Enovix Silicon Anode Chemistry Revolutionizing Battery Energy Storage

Silicon Anode Evolution

The evolution of silicon anodes in lithium-ion batteries represents a significant leap forward in energy storage technology. Traditional graphite anodes have long been the standard, but their limited capacity has prompted researchers to explore alternative materials. Silicon emerged as a promising candidate due to its theoretical capacity, which is nearly ten times that of graphite.

The journey of silicon anodes began in the early 2000s when researchers first recognized silicon's potential. However, initial attempts faced severe challenges, primarily due to silicon's tendency to expand dramatically during lithiation, leading to rapid degradation of the anode structure. This expansion, which could reach up to 300%, caused mechanical stress, electrode pulverization, and loss of electrical contact.

To address these issues, scientists developed various strategies over the years. One of the earliest approaches involved using silicon nanoparticles or nanowires, which could better accommodate the volume changes. This was followed by the development of silicon-carbon composites, where carbon acted as a buffer to mitigate the expansion effects.

As research progressed, more sophisticated structures emerged. Silicon-graphene composites gained attention for their ability to combine silicon's high capacity with graphene's excellent conductivity and mechanical strength. Porous silicon structures were also explored, allowing for better electrolyte penetration and improved cycling stability.

A significant milestone in silicon anode evolution was the development of silicon-dominant anodes, where silicon content exceeded 50% of the anode material. This approach, pioneered by companies like Enovix, aimed to maximize the benefits of silicon while managing its drawbacks through innovative engineering solutions.

Recent advancements have focused on optimizing the electrolyte and binder materials to work synergistically with silicon anodes. Fluoroethylene carbonate (FEC) additives, for instance, have shown promise in forming more stable solid-electrolyte interphase (SEI) layers on silicon surfaces, crucial for long-term cycling stability.

The evolution of silicon anodes has not been limited to material composition alone. Manufacturing processes have also seen significant improvements, from simple mixing methods to more advanced techniques like chemical vapor deposition and atomic layer deposition, enabling precise control over anode structure and composition.

As we look at the current state of silicon anode technology, exemplified by Enovix's innovations, we see a convergence of these evolutionary steps. Their approach combines high silicon content with a unique 3D cell architecture, addressing many of the historical challenges associated with silicon anodes. This represents a culmination of years of research and development in the field, potentially marking a new era in battery energy storage.

Energy Storage Market

The energy storage market has experienced significant growth in recent years, driven by the increasing demand for renewable energy integration, grid stability, and electrification of transportation. This market encompasses various technologies, including lithium-ion batteries, flow batteries, and emerging chemistries. The global energy storage market size was valued at $168.9 billion in 2020 and is projected to reach $422.6 billion by 2027, growing at a CAGR of 14.1% during the forecast period.

Lithium-ion batteries dominate the current energy storage landscape, accounting for over 90% of the market share. This dominance is attributed to their high energy density, long cycle life, and decreasing costs. However, the market is witnessing a shift towards advanced battery technologies that offer improved performance and safety characteristics.

The automotive sector represents a significant portion of the energy storage market, with electric vehicles (EVs) being the primary driver. The global EV market is expected to grow from 3.1 million units in 2020 to 26.8 million units by 2030, creating a substantial demand for high-performance batteries. This growth is supported by government initiatives, environmental regulations, and increasing consumer awareness of sustainable transportation options.

Stationary energy storage systems for grid applications and renewable energy integration are another rapidly growing segment. The increasing penetration of intermittent renewable energy sources, such as solar and wind, has created a need for large-scale energy storage solutions to balance supply and demand. The utility-scale energy storage market is projected to grow from 11.3 GWh in 2020 to 87.3 GWh by 2025, representing a CAGR of 50.4%.

The residential and commercial energy storage markets are also expanding, driven by the desire for energy independence, backup power, and the ability to optimize energy consumption. The global residential energy storage market is expected to grow from $6.3 billion in 2020 to $17.5 billion by 2025, with a CAGR of 22.7%.

Key market players in the energy storage industry include Tesla, LG Chem, Panasonic, Samsung SDI, and CATL. These companies are investing heavily in research and development to improve battery performance, reduce costs, and develop new chemistries. The emergence of silicon anode technology, as demonstrated by Enovix, represents a significant advancement in battery chemistry that could potentially disrupt the market and accelerate the adoption of energy storage solutions across various applications.

