Future of PVDF in Wearables: Enhancing Sensor Sensitivity

PVDF Wearable Sensors: Background and Objectives

Polyvinylidene fluoride (PVDF) has emerged as a promising material for wearable sensor applications due to its unique piezoelectric properties. The evolution of PVDF in wearable technology can be traced back to the 1960s when its piezoelectric properties were first discovered. Since then, PVDF has undergone significant advancements, particularly in the realm of flexible and stretchable electronics.

The development of PVDF-based wearable sensors has been driven by the increasing demand for non-invasive, real-time health monitoring devices. These sensors have the potential to revolutionize personal healthcare by providing continuous, accurate, and comfortable physiological measurements. The technology has progressed from simple pressure sensors to more sophisticated multi-modal sensing platforms capable of detecting various physiological parameters simultaneously.

Recent years have witnessed a surge in research focused on enhancing the sensitivity of PVDF sensors. This trend is motivated by the need for more precise and reliable data collection in wearable devices. Improved sensitivity allows for the detection of subtle physiological changes, which is crucial for early disease detection and personalized healthcare.

The current technological landscape of PVDF in wearables is characterized by efforts to optimize material composition, sensor design, and signal processing techniques. Researchers are exploring various approaches, including nanocomposite formulations, surface modifications, and advanced fabrication methods to enhance the piezoelectric response of PVDF films.

Looking ahead, the future of PVDF in wearable sensors is poised for significant advancements. The primary objective is to develop highly sensitive, flexible, and durable sensors that can seamlessly integrate with the human body. This involves overcoming challenges related to signal-to-noise ratio, biocompatibility, and long-term stability under various environmental conditions.

Another key goal is to expand the range of detectable physiological parameters. While current PVDF sensors excel in measuring mechanical stimuli like pressure and strain, future developments aim to broaden their capabilities to include chemical and biological sensing. This multi-modal sensing approach would provide a more comprehensive picture of an individual's health status.

Furthermore, there is a growing emphasis on developing self-powered PVDF sensors. By harnessing the piezoelectric effect for both sensing and energy harvesting, these devices could potentially operate autonomously, eliminating the need for external power sources and enhancing their practicality for long-term use.

In conclusion, the future of PVDF in wearable sensors is focused on pushing the boundaries of sensitivity, functionality, and integration. As research progresses, we can anticipate the emergence of more sophisticated, reliable, and user-friendly wearable devices that will play a crucial role in preventive healthcare and personalized medicine.

Market Analysis for PVDF-Enhanced Wearables

The market for PVDF-enhanced wearables is experiencing significant growth, driven by the increasing demand for advanced sensor technologies in various applications. PVDF (Polyvinylidene Fluoride) has emerged as a key material in the development of highly sensitive and flexible sensors for wearable devices. The global wearable technology market is projected to reach substantial value in the coming years, with PVDF-based sensors playing a crucial role in this expansion.

The healthcare sector represents a major market opportunity for PVDF-enhanced wearables. These devices offer continuous health monitoring capabilities, enabling real-time tracking of vital signs, movement patterns, and physiological parameters. The growing emphasis on preventive healthcare and remote patient monitoring is fueling the adoption of PVDF-based wearable sensors in medical applications.

In the sports and fitness industry, PVDF-enhanced wearables are gaining traction due to their ability to provide accurate performance metrics and biomechanical data. Athletes and fitness enthusiasts are increasingly relying on these devices for personalized training programs and injury prevention. The market for sports wearables is expected to witness robust growth, with PVDF sensors contributing to enhanced accuracy and reliability of measurements.

The consumer electronics sector is another key market for PVDF-enhanced wearables. Smart clothing, augmented reality devices, and gesture control interfaces are incorporating PVDF sensors to improve user experience and functionality. The demand for more intuitive and responsive wearable devices is driving innovation in this space, creating new opportunities for PVDF-based sensor technologies.

