What role does current density play in anodized aluminum morphology

OCT 11, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Anodization Current Density Background and Objectives

Anodization of aluminum has evolved significantly since its discovery in the early 20th century, with current density emerging as one of the most critical parameters influencing the morphological characteristics of anodic aluminum oxide (AAO) films. The historical progression of anodization technology reveals a gradual understanding of how current density directly affects pore formation, growth kinetics, and overall structural properties of the anodized layer.

Current density, measured in amperes per square decimeter (A/dm²), represents the electrical current flowing through a unit area of the aluminum surface during the anodization process. Early research in the 1930s and 1940s established basic correlations between current density and oxide layer thickness, but lacked comprehensive understanding of the nanoscale morphological implications.

The technological evolution in this field accelerated in the 1970s and 1980s with the advent of advanced microscopy techniques, enabling researchers to observe the direct relationship between applied current density and resulting pore structures. This period marked a significant turning point in understanding how precisely controlled current density could be leveraged to engineer specific morphological features in anodized aluminum.

Contemporary research has established that current density influences several key morphological aspects: pore diameter, interpore distance, porosity percentage, barrier layer thickness, and growth rate of the anodic film. The field has progressed from empirical observations to theoretical models that can predict morphological outcomes based on applied current parameters.

The primary technical objective in this domain is to establish precise control mechanisms for tailoring anodized aluminum morphology through current density manipulation. This includes developing reproducible protocols for achieving specific pore geometries, uniform pore distribution, and controlled oxide layer thickness for various industrial and technological applications.

Secondary objectives include understanding the fundamental electrochemical mechanisms by which current density affects ion migration, oxide dissolution, and barrier layer formation during the anodization process. This mechanistic understanding is crucial for advancing beyond trial-and-error approaches to more predictive and controlled anodization techniques.

The field is currently trending toward developing dynamic current density profiles—varying current density during the anodization process to create hierarchical or gradient structures with unique properties. This represents a frontier in anodization technology with significant implications for advanced materials engineering.

Future technological goals include establishing comprehensive mathematical models that can accurately predict morphological outcomes across diverse aluminum alloys and electrolyte systems, potentially enabling computer-aided design of anodized structures with application-specific morphological characteristics.

Current density, measured in amperes per square decimeter (A/dm²), represents the electrical current flowing through a unit area of the aluminum surface during the anodization process. Early research in the 1930s and 1940s established basic correlations between current density and oxide layer thickness, but lacked comprehensive understanding of the nanoscale morphological implications.

The technological evolution in this field accelerated in the 1970s and 1980s with the advent of advanced microscopy techniques, enabling researchers to observe the direct relationship between applied current density and resulting pore structures. This period marked a significant turning point in understanding how precisely controlled current density could be leveraged to engineer specific morphological features in anodized aluminum.

Contemporary research has established that current density influences several key morphological aspects: pore diameter, interpore distance, porosity percentage, barrier layer thickness, and growth rate of the anodic film. The field has progressed from empirical observations to theoretical models that can predict morphological outcomes based on applied current parameters.

The primary technical objective in this domain is to establish precise control mechanisms for tailoring anodized aluminum morphology through current density manipulation. This includes developing reproducible protocols for achieving specific pore geometries, uniform pore distribution, and controlled oxide layer thickness for various industrial and technological applications.

Secondary objectives include understanding the fundamental electrochemical mechanisms by which current density affects ion migration, oxide dissolution, and barrier layer formation during the anodization process. This mechanistic understanding is crucial for advancing beyond trial-and-error approaches to more predictive and controlled anodization techniques.

The field is currently trending toward developing dynamic current density profiles—varying current density during the anodization process to create hierarchical or gradient structures with unique properties. This represents a frontier in anodization technology with significant implications for advanced materials engineering.

Future technological goals include establishing comprehensive mathematical models that can accurately predict morphological outcomes across diverse aluminum alloys and electrolyte systems, potentially enabling computer-aided design of anodized structures with application-specific morphological characteristics.

