How electrolyte additives affect color uniformity in anodized aluminum

OCT 11, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Anodizing Additives Background and Objectives

Anodizing aluminum has been a critical surface treatment process in industrial applications since its development in the early 20th century. The process, which creates a protective and decorative oxide layer on aluminum surfaces through electrochemical means, has evolved significantly over decades. Initially utilized primarily for corrosion protection, anodizing has expanded to serve aesthetic purposes across industries including architecture, consumer electronics, automotive components, and aerospace applications where consistent color appearance is paramount.

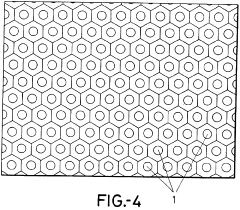

The evolution of anodizing technology has been marked by continuous refinement in electrolyte composition, with additives emerging as key factors in controlling the quality and uniformity of anodized finishes. Traditional sulfuric acid anodizing, while effective for creating durable oxide layers, often presented challenges in achieving consistent color distribution, particularly across large surface areas or complex geometries.

Electrolyte additives represent a sophisticated approach to modifying the anodizing process chemistry. These chemical compounds, when introduced to the anodizing bath in precise concentrations, can significantly alter the formation mechanisms of the oxide layer, influencing pore structure, growth rate, and ultimately color uniformity. The scientific understanding of these interactions has progressed from empirical observations to more systematic studies of electrochemical mechanisms.

Current technical objectives in the field focus on developing additive formulations that can reliably produce uniform color appearance regardless of part geometry, alloy composition variations, or processing conditions. This includes addressing common issues such as edge effects, streaking, and mottling that have historically plagued colored anodized finishes. Additionally, there is growing interest in additives that can enable more environmentally sustainable anodizing processes while maintaining or improving color uniformity.

The intersection of materials science, electrochemistry, and surface engineering drives research in this domain. Recent technological trends indicate a shift toward multi-component additive systems that synergistically address different aspects of the anodizing process. These developments aim to provide more robust solutions for industries where visual consistency is critical to product quality and brand identity.

This technical investigation seeks to comprehensively examine how various electrolyte additives influence the mechanisms governing color uniformity in anodized aluminum, evaluate the effectiveness of current solutions, and identify promising directions for future innovation in this technologically and commercially significant field.

The evolution of anodizing technology has been marked by continuous refinement in electrolyte composition, with additives emerging as key factors in controlling the quality and uniformity of anodized finishes. Traditional sulfuric acid anodizing, while effective for creating durable oxide layers, often presented challenges in achieving consistent color distribution, particularly across large surface areas or complex geometries.

Electrolyte additives represent a sophisticated approach to modifying the anodizing process chemistry. These chemical compounds, when introduced to the anodizing bath in precise concentrations, can significantly alter the formation mechanisms of the oxide layer, influencing pore structure, growth rate, and ultimately color uniformity. The scientific understanding of these interactions has progressed from empirical observations to more systematic studies of electrochemical mechanisms.

Current technical objectives in the field focus on developing additive formulations that can reliably produce uniform color appearance regardless of part geometry, alloy composition variations, or processing conditions. This includes addressing common issues such as edge effects, streaking, and mottling that have historically plagued colored anodized finishes. Additionally, there is growing interest in additives that can enable more environmentally sustainable anodizing processes while maintaining or improving color uniformity.

The intersection of materials science, electrochemistry, and surface engineering drives research in this domain. Recent technological trends indicate a shift toward multi-component additive systems that synergistically address different aspects of the anodizing process. These developments aim to provide more robust solutions for industries where visual consistency is critical to product quality and brand identity.

This technical investigation seeks to comprehensively examine how various electrolyte additives influence the mechanisms governing color uniformity in anodized aluminum, evaluate the effectiveness of current solutions, and identify promising directions for future innovation in this technologically and commercially significant field.

Market Analysis of Color-Uniform Anodized Products

The global market for color-uniform anodized aluminum products has experienced significant growth over the past decade, driven primarily by increasing demand in high-end consumer electronics, architectural applications, and premium automotive sectors. The market value for these specialized products reached approximately $3.2 billion in 2022, with projections indicating a compound annual growth rate of 6.8% through 2028.

