Expanding Electrolytic Cell Applications in Synthetic Biology

AUG 1, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Electrolytic Cells in Synthetic Biology: Background and Objectives

Electrolytic cells have emerged as a powerful tool in the rapidly evolving field of synthetic biology. These electrochemical devices, traditionally used in industrial processes, are now finding novel applications in biological systems. The integration of electrolytic cells into synthetic biology represents a convergence of electrochemistry and genetic engineering, opening up new possibilities for manipulating and controlling biological processes.

The development of electrolytic cell applications in synthetic biology can be traced back to the early 2000s when researchers began exploring the use of bioelectrochemical systems for energy production and waste treatment. Since then, the field has expanded significantly, with electrolytic cells now being used for a wide range of applications, including biosensing, bioproduction, and biocomputing.

The primary objective of expanding electrolytic cell applications in synthetic biology is to harness the power of electrochemistry to enhance and control biological systems. This includes developing more efficient and sustainable methods for producing valuable compounds, creating novel biosensors for detecting specific molecules or environmental conditions, and designing bioelectronic devices that can interface with living organisms.

One of the key drivers behind this technological evolution is the growing need for sustainable and environmentally friendly solutions in various industries. Electrolytic cells offer a unique advantage in this regard, as they can operate under mild conditions and often require less energy input compared to traditional chemical processes. This aligns well with the goals of synthetic biology, which aims to create biological systems that can perform useful functions in a sustainable manner.

The integration of electrolytic cells into synthetic biology also presents opportunities for addressing global challenges, such as climate change and resource scarcity. By combining the precision of genetic engineering with the controllability of electrochemical systems, researchers are exploring ways to develop more efficient carbon capture technologies, produce renewable fuels, and create novel materials from biological feedstocks.

As the field continues to advance, several key technological objectives have emerged. These include improving the efficiency and scalability of bioelectrochemical systems, developing new electrode materials that are biocompatible and can interface effectively with living cells, and creating sophisticated control systems that can precisely regulate the electrochemical environment of biological systems. Additionally, there is a growing focus on understanding the fundamental mechanisms of electron transfer between electrodes and biological entities, which is crucial for optimizing the performance of electrolytic cell applications in synthetic biology.

The development of electrolytic cell applications in synthetic biology can be traced back to the early 2000s when researchers began exploring the use of bioelectrochemical systems for energy production and waste treatment. Since then, the field has expanded significantly, with electrolytic cells now being used for a wide range of applications, including biosensing, bioproduction, and biocomputing.

The primary objective of expanding electrolytic cell applications in synthetic biology is to harness the power of electrochemistry to enhance and control biological systems. This includes developing more efficient and sustainable methods for producing valuable compounds, creating novel biosensors for detecting specific molecules or environmental conditions, and designing bioelectronic devices that can interface with living organisms.

One of the key drivers behind this technological evolution is the growing need for sustainable and environmentally friendly solutions in various industries. Electrolytic cells offer a unique advantage in this regard, as they can operate under mild conditions and often require less energy input compared to traditional chemical processes. This aligns well with the goals of synthetic biology, which aims to create biological systems that can perform useful functions in a sustainable manner.

The integration of electrolytic cells into synthetic biology also presents opportunities for addressing global challenges, such as climate change and resource scarcity. By combining the precision of genetic engineering with the controllability of electrochemical systems, researchers are exploring ways to develop more efficient carbon capture technologies, produce renewable fuels, and create novel materials from biological feedstocks.

As the field continues to advance, several key technological objectives have emerged. These include improving the efficiency and scalability of bioelectrochemical systems, developing new electrode materials that are biocompatible and can interface effectively with living cells, and creating sophisticated control systems that can precisely regulate the electrochemical environment of biological systems. Additionally, there is a growing focus on understanding the fundamental mechanisms of electron transfer between electrodes and biological entities, which is crucial for optimizing the performance of electrolytic cell applications in synthetic biology.