Market Analysis of Anodized Aluminum Applications

The global anodized aluminum market has been experiencing steady growth, valued at approximately $7.2 billion in 2022 and projected to reach $10.1 billion by 2028, with a compound annual growth rate of 5.8%. This growth is primarily driven by increasing demand across multiple sectors including architecture, automotive, consumer electronics, and aerospace industries.

In the architectural sector, anodized aluminum remains the material of choice for building facades, window frames, and decorative elements due to its corrosion resistance and aesthetic versatility. The construction industry accounts for nearly 40% of the total anodized aluminum consumption, with particular growth in regions experiencing rapid urbanization such as Southeast Asia and the Middle East.

The automotive industry represents the second-largest application segment, with anodized aluminum increasingly replacing traditional materials in vehicle components to meet lightweight requirements for fuel efficiency and emission standards. The shift toward electric vehicles has further accelerated this trend, as manufacturers seek to offset battery weight with lighter body components.

Consumer electronics manufacturers continue to favor anodized aluminum for device casings, with Apple's design language influencing industry-wide adoption. The premium look, durability, and heat dissipation properties achieved through specific anodization parameters—particularly current density control—have become standard requirements in high-end electronic products.

Market analysis reveals a growing demand for specialized anodized surfaces with precise morphological characteristics. Industries requiring high-performance coatings, such as aerospace and medical devices, are willing to pay premium prices for anodized aluminum with controlled pore structures that can only be achieved through precise current density management during the anodization process.

Regional market distribution shows Asia-Pacific leading with approximately 45% market share, followed by North America and Europe at 25% and 20% respectively. China dominates production capacity, though concerns about quality consistency and morphological control in mass production have created opportunities for specialized manufacturers in Japan, Germany, and the United States who emphasize precise process control, particularly of current density parameters.

The market is increasingly segmented between commodity anodized products and high-performance specialized applications where morphological characteristics directly impact functionality. This latter segment, growing at 8.7% annually, commands price premiums of 30-50% and represents the most profitable market opportunity for companies with advanced technical capabilities in controlling anodization parameters, particularly current density manipulation for specific pore structures and oxide layer properties.

In the architectural sector, anodized aluminum remains the material of choice for building facades, window frames, and decorative elements due to its corrosion resistance and aesthetic versatility. The construction industry accounts for nearly 40% of the total anodized aluminum consumption, with particular growth in regions experiencing rapid urbanization such as Southeast Asia and the Middle East.

The automotive industry represents the second-largest application segment, with anodized aluminum increasingly replacing traditional materials in vehicle components to meet lightweight requirements for fuel efficiency and emission standards. The shift toward electric vehicles has further accelerated this trend, as manufacturers seek to offset battery weight with lighter body components.

Consumer electronics manufacturers continue to favor anodized aluminum for device casings, with Apple's design language influencing industry-wide adoption. The premium look, durability, and heat dissipation properties achieved through specific anodization parameters—particularly current density control—have become standard requirements in high-end electronic products.

Market analysis reveals a growing demand for specialized anodized surfaces with precise morphological characteristics. Industries requiring high-performance coatings, such as aerospace and medical devices, are willing to pay premium prices for anodized aluminum with controlled pore structures that can only be achieved through precise current density management during the anodization process.

Regional market distribution shows Asia-Pacific leading with approximately 45% market share, followed by North America and Europe at 25% and 20% respectively. China dominates production capacity, though concerns about quality consistency and morphological control in mass production have created opportunities for specialized manufacturers in Japan, Germany, and the United States who emphasize precise process control, particularly of current density parameters.

The market is increasingly segmented between commodity anodized products and high-performance specialized applications where morphological characteristics directly impact functionality. This latter segment, growing at 8.7% annually, commands price premiums of 30-50% and represents the most profitable market opportunity for companies with advanced technical capabilities in controlling anodization parameters, particularly current density manipulation for specific pore structures and oxide layer properties.

Current Density Effects: State-of-Art and Challenges

Current density represents one of the most critical parameters in the anodization process of aluminum, directly influencing the morphological characteristics of the resulting oxide layer. Recent advancements in the field have established clear correlations between applied current density and pore formation mechanisms. At low current densities (typically below 5 mA/cm²), the anodic films exhibit smaller pore diameters with higher pore density, creating more compact structures. Conversely, higher current densities (above 20 mA/cm²) produce larger pores with increased interpore distances, affecting both the mechanical and optical properties of the anodized layer.