Industrial applications of PVDF-enhanced wearables are also on the rise. These devices are being utilized for worker safety monitoring, predictive maintenance, and process optimization in manufacturing environments. The ability of PVDF sensors to withstand harsh conditions and provide reliable data makes them particularly suitable for industrial wearables.

Market trends indicate a growing preference for miniaturized and energy-efficient sensors, which aligns well with the properties of PVDF. The material's high sensitivity and low power consumption make it an attractive choice for next-generation wearable devices. Additionally, the increasing focus on sustainability and eco-friendly materials is expected to further boost the adoption of PVDF in wearable technology.

Geographically, North America and Europe are currently leading the market for PVDF-enhanced wearables, owing to their advanced healthcare systems and high consumer adoption rates of wearable technology. However, the Asia-Pacific region is anticipated to witness the fastest growth, driven by rapid technological advancements and increasing investments in healthcare and consumer electronics sectors.

Current PVDF Sensor Technology and Challenges

Polyvinylidene fluoride (PVDF) has emerged as a promising material for wearable sensor applications due to its unique piezoelectric properties. Current PVDF sensor technology has made significant strides in enhancing sensitivity and flexibility, making it suitable for various wearable devices. However, several challenges remain in fully realizing its potential in this field.

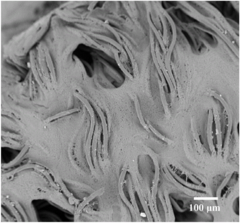

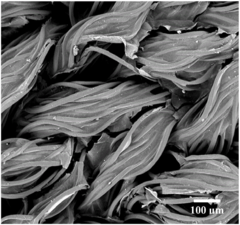

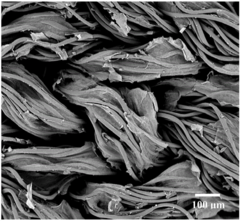

One of the primary advantages of PVDF sensors is their high sensitivity to mechanical stress and strain, allowing for accurate detection of subtle movements and physiological signals. This sensitivity has been further improved through various fabrication techniques, such as electrospinning and solution casting, which enable the production of thin, flexible PVDF films with optimized crystal structures.

Despite these advancements, PVDF sensors still face limitations in terms of signal-to-noise ratio, especially in dynamic environments typical of wearable applications. Environmental factors such as temperature fluctuations and electromagnetic interference can significantly affect sensor performance, necessitating the development of more robust signal processing algorithms and shielding techniques.

Another challenge lies in the integration of PVDF sensors into wearable systems. While PVDF itself is flexible, creating durable and reliable electrical connections between the sensor and other electronic components remains problematic. Current solutions often involve the use of conductive adhesives or direct metallization, but these methods can compromise the sensor's flexibility or long-term stability.

The scalability of PVDF sensor production is also a concern. While laboratory-scale fabrication has shown promising results, transitioning to large-scale, cost-effective manufacturing processes while maintaining consistent sensor quality and performance is an ongoing challenge. This is particularly crucial for the widespread adoption of PVDF sensors in consumer wearable devices.

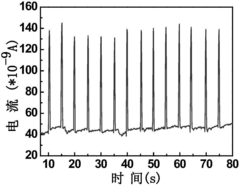

Energy harvesting capabilities of PVDF sensors present both an opportunity and a challenge. The piezoelectric nature of PVDF allows for the conversion of mechanical energy into electrical energy, potentially enabling self-powered wearable devices. However, the current energy conversion efficiency is relatively low, and significant improvements are needed to make this a viable power source for practical applications.

Biocompatibility and long-term stability of PVDF sensors in contact with human skin are additional areas requiring further research. While PVDF is generally considered safe, prolonged exposure in wearable applications may lead to unforeseen issues. Developing appropriate encapsulation methods and conducting extensive long-term studies are necessary to ensure the safety and reliability of PVDF-based wearable sensors.

