Potential of Enovix Batteries in Electric Vehicles Challenges and Opportunities

Enovix EV Battery Tech Evolution

The evolution of Enovix battery technology for electric vehicles (EVs) represents a significant advancement in the field of energy storage. Enovix, a Silicon Valley-based company, has been at the forefront of developing innovative lithium-ion battery architectures that promise to revolutionize the EV industry.

The journey of Enovix's battery technology began with their patented 3D silicon anode structure. This design allows for a higher energy density compared to traditional graphite anodes, addressing one of the primary challenges in EV batteries: range anxiety. As the technology progressed, Enovix focused on improving the silicon anode's stability and cycle life, crucial factors for long-term EV performance.

In the early stages, Enovix batteries were primarily targeted at consumer electronics due to their compact size and high energy density. However, recognizing the potential in the EV market, the company began adapting its technology for larger-scale applications. This transition involved scaling up the battery architecture while maintaining the benefits of the 3D silicon structure.

A key milestone in Enovix's EV battery evolution was the development of their BrakeFlow™ technology. This innovation addresses safety concerns associated with high-energy-density batteries, particularly thermal runaway. By incorporating a proprietary intra-cell system, Enovix batteries can better manage heat generation and dissipation, a critical feature for EV applications.

As the technology matured, Enovix focused on enhancing the fast-charging capabilities of their batteries. This development is particularly significant for EVs, as reducing charging times is essential for widespread adoption. The company's silicon-based anodes have demonstrated the ability to charge to 80% capacity in under 10 minutes, a substantial improvement over many existing EV batteries.

Recent advancements have seen Enovix working on integrating their battery technology with advanced battery management systems (BMS). This integration aims to optimize battery performance, extend lifespan, and provide more accurate state-of-charge and state-of-health information, all crucial for EV applications.

Looking forward, Enovix is exploring the potential of solid-state electrolytes in conjunction with their 3D silicon anode technology. This combination could lead to even higher energy densities and improved safety profiles, potentially marking the next significant leap in EV battery technology.

The evolution of Enovix's battery technology for EVs demonstrates a clear trajectory towards higher energy density, improved safety, faster charging, and better overall performance. As the company continues to refine and scale its technology, it stands poised to make a substantial impact on the future of electric mobility.

EV Market Battery Demand

The electric vehicle (EV) market has been experiencing rapid growth, driving an unprecedented demand for high-performance batteries. As the automotive industry shifts towards electrification, the need for advanced battery technologies has become increasingly critical. The global EV battery market is projected to expand significantly in the coming years, with estimates suggesting a compound annual growth rate (CAGR) of over 25% through 2030.

This surge in demand is primarily fueled by several factors. Firstly, government regulations and incentives aimed at reducing carbon emissions have accelerated the adoption of EVs worldwide. Many countries have set ambitious targets for phasing out internal combustion engine vehicles, creating a strong push for electric alternatives. Secondly, consumer awareness and acceptance of EVs have grown substantially, driven by improvements in range, charging infrastructure, and overall performance of electric vehicles.

The battery demand in the EV market is not only increasing in volume but also evolving in terms of technical requirements. Automakers are constantly seeking batteries with higher energy density, faster charging capabilities, longer lifespan, and improved safety features. This has led to a race among battery manufacturers to innovate and develop next-generation technologies that can meet these demanding specifications.

Currently, lithium-ion batteries dominate the EV market, with various chemistries such as NMC (Nickel Manganese Cobalt) and NCA (Nickel Cobalt Aluminum) being widely used. However, there is a growing interest in solid-state batteries and other advanced technologies that promise even better performance and safety characteristics.

The demand for EV batteries is also driving significant changes in the supply chain. Raw material sourcing, particularly for elements like lithium, cobalt, and nickel, has become a critical concern for manufacturers. This has led to increased efforts in recycling and the development of alternative battery chemistries that rely less on scarce or problematic materials.

As the EV market continues to expand, battery production capacity is becoming a key differentiator for both automakers and battery manufacturers. Many companies are investing heavily in gigafactories to scale up production and meet the growing demand. This expansion is not only happening in traditional automotive manufacturing hubs but also in emerging markets, reflecting the global nature of the EV revolution.