The state-of-the-art understanding indicates that current density modulates the electric field strength at the oxide/electrolyte interface, thereby controlling the rate of oxide dissolution and formation. This dynamic equilibrium determines the final morphology of the anodic aluminum oxide (AAO). Advanced characterization techniques including high-resolution transmission electron microscopy (HRTEM) and atomic force microscopy (AFM) have enabled researchers to visualize these morphological variations with unprecedented precision.

Despite significant progress, several challenges persist in controlling and predicting morphological outcomes based on current density manipulation. The primary challenge involves the non-linear relationship between current density and resulting morphology, particularly at transition points where small changes in current density can lead to dramatic structural alterations. This non-linearity complicates the development of predictive models for industrial applications.

Another significant challenge lies in the interaction between current density and other process parameters such as electrolyte composition, temperature, and anodization time. These complex interdependencies create a multidimensional parameter space that remains incompletely mapped. For instance, the same current density can produce markedly different morphologies when applied in different electrolytes or at varying temperatures, highlighting the context-dependent nature of current density effects.

The phenomenon of current localization presents an additional challenge, particularly in industrial-scale anodization processes. Uneven current distribution across large aluminum surfaces can result in heterogeneous morphology, compromising the quality and performance of the final product. Advanced electrode designs and pulsed current techniques have emerged as potential solutions, though their implementation at scale remains technically demanding.

Temperature management during high current density anodization represents another significant hurdle. The substantial heat generated during high-current processes can lead to local temperature spikes, disrupting the intended morphological development and potentially causing defects in the oxide layer. Sophisticated cooling systems and thermal modeling approaches are being developed to address this challenge, though their effectiveness varies across different anodization setups.

The state-of-the-art understanding indicates that current density modulates the electric field strength at the oxide/electrolyte interface, thereby controlling the rate of oxide dissolution and formation. This dynamic equilibrium determines the final morphology of the anodic aluminum oxide (AAO). Advanced characterization techniques including high-resolution transmission electron microscopy (HRTEM) and atomic force microscopy (AFM) have enabled researchers to visualize these morphological variations with unprecedented precision.

Despite significant progress, several challenges persist in controlling and predicting morphological outcomes based on current density manipulation. The primary challenge involves the non-linear relationship between current density and resulting morphology, particularly at transition points where small changes in current density can lead to dramatic structural alterations. This non-linearity complicates the development of predictive models for industrial applications.

Another significant challenge lies in the interaction between current density and other process parameters such as electrolyte composition, temperature, and anodization time. These complex interdependencies create a multidimensional parameter space that remains incompletely mapped. For instance, the same current density can produce markedly different morphologies when applied in different electrolytes or at varying temperatures, highlighting the context-dependent nature of current density effects.

The phenomenon of current localization presents an additional challenge, particularly in industrial-scale anodization processes. Uneven current distribution across large aluminum surfaces can result in heterogeneous morphology, compromising the quality and performance of the final product. Advanced electrode designs and pulsed current techniques have emerged as potential solutions, though their implementation at scale remains technically demanding.

Temperature management during high current density anodization represents another significant hurdle. The substantial heat generated during high-current processes can lead to local temperature spikes, disrupting the intended morphological development and potentially causing defects in the oxide layer. Sophisticated cooling systems and thermal modeling approaches are being developed to address this challenge, though their effectiveness varies across different anodization setups.