Silicon Anode Challenges

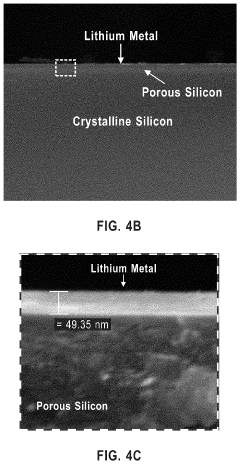

Silicon anodes have long been recognized as a promising technology for enhancing battery energy storage capabilities. However, their widespread adoption has been hindered by several significant challenges. One of the primary issues is the substantial volume expansion that silicon undergoes during lithiation, which can reach up to 300-400%. This expansion causes mechanical stress and strain on the anode structure, leading to pulverization and loss of electrical contact between silicon particles and the current collector.

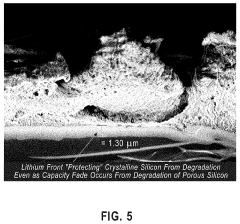

Another major challenge is the formation of an unstable solid-electrolyte interphase (SEI) layer on the silicon surface. The continuous expansion and contraction of silicon during charge-discharge cycles cause repeated breaking and reforming of the SEI layer. This process consumes electrolyte and lithium ions, resulting in capacity fade and reduced cycle life of the battery.

The high reactivity of silicon with the electrolyte is also a significant concern. This reactivity leads to continuous SEI growth and parasitic side reactions, further contributing to capacity loss and degradation of battery performance over time. Additionally, the low electrical conductivity of silicon compared to traditional graphite anodes poses challenges in maintaining efficient electron transport within the electrode.

Manufacturability and scalability of silicon anodes present another set of obstacles. The integration of silicon into existing battery production processes requires careful consideration of factors such as particle size, distribution, and binding mechanisms. Ensuring uniform dispersion of silicon particles and maintaining structural integrity during large-scale production remains a complex task.

The cost-effectiveness of silicon anodes is also a critical factor. While silicon is abundant and relatively inexpensive as a raw material, the processing and engineering required to overcome its inherent challenges can significantly increase production costs. Balancing the enhanced performance with economic viability is crucial for commercial adoption.

Lastly, the long-term stability and safety of silicon anodes under various operating conditions need to be thoroughly addressed. Issues such as thermal runaway, dendrite formation, and gas evolution during cycling must be mitigated to ensure the reliability and safety of silicon-based batteries in real-world applications.

Overcoming these challenges requires innovative approaches in materials science, electrode design, and manufacturing processes. Researchers and companies like Enovix are actively working on solutions such as nanostructured silicon, silicon-carbon composites, and advanced binder systems to harness the full potential of silicon anodes while addressing their inherent limitations.

Enovix Tech Solutions

01 Silicon-based anode materials for lithium-ion batteries

Enovix utilizes silicon-based anode materials in their lithium-ion batteries to improve energy density and storage capacity. Silicon anodes offer higher theoretical capacity compared to traditional graphite anodes, allowing for increased energy storage in a smaller volume. The company's technology addresses challenges associated with silicon expansion during charging cycles.- Silicon-based anode materials for lithium-ion batteries: Enovix utilizes silicon-based anode materials in their lithium-ion batteries to improve energy density and storage capacity. Silicon anodes offer higher theoretical capacity compared to traditional graphite anodes, potentially leading to batteries with increased energy storage capabilities.

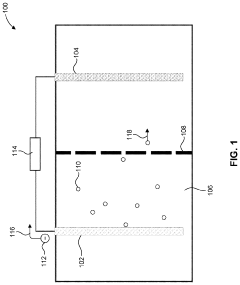

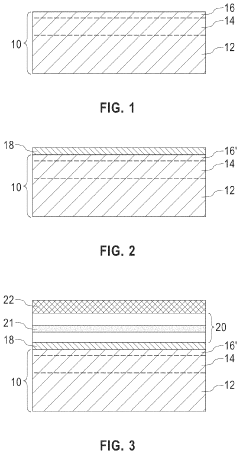

- 3D cell architecture for improved energy density: Enovix employs a unique 3D cell architecture that allows for more efficient use of space within the battery, resulting in higher energy density. This design enables better packing of active materials and improved overall performance of the energy storage system.