In conclusion, the EV market's battery demand presents both challenges and opportunities for the industry. While the rapid growth creates pressure on supply chains and production capacities, it also drives innovation and investment in advanced battery technologies. The success of companies in this space will largely depend on their ability to develop and scale up production of high-performance, cost-effective battery solutions that can meet the evolving needs of the EV market.

Enovix Battery Tech Status

Enovix Corporation has made significant strides in the development of advanced lithium-ion battery technology, particularly with their 3D silicon anode architecture. This innovative approach has positioned Enovix as a potential game-changer in the electric vehicle (EV) battery market. The company's battery technology promises higher energy density, faster charging capabilities, and improved safety features compared to conventional lithium-ion batteries.

The core of Enovix's technology lies in its unique 3D silicon anode structure. Unlike traditional graphite anodes, silicon can theoretically store up to ten times more lithium ions. However, silicon anodes have historically faced challenges with expansion and contraction during charge-discharge cycles, leading to rapid degradation. Enovix's proprietary design addresses this issue by constraining the silicon within a 3D structure, allowing for controlled expansion and maintaining battery integrity over numerous cycles.

Current performance metrics of Enovix batteries are promising for EV applications. The company reports energy densities exceeding 900 Wh/L, significantly higher than conventional lithium-ion batteries used in EVs today. This increased energy density could potentially translate to extended driving ranges for electric vehicles without increasing battery size or weight.

Fast charging capabilities are another notable feature of Enovix's technology. The company claims their batteries can achieve 0-80% charge in as little as 5-10 minutes, addressing one of the primary concerns of EV adoption – lengthy charging times. This rapid charging ability, if successfully implemented in EVs, could significantly enhance the practicality and appeal of electric vehicles for consumers.

Safety improvements are also a key aspect of Enovix's battery technology. The 3D structure and materials used in their batteries are designed to be more resistant to thermal runaway, reducing the risk of fires or explosions – a critical consideration for EV manufacturers and users alike.

Despite these advancements, Enovix faces challenges in scaling up production to meet the demands of the automotive industry. The company is currently focused on smaller format batteries for consumer electronics and is in the process of developing larger format cells suitable for EVs. The transition from small-scale to mass production while maintaining consistent quality and performance will be crucial for Enovix's success in the EV market.

Collaborations and partnerships with established automotive manufacturers will be essential for Enovix to validate their technology for EV applications. While the company has made progress in demonstrating the potential of their batteries, real-world testing in electric vehicles under various conditions is necessary to fully assess their viability and long-term performance.

Enovix Battery Solutions

01 Battery structure and design innovations

Enovix has developed innovative battery structures and designs, including unique electrode arrangements and cell architectures. These advancements aim to improve energy density, performance, and safety of lithium-ion batteries. The designs may incorporate novel materials and manufacturing techniques to enhance overall battery efficiency.- Battery structure and design innovations: Enovix has developed innovative battery structures and designs, including unique electrode arrangements and cell architectures. These advancements aim to improve energy density, performance, and safety of lithium-ion batteries. The designs may incorporate novel separator technologies and electrode configurations to enhance overall battery efficiency.

- Manufacturing processes for advanced batteries: The company has developed specialized manufacturing processes for producing their advanced battery designs. These processes may include novel electrode fabrication techniques, assembly methods, and quality control procedures. The manufacturing innovations are aimed at enabling mass production of high-performance batteries while maintaining consistency and reliability.

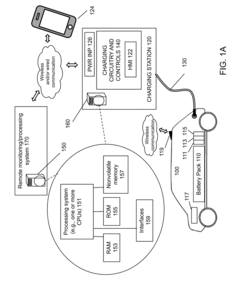

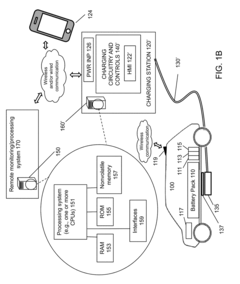

- Battery management and control systems: Enovix has developed sophisticated battery management and control systems to optimize the performance and longevity of their batteries. These systems may include advanced monitoring, balancing, and protection features to ensure safe and efficient operation of the battery packs in various applications.

- Materials science advancements for battery components: The company has made significant advancements in materials science related to battery components. This includes research into novel electrode materials, electrolytes, and additives to enhance battery performance, cycle life, and safety. These material innovations contribute to the overall improvement of battery characteristics.