Consumer electronics represents the largest application segment, accounting for nearly 42% of the total market share. Apple Inc.'s consistent use of precisely color-matched anodized aluminum in their product lineup has established a benchmark for quality that competitors strive to match. This has created a ripple effect throughout the industry, with consumers now expecting perfect color uniformity in premium devices.

The architectural sector follows as the second-largest market segment at 28%, where color consistency across building facades, window frames, and decorative elements is increasingly specified by architects and designers. The trend toward sustainable building materials has further bolstered demand, as anodized aluminum offers durability without the environmental concerns associated with painting or coating processes.

Automotive applications constitute approximately 18% of the market, with luxury vehicle manufacturers incorporating color-uniform anodized aluminum in both exterior trim components and interior design elements. The remaining 12% is distributed across aerospace, medical devices, and consumer goods industries.

Regionally, Asia Pacific dominates production capacity, accounting for 48% of global output, with China, Japan, and South Korea as key manufacturing hubs. North America and Europe follow with 27% and 22% respectively, often specializing in higher-precision, premium-grade products that command price premiums of 30-45% over standard anodized finishes.

Market research indicates that customers are willing to pay an average premium of 15-20% for guaranteed color uniformity across components, highlighting the commercial importance of electrolyte additive technology advancements. This premium increases to 25-35% in luxury applications where visual aesthetics are paramount.

Industry surveys reveal that 78% of procurement specialists in electronics manufacturing cite color consistency as a "critical" or "very important" quality parameter when sourcing anodized components, while 65% report having rejected shipments due to color variation issues. This underscores the significant market opportunity for technologies that can deliver reliable color uniformity.

The competitive landscape features specialized finishing companies that have developed proprietary electrolyte additive formulations, creating significant barriers to entry and allowing for sustained price premiums. These market dynamics have spurred increased R&D investment, with major players allocating 8-12% of revenue toward improving color uniformity technologies.

Consumer electronics represents the largest application segment, accounting for nearly 42% of the total market share. Apple Inc.'s consistent use of precisely color-matched anodized aluminum in their product lineup has established a benchmark for quality that competitors strive to match. This has created a ripple effect throughout the industry, with consumers now expecting perfect color uniformity in premium devices.

The architectural sector follows as the second-largest market segment at 28%, where color consistency across building facades, window frames, and decorative elements is increasingly specified by architects and designers. The trend toward sustainable building materials has further bolstered demand, as anodized aluminum offers durability without the environmental concerns associated with painting or coating processes.

Automotive applications constitute approximately 18% of the market, with luxury vehicle manufacturers incorporating color-uniform anodized aluminum in both exterior trim components and interior design elements. The remaining 12% is distributed across aerospace, medical devices, and consumer goods industries.

Regionally, Asia Pacific dominates production capacity, accounting for 48% of global output, with China, Japan, and South Korea as key manufacturing hubs. North America and Europe follow with 27% and 22% respectively, often specializing in higher-precision, premium-grade products that command price premiums of 30-45% over standard anodized finishes.

Market research indicates that customers are willing to pay an average premium of 15-20% for guaranteed color uniformity across components, highlighting the commercial importance of electrolyte additive technology advancements. This premium increases to 25-35% in luxury applications where visual aesthetics are paramount.

Industry surveys reveal that 78% of procurement specialists in electronics manufacturing cite color consistency as a "critical" or "very important" quality parameter when sourcing anodized components, while 65% report having rejected shipments due to color variation issues. This underscores the significant market opportunity for technologies that can deliver reliable color uniformity.

The competitive landscape features specialized finishing companies that have developed proprietary electrolyte additive formulations, creating significant barriers to entry and allowing for sustained price premiums. These market dynamics have spurred increased R&D investment, with major players allocating 8-12% of revenue toward improving color uniformity technologies.

Current Challenges in Electrolyte Additive Technology

Despite significant advancements in anodizing technology, the industry continues to face several critical challenges related to electrolyte additives and their impact on color uniformity in anodized aluminum. The primary challenge remains the inconsistent performance of additives across different production environments, leading to color variations that compromise product quality and increase rejection rates.