Contemporary Current Density Control Methodologies

01 Porous anodic oxide layer formation

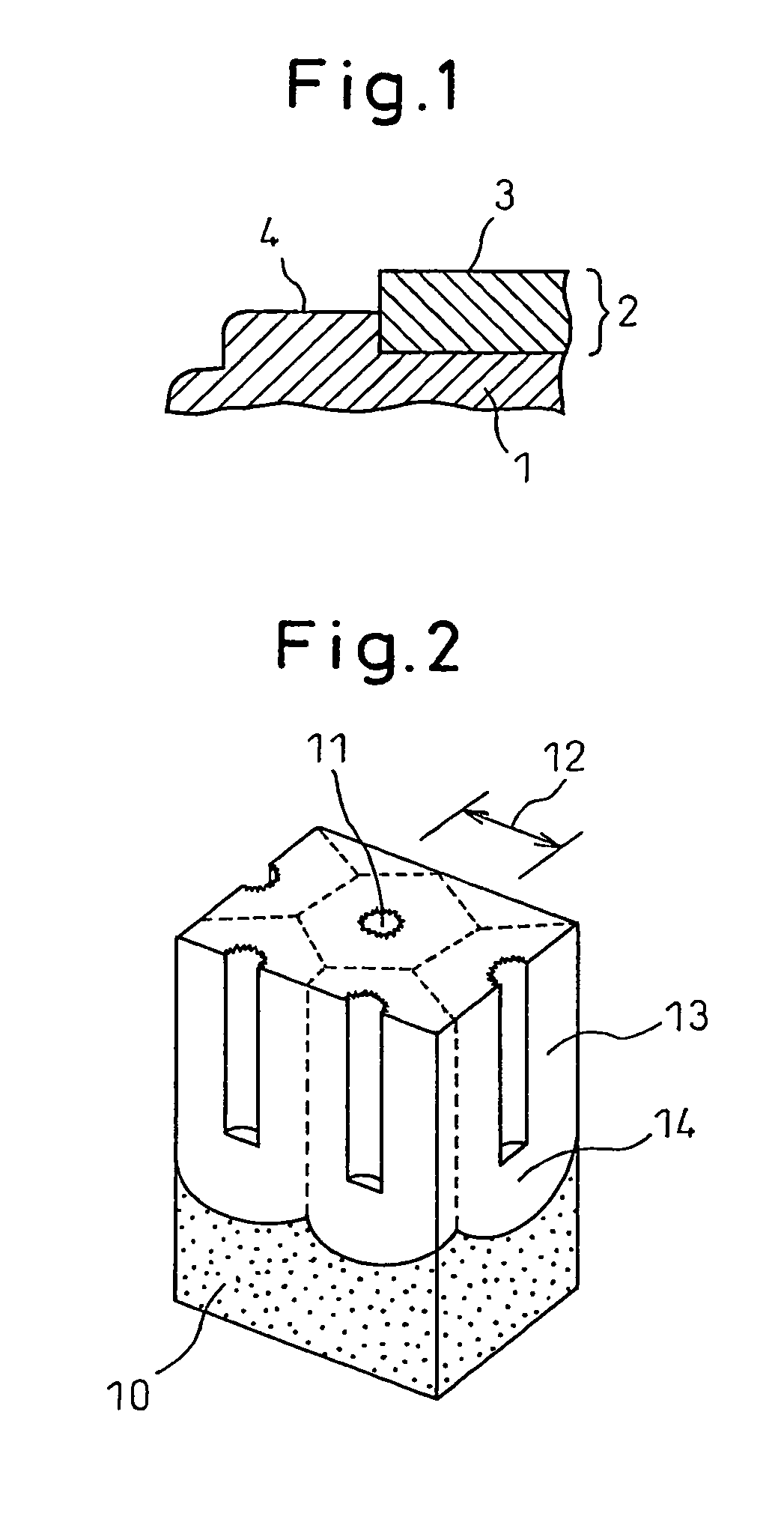

Anodization of aluminum creates a porous oxide layer with specific morphological characteristics. The process involves electrolytic treatment that forms a structured oxide film with nanopores. The pore size, density, and arrangement can be controlled by adjusting anodization parameters such as voltage, current density, electrolyte composition, and temperature. This porous structure provides unique properties to the anodized aluminum surface.- Porous anodic oxide structure formation: Anodized aluminum can develop a porous oxide structure with specific morphological characteristics. The formation of these porous structures depends on anodizing parameters such as electrolyte composition, temperature, voltage, and current density. The resulting pores can be uniform or have varying diameters and depths, creating a honeycomb-like structure on the aluminum surface. This porous morphology is crucial for applications requiring surface area enhancement or subsequent treatments.

