How Does Methanol Activated PVDF Membrane?

PVDF Membrane Activation Background and Objectives

Polyvinylidene fluoride (PVDF) membranes have gained significant attention in various industrial applications due to their excellent chemical resistance, thermal stability, and mechanical strength. The activation of PVDF membranes using methanol has emerged as a crucial process to enhance their performance and expand their potential applications. This technical research report aims to provide a comprehensive overview of the background and objectives of methanol-activated PVDF membrane technology.

The development of PVDF membrane technology can be traced back to the 1960s when it was first introduced as a promising material for filtration and separation processes. Over the years, researchers and engineers have continuously sought ways to improve the properties and functionality of PVDF membranes. The activation of PVDF membranes using methanol represents a significant milestone in this ongoing evolution, addressing several limitations of conventional PVDF membranes.

Methanol activation of PVDF membranes is primarily driven by the need to enhance membrane hydrophilicity and reduce fouling propensity. Unmodified PVDF membranes are inherently hydrophobic, which can lead to decreased flux, increased fouling, and limited applicability in certain aqueous environments. The interaction between methanol and the PVDF polymer structure induces changes in the membrane's surface properties and internal structure, resulting in improved performance characteristics.

The primary objectives of methanol-activated PVDF membrane research and development include increasing membrane hydrophilicity, enhancing antifouling properties, improving flux performance, and expanding the range of applications. By achieving these objectives, researchers aim to create more efficient and versatile membrane systems that can address challenges in water treatment, bioprocessing, and other separation technologies.

Recent technological advancements have focused on optimizing the methanol activation process to achieve desired membrane properties while maintaining the inherent strengths of PVDF. This includes investigating the effects of activation parameters such as methanol concentration, treatment time, and temperature on membrane performance. Additionally, researchers are exploring the combination of methanol activation with other modification techniques to create synergistic effects and further enhance membrane functionality.

The growing interest in methanol-activated PVDF membranes is driven by the increasing demand for high-performance separation technologies in various industries. As global water scarcity and environmental concerns continue to rise, the need for efficient and sustainable membrane technologies becomes more pressing. Methanol-activated PVDF membranes offer a promising solution to address these challenges, potentially revolutionizing water treatment processes and other separation applications.

In conclusion, the background and objectives of methanol-activated PVDF membrane technology reflect a dynamic and evolving field of research. By understanding the historical context, current challenges, and future goals, this report aims to provide a foundation for further exploration and development of this promising technology.

Market Analysis for Methanol-Activated PVDF Membranes

The market for methanol-activated PVDF membranes is experiencing significant growth, driven by increasing demand in various industrial applications. These membranes offer superior performance characteristics, including enhanced hydrophilicity, improved flux rates, and better fouling resistance compared to traditional PVDF membranes. The global market for advanced membrane technologies, including methanol-activated PVDF membranes, is projected to expand at a compound annual growth rate of over 7% in the coming years.

Key industries driving the demand for methanol-activated PVDF membranes include water treatment, pharmaceuticals, food and beverage processing, and chemical manufacturing. The water treatment sector, in particular, represents a substantial market opportunity due to growing concerns over water scarcity and the need for efficient filtration solutions. Methanol-activated PVDF membranes are increasingly being adopted in municipal water treatment plants and industrial wastewater treatment facilities.

In the pharmaceutical industry, these membranes are gaining traction for their ability to provide high-purity filtration in drug manufacturing processes. The food and beverage sector is another significant market, where methanol-activated PVDF membranes are used in various separation and purification applications, ensuring product quality and safety.

Geographically, Asia-Pacific is emerging as the fastest-growing market for methanol-activated PVDF membranes, driven by rapid industrialization, urbanization, and stringent environmental regulations in countries like China and India. North America and Europe remain important markets, with a focus on upgrading existing water treatment infrastructure and adopting advanced membrane technologies.

The competitive landscape of the methanol-activated PVDF membrane market is characterized by the presence of several key players, including multinational corporations and specialized membrane manufacturers. These companies are investing heavily in research and development to improve membrane performance and expand their product portfolios.

