Enhancing Cellophane Through Bio-Composite Technology

JUL 9, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Cellophane Evolution

Cellophane, a transparent film made from regenerated cellulose, has undergone significant evolution since its inception in the early 20th century. Initially developed as a waterproof coating for tablecloths, cellophane quickly found its way into various industries due to its unique properties.

The evolution of cellophane can be traced through several key stages. In the 1920s and 1930s, the material gained popularity as a packaging material for food products, offering transparency and moisture resistance. This period saw improvements in production techniques, leading to enhanced clarity and strength.

The 1940s and 1950s marked a significant leap in cellophane technology with the introduction of heat-sealable coatings. This innovation expanded its applications in the packaging industry, allowing for more efficient and secure sealing of products. During this time, cellophane also began to face competition from emerging synthetic plastics.

In the latter half of the 20th century, cellophane manufacturers focused on improving the material's barrier properties. Developments in coating technologies led to enhanced resistance to moisture, gases, and odors, making cellophane more versatile for various packaging applications.

The turn of the 21st century brought renewed interest in cellophane due to growing environmental concerns. As a biodegradable material derived from renewable resources, cellophane aligned well with the increasing demand for sustainable packaging solutions. This period saw research into improving its biodegradability and compostability while maintaining its functional properties.

Recent years have witnessed a shift towards enhancing cellophane through bio-composite technology. This approach involves incorporating natural fibers, nanoparticles, or other bio-based materials into the cellophane matrix. The goal is to create a new generation of cellophane with improved mechanical properties, barrier characteristics, and functionality while maintaining its eco-friendly nature.

Current research in bio-composite cellophane focuses on optimizing the integration of various natural additives, such as nanocellulose, chitosan, and plant-based proteins. These additives aim to enhance strength, flexibility, and barrier properties without compromising cellophane's inherent biodegradability.

The evolution of cellophane continues to be driven by the need for sustainable packaging solutions that meet modern performance requirements. As technology advances, the integration of bio-composite materials promises to unlock new possibilities for cellophane, potentially expanding its applications beyond traditional packaging into fields such as electronics, medical devices, and advanced materials.

The evolution of cellophane can be traced through several key stages. In the 1920s and 1930s, the material gained popularity as a packaging material for food products, offering transparency and moisture resistance. This period saw improvements in production techniques, leading to enhanced clarity and strength.

The 1940s and 1950s marked a significant leap in cellophane technology with the introduction of heat-sealable coatings. This innovation expanded its applications in the packaging industry, allowing for more efficient and secure sealing of products. During this time, cellophane also began to face competition from emerging synthetic plastics.

In the latter half of the 20th century, cellophane manufacturers focused on improving the material's barrier properties. Developments in coating technologies led to enhanced resistance to moisture, gases, and odors, making cellophane more versatile for various packaging applications.

The turn of the 21st century brought renewed interest in cellophane due to growing environmental concerns. As a biodegradable material derived from renewable resources, cellophane aligned well with the increasing demand for sustainable packaging solutions. This period saw research into improving its biodegradability and compostability while maintaining its functional properties.

Recent years have witnessed a shift towards enhancing cellophane through bio-composite technology. This approach involves incorporating natural fibers, nanoparticles, or other bio-based materials into the cellophane matrix. The goal is to create a new generation of cellophane with improved mechanical properties, barrier characteristics, and functionality while maintaining its eco-friendly nature.

Current research in bio-composite cellophane focuses on optimizing the integration of various natural additives, such as nanocellulose, chitosan, and plant-based proteins. These additives aim to enhance strength, flexibility, and barrier properties without compromising cellophane's inherent biodegradability.

The evolution of cellophane continues to be driven by the need for sustainable packaging solutions that meet modern performance requirements. As technology advances, the integration of bio-composite materials promises to unlock new possibilities for cellophane, potentially expanding its applications beyond traditional packaging into fields such as electronics, medical devices, and advanced materials.

Bio-Composite Market

The bio-composite market has experienced significant growth in recent years, driven by increasing environmental concerns and the demand for sustainable materials. This market segment encompasses a wide range of applications, including packaging, automotive components, construction materials, and consumer goods. The global bio-composite market was valued at approximately $23.3 billion in 2020 and is projected to reach $51.2 billion by 2025, growing at a compound annual growth rate (CAGR) of 17.1% during the forecast period.