Temperature sensitivity presents a major obstacle, as many current electrolyte additives exhibit unstable behavior within narrow temperature ranges. Even minor fluctuations of 2-3°C in bath temperature can significantly alter the interaction between additives and the aluminum substrate, resulting in visible color inconsistencies across the same batch of products.

Bath contamination represents another persistent challenge, as metal ions and organic impurities accumulate over time, interfering with additive functionality. These contaminants can form complexes with additives, reducing their effectiveness and creating unpredictable color outcomes. Current filtration systems struggle to selectively remove these contaminants without also removing beneficial additives.

The aging behavior of electrolyte solutions containing additives remains poorly understood. Many facilities report gradual changes in color outcomes over the lifespan of an electrolyte bath, even when maintaining consistent parameters. This time-dependent behavior creates difficulties in maintaining color standards across production runs and necessitates frequent bath replacements, increasing operational costs.

Scaling issues present significant barriers when transferring laboratory-optimized additive formulations to industrial-scale production. Additives that perform excellently in small-scale tests often exhibit diminished effectiveness or unexpected behaviors in large production tanks, where surface-to-volume ratios and fluid dynamics differ substantially.

The lack of standardized testing protocols for evaluating additive performance specifically for color uniformity hampers development efforts. Current industry standards focus primarily on corrosion resistance and hardness properties, with color uniformity assessment remaining largely subjective and manufacturer-specific.

Environmental and regulatory constraints increasingly limit the use of certain effective additives, particularly those containing heavy metals or persistent organic compounds. This regulatory landscape forces manufacturers to adopt less effective alternatives that struggle to deliver consistent color results while meeting environmental compliance requirements.

The complex interplay between different additives in multi-component electrolyte systems presents another significant challenge. Synergistic and antagonistic effects between additives remain difficult to predict, with minor formulation changes sometimes producing disproportionate impacts on color uniformity outcomes.

Temperature sensitivity presents a major obstacle, as many current electrolyte additives exhibit unstable behavior within narrow temperature ranges. Even minor fluctuations of 2-3°C in bath temperature can significantly alter the interaction between additives and the aluminum substrate, resulting in visible color inconsistencies across the same batch of products.

Bath contamination represents another persistent challenge, as metal ions and organic impurities accumulate over time, interfering with additive functionality. These contaminants can form complexes with additives, reducing their effectiveness and creating unpredictable color outcomes. Current filtration systems struggle to selectively remove these contaminants without also removing beneficial additives.

The aging behavior of electrolyte solutions containing additives remains poorly understood. Many facilities report gradual changes in color outcomes over the lifespan of an electrolyte bath, even when maintaining consistent parameters. This time-dependent behavior creates difficulties in maintaining color standards across production runs and necessitates frequent bath replacements, increasing operational costs.

Scaling issues present significant barriers when transferring laboratory-optimized additive formulations to industrial-scale production. Additives that perform excellently in small-scale tests often exhibit diminished effectiveness or unexpected behaviors in large production tanks, where surface-to-volume ratios and fluid dynamics differ substantially.

The lack of standardized testing protocols for evaluating additive performance specifically for color uniformity hampers development efforts. Current industry standards focus primarily on corrosion resistance and hardness properties, with color uniformity assessment remaining largely subjective and manufacturer-specific.

Environmental and regulatory constraints increasingly limit the use of certain effective additives, particularly those containing heavy metals or persistent organic compounds. This regulatory landscape forces manufacturers to adopt less effective alternatives that struggle to deliver consistent color results while meeting environmental compliance requirements.

The complex interplay between different additives in multi-component electrolyte systems presents another significant challenge. Synergistic and antagonistic effects between additives remain difficult to predict, with minor formulation changes sometimes producing disproportionate impacts on color uniformity outcomes.

Established Electrolyte Additive Formulations

01 Electrolyte additives for improving color uniformity in batteries

Specific electrolyte additives can be incorporated into battery formulations to enhance color uniformity during manufacturing and operation. These additives help to stabilize the electrolyte solution and prevent discoloration that may occur due to chemical reactions or degradation processes. By maintaining consistent coloration throughout the battery components, these additives contribute to quality control and visual consistency of the final product.- Electrolyte additives for improved color uniformity in batteries: Specific electrolyte additives can significantly improve the color uniformity of battery components during manufacturing and operation. These additives help to stabilize the electrochemical reactions and prevent uneven coloration that may indicate inconsistent performance. Compounds such as fluorinated carbonates and certain lithium salts can be incorporated into the electrolyte formulation to ensure consistent color distribution across electrode surfaces, which serves as a visual indicator of uniform electrochemical processes.

