms to optimize electrolytic processes dynamically. These technologies can analyze vast amounts of data from multiple sources within the factory, adjusting operational parameters in real-time to maintain optimal conditions and predict maintenance needs before failures occur. This proactive approach not only improves productivity but also extends the lifespan of equipment and reduces downtime.

Furthermore, the integration seeks to address environmental concerns by minimizing energy consumption and reducing the carbon footprint of electrolytic processes. Smart factory systems can enable more precise control over energy inputs, potentially leading to significant reductions in power consumption and associated greenhouse gas emissions. This aligns with global sustainability goals and increasingly stringent environmental regulations.

As we explore the integration of electrolytic cells in smart factory systems, it is crucial to understand the historical context, current technological landscape, and future trajectories. This technological fusion promises to revolutionize traditional industries, making them more efficient, sustainable, and competitive in the global market. The following sections will delve deeper into the market demands, technical challenges, and innovative solutions driving this transformative integration.

The evolution of electrolytic cell technology has been marked by incremental improvements in electrode materials, cell design, and process control. However, the advent of Industry 4.0 and the concept of smart factories have opened new avenues for revolutionary advancements. The integration of electrolytic cells into smart factory systems represents a paradigm shift in how these fundamental industrial processes are managed and optimized.

The primary objective of this integration is to create a seamless, data-driven ecosystem where electrolytic processes are not isolated operations but integral components of a larger, interconnected manufacturing network. This involves the implementation of advanced sensors, real-time monitoring systems, and predictive analytics to enhance the performance and reliability of electrolytic cells. By doing so, manufacturers aim to achieve unprecedented levels of process control, energy efficiency, and product quality.

Another key goal is to leverage the power of artificial intelligence and machine learning algorithms to optimize electrolytic processes dynamically. These technologies can analyze vast amounts of data from multiple sources within the factory, adjusting operational parameters in real-time to maintain optimal conditions and predict maintenance needs before failures occur. This proactive approach not only improves productivity but also extends the lifespan of equipment and reduces downtime.

Furthermore, the integration seeks to address environmental concerns by minimizing energy consumption and reducing the carbon footprint of electrolytic processes. Smart factory systems can enable more precise control over energy inputs, potentially leading to significant reductions in power consumption and associated greenhouse gas emissions. This aligns with global sustainability goals and increasingly stringent environmental regulations.

As we explore the integration of electrolytic cells in smart factory systems, it is crucial to understand the historical context, current technological landscape, and future trajectories. This technological fusion promises to revolutionize traditional industries, making them more efficient, sustainable, and competitive in the global market. The following sections will delve deeper into the market demands, technical challenges, and innovative solutions driving this transformative integration.

Market Demand for Integrated Electrolytic Systems

The integration of electrolytic cells in smart factory systems represents a significant market opportunity driven by the increasing demand for advanced manufacturing processes and sustainable production methods. This trend is fueled by the growing need for efficient resource utilization, waste reduction, and improved product quality across various industries.

In the chemical sector, there is a rising demand for integrated electrolytic systems that can enhance the production of chlorine, sodium hydroxide, and hydrogen. These systems offer precise control over electrolysis processes, leading to higher yields and reduced energy consumption. The market for such integrated solutions is expected to grow as chemical manufacturers seek to optimize their operations and meet stringent environmental regulations.

The metal production and refining industry is another key driver of market demand for integrated electrolytic systems. Aluminum smelters, in particular, are increasingly adopting smart factory technologies to improve the efficiency of their electrolytic processes. These integrated systems enable real-time monitoring of cell performance, predictive maintenance, and automated adjustments to process parameters, resulting in significant cost savings and improved product quality.

In the water treatment sector, there is a growing interest in integrating electrolytic cells into smart water purification systems. This demand is driven by the need for more efficient and environmentally friendly water treatment solutions in both industrial and municipal applications. Integrated electrolytic systems offer advantages such as reduced chemical usage, improved disinfection efficacy, and the ability to handle varying water quality conditions through adaptive control mechanisms.