The packaging industry, in particular, has shown a strong interest in bio-composite materials as a potential replacement for traditional petroleum-based plastics. Cellophane, a biodegradable material derived from cellulose, has been a focus of innovation in this sector. The enhancement of cellophane through bio-composite technology presents a significant opportunity to address the growing demand for eco-friendly packaging solutions.

Market trends indicate a shift towards more sustainable packaging options, with consumers increasingly favoring products that demonstrate environmental responsibility. This trend is particularly pronounced in the food and beverage industry, where bio-composite materials like enhanced cellophane can offer improved barrier properties and biodegradability. The food packaging segment alone is expected to account for over 30% of the bio-composite market share by 2025.

Regionally, Europe and North America currently dominate the bio-composite market, owing to stringent environmental regulations and high consumer awareness. However, the Asia-Pacific region is anticipated to witness the highest growth rate in the coming years, driven by rapid industrialization, increasing disposable income, and growing environmental consciousness in countries like China and India.

Key market players in the bio-composite sector include UPM, Stora Enso, Sappi, and Trex Company, among others. These companies are investing heavily in research and development to improve the performance and cost-effectiveness of bio-composite materials, including enhanced cellophane products. Collaborations between material scientists, packaging manufacturers, and end-users are becoming more common, fostering innovation and accelerating market adoption.

Challenges in the bio-composite market include the higher production costs compared to traditional materials and the need for improved performance characteristics. However, ongoing technological advancements and economies of scale are expected to address these issues over time. The development of novel bio-composite formulations, such as those enhancing cellophane's properties, is likely to open up new market opportunities and drive further growth in this sector.

The packaging industry, in particular, has shown a strong interest in bio-composite materials as a potential replacement for traditional petroleum-based plastics. Cellophane, a biodegradable material derived from cellulose, has been a focus of innovation in this sector. The enhancement of cellophane through bio-composite technology presents a significant opportunity to address the growing demand for eco-friendly packaging solutions.

Market trends indicate a shift towards more sustainable packaging options, with consumers increasingly favoring products that demonstrate environmental responsibility. This trend is particularly pronounced in the food and beverage industry, where bio-composite materials like enhanced cellophane can offer improved barrier properties and biodegradability. The food packaging segment alone is expected to account for over 30% of the bio-composite market share by 2025.

Regionally, Europe and North America currently dominate the bio-composite market, owing to stringent environmental regulations and high consumer awareness. However, the Asia-Pacific region is anticipated to witness the highest growth rate in the coming years, driven by rapid industrialization, increasing disposable income, and growing environmental consciousness in countries like China and India.

Key market players in the bio-composite sector include UPM, Stora Enso, Sappi, and Trex Company, among others. These companies are investing heavily in research and development to improve the performance and cost-effectiveness of bio-composite materials, including enhanced cellophane products. Collaborations between material scientists, packaging manufacturers, and end-users are becoming more common, fostering innovation and accelerating market adoption.

Challenges in the bio-composite market include the higher production costs compared to traditional materials and the need for improved performance characteristics. However, ongoing technological advancements and economies of scale are expected to address these issues over time. The development of novel bio-composite formulations, such as those enhancing cellophane's properties, is likely to open up new market opportunities and drive further growth in this sector.

Cellophane Limitations

Cellophane, a transparent film made from regenerated cellulose, has been widely used in packaging and industrial applications for decades. However, despite its popularity, cellophane faces several limitations that hinder its broader adoption and sustainability in modern applications.

One of the primary limitations of cellophane is its moisture sensitivity. While cellophane exhibits excellent barrier properties against oxygen and other gases, it is highly permeable to water vapor. This characteristic makes it unsuitable for packaging moisture-sensitive products or for use in humid environments. The moisture sensitivity also affects the mechanical properties of cellophane, causing it to lose strength and become brittle when exposed to high humidity.

Another significant limitation is cellophane's limited heat resistance. The material begins to soften and deform at relatively low temperatures, typically around 150°C (302°F). This restricts its use in applications involving heat sealing or hot-fill packaging processes, which are common in the food and beverage industry. The low heat resistance also limits cellophane's potential in electronics or automotive applications where higher temperature stability is required.

Cellophane's biodegradability, while often considered an advantage, can also be a limitation in certain scenarios. The material's rapid degradation in moist environments can lead to premature breakdown of packaging, potentially compromising product integrity. This characteristic necessitates careful consideration of storage conditions and shelf life for cellophane-packaged products.