In conclusion, while PVDF sensor technology has shown great promise for wearable applications, addressing these challenges is crucial for realizing its full potential. Ongoing research efforts are focused on improving sensitivity, signal processing, integration techniques, manufacturing scalability, energy harvesting efficiency, and biocompatibility to overcome these hurdles and pave the way for next-generation wearable devices.

Existing PVDF Sensitivity Enhancement Techniques

01 Nanostructured PVDF for enhanced sensitivity

Utilizing nanostructured PVDF materials, such as nanofibers or nanoparticles, can significantly improve sensor sensitivity. These nanostructures increase the surface area and piezoelectric response, leading to more efficient energy conversion and higher sensitivity in detecting various stimuli.- Enhancing PVDF sensor sensitivity through nanostructures: Incorporating nanostructures into PVDF sensors can significantly improve their sensitivity. This approach involves using nanomaterials or creating nanopatterns on the PVDF surface, which increases the active sensing area and enhances the piezoelectric response. These nanostructured PVDF sensors demonstrate higher sensitivity to mechanical stimuli and environmental changes.

- Composite materials for improved PVDF sensor performance: Combining PVDF with other materials to form composites can enhance sensor sensitivity. These composites may include conductive fillers, ceramic particles, or other polymers that synergistically improve the piezoelectric properties of PVDF. The resulting sensors exhibit increased sensitivity to various stimuli, including pressure, temperature, and chemical changes.

- Optimizing PVDF film thickness and crystallinity: The sensitivity of PVDF sensors can be improved by optimizing the film thickness and crystallinity. Thinner films often exhibit higher sensitivity due to increased flexibility. Additionally, controlling the crystalline phase of PVDF, particularly promoting the β-phase, can significantly enhance the piezoelectric response and overall sensor sensitivity.

- Surface modification techniques for PVDF sensors: Various surface modification techniques can be applied to PVDF sensors to increase their sensitivity. These may include plasma treatment, chemical functionalization, or the application of specific coatings. Such modifications can alter the surface properties of PVDF, enhancing its interaction with the target analytes or improving its overall sensing capabilities.

- Integration of PVDF sensors with advanced signal processing: Enhancing the sensitivity of PVDF sensors can be achieved through the integration of advanced signal processing techniques. This approach involves using sophisticated algorithms, machine learning, or artificial intelligence to analyze and interpret the sensor output. By employing these methods, even subtle changes in the PVDF sensor response can be detected and accurately measured, effectively increasing the overall sensitivity of the sensing system.

02 Composite materials with PVDF for improved performance

Combining PVDF with other materials like carbon nanotubes, graphene, or metal oxides can enhance sensor sensitivity. These composites often exhibit synergistic effects, resulting in improved mechanical properties, electrical conductivity, and overall sensing capabilities.Expand Specific Solutions03 Surface modification techniques for PVDF sensors

Applying various surface modification techniques to PVDF sensors can increase their sensitivity. These methods may include plasma treatment, chemical functionalization, or the addition of specific functional groups to enhance the interaction between the sensor and target analytes.Expand Specific Solutions04 Optimized sensor design and structure

Improving the design and structure of PVDF-based sensors can lead to enhanced sensitivity. This may involve optimizing electrode configurations, developing novel sensor geometries, or incorporating microstructures that amplify the piezoelectric response of the PVDF material.Expand Specific Solutions05 Signal processing and data analysis techniques

Implementing advanced signal processing and data analysis techniques can significantly improve the sensitivity of PVDF sensors. This may include noise reduction algorithms, machine learning approaches for pattern recognition, or the development of specialized software for interpreting sensor outputs.Expand Specific Solutions

Key Players in PVDF Wearable Sensor Industry

The future of PVDF in wearables for enhancing sensor sensitivity is in a growth phase, with increasing market size and technological advancements. The market is driven by the rising demand for smart wearables and IoT devices. While the technology is maturing, there's still room for innovation. Key players like Purdue Research Foundation, The Regents of the University of California, and QUALCOMM, Inc. are actively researching and developing PVDF-based sensors. Universities such as the University of Electronic Science & Technology of China and Xiamen University are contributing to academic research, while companies like Shenzhen Ruihu Technology Co., Ltd. and Sharp Display Technology Corp. are focusing on commercial applications. The collaboration between academia and industry is accelerating the technology's maturity and market adoption.