The electronics industry is also contributing to the market demand for integrated electrolytic systems, particularly in the production of printed circuit boards and semiconductor devices. These systems enable precise control of electroplating processes, ensuring uniform metal deposition and improved product quality. As the electronics industry continues to evolve towards miniaturization and increased functionality, the demand for advanced electrolytic solutions is expected to grow.

Furthermore, the automotive sector is showing interest in integrated electrolytic systems for applications such as fuel cell production and battery manufacturing. As the shift towards electric vehicles accelerates, there is a growing need for efficient and scalable production processes for these critical components. Integrated electrolytic systems offer the potential for improved energy efficiency, reduced material waste, and enhanced quality control in these manufacturing processes.

The market demand for integrated electrolytic systems in smart factories is also driven by the broader trend towards Industry 4.0 and the Industrial Internet of Things (IIoT). Manufacturers across various sectors are seeking to leverage data analytics, artificial intelligence, and automation to optimize their production processes. Integrated electrolytic systems that can seamlessly connect with other factory systems and provide real-time data for analysis and decision-making are increasingly valued in this context.

In the chemical sector, there is a rising demand for integrated electrolytic systems that can enhance the production of chlorine, sodium hydroxide, and hydrogen. These systems offer precise control over electrolysis processes, leading to higher yields and reduced energy consumption. The market for such integrated solutions is expected to grow as chemical manufacturers seek to optimize their operations and meet stringent environmental regulations.

The metal production and refining industry is another key driver of market demand for integrated electrolytic systems. Aluminum smelters, in particular, are increasingly adopting smart factory technologies to improve the efficiency of their electrolytic processes. These integrated systems enable real-time monitoring of cell performance, predictive maintenance, and automated adjustments to process parameters, resulting in significant cost savings and improved product quality.

In the water treatment sector, there is a growing interest in integrating electrolytic cells into smart water purification systems. This demand is driven by the need for more efficient and environmentally friendly water treatment solutions in both industrial and municipal applications. Integrated electrolytic systems offer advantages such as reduced chemical usage, improved disinfection efficacy, and the ability to handle varying water quality conditions through adaptive control mechanisms.

The electronics industry is also contributing to the market demand for integrated electrolytic systems, particularly in the production of printed circuit boards and semiconductor devices. These systems enable precise control of electroplating processes, ensuring uniform metal deposition and improved product quality. As the electronics industry continues to evolve towards miniaturization and increased functionality, the demand for advanced electrolytic solutions is expected to grow.

Furthermore, the automotive sector is showing interest in integrated electrolytic systems for applications such as fuel cell production and battery manufacturing. As the shift towards electric vehicles accelerates, there is a growing need for efficient and scalable production processes for these critical components. Integrated electrolytic systems offer the potential for improved energy efficiency, reduced material waste, and enhanced quality control in these manufacturing processes.

The market demand for integrated electrolytic systems in smart factories is also driven by the broader trend towards Industry 4.0 and the Industrial Internet of Things (IIoT). Manufacturers across various sectors are seeking to leverage data analytics, artificial intelligence, and automation to optimize their production processes. Integrated electrolytic systems that can seamlessly connect with other factory systems and provide real-time data for analysis and decision-making are increasingly valued in this context.

Current Challenges in Electrolytic Cell Integration

The integration of electrolytic cells into smart factory systems presents several significant challenges that need to be addressed for successful implementation. One of the primary obstacles is the complexity of real-time monitoring and control of electrolytic processes. These processes are highly sensitive to various parameters, including temperature, pH levels, and electrical current, which require constant adjustment to maintain optimal efficiency. Developing robust sensor networks and control algorithms capable of handling the dynamic nature of electrolytic reactions in an industrial setting remains a formidable task.