- Color stabilizing additives for electrolyte solutions: Certain additives can be incorporated into electrolyte solutions to stabilize their color during storage and use. These stabilizing agents prevent degradation reactions that often lead to discoloration, ensuring consistent visual appearance throughout the product lifecycle. Examples include antioxidants, UV stabilizers, and specific organic compounds that inhibit oxidation reactions which typically cause yellowing or browning of the electrolyte solution over time.

- Functional additives for enhancing electrode color consistency: Functional additives can be incorporated into electrolyte formulations to enhance the color consistency of electrodes in electrochemical devices. These additives work by forming uniform solid electrolyte interphase (SEI) layers on electrode surfaces, preventing patchy or uneven coloration that indicates inconsistent performance. The additives can include specific cyclic carbonates, sulfur-containing compounds, and nitrile-based substances that promote homogeneous reactions across the electrode surface.

- Electrolyte composition for uniform color development in electrochromic devices: Specialized electrolyte compositions can be formulated to ensure uniform color development in electrochromic devices. These formulations typically contain specific ionic liquids, polymeric components, and additives that facilitate even ion distribution and transport across the electrochromic layer. The uniform ion movement results in consistent color change throughout the device, eliminating patchy or uneven coloration that can compromise both aesthetic appeal and functional performance of displays, smart windows, and other electrochromic applications.

- Color-indicating additives for electrolyte performance monitoring: Color-indicating additives can be incorporated into electrolyte formulations to provide visual feedback on electrolyte performance and condition. These additives change color in response to specific conditions such as pH shifts, concentration changes, or the presence of contaminants, allowing for easy monitoring of electrolyte health. The color indicators help maintain optimal performance by signaling when maintenance or replacement is needed, and can be particularly valuable in applications where electrolyte degradation might otherwise go undetected until system failure.

02 Color stabilizing compounds for electrolyte solutions

Various compounds can be added to electrolyte solutions to maintain color stability over time and under different operating conditions. These stabilizing compounds prevent unwanted color changes by neutralizing reactive species or inhibiting oxidation reactions that lead to discoloration. The incorporation of these compounds ensures that the electrolyte maintains its original appearance throughout the product lifecycle, which is particularly important for applications where visual inspection is part of quality assessment.Expand Specific Solutions03 Electrolyte formulations for uniform electrode coloration

Specialized electrolyte formulations can be designed to promote uniform coloration of electrodes during electrochemical processes. These formulations contain additives that ensure even distribution of active materials and consistent reaction rates across the electrode surface. By controlling the deposition or reaction patterns, these electrolyte systems help achieve visually uniform electrodes, which is critical for both aesthetic purposes and functional performance in devices like displays or electrochromic windows.Expand Specific Solutions04 Surfactants and dispersants for color homogeneity in electrolyte systems

Surfactants and dispersants can be incorporated into electrolyte formulations to improve the dispersion of colorants or pigments, resulting in enhanced color homogeneity. These additives reduce agglomeration and promote even distribution of color-contributing components throughout the electrolyte medium. The improved dispersion leads to consistent optical properties and uniform appearance in applications such as electrochromic devices, displays, and certain types of batteries where visual uniformity is important.Expand Specific Solutions05 pH regulators and buffers for consistent coloration in electrolyte-based systems

pH regulators and buffer compounds can be added to electrolyte solutions to maintain optimal acidity or alkalinity levels that ensure consistent coloration. Since many color-producing reactions are pH-dependent, controlling the pH within a narrow range helps achieve uniform color development and stability. These additives prevent localized pH variations that could otherwise lead to uneven coloration or spotting in the final product, particularly important in applications such as electroplating, anodizing, or electrochromic devices.Expand Specific Solutions