Market Analysis for Synthetic Biology Applications

The synthetic biology market has been experiencing significant growth in recent years, driven by advancements in genetic engineering, DNA sequencing, and bioinformatics. The global synthetic biology market size was valued at approximately $9.5 billion in 2021 and is projected to expand at a compound annual growth rate (CAGR) of around 23% from 2022 to 2030. This rapid growth is attributed to increasing investments in research and development, rising demand for synthetic biology products in various industries, and growing applications in healthcare and pharmaceuticals.

The expanding applications of electrolytic cells in synthetic biology are expected to contribute significantly to this market growth. Electrolytic cells have shown promise in various synthetic biology applications, including biosensors, biofuel production, and bioelectrochemical systems. The integration of electrolytic cells with synthetic biology techniques offers potential solutions for sustainable energy production, environmental remediation, and advanced biosensing technologies.

In the healthcare sector, synthetic biology applications utilizing electrolytic cells are gaining traction for drug discovery, personalized medicine, and diagnostics. The pharmaceutical industry is increasingly adopting synthetic biology approaches for the production of novel therapeutics and biopharmaceuticals. This trend is expected to drive the demand for electrolytic cell applications in synthetic biology within the healthcare market.

The industrial biotechnology segment is another key area where electrolytic cell applications in synthetic biology are finding increased adoption. Biofuel production, particularly microbial electrosynthesis for the conversion of carbon dioxide to valuable chemicals and fuels, is an emerging application that shows significant market potential. Additionally, the use of bioelectrochemical systems for waste treatment and resource recovery is attracting attention from environmental and sustainability-focused industries.

Geographically, North America currently dominates the synthetic biology market, followed by Europe and Asia-Pacific. However, the Asia-Pacific region is expected to witness the highest growth rate in the coming years due to increasing investments in research and development, growing awareness of synthetic biology applications, and supportive government initiatives.

Key market players in the synthetic biology space, including those focusing on electrolytic cell applications, are actively engaged in research and development activities to expand their product portfolios and gain a competitive edge. Collaborations between academic institutions, biotechnology companies, and industrial partners are becoming increasingly common, fostering innovation and accelerating the commercialization of synthetic biology products and technologies.

Despite the promising market outlook, challenges such as regulatory hurdles, ethical concerns, and high initial investment costs may impact the growth of electrolytic cell applications in synthetic biology. Addressing these challenges through regulatory frameworks, public engagement, and continued technological advancements will be crucial for realizing the full market potential of these applications.

The expanding applications of electrolytic cells in synthetic biology are expected to contribute significantly to this market growth. Electrolytic cells have shown promise in various synthetic biology applications, including biosensors, biofuel production, and bioelectrochemical systems. The integration of electrolytic cells with synthetic biology techniques offers potential solutions for sustainable energy production, environmental remediation, and advanced biosensing technologies.

In the healthcare sector, synthetic biology applications utilizing electrolytic cells are gaining traction for drug discovery, personalized medicine, and diagnostics. The pharmaceutical industry is increasingly adopting synthetic biology approaches for the production of novel therapeutics and biopharmaceuticals. This trend is expected to drive the demand for electrolytic cell applications in synthetic biology within the healthcare market.

The industrial biotechnology segment is another key area where electrolytic cell applications in synthetic biology are finding increased adoption. Biofuel production, particularly microbial electrosynthesis for the conversion of carbon dioxide to valuable chemicals and fuels, is an emerging application that shows significant market potential. Additionally, the use of bioelectrochemical systems for waste treatment and resource recovery is attracting attention from environmental and sustainability-focused industries.

Geographically, North America currently dominates the synthetic biology market, followed by Europe and Asia-Pacific. However, the Asia-Pacific region is expected to witness the highest growth rate in the coming years due to increasing investments in research and development, growing awareness of synthetic biology applications, and supportive government initiatives.

Key market players in the synthetic biology space, including those focusing on electrolytic cell applications, are actively engaged in research and development activities to expand their product portfolios and gain a competitive edge. Collaborations between academic institutions, biotechnology companies, and industrial partners are becoming increasingly common, fostering innovation and accelerating the commercialization of synthetic biology products and technologies.