Another major challenge lies in the integration of electrolytic cell data with existing manufacturing execution systems (MES) and enterprise resource planning (ERP) platforms. The vast amount of data generated by electrolytic cells needs to be seamlessly incorporated into the broader smart factory ecosystem, allowing for comprehensive analysis and decision-making. This integration often requires significant modifications to existing software architectures and the development of custom interfaces, which can be both time-consuming and costly.

Energy management poses yet another hurdle in the integration process. Electrolytic cells are typically energy-intensive, and their power consumption patterns can be highly variable. Incorporating these cells into smart factory systems necessitates the development of sophisticated energy management strategies that can balance the power demands of electrolytic processes with other manufacturing operations while optimizing overall energy efficiency. This challenge is further compounded by the increasing focus on sustainability and the need to integrate renewable energy sources into industrial processes.

The maintenance and lifecycle management of electrolytic cells within a smart factory environment also present significant challenges. These cells often require specialized maintenance procedures and have unique wear patterns that can be difficult to predict and manage using conventional maintenance strategies. Developing predictive maintenance models that can accurately forecast the performance degradation of electrolytic cells and schedule maintenance activities accordingly is crucial for ensuring continuous operation and minimizing downtime.

Safety considerations add another layer of complexity to the integration process. Electrolytic cells often involve hazardous materials and high-voltage electrical systems, necessitating the implementation of robust safety protocols and fail-safe mechanisms. Integrating these safety systems with the broader smart factory infrastructure while ensuring compliance with relevant regulations and standards can be a complex and resource-intensive endeavor.

Lastly, the skills gap in the workforce presents a significant challenge. The integration of electrolytic cells into smart factory systems requires a unique blend of expertise in electrochemistry, automation, data analytics, and industrial engineering. Finding and training personnel with this multidisciplinary skill set can be difficult, potentially slowing down the integration process and limiting the full realization of smart factory benefits in electrolytic cell operations.

Another major challenge lies in the integration of electrolytic cell data with existing manufacturing execution systems (MES) and enterprise resource planning (ERP) platforms. The vast amount of data generated by electrolytic cells needs to be seamlessly incorporated into the broader smart factory ecosystem, allowing for comprehensive analysis and decision-making. This integration often requires significant modifications to existing software architectures and the development of custom interfaces, which can be both time-consuming and costly.

Energy management poses yet another hurdle in the integration process. Electrolytic cells are typically energy-intensive, and their power consumption patterns can be highly variable. Incorporating these cells into smart factory systems necessitates the development of sophisticated energy management strategies that can balance the power demands of electrolytic processes with other manufacturing operations while optimizing overall energy efficiency. This challenge is further compounded by the increasing focus on sustainability and the need to integrate renewable energy sources into industrial processes.

The maintenance and lifecycle management of electrolytic cells within a smart factory environment also present significant challenges. These cells often require specialized maintenance procedures and have unique wear patterns that can be difficult to predict and manage using conventional maintenance strategies. Developing predictive maintenance models that can accurately forecast the performance degradation of electrolytic cells and schedule maintenance activities accordingly is crucial for ensuring continuous operation and minimizing downtime.

Safety considerations add another layer of complexity to the integration process. Electrolytic cells often involve hazardous materials and high-voltage electrical systems, necessitating the implementation of robust safety protocols and fail-safe mechanisms. Integrating these safety systems with the broader smart factory infrastructure while ensuring compliance with relevant regulations and standards can be a complex and resource-intensive endeavor.

Lastly, the skills gap in the workforce presents a significant challenge. The integration of electrolytic cells into smart factory systems requires a unique blend of expertise in electrochemistry, automation, data analytics, and industrial engineering. Finding and training personnel with this multidisciplinary skill set can be difficult, potentially slowing down the integration process and limiting the full realization of smart factory benefits in electrolytic cell operations.