Purdue Research Foundation

QUALCOMM, Inc.

Innovative PVDF Sensor Designs and Materials

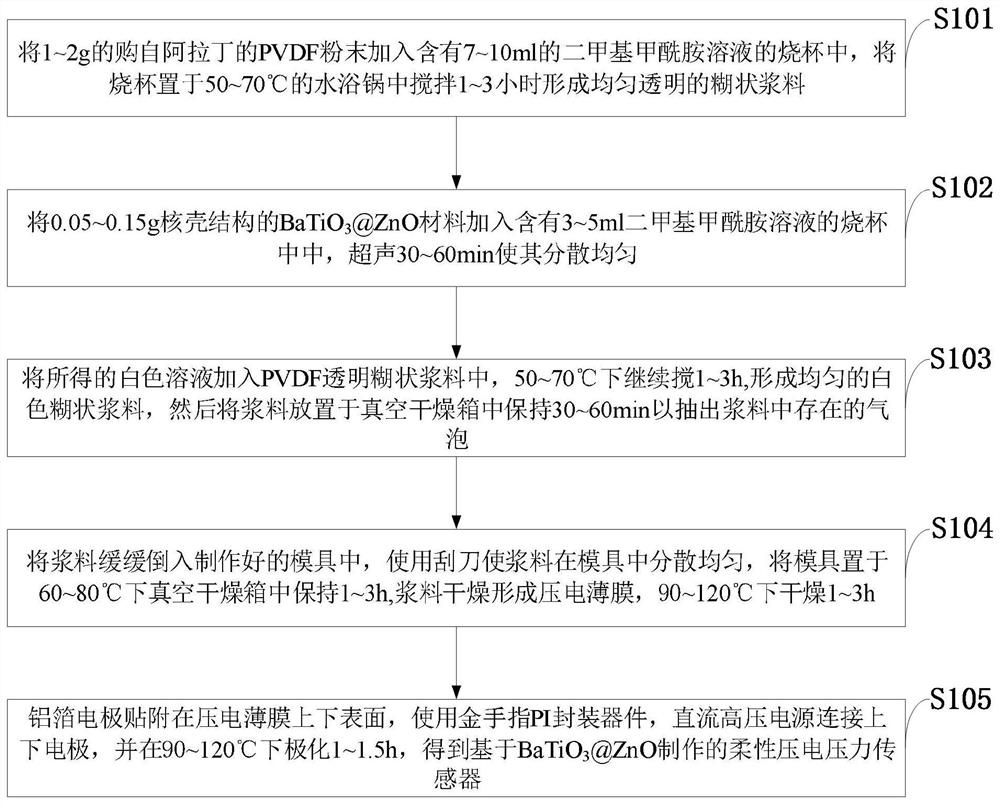

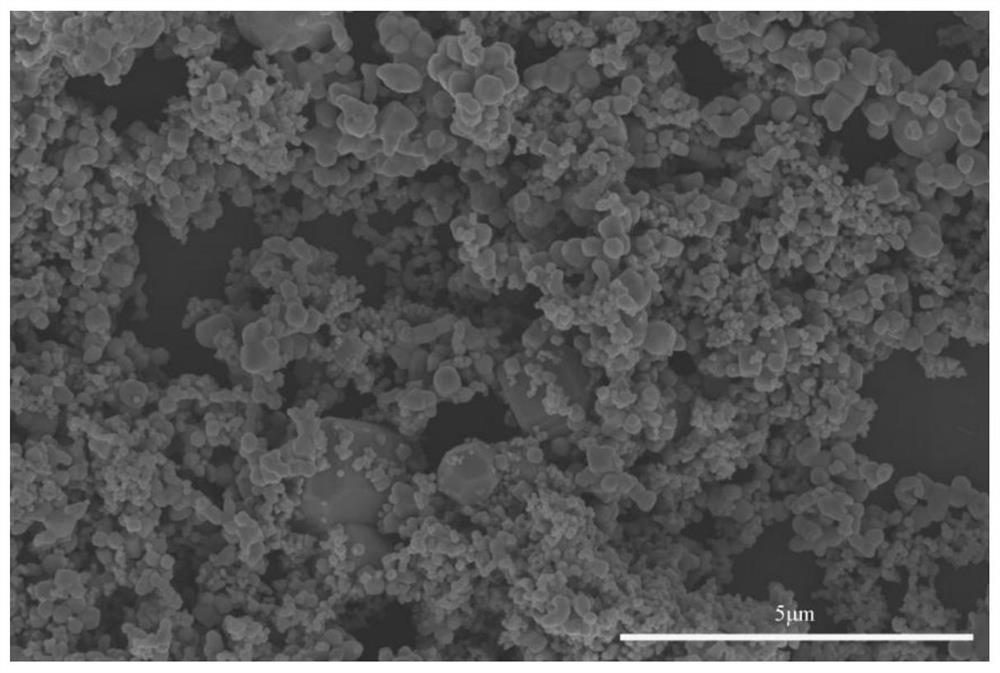

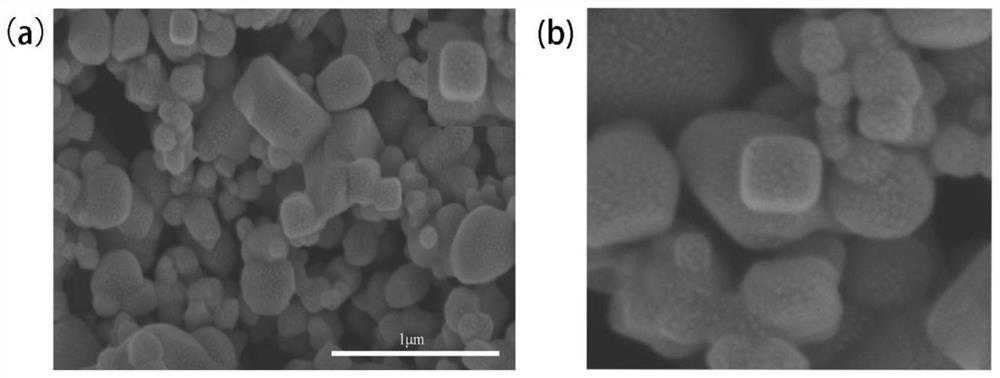

- The sol-gel method is used to coat the surface of BaTiO3 with wurtzite piezoelectric material ZnO nanoparticles. Zn(OH)2 is generated through complexation reaction and ZnO nanoparticles attached to the surface of BaTiO3 are synthesized at high temperature to improve the performance of BaTiO3 in the PVDF matrix. dispersion and piezoelectric properties.

- Using a self-responsive PVDF/graphene/elastic fabric composite sensor preparation method, the pre-treated elastic fabric is immersed in graphene oxide dispersion, reduced, cleaned, and then immersed in PVDF solution and subjected to high-voltage polarization, which does not require additional power supply. self-responsive sensor.

Biocompatibility and Safety Considerations

As the integration of PVDF (Polyvinylidene fluoride) in wearable technology continues to advance, particularly in enhancing sensor sensitivity, it is crucial to address the biocompatibility and safety considerations associated with its use. PVDF, known for its piezoelectric properties, offers significant potential in creating highly sensitive sensors for wearable devices. However, its direct contact with human skin necessitates a thorough evaluation of its biological interactions and potential health impacts.

The biocompatibility of PVDF in wearable applications is generally considered favorable. Studies have shown that PVDF exhibits low cytotoxicity and does not typically elicit significant inflammatory responses when in contact with human tissue. This characteristic makes it a suitable candidate for long-term wear applications. However, the processing methods and any additives used in PVDF formulations can influence its biocompatibility profile. Therefore, rigorous testing is essential to ensure that the specific PVDF composition used in wearable sensors meets biocompatibility standards.