Despite the promising market outlook, challenges such as regulatory hurdles, ethical concerns, and high initial investment costs may impact the growth of electrolytic cell applications in synthetic biology. Addressing these challenges through regulatory frameworks, public engagement, and continued technological advancements will be crucial for realizing the full market potential of these applications.

Current Challenges in Electrolytic Cell Integration

The integration of electrolytic cells into synthetic biology applications faces several significant challenges that hinder their widespread adoption and effectiveness. One of the primary obstacles is the complexity of designing and optimizing electrolytic systems for biological environments. The intricate interplay between electrochemical processes and biological systems requires a deep understanding of both fields, which is often lacking in traditional synthetic biology approaches.

Scalability remains a major hurdle in the implementation of electrolytic cells in synthetic biology. While small-scale laboratory experiments have shown promising results, translating these successes to industrial-scale applications presents numerous technical difficulties. Issues such as maintaining consistent electrical field distribution, managing heat generation, and ensuring uniform current density across larger volumes of biological material pose significant engineering challenges.

Biocompatibility is another critical concern in the integration of electrolytic cells. The materials used for electrodes and other components must not only be conductive and durable but also non-toxic to living organisms. Finding materials that meet these criteria while maintaining optimal electrochemical performance is an ongoing challenge. Additionally, the potential formation of reactive oxygen species and other byproducts during electrolysis can have detrimental effects on biological systems, necessitating careful control and mitigation strategies.

The precise control of electrochemical reactions within biological systems presents another set of challenges. Achieving spatiotemporal control over electrolytic processes to selectively influence specific biological pathways or cellular functions requires sophisticated engineering and control systems. The development of advanced electrode designs, precise voltage regulation mechanisms, and real-time monitoring technologies is crucial for overcoming these limitations.

Energy efficiency and sustainability are also significant concerns in the integration of electrolytic cells. The power requirements for maintaining electrolytic processes can be substantial, particularly in large-scale applications. Improving the energy efficiency of these systems while minimizing their environmental impact is essential for their long-term viability and adoption in industrial settings.

Lastly, the regulatory landscape surrounding the use of electrolytic cells in synthetic biology applications remains complex and evolving. Ensuring compliance with safety standards and obtaining regulatory approvals for novel electrolytic cell-based products and processes presents additional challenges for researchers and companies working in this field. The development of clear regulatory frameworks and standardized testing protocols is necessary to facilitate the commercialization and widespread adoption of these technologies.

Scalability remains a major hurdle in the implementation of electrolytic cells in synthetic biology. While small-scale laboratory experiments have shown promising results, translating these successes to industrial-scale applications presents numerous technical difficulties. Issues such as maintaining consistent electrical field distribution, managing heat generation, and ensuring uniform current density across larger volumes of biological material pose significant engineering challenges.

Biocompatibility is another critical concern in the integration of electrolytic cells. The materials used for electrodes and other components must not only be conductive and durable but also non-toxic to living organisms. Finding materials that meet these criteria while maintaining optimal electrochemical performance is an ongoing challenge. Additionally, the potential formation of reactive oxygen species and other byproducts during electrolysis can have detrimental effects on biological systems, necessitating careful control and mitigation strategies.

The precise control of electrochemical reactions within biological systems presents another set of challenges. Achieving spatiotemporal control over electrolytic processes to selectively influence specific biological pathways or cellular functions requires sophisticated engineering and control systems. The development of advanced electrode designs, precise voltage regulation mechanisms, and real-time monitoring technologies is crucial for overcoming these limitations.

Energy efficiency and sustainability are also significant concerns in the integration of electrolytic cells. The power requirements for maintaining electrolytic processes can be substantial, particularly in large-scale applications. Improving the energy efficiency of these systems while minimizing their environmental impact is essential for their long-term viability and adoption in industrial settings.