Existing Integration Approaches for Electrolytic Cells

01 Design and structure of electrolytic cells

Electrolytic cells are designed with specific structures to facilitate the electrolysis process. These designs may include various components such as electrodes, membranes, and compartments to optimize the efficiency of the electrochemical reactions. The structure of the cell can be tailored to suit different applications and improve overall performance.- Electrolytic cell design and components: Electrolytic cells are designed with specific components to facilitate electrochemical reactions. These components typically include electrodes (anode and cathode), electrolyte, and a separator. The design of these cells can vary based on the intended application, such as energy storage, metal production, or water treatment. Innovations in cell design focus on improving efficiency, durability, and performance.

- Electrode materials and configurations: The choice of electrode materials and their configurations play a crucial role in the performance of electrolytic cells. Research focuses on developing novel electrode materials with enhanced conductivity, stability, and catalytic activity. Electrode configurations are optimized to increase surface area and improve reaction kinetics. Innovations in this area aim to enhance overall cell efficiency and longevity.

- Electrolyte composition and management: The electrolyte is a key component in electrolytic cells, serving as the medium for ion transport. Research in this area focuses on developing new electrolyte compositions to improve conductivity, stability, and safety. Electrolyte management systems are designed to maintain optimal concentration and prevent degradation. Innovations aim to enhance cell performance and extend operational life.

- Control systems and monitoring: Advanced control systems and monitoring techniques are essential for optimal operation of electrolytic cells. These systems regulate parameters such as temperature, pressure, and current density. Real-time monitoring helps in maintaining efficiency and detecting potential issues. Innovations in this area focus on developing intelligent control algorithms and sensor technologies for improved cell management.

- Applications and specialized cell designs: Electrolytic cells find applications in various industries, including energy storage, metal production, and water treatment. Specialized cell designs are developed to meet specific application requirements. For example, cells for hydrogen production, metal refining, or desalination may have unique features tailored to their respective processes. Research in this area focuses on optimizing cell designs for specific applications and exploring new potential uses.

02 Electrode materials and configurations

The choice of electrode materials and their configurations play a crucial role in the efficiency of electrolytic cells. Different materials may be used for anodes and cathodes, depending on the specific electrochemical process. Electrode configurations can be optimized to enhance surface area, reduce resistance, and improve overall cell performance.Expand Specific Solutions03 Electrolyte composition and management

The composition of the electrolyte solution is critical for the operation of electrolytic cells. Various electrolytes may be used depending on the desired reactions. Proper management of the electrolyte, including concentration control and circulation, can significantly impact the efficiency and longevity of the cell.Expand Specific Solutions04 Control systems and monitoring

Advanced control systems and monitoring techniques are employed in modern electrolytic cells to optimize performance and ensure safety. These may include sensors for measuring voltage, current, temperature, and electrolyte composition. Automated control systems can adjust operating parameters in real-time to maintain optimal conditions.Expand Specific Solutions05 Applications and specialized electrolytic cells

Electrolytic cells are used in various applications, including metal production, water treatment, and energy storage. Specialized cells are designed for specific purposes, such as chlor-alkali production or hydrogen generation. These specialized cells may incorporate unique features or materials to enhance their performance for the intended application.Expand Specific Solutions

Key Players in Smart Factory Electrolytic Solutions

The integration of electrolytic cells in smart factory systems is in an early development stage, with a growing market driven by increasing demand for green hydrogen and industrial automation. The technology's maturity varies among key players, with companies like Siemens Energy, Applied Materials, and Thyssenkrupp leading in industrial applications. Research institutions such as Fraunhofer-Gesellschaft and Dalian Institute of Chemical Physics are advancing fundamental technologies. Emerging players like EvolOH and POCell Tech are focusing on innovative electrolysis solutions. The market is expected to expand rapidly as industries seek to decarbonize their processes, with major automotive and electronics manufacturers like Honda, Sony, and LG Chem exploring integration possibilities.

Siemens Energy Global GmbH & Co. KG

Technical Solution: Siemens Energy has developed an advanced integration system for electrolytic cells in smart factory environments. Their solution incorporates AI-driven predictive maintenance, real-time monitoring, and adaptive control systems. The system utilizes digital twin technology to create virtual models of electrolytic cells, enabling optimization of performance and energy efficiency[1]. Siemens' approach includes a modular design that allows for easy scalability and integration with existing factory infrastructure. The company has also implemented advanced data analytics to improve process efficiency and reduce downtime[2]. Their electrolytic cell integration system is designed to work seamlessly with renewable energy sources, supporting the transition to green hydrogen production[3].