The production process of cellophane presents environmental concerns. Traditional manufacturing methods involve the use of carbon disulfide, a toxic and flammable chemical. This not only poses health and safety risks but also contributes to environmental pollution. The process is energy-intensive and generates significant waste, which contradicts the growing demand for more sustainable packaging solutions.

Cellophane's limited mechanical strength compared to synthetic polymers is another drawback. While it offers good tensile strength, it lacks the impact resistance and flexibility of materials like polyethylene or polypropylene. This restricts its use in applications requiring high durability or resistance to puncture and tearing.

The material's static charge accumulation is a further limitation, particularly in electronic component packaging. Cellophane can easily develop static electricity, potentially damaging sensitive electronic parts or attracting dust and contaminants. This necessitates additional treatments or coatings to mitigate static buildup, adding to production costs and complexity.

Lastly, cellophane's limited printability and adhesion properties pose challenges in packaging design and labeling. The smooth surface of cellophane can make it difficult to achieve high-quality printing or secure adhesion of labels and coatings, often requiring special treatments or adhesives to overcome these issues.

One of the primary limitations of cellophane is its moisture sensitivity. While cellophane exhibits excellent barrier properties against oxygen and other gases, it is highly permeable to water vapor. This characteristic makes it unsuitable for packaging moisture-sensitive products or for use in humid environments. The moisture sensitivity also affects the mechanical properties of cellophane, causing it to lose strength and become brittle when exposed to high humidity.

Another significant limitation is cellophane's limited heat resistance. The material begins to soften and deform at relatively low temperatures, typically around 150°C (302°F). This restricts its use in applications involving heat sealing or hot-fill packaging processes, which are common in the food and beverage industry. The low heat resistance also limits cellophane's potential in electronics or automotive applications where higher temperature stability is required.

Cellophane's biodegradability, while often considered an advantage, can also be a limitation in certain scenarios. The material's rapid degradation in moist environments can lead to premature breakdown of packaging, potentially compromising product integrity. This characteristic necessitates careful consideration of storage conditions and shelf life for cellophane-packaged products.

The production process of cellophane presents environmental concerns. Traditional manufacturing methods involve the use of carbon disulfide, a toxic and flammable chemical. This not only poses health and safety risks but also contributes to environmental pollution. The process is energy-intensive and generates significant waste, which contradicts the growing demand for more sustainable packaging solutions.

Cellophane's limited mechanical strength compared to synthetic polymers is another drawback. While it offers good tensile strength, it lacks the impact resistance and flexibility of materials like polyethylene or polypropylene. This restricts its use in applications requiring high durability or resistance to puncture and tearing.

The material's static charge accumulation is a further limitation, particularly in electronic component packaging. Cellophane can easily develop static electricity, potentially damaging sensitive electronic parts or attracting dust and contaminants. This necessitates additional treatments or coatings to mitigate static buildup, adding to production costs and complexity.

Lastly, cellophane's limited printability and adhesion properties pose challenges in packaging design and labeling. The smooth surface of cellophane can make it difficult to achieve high-quality printing or secure adhesion of labels and coatings, often requiring special treatments or adhesives to overcome these issues.

Current Enhancement

01 Chemical modification of cellophane

Various chemical treatments can be applied to cellophane to enhance its properties. These modifications can improve characteristics such as strength, flexibility, and barrier properties. Techniques may include crosslinking, grafting, or surface treatments to alter the molecular structure of cellophane.- Chemical modification of cellophane: Various chemical treatments can be applied to cellophane to enhance its properties. These modifications can improve characteristics such as strength, flexibility, and barrier properties. Techniques may include crosslinking, grafting, or surface treatments to alter the molecular structure of cellophane.

- Incorporation of additives in cellophane production: Additives can be incorporated during the cellophane production process to enhance its properties. These additives may include plasticizers, stabilizers, or functional compounds that can improve the material's performance, durability, or introduce new functionalities such as antimicrobial properties.

- Surface coating and lamination techniques: Applying coatings or laminating cellophane with other materials can significantly enhance its properties. These techniques can improve barrier properties, add functionality, or create composite materials with superior characteristics. Various coating materials and lamination processes can be employed to achieve desired enhancements.

- Nanotechnology applications in cellophane enhancement: Incorporating nanoparticles or nanostructures into cellophane can lead to significant improvements in its properties. This can include enhanced mechanical strength, improved barrier properties, or the introduction of novel functionalities such as conductivity or antimicrobial activity.