- Advanced electrolyte formulations for silicon anodes: To address challenges associated with silicon anodes, such as volume expansion and electrolyte decomposition, Enovix develops advanced electrolyte formulations. These specialized electrolytes help improve the cycling stability and longevity of silicon-based lithium-ion batteries.

- Electrode design and manufacturing techniques: Enovix has developed innovative electrode design and manufacturing techniques to optimize the performance of their silicon anode batteries. These methods focus on improving the structural integrity of the electrodes, enhancing conductivity, and maximizing the utilization of active materials.

- Battery management systems for silicon anode cells: To fully leverage the benefits of silicon anode chemistry, Enovix incorporates advanced battery management systems. These systems are designed to optimize charging and discharging protocols, monitor cell health, and ensure safe operation of the high-energy-density batteries.

02 3D cell architecture for improved energy density

Enovix employs a unique 3D cell architecture that enables more efficient use of space within the battery. This design allows for higher energy density by maximizing the active material content and minimizing inactive components. The 3D structure also helps manage silicon expansion and contraction during charge-discharge cycles.Expand Specific Solutions03 Advanced electrolyte formulations for silicon anodes

To address the challenges of silicon anodes, Enovix develops specialized electrolyte formulations. These electrolytes are designed to form stable solid-electrolyte interphase (SEI) layers on silicon surfaces, reducing irreversible capacity loss and improving cycle life. The formulations may include additives that enhance silicon anode performance and stability.Expand Specific Solutions04 Electrode fabrication techniques for silicon-based anodes

Enovix has developed innovative electrode fabrication techniques to optimize silicon anode performance. These methods may include specialized coating processes, binder systems, and conductive additives to improve silicon utilization, electrical conductivity, and mechanical stability of the electrode structure. The techniques aim to maximize energy density while maintaining long-term cycling stability.Expand Specific Solutions05 Battery management systems for silicon anode batteries

To fully leverage the benefits of silicon anodes, Enovix incorporates advanced battery management systems. These systems are designed to optimize charging protocols, monitor cell performance, and manage thermal characteristics specific to silicon-based batteries. The management systems help extend battery life, improve safety, and maximize the energy storage capabilities of the silicon anode chemistry.Expand Specific Solutions

Key Battery Players

The competition landscape for Enovix Silicon Anode Chemistry in battery energy storage is evolving rapidly. The industry is in a growth phase, with significant market potential driven by increasing demand for high-performance batteries in electric vehicles and renewable energy storage. The global lithium-ion battery market is projected to reach $100 billion by 2025. While silicon anode technology is still maturing, companies like Graphenix Development, Wildcat Discovery Technologies, and Norcsi GmbH are making strides in commercializing advanced anode materials. Established players such as Bosch, Intel, and IBM are also investing in this space, indicating the technology's strategic importance. Universities and research institutions worldwide are contributing to fundamental advancements, suggesting a collaborative ecosystem for innovation.

Graphenix Development, Inc.

Robert Bosch GmbH

Silicon Anode Patents

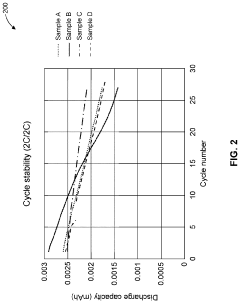

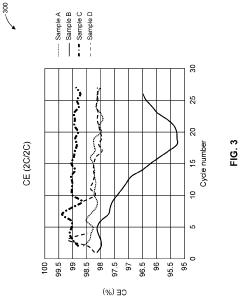

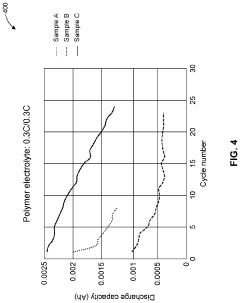

- A composite electrode structure comprising 40-80% silicon, 15-40% graphite, 5-15% carbon black, 0-15% carboxymethyl cellulose, 0-5% styrene-butadiene rubber, and 5-20% poly(acrylic acid) with a polymer electrolyte of 90-98% poly(ethylene glycol) methyl ether acrylate and 2-10% polyethylene glycol diacrylate, and lithium hexafluorophosphate, which mitigates volume expansion and enhances energy storage capabilities.

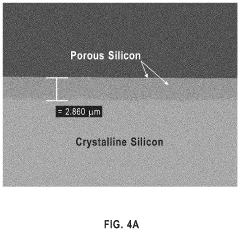

- A pre-lithiated silicon anode with a porous and non-porous region, combined with a carbon nanotube-based cathode and an ionic-permeable electron-insulating separator, within a liquid electrolyte, which accommodates volume changes and prevents self-pulverization, enabling high cycle life and capacity retention.