Strengths: Comprehensive integration with existing smart factory systems, advanced AI and digital twin capabilities, scalability, and support for green energy transition. Weaknesses: Potentially high initial implementation costs and complexity in retrofitting older electrolytic cell systems.

Fraunhofer-Gesellschaft eV

Technical Solution: Fraunhofer-Gesellschaft has developed a holistic approach to integrating electrolytic cells into smart factory systems. Their solution focuses on creating a highly efficient and flexible production environment. The system incorporates advanced sensors and IoT devices to monitor electrolytic cell performance in real-time[4]. Fraunhofer's approach includes the development of novel electrode materials and cell designs that enhance efficiency and durability. They have also implemented machine learning algorithms for process optimization and predictive maintenance[5]. The integration system is designed to be adaptable to various electrolysis technologies, including PEM and alkaline electrolysis. Fraunhofer has also developed innovative heat recovery systems to improve overall energy efficiency in the electrolysis process[6].

Strengths: Cutting-edge research in materials and cell design, adaptability to different electrolysis technologies, and focus on energy efficiency. Weaknesses: Potential challenges in scaling from research to large-scale industrial implementation.

Innovative Electrolytic Cell Integration Techniques

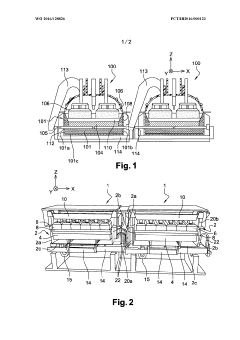

Electrolysis cell

PatentWO2016128826A1

Innovation

- The electrolytic cell design features flexible electrical conductors that deform under the cell, allowing vertical movement and maintaining electrical connections, reducing the need for bulky conductor arrangements and minimizing inter-tank space, with flexible portions positioned under the cell to facilitate easier handling and space savings.

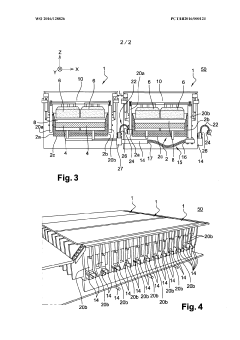

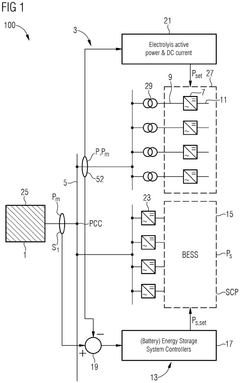

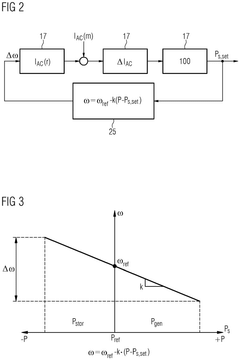

Electrolysis system comprising an electrolysis plant and a renewable power generation plant and method for controlling an electrolysis system

PatentPendingEP4513702A1

Innovation

- An electrolysis system comprising a renewable power generation plant and an electrolysis plant connected to a common AC bus bar, with an inverter-based energy storage system that emulates the operation of a synchronous generator to stabilize the AC input voltage and provide necessary short circuit power at the point of common coupling.

Energy Efficiency and Sustainability Considerations

The integration of electrolytic cells in smart factory systems presents significant opportunities for enhancing energy efficiency and sustainability. These systems can optimize energy consumption by precisely controlling the electrolysis process, reducing waste and improving overall resource utilization.

Smart factory systems enable real-time monitoring and adjustment of electrolytic cell parameters, such as current density, temperature, and electrolyte composition. This level of control allows for dynamic optimization of energy input based on production demands and energy availability. By implementing advanced algorithms and machine learning techniques, these systems can predict and prevent energy-intensive anomalies, further reducing energy waste.