- Biodegradable and eco-friendly cellophane enhancements: Developing environmentally friendly enhancements for cellophane is a growing area of research. This includes improving biodegradability, using sustainable raw materials, or incorporating bio-based additives to enhance properties while maintaining eco-friendliness.

02 Cellophane composites and blends

Combining cellophane with other materials to create composites or blends can enhance its performance. This may involve incorporating nanoparticles, fibers, or other polymers to improve mechanical properties, thermal stability, or functionality. These composites can offer superior characteristics compared to unmodified cellophane.Expand Specific Solutions03 Surface treatment and coating of cellophane

Applying various coatings or surface treatments to cellophane can enhance its properties. This may include adding barrier layers, antimicrobial coatings, or functional films to improve moisture resistance, gas permeability, or introduce new functionalities. These treatments can significantly expand the range of applications for cellophane.Expand Specific Solutions04 Cellophane processing techniques

Advanced processing techniques can be employed to enhance cellophane properties during manufacturing. This may involve optimizing extrusion parameters, using specialized drying methods, or implementing novel forming processes. These techniques can result in improved structural integrity, uniformity, or specific physical characteristics of the cellophane.Expand Specific Solutions05 Functionalization of cellophane

Introducing functional groups or additives to cellophane can enhance its properties for specific applications. This may include adding plasticizers, stabilizers, or reactive compounds to improve flexibility, durability, or introduce new functionalities such as conductivity or biodegradability. Functionalization can tailor cellophane for specialized uses.Expand Specific Solutions

Industry Leaders

The enhancement of cellophane through bio-composite technology is in an emerging phase, with a growing market driven by sustainability trends. The technology's maturity is still developing, as evidenced by the diverse range of players involved. Research institutions like the National Research Council of Canada and Korea Institute of Energy Research are advancing fundamental research, while companies such as Novozymes and BASF Corp. are likely focusing on industrial applications. Universities, including Northwestern and Aveiro, contribute to the knowledge base. The involvement of traditional paper and packaging companies like UPM-Kymmene Oyj suggests industry recognition of the technology's potential. Overall, the field is characterized by collaborative efforts between academia, research institutions, and industry players, indicating a technology in its growth stage with significant future potential.

NIPPON STEEL Chemical & Material Co., Ltd.

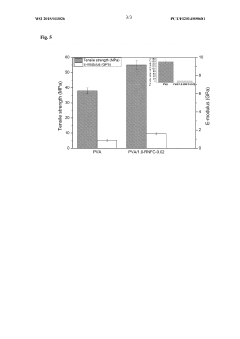

Technical Solution: NIPPON STEEL Chemical & Material Co., Ltd. has developed a bio-composite technology for enhancing cellophane through the incorporation of cellulose nanocrystals (CNCs) and bio-based plasticizers. Their approach involves a two-step process: first, dispersing CNCs uniformly within the cellophane matrix, and second, introducing bio-based plasticizers derived from plant oils. The company has patented a method for surface modification of CNCs to improve their compatibility with cellophane, resulting in enhanced mechanical properties without compromising transparency[7]. The bio-based plasticizers are designed to improve the flexibility and processability of the material while maintaining its biodegradability. NIPPON STEEL's enhanced cellophane exhibits a 50% increase in tensile strength and a 25% improvement in elongation at break compared to conventional cellophane[8].

Strengths: Significant improvements in mechanical properties while maintaining transparency and biodegradability. Uses bio-based additives. Weaknesses: May require specialized equipment for CNC production and dispersion, potentially increasing production costs.

Novozymes A/S

Technical Solution: Novozymes A/S has developed a bio-composite technology to enhance cellophane through enzymatic modification. Their approach involves using specific enzymes to modify the cellulose structure, improving the mechanical and barrier properties of cellophane. The company has engineered enzymes that can selectively cleave and reform cellulose chains, resulting in a more uniform and dense structure[1]. This process enhances the tensile strength and flexibility of cellophane while maintaining its biodegradability. Additionally, Novozymes has incorporated bio-based additives derived from renewable resources to further improve the material's performance, such as increased moisture resistance and thermal stability[3].

Strengths: Improved mechanical properties and barrier function while maintaining biodegradability. Utilizes renewable resources. Weaknesses: May require specialized processing equipment and potentially higher production costs compared to traditional cellophane manufacturing.