Lastly, the regulatory landscape surrounding the use of electrolytic cells in synthetic biology applications remains complex and evolving. Ensuring compliance with safety standards and obtaining regulatory approvals for novel electrolytic cell-based products and processes presents additional challenges for researchers and companies working in this field. The development of clear regulatory frameworks and standardized testing protocols is necessary to facilitate the commercialization and widespread adoption of these technologies.

Existing Electrolytic Cell Applications in Synthetic Biology

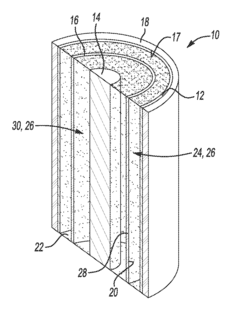

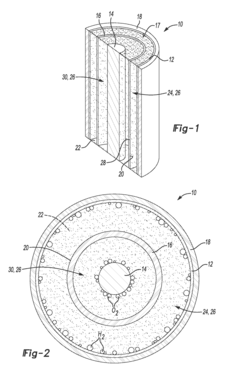

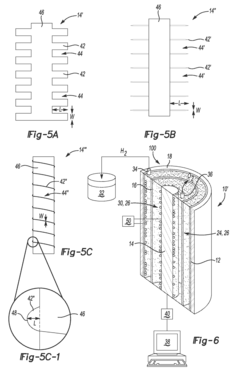

01 Electrolytic cell design and components

Electrolytic cells are designed with specific components to facilitate electrolysis. These components typically include electrodes (anode and cathode), an electrolyte, and a power source. The design may incorporate features to enhance efficiency, such as membrane separators or specialized electrode materials. The arrangement and selection of these components can significantly impact the cell's performance and the products of electrolysis.- Electrolytic cell design and components: Electrolytic cells are designed with specific components to facilitate electrochemical reactions. These components typically include electrodes (anode and cathode), an electrolyte, and a separator. The design of these components and their arrangement within the cell can significantly impact the efficiency and performance of the electrolytic process.

- Electrode materials and coatings: The choice of electrode materials and coatings plays a crucial role in electrolytic cell performance. Various materials and coatings are used to enhance conductivity, catalytic activity, and durability of the electrodes. These can include precious metals, metal oxides, and composite materials, each selected based on the specific electrochemical process and desired outcomes.

- Electrolyte composition and management: The electrolyte in an electrolytic cell serves as the medium for ion transport between electrodes. The composition of the electrolyte can be tailored to optimize conductivity, stability, and reaction kinetics. Proper management of the electrolyte, including circulation and temperature control, is essential for maintaining cell efficiency and longevity.

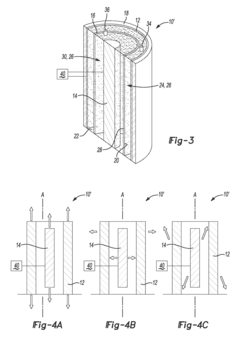

- Cell configuration and scaling: Electrolytic cells can be configured in various ways, including monopolar and bipolar arrangements. The configuration affects factors such as current distribution, voltage requirements, and overall efficiency. Scaling considerations are important when designing cells for industrial applications, balancing factors like production capacity, energy consumption, and space requirements.

- Monitoring and control systems: Advanced monitoring and control systems are crucial for optimizing electrolytic cell performance. These systems can include sensors for measuring parameters such as voltage, current, temperature, and electrolyte composition. Automated control mechanisms can adjust operating conditions in real-time to maintain optimal performance and safety.

