Enovix Batteries for Portable Power Tools Transforming Productivity

Enovix Battery Tech Evolution

Enovix's battery technology has undergone significant evolution since the company's inception in 2007. Initially focused on developing silicon-based anodes for lithium-ion batteries, Enovix has made substantial progress in addressing the challenges associated with silicon expansion during charging cycles. Their proprietary 3D cell architecture, introduced in the early 2010s, marked a pivotal moment in their technological journey.

This innovative design allows for the efficient use of silicon as the primary anode material, overcoming the volumetric expansion issues that had previously limited silicon's widespread adoption in battery technology. The 3D structure provides mechanical constraints that prevent the silicon from expanding and contracting excessively during charge and discharge cycles, thereby maintaining the battery's structural integrity and performance over time.

As Enovix refined their technology, they introduced the concept of "constraint system" in the mid-2010s. This system further enhanced the stability of their silicon anodes, allowing for even higher energy densities without compromising cycle life or safety. The constraint system works in tandem with the 3D architecture to distribute stress evenly across the battery structure, minimizing degradation and extending overall battery lifespan.

In recent years, Enovix has focused on scaling their technology for commercial applications, particularly in the portable power tool sector. They have developed manufacturing processes that enable the mass production of their advanced batteries while maintaining the high quality and performance standards established in their prototypes. This scaling effort has been crucial in positioning Enovix as a viable supplier for the power tool industry.

The company has also made strides in improving the fast-charging capabilities of their batteries. By optimizing the electrode design and electrolyte composition, Enovix has achieved charging rates that significantly outperform traditional lithium-ion batteries. This advancement is particularly relevant for power tool applications, where minimizing downtime is critical for productivity.

Furthermore, Enovix has invested in enhancing the safety features of their batteries. The inherent stability of their 3D architecture, combined with advanced thermal management systems, has resulted in batteries that are more resistant to thermal runaway and other safety concerns often associated with high-energy-density cells.

As Enovix continues to evolve their technology, they are exploring the integration of advanced materials beyond silicon. This includes research into composite anodes that combine silicon with other high-capacity materials, as well as investigations into solid-state electrolytes that could further improve energy density and safety. These ongoing developments suggest that Enovix's battery technology will continue to advance, potentially revolutionizing the portable power tool industry and beyond.

Power Tool Market Demand

The power tool market has experienced significant growth in recent years, driven by increasing construction activities, home improvement projects, and industrial applications. This surge in demand has created a pressing need for more efficient and powerful portable tools, with batteries playing a crucial role in their performance and productivity.

In the construction sector, which accounts for a substantial portion of power tool usage, there is a growing emphasis on cordless tools due to their flexibility and improved safety on job sites. This shift has led to a higher demand for advanced battery technologies that can provide longer runtime and faster charging capabilities. The automotive and manufacturing industries also contribute significantly to the power tool market, with a focus on precision tools and those capable of high-torque applications.

The DIY and home improvement segment has seen a notable uptick, particularly in the wake of the global pandemic, as more individuals engage in home renovation projects. This trend has further fueled the demand for user-friendly, lightweight power tools with extended battery life. Consumers in this segment prioritize tools that offer a balance between performance and ease of use, making battery efficiency a key selling point.

Geographically, North America and Europe remain the largest markets for power tools, with Asia-Pacific showing the fastest growth rate. This regional disparity in market maturity and growth potential influences the demand for different types of battery technologies and power tool specifications.

The increasing focus on sustainability and environmental regulations has also shaped market demand, pushing manufacturers to develop more energy-efficient tools and eco-friendly battery solutions. This trend aligns with the growing consumer preference for products with reduced environmental impact, creating opportunities for innovative battery technologies like those developed by Enovix.

As the power tool market continues to evolve, there is a clear trend towards higher voltage systems, with 18V and 20V platforms becoming increasingly popular. This shift necessitates batteries that can deliver higher power output while maintaining compact form factors. Additionally, the integration of smart features and connectivity in power tools is creating demand for batteries that can support these advanced functionalities without compromising on runtime or weight.

The market also shows a growing interest in fast-charging technologies, as minimizing downtime is crucial for professional users. This has led to increased research and development efforts in rapid charging solutions and battery management systems that can optimize performance and longevity.

Current Battery Challenges

The current landscape of battery technology for portable power tools presents several significant challenges that hinder the full realization of their potential. One of the primary issues is the limited energy density of existing battery solutions. Despite advancements in lithium-ion technology, the power-to-weight ratio remains a critical constraint, impacting the overall performance and usability of cordless tools. This limitation often forces users to carry multiple battery packs or frequently interrupt work for recharging, reducing productivity and increasing operational costs.

Another pressing challenge is the trade-off between power output and battery life. High-performance power tools require substantial energy delivery, which can rapidly deplete battery charge. This creates a constant balancing act between providing sufficient power for demanding tasks and ensuring adequate runtime for extended use. The inability to consistently meet both requirements often results in compromised tool performance or reduced work efficiency.