Leading Manufacturers and Research Institutions

The electrolyte additives market for anodized aluminum color uniformity is currently in a growth phase, with increasing demand driven by expanding applications in automotive, aerospace, and consumer electronics sectors. Market size is projected to reach significant value as industries prioritize aesthetic consistency in aluminum components. Technologically, companies like Henkel AG, BASF Corp., and Kansai Paint are leading with advanced formulations, while research institutions such as Central South University and South China University of Technology contribute fundamental innovations. Emerging players including Techtrans Co. and Huizhou Antaipu are developing specialized solutions. Apple and Lenovo represent major end-users driving quality requirements. The technology shows moderate maturity with ongoing R&D focused on environmentally sustainable additives and process optimization for complex aluminum alloys.

Henkel AG & Co. KGaA

Technical Solution: Henkel has developed proprietary electrolyte additive systems specifically designed to enhance color uniformity in anodized aluminum. Their technology focuses on organic acid-based additives that modify the pore structure during anodization. The company's BONDERITE® product line includes specialized additives that incorporate sulfonic acid derivatives and polyhydroxy compounds which interact with the aluminum oxide layer during formation. These additives work by controlling the dissolution rate of the oxide layer and promoting more uniform pore development across the substrate surface. Henkel's research has demonstrated that their additives can reduce color variation by up to 40% in architectural applications and 30% in consumer electronics components where visual consistency is critical. Their formulations also include stabilizing agents that maintain bath chemistry over extended production runs, reducing the need for frequent electrolyte replacement.

Strengths: Comprehensive formulation expertise across multiple industries; global technical support network; solutions compatible with both sulfuric and organic acid electrolytes. Weaknesses: Higher cost compared to conventional additives; some formulations require precise temperature control within ±1°C for optimal results.

BASF Corp.

Technical Solution: BASF has pioneered advanced electrolyte additive systems for anodizing aluminum with superior color uniformity. Their technology centers on a multi-component approach combining organic and inorganic additives that work synergistically to modify the anodic film structure. BASF's proprietary additives include specialized polycarboxylic compounds and metal chelating agents that regulate the oxide layer growth rate and pore formation. Their research has shown that controlling the electric field distribution during anodization is critical for color uniformity, which they achieve through ionic strength modifiers in their formulations. BASF has developed specific additive packages for different aluminum alloys, recognizing that alloy composition significantly impacts color development. Their additives have been documented to reduce Delta-E color variation by up to 60% in architectural applications and improve batch-to-batch consistency by establishing more uniform oxide layer thickness and pore geometry across the substrate surface.

Strengths: Extensive R&D capabilities with dedicated aluminum surface treatment laboratories; customized solutions for specific alloys; additives designed for both decorative and functional anodizing. Weaknesses: Complex implementation requiring process optimization; some formulations may increase total anodizing time.

Critical Patents in Anodizing Color Uniformity

Electrolyte additive for a colorant bath for colouring aluminium and process for colouring aluminium

PatentInactiveEP0555244A1

Innovation

- A synergistic mixture of antioxidants and scattering improvers, specifically compounds of general formulas I to IV and V, is added to the sulfuric acid tin(II)-containing dye bath, ensuring oxidation stability and improved throwing power by using functional groups like carboxyl, hydroxyl, and sulfonic acid radicals, which are water-soluble and oxidation-stable.

Electrolytic process for the coloration of anodized aluminium by modification and control of the anodic film transmission colour

PatentWO1998005806A1

Innovation

- An electrolytic system that modifies and controls the transmission color of anodic metal oxide films by adjusting parameters such as electrolyte dissolving power, temperature, and current patterns to independently control colorimetric characteristics like saturation, hue, and luminosity, allowing for the production of a wide range of colors.

Environmental Impact of Anodizing Processes

The anodizing process, while providing excellent corrosion resistance and aesthetic appeal to aluminum products, carries significant environmental implications that warrant careful consideration. Traditional anodizing processes utilize substantial quantities of chemicals including sulfuric acid, chromic acid, and various metal salts that can be harmful to aquatic ecosystems when discharged without proper treatment. The introduction of electrolyte additives to improve color uniformity further complicates the environmental footprint of these processes.