02 Electrolyte composition and properties

The composition and properties of the electrolyte play a crucial role in the operation of an electrolytic cell. Electrolytes can be aqueous solutions, molten salts, or ionic liquids, each offering different advantages for specific applications. The concentration, pH, and additives in the electrolyte can affect conductivity, reaction kinetics, and the nature of the products formed during electrolysis.Expand Specific Solutions03 Electrode materials and configurations

The choice of electrode materials and their configurations are critical factors in electrolytic cell performance. Electrodes can be made from various materials such as metals, alloys, or carbon-based materials, each offering different properties in terms of conductivity, catalytic activity, and corrosion resistance. The shape, size, and arrangement of electrodes within the cell can also influence the efficiency and selectivity of the electrolytic process.Expand Specific Solutions04 Control and optimization of electrolysis parameters

Optimizing the performance of an electrolytic cell involves controlling various parameters such as current density, voltage, temperature, and pressure. Advanced control systems and monitoring techniques can be employed to maintain optimal conditions throughout the electrolysis process. This may include the use of sensors, feedback loops, and automated adjustment mechanisms to ensure consistent and efficient operation of the cell.Expand Specific Solutions05 Applications and specialized electrolytic cell designs

Electrolytic cells find applications in various industries, including chemical production, metal refining, and energy storage. Specialized cell designs have been developed for specific applications, such as chlor-alkali production, water electrolysis for hydrogen generation, or electroplating. These designs may incorporate unique features like gas diffusion electrodes, bipolar membranes, or flow-through configurations to enhance performance for their intended use.Expand Specific Solutions

Key Players in Synthetic Biology and Electrolysis

The field of expanding electrolytic cell applications in synthetic biology is in its early growth stage, with increasing market potential as researchers explore novel uses in bioengineering and bioproduction. The global market size for synthetic biology is projected to reach $30 billion by 2026, with electrolytic cell applications representing a growing segment. While the technology is still maturing, companies like Angiocrine Bioscience and STEMCELL Technologies are advancing cell-based platforms, while academic institutions such as Southeast University and Xiamen University are conducting foundational research. As the technology progresses, we can expect increased industry involvement from major players like Siemens Energy and General Electric to scale up applications for industrial use.

Xiamen University

Technical Solution: Xiamen University has made significant strides in expanding electrolytic cell applications in synthetic biology, particularly in the field of microbial electrosynthesis. Their research focuses on developing novel electrode materials and optimizing biofilm-electrode interactions to enhance electron transfer efficiency[3]. They have successfully engineered electroactive microorganisms capable of producing high-value chemicals and biofuels using CO2 as a feedstock. The university has also pioneered the integration of synthetic biology tools with bioelectrochemical systems, creating programmable cellular factories that can be controlled through electrical signals[4]. This approach allows for dynamic regulation of metabolic pathways and improved product yields.

Strengths: Strong expertise in electrode materials and biofilm engineering. Weaknesses: Limited commercial-scale demonstrations, potential regulatory hurdles.

The Regents of the University of California

Technical Solution: The University of California has developed advanced electrolytic cell applications for synthetic biology, focusing on bioelectrochemical systems. They have engineered microbial electrosynthesis platforms that utilize electricity-driven CO2 fixation for the production of value-added chemicals[1]. Their approach combines electrochemistry with metabolic engineering to create highly efficient bioproduction systems. The university has also pioneered the development of bioelectronic devices that integrate living cells with electronic components, enabling precise control and monitoring of cellular processes[2]. These innovations have significant implications for sustainable biomanufacturing and environmental remediation.

Strengths: Cutting-edge research in bioelectrochemistry, strong interdisciplinary approach. Weaknesses: Potential scalability challenges, high initial investment costs.

Innovative Electrolytic Cell Designs for Bioengineering

Electrolysis cell having conductive polymer electrodes and method of electrolysis

PatentWO2009155543A1

Innovation

- The use of conductive polymer electrodes in an electrolysis cell, combined with an ion-selective membrane, to electrochemically activate liquids by applying a voltage, producing anolyte and catholyte EA liquids with improved sanitizing and cleaning properties, and a hand-held spray bottle design with a switch-activated electrolysis cell for on-demand liquid treatment.

Electrolytic cell, method for enhancing electrolytic cell performance, and hydrogen fueling system

PatentInactiveUS9487872B2

Innovation

- Sonication of the electrolyte solution using a transducer attached to the electrodes to oscillate them, promoting gas bubble formation and transport away from the electrodes, eliminating the need for rest periods and enhancing high-pressure operation.