Market trends indicate a growing preference for customized membrane solutions tailored to specific industrial applications. This trend is driving collaborations between membrane manufacturers and end-users to develop application-specific products. Additionally, there is an increasing focus on developing sustainable and eco-friendly membrane technologies, which is expected to further boost the adoption of methanol-activated PVDF membranes.

Despite the positive market outlook, challenges such as high initial costs and the need for specialized expertise in membrane operation and maintenance may hinder market growth in some regions. However, ongoing technological advancements and increasing awareness of the benefits of advanced membrane technologies are expected to overcome these barriers in the long term.

Current Challenges in PVDF Membrane Activation

Despite the widespread use of PVDF membranes in various applications, several challenges persist in the activation process using methanol. One of the primary issues is the inconsistency in activation efficiency across different batches of PVDF membranes. This variability can lead to unpredictable performance in filtration and separation processes, affecting the overall reliability of membrane-based systems.

Another significant challenge is the environmental and safety concerns associated with methanol usage. As a toxic and flammable solvent, methanol poses risks to both workers and the environment. Stringent safety protocols and waste management procedures are necessary, which can increase operational costs and complexity.

The activation process itself presents challenges in terms of optimization. Factors such as methanol concentration, activation time, and temperature all play crucial roles in determining the final membrane properties. Achieving the right balance to maximize hydrophilicity without compromising the membrane's mechanical integrity remains a complex task.

Furthermore, the scalability of methanol activation for large-scale industrial applications is a persistent issue. Ensuring uniform activation across large membrane surfaces while maintaining cost-effectiveness and process efficiency is challenging, particularly for continuous production systems.

The long-term stability of methanol-activated PVDF membranes is another area of concern. Some studies have reported a gradual loss of hydrophilicity over time, potentially due to the reorientation of polymer chains or the leaching of activated surface layers. This phenomenon can lead to decreased membrane performance and shorter operational lifetimes.

Additionally, the activation process can sometimes result in undesired changes to the membrane structure, such as pore size alterations or surface roughness modifications. These changes may impact the membrane's filtration characteristics and fouling propensity, necessitating careful control and characterization of the activation process.

Lastly, there is a growing need for more sustainable and environmentally friendly activation methods. While methanol activation is effective, the search for greener alternatives that can achieve similar or better results without the associated environmental and safety risks remains an ongoing challenge in the field of PVDF membrane technology.

Methanol Activation Mechanisms for PVDF Membranes

01 Chemical treatment for PVDF membrane activation

Chemical treatments are used to activate PVDF membranes, enhancing their surface properties and functionality. This process may involve the use of various chemicals or solutions to modify the membrane surface, improving its hydrophilicity, reactivity, or other desired characteristics.- Chemical treatment for PVDF membrane activation: Chemical treatments are used to activate PVDF membranes, enhancing their surface properties and functionality. This process may involve the use of various reagents to modify the membrane surface, improving its hydrophilicity, reactivity, or other desired characteristics.

- Plasma treatment for PVDF membrane activation: Plasma treatment is employed to activate PVDF membranes, altering their surface properties without affecting the bulk material. This method can enhance membrane wettability, adhesion, and overall performance for various applications.

- UV irradiation for PVDF membrane activation: UV irradiation is utilized to activate PVDF membranes, inducing photochemical reactions on the membrane surface. This technique can improve membrane hydrophilicity, introduce functional groups, and enhance overall membrane performance.

- Grafting techniques for PVDF membrane activation: Grafting methods are employed to activate PVDF membranes by attaching functional molecules or polymers to the membrane surface. This process can significantly alter membrane properties, such as hydrophilicity, selectivity, and fouling resistance.

- Thermal treatment for PVDF membrane activation: Thermal treatment is used to activate PVDF membranes, involving controlled heating processes to modify membrane structure and properties. This method can enhance membrane stability, mechanical strength, and overall performance in various applications.