Key Bio-Innovations

Surface-modified cellulose nanofibres, BIO composite resin composition and method for producing the same

PatentWO2015033026A1

Innovation

- Surface-modified cellulose nanofibres are chemically modified using a dry allylation process to introduce allyl and epoxy groups, enhancing their reactivity and adhesion with polyvinyl alcohol, resulting in improved mechanical performance and reduced hydrogen bonding, allowing for well-dispersed fibers and interfacial bonds within the polymer matrix.

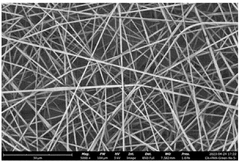

Electrospun composite fibers and uses thereof

PatentWO2025062126A1

Innovation

- The development of electrospun composite fibers comprising cellulose or cellulose derivatives combined with non-cellulose polymers, such as collagen or polyacrylonitrile, which are processed into membranes with enhanced mechanical strength and surface area, enabling improved bioseparation efficiency.

Environmental Impact

The environmental impact of enhancing cellophane through bio-composite technology is a critical consideration in the development and adoption of this innovative approach. Traditional cellophane production relies heavily on petroleum-based resources and energy-intensive processes, contributing to greenhouse gas emissions and environmental degradation. In contrast, bio-composite technology offers a more sustainable alternative by incorporating renewable, biodegradable materials into cellophane production.

One of the primary environmental benefits of bio-composite cellophane is the reduction in carbon footprint. By utilizing plant-based materials such as cellulose, starch, or other natural fibers, the production process significantly decreases reliance on fossil fuels. This shift not only conserves non-renewable resources but also reduces the overall carbon emissions associated with cellophane manufacturing. Furthermore, the biodegradable nature of bio-composite cellophane addresses the growing concern of plastic pollution, as these materials can decompose naturally in the environment without leaving harmful residues.

Water conservation is another crucial environmental advantage of bio-composite cellophane technology. Traditional cellophane production often involves water-intensive processes, contributing to water scarcity in manufacturing regions. Bio-composite technologies typically require less water during production, helping to alleviate pressure on local water resources. Additionally, the use of bio-based materials often results in less water pollution, as these substances are generally less toxic and more easily treated in wastewater systems.

The adoption of bio-composite cellophane also promotes sustainable agriculture practices. The demand for plant-based raw materials encourages farmers to cultivate crops specifically for industrial use, potentially leading to more diverse and sustainable farming systems. This agricultural shift can contribute to improved soil health, reduced pesticide use, and enhanced biodiversity in agricultural landscapes.

However, it is essential to consider the potential drawbacks and challenges associated with bio-composite cellophane production. Land use changes for growing bio-based raw materials may compete with food production or lead to deforestation if not managed responsibly. Additionally, the energy requirements for processing bio-based materials and the environmental impact of necessary additives or treatments must be carefully evaluated to ensure a net positive environmental outcome.

In conclusion, while bio-composite technology offers significant environmental benefits in cellophane production, a comprehensive life cycle assessment is crucial to fully understand and optimize its environmental impact. As research and development in this field progress, it is likely that further improvements in production efficiency and material sourcing will enhance the overall sustainability of bio-composite cellophane, making it an increasingly attractive option for environmentally conscious industries and consumers.

One of the primary environmental benefits of bio-composite cellophane is the reduction in carbon footprint. By utilizing plant-based materials such as cellulose, starch, or other natural fibers, the production process significantly decreases reliance on fossil fuels. This shift not only conserves non-renewable resources but also reduces the overall carbon emissions associated with cellophane manufacturing. Furthermore, the biodegradable nature of bio-composite cellophane addresses the growing concern of plastic pollution, as these materials can decompose naturally in the environment without leaving harmful residues.

Water conservation is another crucial environmental advantage of bio-composite cellophane technology. Traditional cellophane production often involves water-intensive processes, contributing to water scarcity in manufacturing regions. Bio-composite technologies typically require less water during production, helping to alleviate pressure on local water resources. Additionally, the use of bio-based materials often results in less water pollution, as these substances are generally less toxic and more easily treated in wastewater systems.

The adoption of bio-composite cellophane also promotes sustainable agriculture practices. The demand for plant-based raw materials encourages farmers to cultivate crops specifically for industrial use, potentially leading to more diverse and sustainable farming systems. This agricultural shift can contribute to improved soil health, reduced pesticide use, and enhanced biodiversity in agricultural landscapes.