Biosafety and Regulatory Considerations

As synthetic biology applications of electrolytic cells expand, addressing biosafety and regulatory considerations becomes increasingly critical. The integration of electrochemical systems with living organisms raises unique safety concerns that must be carefully evaluated and mitigated. Potential risks include the generation of reactive oxygen species, pH changes, and the production of potentially harmful electrochemical byproducts within biological systems. These factors could impact cell viability, genetic stability, and overall biosystem function.

Regulatory frameworks for electrolytic cell applications in synthetic biology are still evolving. Current regulations often lag behind technological advancements, creating a need for proactive engagement between researchers, industry stakeholders, and regulatory bodies. Key areas of focus include containment strategies, risk assessment protocols, and standardized safety testing procedures specific to electrochemical-biological interfaces.

Biosafety considerations extend beyond the immediate experimental environment to potential ecological impacts. The release of genetically modified organisms incorporating electrolytic components could have unforeseen consequences on natural ecosystems. Developing robust containment measures and conducting comprehensive environmental risk assessments are essential steps in addressing these concerns.

Ethical considerations also play a significant role in the regulatory landscape. The manipulation of living systems using electrochemical techniques raises questions about the boundaries of synthetic biology and the responsible development of bio-hybrid technologies. Establishing clear ethical guidelines and fostering public dialogue are crucial for building trust and ensuring responsible innovation in this field.

International harmonization of regulatory approaches is another key challenge. As research and applications in this area become increasingly global, disparities in regulatory frameworks between countries could hinder scientific collaboration and commercial development. Efforts to establish common standards and regulatory pathways will be essential for the advancement of electrolytic cell applications in synthetic biology.

Addressing these biosafety and regulatory considerations requires a multidisciplinary approach, involving expertise from synthetic biology, electrochemistry, toxicology, environmental science, and policy-making. Collaborative efforts between academia, industry, and regulatory agencies will be crucial in developing comprehensive and adaptable regulatory frameworks that can keep pace with rapid technological advancements in this field.

Regulatory frameworks for electrolytic cell applications in synthetic biology are still evolving. Current regulations often lag behind technological advancements, creating a need for proactive engagement between researchers, industry stakeholders, and regulatory bodies. Key areas of focus include containment strategies, risk assessment protocols, and standardized safety testing procedures specific to electrochemical-biological interfaces.

Biosafety considerations extend beyond the immediate experimental environment to potential ecological impacts. The release of genetically modified organisms incorporating electrolytic components could have unforeseen consequences on natural ecosystems. Developing robust containment measures and conducting comprehensive environmental risk assessments are essential steps in addressing these concerns.

Ethical considerations also play a significant role in the regulatory landscape. The manipulation of living systems using electrochemical techniques raises questions about the boundaries of synthetic biology and the responsible development of bio-hybrid technologies. Establishing clear ethical guidelines and fostering public dialogue are crucial for building trust and ensuring responsible innovation in this field.

International harmonization of regulatory approaches is another key challenge. As research and applications in this area become increasingly global, disparities in regulatory frameworks between countries could hinder scientific collaboration and commercial development. Efforts to establish common standards and regulatory pathways will be essential for the advancement of electrolytic cell applications in synthetic biology.

Addressing these biosafety and regulatory considerations requires a multidisciplinary approach, involving expertise from synthetic biology, electrochemistry, toxicology, environmental science, and policy-making. Collaborative efforts between academia, industry, and regulatory agencies will be crucial in developing comprehensive and adaptable regulatory frameworks that can keep pace with rapid technological advancements in this field.

Scalability and Industrial Implementation

The scalability and industrial implementation of electrolytic cell applications in synthetic biology present both significant opportunities and challenges. As these technologies move from laboratory-scale experiments to large-scale production, several key factors must be considered to ensure successful translation.