02 Plasma treatment for PVDF membrane activation

Plasma treatment is an effective method for activating PVDF membranes. This process involves exposing the membrane to ionized gas, which can modify the surface properties, increase hydrophilicity, and improve the membrane's overall performance for various applications.Expand Specific Solutions03 UV irradiation for PVDF membrane activation

Ultraviolet (UV) irradiation is used to activate PVDF membranes by inducing photochemical reactions on the membrane surface. This method can alter the membrane's surface properties, potentially improving its wettability, biocompatibility, or other functional characteristics.Expand Specific Solutions04 Thermal treatment for PVDF membrane activation

Thermal treatment methods are employed to activate PVDF membranes. This process involves exposing the membrane to controlled heat, which can modify its crystalline structure, surface properties, or induce chemical changes that enhance the membrane's performance for specific applications.Expand Specific Solutions05 Grafting techniques for PVDF membrane activation

Grafting techniques are used to activate PVDF membranes by attaching functional groups or polymers to the membrane surface. This process can significantly alter the membrane's properties, such as hydrophilicity, selectivity, or fouling resistance, tailoring it for specific applications.Expand Specific Solutions

Key Players in PVDF Membrane Industry

The methanol-activated PVDF membrane technology is in a growth stage, with increasing market size and evolving applications. The global market for PVDF membranes is expanding, driven by demand in water treatment, pharmaceuticals, and energy storage. Technologically, it's advancing from early-stage research to commercial applications. Companies like Samsung SDI, Toshiba, and Toray Industries are at the forefront, developing innovative solutions. Academic institutions such as Harbin Institute of Technology and South China University of Technology are contributing significant research. The technology's maturity varies, with some players focusing on fundamental research while others are moving towards product commercialization, indicating a competitive and dynamic landscape.

Samsung SDI Co., Ltd.

Toshiba Corp.

Innovations in Methanol-PVDF Interaction Research

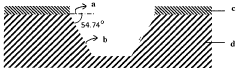

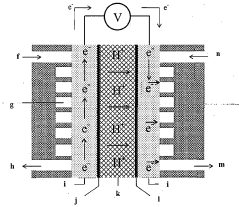

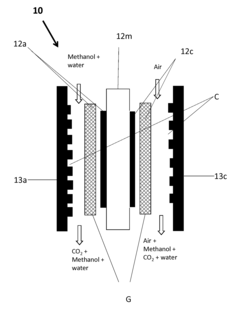

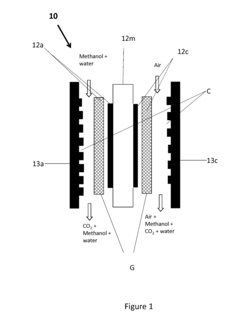

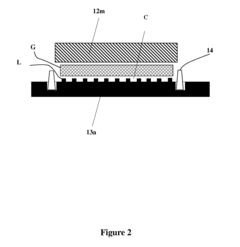

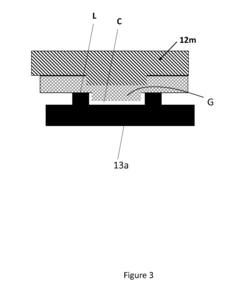

- The use of micro-channels fabricated from silicon wafers with a specific orientation and a P(VDF-TrFE) coated nafion membrane as the proton exchange membrane, combined with Pt nano particles at the anode and Pt-Ru nano particles at the cathode, enhances reactant flow and proton conductivity, improving overall fuel cell efficiency.

- An insulator layer with reduced compressibility is secured to the flow field plate, allowing the catalyst coated membrane to swell while preventing further expansion by providing a hard-stop, thus maintaining optimal compression of the gas diffusion layers and minimizing contact resistance.

Environmental Impact of Methanol Activation Process

The methanol activation process for PVDF membranes, while effective in enhancing membrane performance, raises several environmental concerns that warrant careful consideration. The primary environmental impact stems from the use and disposal of methanol, a volatile organic compound (VOC) with potential harmful effects on both human health and ecosystems.