Safety considerations for PVDF in wearables extend beyond mere skin contact. The potential for PVDF to release particles or leach chemicals over time must be thoroughly investigated. While PVDF is known for its chemical stability, prolonged exposure to environmental factors such as UV radiation, sweat, and mechanical stress could potentially alter its properties. Manufacturers must conduct comprehensive durability and degradation studies to assess the long-term safety of PVDF-based sensors in various wear conditions.

Electrical safety is another critical aspect when considering PVDF in wearable sensors. As a piezoelectric material, PVDF generates electrical charges in response to mechanical stress. While this property is fundamental to its function as a sensor, it also raises concerns about potential electrical interactions with the human body. Proper insulation and charge management systems must be implemented to prevent any unintended electrical stimulation or interference with other electronic devices worn by the user.

The regulatory landscape surrounding the use of PVDF in wearable technology is evolving. As these devices often straddle the line between consumer electronics and medical devices, manufacturers must navigate complex regulatory requirements. Compliance with standards such as ISO 10993 for biocompatibility evaluation and IEC 60601 for medical electrical equipment safety is crucial. Additionally, as wearable technology becomes more sophisticated, there may be a need for new or updated standards specifically addressing the unique challenges posed by materials like PVDF in close-contact, long-term wear scenarios.

In conclusion, while PVDF shows great promise in enhancing the sensitivity of wearable sensors, its successful integration into consumer products hinges on addressing these biocompatibility and safety considerations. Ongoing research and development efforts should focus not only on improving sensor performance but also on ensuring the long-term safety and reliability of PVDF-based wearable devices. This balanced approach will be key to realizing the full potential of PVDF in the future of wearable technology.

Energy Harvesting Potential of PVDF in Wearables

Polyvinylidene fluoride (PVDF) has emerged as a promising material for energy harvesting in wearable devices, offering unique properties that make it particularly suitable for this application. The piezoelectric nature of PVDF allows it to generate electrical energy from mechanical stress or strain, making it an ideal candidate for harvesting energy from human body movements.

In wearable devices, PVDF can be integrated into various forms, such as thin films or fibers, to capture energy from everyday activities like walking, breathing, or even subtle muscle movements. This harvested energy can potentially power low-energy consumption sensors, displays, or other electronic components within the wearable device, reducing the reliance on traditional batteries and extending the device's operational time.

The energy harvesting potential of PVDF in wearables is further enhanced by its flexibility and durability. These properties allow for seamless integration into clothing or accessories without compromising user comfort or the material's functionality. Additionally, PVDF's biocompatibility makes it safe for prolonged skin contact, a crucial factor for wearable applications.

Recent advancements in PVDF nanocomposites and fabrication techniques have significantly improved its energy conversion efficiency. By incorporating nanoparticles or creating specific nanostructures, researchers have been able to enhance the piezoelectric response of PVDF, thereby increasing its energy harvesting capabilities. This progress opens up new possibilities for self-powered wearable devices that can operate continuously without the need for external charging.

The scalability of PVDF-based energy harvesting systems is another key advantage. From small, localized harvesters for individual sensors to larger arrays integrated into clothing, PVDF can be tailored to meet various energy requirements. This versatility allows for the development of a wide range of wearable applications, from health monitoring devices to smart textiles.

However, challenges remain in optimizing the energy output of PVDF-based harvesters for practical wearable applications. Factors such as the positioning of the harvester, the frequency and amplitude of human movements, and the efficiency of energy storage and management systems all play crucial roles in determining the overall effectiveness of PVDF in wearable energy harvesting.

As research in this field progresses, we can expect to see more efficient PVDF-based energy harvesting solutions for wearables. This could lead to a new generation of self-powered wearable devices that are more sustainable, user-friendly, and capable of continuous operation without the limitations of traditional power sources.