One of the primary considerations is the design and optimization of bioreactors capable of supporting electrolytic processes at industrial scales. This involves engineering systems that can maintain consistent electrical potentials across large volumes while ensuring uniform distribution of substrates and products. Advanced electrode materials and configurations are being developed to enhance surface area and catalytic efficiency, crucial for maintaining high productivity in scaled-up operations.

Process control and monitoring systems play a vital role in maintaining optimal conditions for electrolytic cell function. Real-time sensors and feedback mechanisms are essential for regulating pH, temperature, and electrical parameters across large-scale bioreactors. The integration of artificial intelligence and machine learning algorithms is increasingly being explored to optimize process conditions and predict system behavior, potentially leading to more efficient and robust industrial implementations.

The economic viability of scaled-up electrolytic cell applications depends heavily on energy efficiency. Researchers are focusing on developing low-resistance membranes and high-performance catalysts to minimize energy losses during electron transfer processes. Additionally, the integration of renewable energy sources, such as solar or wind power, is being investigated to reduce operational costs and improve the sustainability of large-scale electrolytic bioprocesses.

Downstream processing and product recovery present unique challenges in industrial-scale electrolytic cell applications. Novel separation techniques, such as electrochemical extraction or selective membrane technologies, are being developed to efficiently isolate and purify products from complex reaction mixtures. These advancements are crucial for maintaining product quality and yield at industrial scales.

Regulatory considerations and safety protocols are also critical aspects of scaling up electrolytic cell applications. Establishing standardized operating procedures and risk assessment frameworks is essential for ensuring compliance with industrial safety standards and environmental regulations. This includes addressing potential issues related to gas evolution, waste management, and the handling of electroactive compounds at large scales.

As the field progresses, interdisciplinary collaboration between synthetic biologists, chemical engineers, and electrical engineers becomes increasingly important. This cross-disciplinary approach is driving innovations in reactor design, process integration, and control systems, paving the way for more efficient and cost-effective industrial implementations of electrolytic cell technologies in synthetic biology.

One of the primary considerations is the design and optimization of bioreactors capable of supporting electrolytic processes at industrial scales. This involves engineering systems that can maintain consistent electrical potentials across large volumes while ensuring uniform distribution of substrates and products. Advanced electrode materials and configurations are being developed to enhance surface area and catalytic efficiency, crucial for maintaining high productivity in scaled-up operations.

Process control and monitoring systems play a vital role in maintaining optimal conditions for electrolytic cell function. Real-time sensors and feedback mechanisms are essential for regulating pH, temperature, and electrical parameters across large-scale bioreactors. The integration of artificial intelligence and machine learning algorithms is increasingly being explored to optimize process conditions and predict system behavior, potentially leading to more efficient and robust industrial implementations.

The economic viability of scaled-up electrolytic cell applications depends heavily on energy efficiency. Researchers are focusing on developing low-resistance membranes and high-performance catalysts to minimize energy losses during electron transfer processes. Additionally, the integration of renewable energy sources, such as solar or wind power, is being investigated to reduce operational costs and improve the sustainability of large-scale electrolytic bioprocesses.

Downstream processing and product recovery present unique challenges in industrial-scale electrolytic cell applications. Novel separation techniques, such as electrochemical extraction or selective membrane technologies, are being developed to efficiently isolate and purify products from complex reaction mixtures. These advancements are crucial for maintaining product quality and yield at industrial scales.

Regulatory considerations and safety protocols are also critical aspects of scaling up electrolytic cell applications. Establishing standardized operating procedures and risk assessment frameworks is essential for ensuring compliance with industrial safety standards and environmental regulations. This includes addressing potential issues related to gas evolution, waste management, and the handling of electroactive compounds at large scales.

As the field progresses, interdisciplinary collaboration between synthetic biologists, chemical engineers, and electrical engineers becomes increasingly important. This cross-disciplinary approach is driving innovations in reactor design, process integration, and control systems, paving the way for more efficient and cost-effective industrial implementations of electrolytic cell technologies in synthetic biology.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!