The integration of renewable energy sources with electrolytic processes in smart factories can significantly enhance sustainability. Electrolytic cells can be synchronized with intermittent renewable energy supplies, such as solar or wind power, to maximize the use of clean energy. This integration can help balance grid loads and reduce reliance on fossil fuels, contributing to a more sustainable industrial ecosystem.

Smart factory systems also facilitate the implementation of energy recovery mechanisms in electrolytic processes. Waste heat generated during electrolysis can be captured and repurposed for other industrial processes or converted back into electricity, improving overall energy efficiency. Additionally, these systems can optimize the recycling of byproducts and spent electrolytes, minimizing waste and reducing the environmental impact of electrolytic operations.

The use of advanced materials and designs in electrolytic cells, guided by smart factory data analytics, can lead to improved energy efficiency. For instance, the development of more efficient electrode materials or the optimization of cell geometry based on performance data can significantly reduce energy consumption per unit of product.

Furthermore, smart factory systems enable comprehensive life cycle assessments of electrolytic processes. By tracking energy consumption, material flows, and emissions throughout the production chain, manufacturers can identify areas for sustainability improvements and make data-driven decisions to reduce their environmental footprint.

The integration of electrolytic cells in smart factory systems also supports the concept of circular economy. By optimizing resource use, minimizing waste, and enhancing recycling processes, these systems contribute to closing the loop in industrial production. This approach not only improves sustainability but also can lead to cost savings and new revenue streams from recovered materials and energy.

Smart factory systems enable real-time monitoring and adjustment of electrolytic cell parameters, such as current density, temperature, and electrolyte composition. This level of control allows for dynamic optimization of energy input based on production demands and energy availability. By implementing advanced algorithms and machine learning techniques, these systems can predict and prevent energy-intensive anomalies, further reducing energy waste.

The integration of renewable energy sources with electrolytic processes in smart factories can significantly enhance sustainability. Electrolytic cells can be synchronized with intermittent renewable energy supplies, such as solar or wind power, to maximize the use of clean energy. This integration can help balance grid loads and reduce reliance on fossil fuels, contributing to a more sustainable industrial ecosystem.

Smart factory systems also facilitate the implementation of energy recovery mechanisms in electrolytic processes. Waste heat generated during electrolysis can be captured and repurposed for other industrial processes or converted back into electricity, improving overall energy efficiency. Additionally, these systems can optimize the recycling of byproducts and spent electrolytes, minimizing waste and reducing the environmental impact of electrolytic operations.

The use of advanced materials and designs in electrolytic cells, guided by smart factory data analytics, can lead to improved energy efficiency. For instance, the development of more efficient electrode materials or the optimization of cell geometry based on performance data can significantly reduce energy consumption per unit of product.

Furthermore, smart factory systems enable comprehensive life cycle assessments of electrolytic processes. By tracking energy consumption, material flows, and emissions throughout the production chain, manufacturers can identify areas for sustainability improvements and make data-driven decisions to reduce their environmental footprint.

The integration of electrolytic cells in smart factory systems also supports the concept of circular economy. By optimizing resource use, minimizing waste, and enhancing recycling processes, these systems contribute to closing the loop in industrial production. This approach not only improves sustainability but also can lead to cost savings and new revenue streams from recovered materials and energy.

Data Analytics for Electrolytic Process Optimization

Data analytics plays a crucial role in optimizing electrolytic processes within smart factory systems. By leveraging advanced analytical techniques, manufacturers can significantly enhance the efficiency, quality, and sustainability of their electrolytic operations. The integration of data-driven insights enables real-time monitoring, predictive maintenance, and adaptive control of electrolytic cells.

One of the primary applications of data analytics in electrolytic process optimization is the development of predictive models. These models utilize historical data and real-time sensor inputs to forecast process outcomes, such as product quality, energy consumption, and electrode degradation. Machine learning algorithms, including neural networks and decision trees, can be employed to identify complex patterns and relationships within the vast amounts of data generated by electrolytic cells.