- Integration and application-specific battery solutions: Enovix has developed solutions for integrating their advanced batteries into various applications and devices. This includes designing battery packs and systems tailored for specific use cases, such as consumer electronics, electric vehicles, or grid storage. The focus is on optimizing the battery's performance and form factor for each application.

02 Advanced electrode materials and compositions

The company focuses on developing advanced electrode materials and compositions for their batteries. This includes research into novel cathode and anode materials, as well as electrolyte formulations. These materials are designed to enhance battery capacity, cycling performance, and longevity while potentially reducing costs and environmental impact.Expand Specific Solutions03 Manufacturing processes and techniques

Enovix has developed proprietary manufacturing processes and techniques for their battery technology. These may include specialized equipment, automated production lines, and quality control measures. The focus is on scalable and efficient production methods that maintain the integrity of their advanced battery designs.Expand Specific Solutions04 Battery management and control systems

The company has invested in developing sophisticated battery management and control systems. These systems are designed to optimize battery performance, monitor health, and ensure safe operation. They may include advanced algorithms for charge/discharge control, thermal management, and predictive maintenance.Expand Specific Solutions05 Integration and application-specific designs

Enovix focuses on creating battery solutions tailored for specific applications and integration requirements. This includes designing batteries for consumer electronics, electric vehicles, and energy storage systems. The company considers factors such as form factor, power requirements, and environmental conditions in their application-specific designs.Expand Specific Solutions

EV Battery Industry Players

The electric vehicle battery market is in a dynamic growth phase, with Enovix Batteries emerging as a potential disruptor. The industry is characterized by intense competition among established players like Contemporary Amperex Technology, BYD, and LG Electronics, as well as newer entrants. Market size is expanding rapidly, driven by increasing EV adoption globally. Technologically, lithium-ion batteries dominate, but innovations in energy density, charging speed, and safety are ongoing. Enovix's silicon anode technology shows promise in addressing these challenges, potentially offering higher energy density and improved safety. However, scaling production and integrating with existing manufacturing processes remain key hurdles for new technologies in this mature yet evolving market.

Contemporary Amperex Technology Co., Ltd.

BYD Co., Ltd.

Enovix Core Innovations

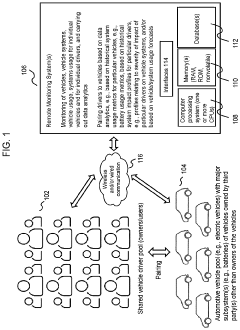

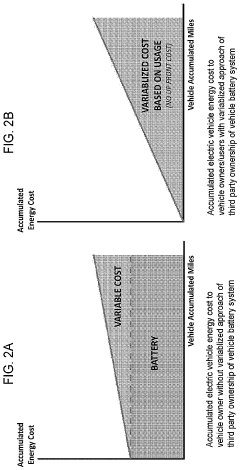

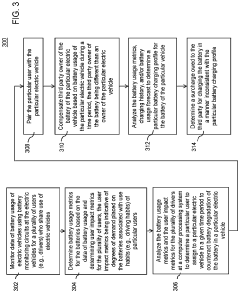

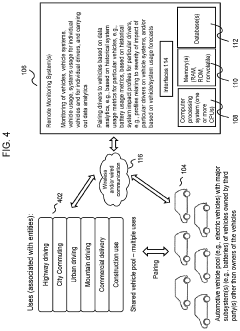

- A method and system utilizing battery monitoring sensors to collect data on electric vehicle usage, determining usage metrics and user impact metrics to dynamically pair users with vehicles, thereby counteracting battery degradation and optimizing battery life and performance.

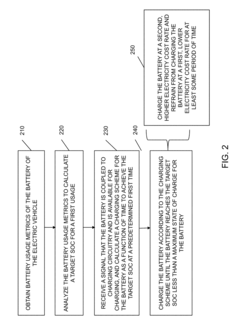

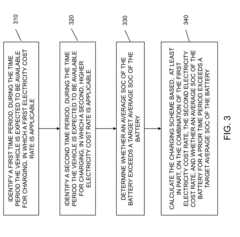

- A method and system that analyze battery usage metrics and environmental conditions to determine a target state of charge and implement a charging scheme with varying charge rates over time, balancing electricity costs and battery degradation, using a computer processing system and charging circuitry to control the charging process.