Electrolyte additives such as organic acids, metal salts, and surfactants, while beneficial for achieving consistent coloration, often contain compounds that are not readily biodegradable. These substances can persist in wastewater streams and potentially bioaccumulate in aquatic organisms. Research indicates that certain additives containing heavy metals like nickel, cobalt, and tin pose particular environmental concerns due to their toxicity at even low concentrations.

Energy consumption represents another critical environmental aspect of anodizing processes. The electrical current required for anodization contributes significantly to the carbon footprint of aluminum finishing operations. Studies show that processes utilizing additives for color uniformity may require extended anodizing times or higher current densities, thereby increasing energy demands and associated greenhouse gas emissions.

Water usage in anodizing facilities presents a substantial environmental challenge, with typical operations consuming between 30-100 liters of water per square meter of processed aluminum. Additives that enhance color uniformity often necessitate additional rinsing steps to remove residual chemicals, further increasing water consumption. This aspect becomes particularly problematic in regions experiencing water scarcity.

Recent regulatory frameworks worldwide have begun addressing these environmental concerns. The European Union's REACH regulations and similar initiatives in North America have restricted certain additives previously common in anodizing processes. This regulatory landscape has driven innovation toward more environmentally benign alternatives that maintain color uniformity while reducing ecological impact.

Promising developments in green chemistry approaches have emerged, focusing on biodegradable additives derived from renewable resources. These alternatives aim to deliver comparable color uniformity while minimizing environmental persistence. Additionally, closed-loop systems that recycle process solutions and recover valuable materials from spent electrolytes are gaining traction as sustainable practices within the industry.

Life cycle assessment studies comparing traditional anodizing processes with those utilizing newer, environmentally optimized additives demonstrate potential reductions in environmental impact by 30-45% across multiple indicators including ecotoxicity, eutrophication potential, and resource depletion. These findings underscore the importance of considering environmental factors when selecting electrolyte additives for color uniformity applications.

Electrolyte additives such as organic acids, metal salts, and surfactants, while beneficial for achieving consistent coloration, often contain compounds that are not readily biodegradable. These substances can persist in wastewater streams and potentially bioaccumulate in aquatic organisms. Research indicates that certain additives containing heavy metals like nickel, cobalt, and tin pose particular environmental concerns due to their toxicity at even low concentrations.

Energy consumption represents another critical environmental aspect of anodizing processes. The electrical current required for anodization contributes significantly to the carbon footprint of aluminum finishing operations. Studies show that processes utilizing additives for color uniformity may require extended anodizing times or higher current densities, thereby increasing energy demands and associated greenhouse gas emissions.

Water usage in anodizing facilities presents a substantial environmental challenge, with typical operations consuming between 30-100 liters of water per square meter of processed aluminum. Additives that enhance color uniformity often necessitate additional rinsing steps to remove residual chemicals, further increasing water consumption. This aspect becomes particularly problematic in regions experiencing water scarcity.

Recent regulatory frameworks worldwide have begun addressing these environmental concerns. The European Union's REACH regulations and similar initiatives in North America have restricted certain additives previously common in anodizing processes. This regulatory landscape has driven innovation toward more environmentally benign alternatives that maintain color uniformity while reducing ecological impact.

Promising developments in green chemistry approaches have emerged, focusing on biodegradable additives derived from renewable resources. These alternatives aim to deliver comparable color uniformity while minimizing environmental persistence. Additionally, closed-loop systems that recycle process solutions and recover valuable materials from spent electrolytes are gaining traction as sustainable practices within the industry.

Life cycle assessment studies comparing traditional anodizing processes with those utilizing newer, environmentally optimized additives demonstrate potential reductions in environmental impact by 30-45% across multiple indicators including ecotoxicity, eutrophication potential, and resource depletion. These findings underscore the importance of considering environmental factors when selecting electrolyte additives for color uniformity applications.

Quality Control Standards for Anodized Finishes

Quality control standards for anodized aluminum finishes are critical in ensuring consistent color uniformity, especially when considering the impact of electrolyte additives. These standards typically encompass several key parameters that must be rigorously monitored and controlled throughout the anodization process.