Regulatory Framework

The regulatory framework surrounding silicon anode battery technology, particularly in the context of Enovix's innovative approach, is a complex and evolving landscape. As this technology represents a significant advancement in energy storage capabilities, regulatory bodies are closely monitoring its development and potential implementation.

At the federal level in the United States, the Department of Energy (DOE) plays a crucial role in overseeing and supporting the development of advanced battery technologies. The DOE's Office of Energy Efficiency and Renewable Energy has established guidelines and standards for battery performance, safety, and environmental impact. These regulations are particularly relevant to Enovix's silicon anode chemistry, as it promises higher energy density and improved performance compared to traditional lithium-ion batteries.

The Environmental Protection Agency (EPA) also has a stake in regulating battery technologies, focusing on the environmental impact of production processes and end-of-life disposal. As silicon anode batteries may require different manufacturing techniques and materials, Enovix must ensure compliance with EPA regulations regarding emissions, waste management, and recycling.

Safety considerations are paramount in battery technology, and the Consumer Product Safety Commission (CPSC) has established strict guidelines for battery safety in consumer electronics. Enovix's silicon anode chemistry must meet or exceed these safety standards to gain market acceptance and regulatory approval.

Internationally, the regulatory landscape becomes more complex. The European Union, through its Battery Directive and REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) regulation, imposes stringent requirements on battery composition, performance, and recycling. Enovix must navigate these regulations to enter the European market successfully.

In Asia, countries like China, Japan, and South Korea have their own sets of regulations governing battery technology. China, in particular, has been aggressive in promoting electric vehicle adoption and has implemented policies to support advanced battery technologies. Enovix's silicon anode chemistry may find a receptive regulatory environment in these markets, provided it can meet local safety and performance standards.

As the technology progresses, regulatory bodies are likely to adapt their frameworks to address the specific characteristics of silicon anode batteries. This may include updates to existing standards or the creation of new guidelines tailored to this emerging technology. Enovix and other companies in this space must maintain open communication with regulatory agencies to ensure compliance and contribute to the development of appropriate regulatory frameworks.

Environmental Impact

The environmental impact of Enovix's silicon anode chemistry in revolutionizing battery energy storage is a critical aspect to consider. This innovative technology offers significant potential for reducing the overall environmental footprint of battery production and usage.

Silicon anodes, compared to traditional graphite anodes, enable higher energy density in batteries. This increased energy density translates to longer-lasting batteries, potentially reducing the frequency of battery replacements and, consequently, the amount of electronic waste generated. The extended lifespan of these batteries could lead to a decrease in the demand for raw materials and energy required for battery production, thereby lowering the associated environmental impacts.

Furthermore, the silicon anode technology allows for more compact and lightweight batteries. This characteristic is particularly beneficial in electric vehicles, as it can contribute to improved energy efficiency and extended driving ranges. The reduced weight of vehicles equipped with these advanced batteries could lead to lower energy consumption during operation, indirectly reducing greenhouse gas emissions from the transportation sector.

The production process of silicon anodes may also offer environmental advantages. Silicon is one of the most abundant elements in the Earth's crust, potentially reducing the reliance on scarce or environmentally problematic materials used in some current battery technologies. However, it is essential to consider the energy intensity and potential emissions associated with silicon processing and anode manufacturing.

Enovix's approach to battery design and manufacturing may also contribute to improved recyclability. The company's 3D cell architecture could potentially simplify the separation of battery components at the end of their life cycle, facilitating more efficient recycling processes. This aspect is crucial for establishing a more circular economy in the battery industry and reducing the environmental impact of battery disposal.

It is worth noting that while silicon anode technology shows promise in terms of environmental benefits, a comprehensive life cycle assessment would be necessary to fully quantify its environmental impact compared to existing battery technologies. This assessment should consider factors such as raw material extraction, manufacturing processes, energy consumption during use, and end-of-life management.

As the technology matures and scales up, there may be opportunities for further environmental improvements through optimized production processes, increased use of renewable energy in manufacturing, and the development of more efficient recycling techniques specific to silicon anode batteries. These advancements could further enhance the environmental credentials of Enovix's silicon anode chemistry in the context of revolutionizing battery energy storage.