Durability and safety concerns also plague current battery technologies. The harsh operating conditions typical in construction and industrial environments, including exposure to extreme temperatures, dust, and vibrations, can significantly impact battery longevity and reliability. Moreover, the risk of thermal runaway and potential fire hazards associated with lithium-ion batteries necessitates robust safety mechanisms, which can add weight and complexity to the battery design.

The charging speed of batteries remains a bottleneck in the workflow of many professionals. Even with fast-charging technologies, the downtime required for recharging can disrupt productivity, especially in high-intensity work environments where continuous operation is crucial. This limitation often leads to the need for multiple sets of batteries, increasing the overall cost of ownership for power tool users.

Environmental sustainability is an increasingly important consideration in battery technology. The current reliance on materials with limited global reserves, such as cobalt and lithium, raises concerns about long-term scalability and environmental impact. Additionally, the end-of-life management of batteries, including recycling and disposal, presents significant ecological challenges that need to be addressed for a more sustainable future in power tool technology.

Lastly, the cost factor remains a substantial hurdle in the widespread adoption of advanced battery technologies. While innovations promise improved performance, the associated increase in production costs can make these solutions prohibitively expensive for many users, slowing down the transition to more efficient and powerful battery-operated tools.

Enovix Battery Solutions

01 Battery manufacturing process optimization

Enovix focuses on improving battery manufacturing processes to enhance productivity. This includes optimizing production line layouts, implementing advanced automation techniques, and refining assembly procedures to reduce cycle times and increase output efficiency.- Battery manufacturing process optimization: Enovix has developed advanced manufacturing processes to improve battery productivity. This includes optimizing production lines, implementing automated systems, and refining assembly techniques to increase output and efficiency in battery production.

- Energy storage capacity enhancement: The company focuses on improving energy storage capacity in their batteries. This involves developing new electrode materials, optimizing cell design, and enhancing electrolyte formulations to increase the overall energy density and performance of their batteries.

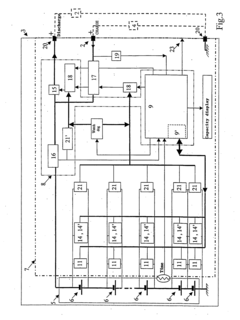

- Battery management system integration: Enovix incorporates advanced battery management systems to optimize battery performance and longevity. These systems monitor and control various parameters such as temperature, charge/discharge rates, and cell balancing to enhance overall battery productivity and lifespan.

- Quality control and testing procedures: The company implements rigorous quality control and testing procedures throughout the battery production process. This includes automated inspection systems, performance testing, and reliability assessments to ensure consistent high-quality output and improve overall productivity.

- Supply chain and resource management: Enovix focuses on optimizing their supply chain and resource management to enhance battery productivity. This involves streamlining material sourcing, inventory management, and logistics to ensure efficient production flow and minimize bottlenecks in the manufacturing process.

02 Advanced battery design for increased energy density

The company develops innovative battery designs that maximize energy density while maintaining or improving production efficiency. This involves novel electrode structures, improved cell architectures, and optimized material compositions to enhance overall battery performance and manufacturability.Expand Specific Solutions03 Quality control and testing systems

Enovix implements sophisticated quality control and testing systems throughout the production process. These systems utilize advanced sensors, machine learning algorithms, and real-time data analysis to identify and address potential issues, ensuring high-quality output and minimizing waste.Expand Specific Solutions04 Supply chain management and resource optimization

The company employs advanced supply chain management techniques and resource optimization strategies to improve overall productivity. This includes implementing just-in-time inventory systems, developing strategic partnerships with suppliers, and utilizing predictive analytics for demand forecasting and resource allocation.Expand Specific Solutions05 Workforce training and performance management

Enovix invests in comprehensive workforce training programs and performance management systems to enhance employee productivity. This includes implementing skill development initiatives, utilizing performance tracking tools, and fostering a culture of continuous improvement to maximize human resource efficiency in battery production.Expand Specific Solutions

Key Battery Manufacturers

The research on Enovix Batteries for portable power tools is in an early development stage, with the market poised for significant growth. The technology's potential to transform productivity in the power tool industry has attracted attention from major players. Companies like Robert Bosch GmbH, Milwaukee Electric Tool Corp., and Makita Corp. are likely to be at the forefront of adopting and integrating this technology. The market size is expected to expand rapidly as the benefits of Enovix Batteries become more apparent. However, the technology's maturity is still evolving, with companies like Techtronic Cordless GP and Greenworks (Jiangsu) Co., Ltd. potentially contributing to its advancement and commercialization.

Robert Bosch GmbH

Hilti AG

Enovix Core Innovations

- The integration of lithium ion or lithium polymer batteries with multiple cells in series, coupled with an electronic control module for managing and optimizing battery performance, including current limitation and charging systems, to provide high voltage and efficient energy delivery.