The AAMA (American Architectural Manufacturers Association) and ASTM (American Society for Testing and Materials) have established comprehensive guidelines that specifically address color uniformity in anodized aluminum. These standards include AAMA 611 and ASTM B244, which provide detailed specifications for thickness measurements and color consistency evaluation.

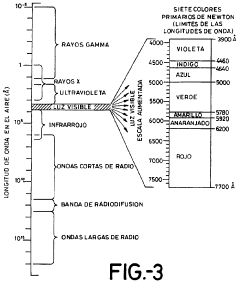

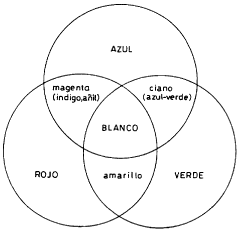

For color uniformity assessment, the industry commonly employs colorimetric measurements using the CIE L*a*b* color space system. This allows for quantitative evaluation of color differences between samples or across a single component. The acceptable Delta E value (total color difference) typically ranges from 1.0 to 5.0, depending on the application's requirements and industry standards.

When electrolyte additives are introduced to the anodizing bath, quality control becomes even more crucial. Standards often specify permissible concentration ranges for additives such as organic acids, metal salts, and surfactants. For instance, when using sulfuric acid with organic acid additives, the concentration must be maintained within ±0.5% of the target value to ensure color consistency.

Temperature control standards are equally important, as electrolyte additives can alter the optimal processing temperature. Most standards require temperature maintenance within ±1°C during the anodizing process, with more stringent requirements (±0.5°C) for specialized architectural applications where color matching is critical.

Regular bath analysis and documentation form another essential component of quality control standards. The frequency of testing typically increases when using additives, with recommendations for hourly monitoring of pH, conductivity, and additive concentration during production runs. Many standards mandate the use of statistical process control (SPC) methods to track these parameters over time.

Visual inspection protocols complement instrumental measurements, with standards often requiring evaluation under standardized lighting conditions (typically D65 illuminant) at specific viewing angles and distances. For architectural applications, inspection distances of 3 meters are common, while more critical applications may require closer examination.

Accelerated weathering tests, such as those outlined in ASTM G154 and ISO 11341, are prescribed to evaluate the long-term color stability of anodized finishes, particularly when new electrolyte additives are employed. These tests help ensure that the initial color uniformity achieved through additive use remains stable throughout the product's service life.

The AAMA (American Architectural Manufacturers Association) and ASTM (American Society for Testing and Materials) have established comprehensive guidelines that specifically address color uniformity in anodized aluminum. These standards include AAMA 611 and ASTM B244, which provide detailed specifications for thickness measurements and color consistency evaluation.

For color uniformity assessment, the industry commonly employs colorimetric measurements using the CIE L*a*b* color space system. This allows for quantitative evaluation of color differences between samples or across a single component. The acceptable Delta E value (total color difference) typically ranges from 1.0 to 5.0, depending on the application's requirements and industry standards.

When electrolyte additives are introduced to the anodizing bath, quality control becomes even more crucial. Standards often specify permissible concentration ranges for additives such as organic acids, metal salts, and surfactants. For instance, when using sulfuric acid with organic acid additives, the concentration must be maintained within ±0.5% of the target value to ensure color consistency.

Temperature control standards are equally important, as electrolyte additives can alter the optimal processing temperature. Most standards require temperature maintenance within ±1°C during the anodizing process, with more stringent requirements (±0.5°C) for specialized architectural applications where color matching is critical.

Regular bath analysis and documentation form another essential component of quality control standards. The frequency of testing typically increases when using additives, with recommendations for hourly monitoring of pH, conductivity, and additive concentration during production runs. Many standards mandate the use of statistical process control (SPC) methods to track these parameters over time.

Visual inspection protocols complement instrumental measurements, with standards often requiring evaluation under standardized lighting conditions (typically D65 illuminant) at specific viewing angles and distances. For architectural applications, inspection distances of 3 meters are common, while more critical applications may require closer examination.

Accelerated weathering tests, such as those outlined in ASTM G154 and ISO 11341, are prescribed to evaluate the long-term color stability of anodized finishes, particularly when new electrolyte additives are employed. These tests help ensure that the initial color uniformity achieved through additive use remains stable throughout the product's service life.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!