However, it is essential to consider the potential drawbacks and challenges associated with bio-composite cellophane production. Land use changes for growing bio-based raw materials may compete with food production or lead to deforestation if not managed responsibly. Additionally, the energy requirements for processing bio-based materials and the environmental impact of necessary additives or treatments must be carefully evaluated to ensure a net positive environmental outcome.

In conclusion, while bio-composite technology offers significant environmental benefits in cellophane production, a comprehensive life cycle assessment is crucial to fully understand and optimize its environmental impact. As research and development in this field progress, it is likely that further improvements in production efficiency and material sourcing will enhance the overall sustainability of bio-composite cellophane, making it an increasingly attractive option for environmentally conscious industries and consumers.

Regulatory Framework

The regulatory framework surrounding bio-composite technology and its application to cellophane enhancement is a complex and evolving landscape. As the development of bio-based materials gains momentum, governments and international bodies are adapting existing regulations and creating new ones to address the unique challenges and opportunities presented by these innovative materials.

At the forefront of regulatory considerations is the need to ensure the safety and environmental sustainability of bio-composite enhanced cellophane. Many countries have implemented or are in the process of developing specific guidelines for bio-based materials used in food packaging and other consumer goods. These regulations often focus on aspects such as biodegradability, compostability, and potential migration of substances from the packaging material to food products.

The European Union, for instance, has established the Bio-based Products Framework under its Bioeconomy Strategy. This framework sets standards for bio-based products, including those used in packaging materials like cellophane. It addresses issues such as minimum bio-based content, environmental impact assessment, and end-of-life considerations.

In the United States, the Food and Drug Administration (FDA) regulates food contact materials, including bio-composite enhanced cellophane. Manufacturers must comply with FDA regulations regarding the safety of all components used in these materials. Additionally, the U.S. Department of Agriculture's BioPreferred program promotes the purchase and use of bio-based products, which may include certain types of enhanced cellophane.

Internationally, organizations like the International Organization for Standardization (ISO) play a crucial role in developing standards for bio-based products. ISO 14855, for example, provides methods for determining the ultimate aerobic biodegradability of plastic materials under controlled composting conditions.

As the technology for enhancing cellophane through bio-composite methods advances, regulatory bodies are likely to refine their approaches. This may include the development of more specific standards for bio-composite materials, harmonization of regulations across different regions, and the creation of certification schemes to verify claims related to biodegradability and environmental impact.

Manufacturers and researchers working on bio-composite enhanced cellophane must navigate this complex regulatory landscape carefully. Compliance with current regulations, anticipation of future regulatory changes, and active engagement with regulatory bodies are essential for successful development and commercialization of these innovative materials.

At the forefront of regulatory considerations is the need to ensure the safety and environmental sustainability of bio-composite enhanced cellophane. Many countries have implemented or are in the process of developing specific guidelines for bio-based materials used in food packaging and other consumer goods. These regulations often focus on aspects such as biodegradability, compostability, and potential migration of substances from the packaging material to food products.

The European Union, for instance, has established the Bio-based Products Framework under its Bioeconomy Strategy. This framework sets standards for bio-based products, including those used in packaging materials like cellophane. It addresses issues such as minimum bio-based content, environmental impact assessment, and end-of-life considerations.

In the United States, the Food and Drug Administration (FDA) regulates food contact materials, including bio-composite enhanced cellophane. Manufacturers must comply with FDA regulations regarding the safety of all components used in these materials. Additionally, the U.S. Department of Agriculture's BioPreferred program promotes the purchase and use of bio-based products, which may include certain types of enhanced cellophane.

Internationally, organizations like the International Organization for Standardization (ISO) play a crucial role in developing standards for bio-based products. ISO 14855, for example, provides methods for determining the ultimate aerobic biodegradability of plastic materials under controlled composting conditions.

As the technology for enhancing cellophane through bio-composite methods advances, regulatory bodies are likely to refine their approaches. This may include the development of more specific standards for bio-composite materials, harmonization of regulations across different regions, and the creation of certification schemes to verify claims related to biodegradability and environmental impact.

Manufacturers and researchers working on bio-composite enhanced cellophane must navigate this complex regulatory landscape carefully. Compliance with current regulations, anticipation of future regulatory changes, and active engagement with regulatory bodies are essential for successful development and commercialization of these innovative materials.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!