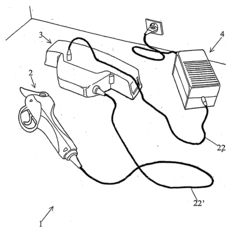

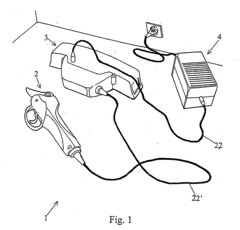

- A device for storing and releasing energy using lithium-ion accumulators with a battery management system, an inverter for current inversion, and a separate mobile transport and storage unit, decoupling the weight of the energy storage from the tool, enabling flexible and prolonged power supply without noise or emissions.

Safety and Regulations

Safety and regulations play a crucial role in the development and adoption of Enovix batteries for portable power tools. As these innovative batteries aim to transform productivity in the industry, ensuring their safe operation and compliance with regulatory standards is paramount.

The lithium-ion battery technology used by Enovix presents unique safety challenges that must be addressed. One of the primary concerns is thermal runaway, a phenomenon where the battery's internal temperature rises uncontrollably, potentially leading to fire or explosion. To mitigate this risk, Enovix has implemented advanced safety features, including a proprietary 3D cell architecture that enhances thermal management and reduces the likelihood of thermal runaway events.

Regulatory bodies such as the International Electrotechnical Commission (IEC) and Underwriters Laboratories (UL) have established stringent safety standards for lithium-ion batteries used in portable power tools. These standards encompass various aspects, including electrical safety, mechanical integrity, and thermal performance. Enovix batteries must undergo rigorous testing and certification processes to demonstrate compliance with these standards before they can be integrated into commercial power tools.

The transportation of lithium-ion batteries is subject to strict regulations due to their potential fire hazard. The International Air Transport Association (IATA) and the U.S. Department of Transportation (DOT) have implemented specific guidelines for the packaging, labeling, and shipping of these batteries. Manufacturers and distributors of Enovix-powered tools must adhere to these regulations to ensure safe transportation and storage of their products.

Environmental regulations also play a significant role in the lifecycle management of Enovix batteries. The European Union's Battery Directive and similar regulations in other regions mandate proper disposal and recycling of lithium-ion batteries. As Enovix batteries gain market share, establishing efficient recycling processes and infrastructure will be essential to comply with these environmental regulations and promote sustainability.

Workplace safety regulations, such as those enforced by the Occupational Safety and Health Administration (OSHA) in the United States, require employers to provide proper training and protective equipment for workers using power tools. The introduction of Enovix batteries may necessitate updates to existing safety protocols and training programs to address any unique characteristics or handling requirements of these advanced energy storage devices.

As the technology continues to evolve, regulatory frameworks may need to adapt to keep pace with innovations in battery design and performance. Enovix and other stakeholders in the portable power tool industry must actively engage with regulatory bodies to ensure that safety standards remain relevant and effective while allowing for technological advancements that enhance productivity and user experience.

Environmental Impact

The adoption of Enovix batteries in portable power tools has significant implications for environmental sustainability. These advanced silicon-anode lithium-ion batteries offer higher energy density and longer cycle life compared to traditional lithium-ion batteries, potentially reducing the overall environmental impact of power tool usage and production.

One of the primary environmental benefits of Enovix batteries is their increased energy density, which allows for longer runtime and reduced charging frequency. This translates to less energy consumption over the lifetime of the power tool, contributing to lower carbon emissions associated with electricity generation. Additionally, the extended cycle life of Enovix batteries means fewer battery replacements are needed, reducing the demand for raw materials and minimizing electronic waste.

The manufacturing process of Enovix batteries also presents opportunities for environmental improvement. The company's 3D cell architecture enables more efficient use of materials, potentially reducing the overall resource consumption in battery production. Furthermore, the use of silicon anodes instead of traditional graphite anodes may lead to a reduction in the mining and processing of graphite, which can have significant environmental impacts.

However, it is important to consider the potential environmental challenges associated with the increased use of silicon in battery production. The extraction and processing of silicon can have its own environmental footprint, including energy consumption and potential habitat disruption. As Enovix batteries gain wider adoption, careful management of silicon sourcing and processing will be crucial to ensure a net positive environmental impact.

The end-of-life management of Enovix batteries is another critical aspect of their environmental impact. The longer lifespan of these batteries inherently reduces the frequency of disposal, but proper recycling infrastructure will be essential to recover valuable materials and prevent environmental contamination. Developing efficient recycling processes for silicon-anode batteries will be a key challenge as this technology becomes more prevalent in the power tool industry.

In the context of portable power tools, the improved performance of Enovix batteries may lead to changes in tool design and usage patterns. More powerful and longer-lasting batteries could enable the development of cordless tools for applications that previously required corded or gas-powered alternatives. This shift could result in reduced emissions from small engines and decreased reliance on disposable fuel canisters, further enhancing the environmental benefits of this technology.