Process control optimization is another key area where data analytics proves invaluable. By analyzing process variables and their interdependencies, manufacturers can implement advanced control strategies that maintain optimal operating conditions. This may involve the use of multivariate statistical process control (MSPC) techniques or model predictive control (MPC) algorithms to adjust process parameters dynamically.

Energy efficiency is a critical concern in electrolytic processes, and data analytics offers powerful tools for minimizing energy consumption. By analyzing energy usage patterns and correlating them with production metrics, manufacturers can identify opportunities for reducing energy waste and optimizing power distribution across multiple cells. This may involve load balancing strategies or the implementation of demand response programs in coordination with smart grid systems.

Quality assurance and defect detection benefit greatly from the application of data analytics in electrolytic processes. Advanced image processing and spectral analysis techniques can be used to detect impurities or irregularities in real-time, enabling rapid intervention and minimizing product losses. Statistical process control methods can be enhanced with machine learning algorithms to detect subtle deviations that may indicate emerging quality issues.

The integration of data analytics with Internet of Things (IoT) technologies further enhances the capabilities of smart factory systems in managing electrolytic processes. IoT sensors provide a continuous stream of data on various process parameters, which can be analyzed in real-time to enable adaptive control and rapid response to changing conditions. This integration also facilitates the implementation of digital twin technologies, allowing for virtual simulation and optimization of electrolytic processes.

As the field of data analytics continues to evolve, new opportunities for electrolytic process optimization are emerging. The application of deep learning techniques and reinforcement learning algorithms holds promise for developing more sophisticated control strategies that can adapt to complex, non-linear process dynamics. Additionally, the integration of blockchain technology with data analytics systems may enhance the traceability and security of electrolytic production data, particularly in industries where regulatory compliance is critical.

One of the primary applications of data analytics in electrolytic process optimization is the development of predictive models. These models utilize historical data and real-time sensor inputs to forecast process outcomes, such as product quality, energy consumption, and electrode degradation. Machine learning algorithms, including neural networks and decision trees, can be employed to identify complex patterns and relationships within the vast amounts of data generated by electrolytic cells.

Process control optimization is another key area where data analytics proves invaluable. By analyzing process variables and their interdependencies, manufacturers can implement advanced control strategies that maintain optimal operating conditions. This may involve the use of multivariate statistical process control (MSPC) techniques or model predictive control (MPC) algorithms to adjust process parameters dynamically.

Energy efficiency is a critical concern in electrolytic processes, and data analytics offers powerful tools for minimizing energy consumption. By analyzing energy usage patterns and correlating them with production metrics, manufacturers can identify opportunities for reducing energy waste and optimizing power distribution across multiple cells. This may involve load balancing strategies or the implementation of demand response programs in coordination with smart grid systems.

Quality assurance and defect detection benefit greatly from the application of data analytics in electrolytic processes. Advanced image processing and spectral analysis techniques can be used to detect impurities or irregularities in real-time, enabling rapid intervention and minimizing product losses. Statistical process control methods can be enhanced with machine learning algorithms to detect subtle deviations that may indicate emerging quality issues.

The integration of data analytics with Internet of Things (IoT) technologies further enhances the capabilities of smart factory systems in managing electrolytic processes. IoT sensors provide a continuous stream of data on various process parameters, which can be analyzed in real-time to enable adaptive control and rapid response to changing conditions. This integration also facilitates the implementation of digital twin technologies, allowing for virtual simulation and optimization of electrolytic processes.

As the field of data analytics continues to evolve, new opportunities for electrolytic process optimization are emerging. The application of deep learning techniques and reinforcement learning algorithms holds promise for developing more sophisticated control strategies that can adapt to complex, non-linear process dynamics. Additionally, the integration of blockchain technology with data analytics systems may enhance the traceability and security of electrolytic production data, particularly in industries where regulatory compliance is critical.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!