EV Battery Regulations

The regulatory landscape for electric vehicle (EV) batteries is rapidly evolving to address safety concerns, environmental impact, and performance standards. In the United States, the National Highway Traffic Safety Administration (NHTSA) has established guidelines for EV battery safety, including requirements for thermal management systems and crash protection. The Environmental Protection Agency (EPA) regulates the disposal and recycling of EV batteries under the Resource Conservation and Recovery Act.

In the European Union, the Battery Directive sets standards for battery production, collection, and recycling. The EU is also developing new regulations specifically for EV batteries, focusing on sustainability, carbon footprint, and end-of-life management. These regulations aim to ensure that batteries used in EVs are produced with minimal environmental impact and can be easily recycled at the end of their lifecycle.

China, as the world's largest EV market, has implemented its own set of regulations. The Ministry of Industry and Information Technology (MIIT) has established standards for EV battery performance, safety, and recycling. These regulations include requirements for battery energy density, cycle life, and thermal runaway prevention.

Global efforts are underway to harmonize EV battery regulations across different regions. The United Nations Economic Commission for Europe (UNECE) is working on developing Global Technical Regulations (GTR) for EV batteries, which aim to create a unified set of standards for battery safety and performance across member countries.

Enovix batteries, with their silicon-anode technology, must comply with these evolving regulations to be viable for use in electric vehicles. The company will need to demonstrate that their batteries meet or exceed safety standards, particularly in areas such as thermal management and crash resistance. Additionally, Enovix will need to address the environmental aspects of their battery production and end-of-life management to comply with sustainability-focused regulations.

As regulations continue to evolve, Enovix may face challenges in adapting their technology to meet new requirements. However, this also presents opportunities for the company to differentiate itself by developing batteries that not only comply with current regulations but also anticipate future regulatory trends. By focusing on safety, sustainability, and performance, Enovix can position itself as a leader in the EV battery market while navigating the complex regulatory landscape.

Enovix Production Scaling

Enovix, a pioneering battery technology company, faces significant challenges in scaling up its production to meet the demands of the electric vehicle (EV) market. The company's innovative 3D silicon lithium-ion battery architecture promises higher energy density and improved safety compared to traditional lithium-ion batteries. However, transitioning from small-scale production to mass manufacturing for the automotive industry requires overcoming several hurdles.

One of the primary challenges is the development of high-volume production processes that maintain the precision and quality required for Enovix's unique battery design. The company's current production capacity is limited, and scaling up while preserving the integrity of its 3D silicon anode structure is crucial. This involves optimizing manufacturing techniques, automating processes, and ensuring consistent quality across large-scale production runs.

Another critical aspect of production scaling is the establishment of a robust supply chain. Enovix must secure reliable sources for key materials, including high-purity silicon and specialized electrolytes. As production volumes increase, the company needs to negotiate long-term supply agreements and potentially develop strategic partnerships with material suppliers to ensure a steady and cost-effective flow of components.

Investment in advanced manufacturing equipment and facilities is also essential for Enovix to achieve the necessary production scale. This includes the acquisition of specialized machinery for electrode fabrication, cell assembly, and quality control. The company may need to construct new manufacturing plants or expand existing facilities, which requires significant capital expenditure and careful planning to align with projected demand from the EV market.

Workforce development is another crucial factor in Enovix's production scaling efforts. The company must recruit and train skilled personnel capable of operating and maintaining its advanced manufacturing equipment. This may involve partnerships with educational institutions and the implementation of comprehensive training programs to build a workforce with the necessary expertise in battery production and quality assurance.

Quality control and consistency become increasingly critical as production scales up. Enovix must implement rigorous testing and inspection protocols throughout the manufacturing process to ensure that each battery meets the stringent performance and safety standards required for automotive applications. This may involve the development of new testing methodologies and the integration of advanced monitoring systems into the production line.

Lastly, Enovix must navigate regulatory requirements and certification processes as it scales production for the EV market. This includes obtaining necessary approvals from automotive industry regulators and demonstrating compliance with safety and performance standards. The company may need to invest in extensive testing and validation programs to meet the rigorous requirements of automotive OEMs and regulatory bodies.