During the activation process, methanol vapors are released into the atmosphere, contributing to air pollution and potentially affecting local air quality. These emissions can lead to the formation of ground-level ozone and smog, which have adverse effects on respiratory health and plant life. Furthermore, methanol is highly toxic if ingested or absorbed through the skin, posing risks to workers and nearby communities if not properly handled and contained.

Water pollution is another significant concern associated with methanol activation. Residual methanol from the process can contaminate wastewater streams if not adequately treated. When released into aquatic environments, methanol can deplete oxygen levels, harming aquatic life and disrupting ecosystem balance. Additionally, methanol can persist in groundwater, potentially affecting drinking water sources and soil quality.

The production and transportation of methanol for the activation process also contribute to the overall environmental footprint. Methanol is typically derived from natural gas or coal, both non-renewable resources. The extraction and processing of these fossil fuels result in greenhouse gas emissions and other environmental impacts associated with resource depletion and habitat disruption.

Waste management is a critical aspect of the environmental impact assessment. Spent methanol and other byproducts from the activation process require proper disposal or recycling to prevent environmental contamination. Improper handling of these wastes can lead to soil and water pollution, as well as potential long-term ecological damage.

To mitigate these environmental impacts, several strategies can be implemented. Closed-loop systems that capture and recycle methanol can significantly reduce emissions and waste. Advanced air filtration systems can minimize the release of methanol vapors into the atmosphere. Additionally, exploring alternative, more environmentally friendly solvents or activation methods could potentially reduce the reliance on methanol and its associated impacts.

In conclusion, while methanol activation of PVDF membranes offers significant performance benefits, it is crucial to address and mitigate its environmental impacts through responsible management practices, technological innovations, and regulatory compliance to ensure sustainable membrane production and use.

Regulatory Compliance for Activated PVDF Membranes

Regulatory compliance for activated PVDF membranes is a critical aspect of their development, production, and application. As these membranes are widely used in various industries, including water treatment, pharmaceuticals, and food processing, adherence to regulatory standards is essential to ensure safety, quality, and environmental protection.

In the United States, the Food and Drug Administration (FDA) plays a crucial role in regulating PVDF membranes used in food and pharmaceutical applications. The FDA's Code of Federal Regulations (CFR) Title 21, Part 177, Subpart B, Section 177.2510 specifically addresses the use of PVDF in food contact applications. Manufacturers must ensure that their methanol-activated PVDF membranes comply with these regulations, including limitations on extractables and leachables.

The Environmental Protection Agency (EPA) also has regulatory oversight for PVDF membranes used in water treatment applications. Compliance with the Safe Drinking Water Act (SDWA) and the Clean Water Act (CWA) is mandatory for membranes used in municipal water treatment facilities. Manufacturers must demonstrate that their activated PVDF membranes meet the performance standards set by these regulations and do not introduce harmful contaminants into the treated water.

In the European Union, the Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) regulation governs the use of chemical substances, including those used in PVDF membrane production and activation. Manufacturers must register their substances with the European Chemicals Agency (ECHA) and provide safety data sheets for their products. Additionally, the EU's Drinking Water Directive (98/83/EC) sets standards for materials in contact with drinking water, which applies to PVDF membranes used in water treatment applications.

For medical applications, activated PVDF membranes must comply with ISO 10993 standards for biocompatibility. This series of standards evaluates the biological safety of medical devices and materials, including membranes used in medical filtration processes. Manufacturers must conduct extensive testing to ensure their membranes meet these stringent requirements.

Globally, the International Organization for Standardization (ISO) provides several relevant standards for membrane technology, such as ISO 16075 for water reuse in irrigation and ISO 15747 for sterile plastic containers for human blood and blood components. While not specific to PVDF membranes, these standards often apply to products utilizing these membranes and must be considered in the regulatory compliance process.

Manufacturers of methanol-activated PVDF membranes must also adhere to Good Manufacturing Practices (GMP) and implement robust quality management systems to ensure consistent production of high-quality, compliant membranes. This includes maintaining detailed documentation of the activation process, raw material sourcing, and quality control measures.