- Barrier layer and pore modification techniques: The morphology of anodized aluminum includes a thin, non-porous barrier layer at the base of the pores. Various techniques can be employed to modify the pore structure, including pore widening through chemical etching, sealing processes to close pores, and two-step anodization to create highly ordered pore arrays. These modifications allow for tailoring the surface properties to specific applications, enhancing corrosion resistance, adhesion properties, or optical characteristics.

- Nano-textured and hierarchical surface structures: Advanced anodization techniques can create nano-textured surfaces and hierarchical structures on aluminum. These include nanowires, nanotubes, and other complex morphologies that provide unique surface properties. The hierarchical structures combine micro and nano-scale features, offering enhanced hydrophobicity, optical properties, or mechanical characteristics. These specialized morphologies are achieved through precise control of anodizing conditions and post-treatments.

- Coloration and optical properties related to morphology: The morphological characteristics of anodized aluminum directly influence its optical properties and coloration capabilities. Interference effects from the pore structure and thickness of the oxide layer create distinctive colors. Metal deposition within pores can enhance or modify these optical properties. The relationship between pore size, depth, and arrangement affects light reflection, absorption, and interference patterns, enabling decorative applications and functional optical surfaces.

- Environmental and process factors affecting morphology: Environmental conditions and processing parameters significantly impact the final morphology of anodized aluminum surfaces. Factors such as electrolyte temperature, composition, agitation, and impurities can alter pore formation and growth. Pre-treatments like etching or polishing influence the initial surface condition before anodization. Post-treatments including sealing, dyeing, or thermal processing further modify the surface structure. Understanding these factors enables precise control over the resulting morphological characteristics.

02 Barrier layer and pore structure control

The morphology of anodized aluminum consists of two distinct layers: a thin, non-porous barrier layer adjacent to the metal substrate and a porous layer above it. The barrier layer thickness and pore structure can be engineered through specific anodizing conditions. Various techniques allow for the creation of ordered pore arrays, branched pores, or tapered structures. These morphological features significantly influence the functional properties of the anodized surface.Expand Specific Solutions03 Surface treatment effects on morphology

Pre-treatment and post-treatment processes significantly affect the final morphology of anodized aluminum surfaces. Techniques such as etching, polishing, and sealing can modify the surface structure. Sealing processes can close the pores through hydration or deposition of materials within the pores, altering the surface morphology. These treatments can enhance corrosion resistance, wear resistance, and aesthetic properties of the anodized layer.Expand Specific Solutions04 Specialized anodizing techniques for unique morphologies

Advanced anodizing techniques have been developed to create specialized morphological features. These include hard anodizing for thicker, more wear-resistant layers; pulse anodizing for more uniform pore structures; and two-step anodizing for highly ordered nanopore arrays. Each technique produces distinct morphological characteristics that can be tailored for specific applications, from decorative finishes to functional surfaces for electronics or catalysis.Expand Specific Solutions05 Characterization and analysis of anodized aluminum morphology

Various analytical techniques are employed to characterize the morphology of anodized aluminum surfaces. Scanning electron microscopy (SEM), transmission electron microscopy (TEM), atomic force microscopy (AFM), and X-ray diffraction (XRD) are commonly used to examine pore size, distribution, layer thickness, and crystallinity. These characterization methods provide crucial information for understanding structure-property relationships and optimizing anodization processes for specific applications.Expand Specific Solutions

Leading Manufacturers and Research Institutions

Current density plays a crucial role in determining anodized aluminum morphology, with the competitive landscape reflecting a mature yet evolving market. The industry is in a consolidation phase, with established players like Applied Materials, Aluminum Corp. of China, and FUJIFILM Corp. leading technological advancements. The global anodized aluminum market is projected to reach approximately $10 billion by 2027, growing at a CAGR of 6-7%. Technical maturity varies across applications, with companies like DENSO Corp. and Kobe Steel focusing on high-precision industrial applications, while research institutions such as Industrial Technology Research Institute and Central South University drive innovation in nano-porous structures and novel electrolyte formulations. Applied Materials and Siemens AG are leveraging their expertise in precision manufacturing to develop advanced control systems for optimizing current density parameters.

Applied Materials, Inc.

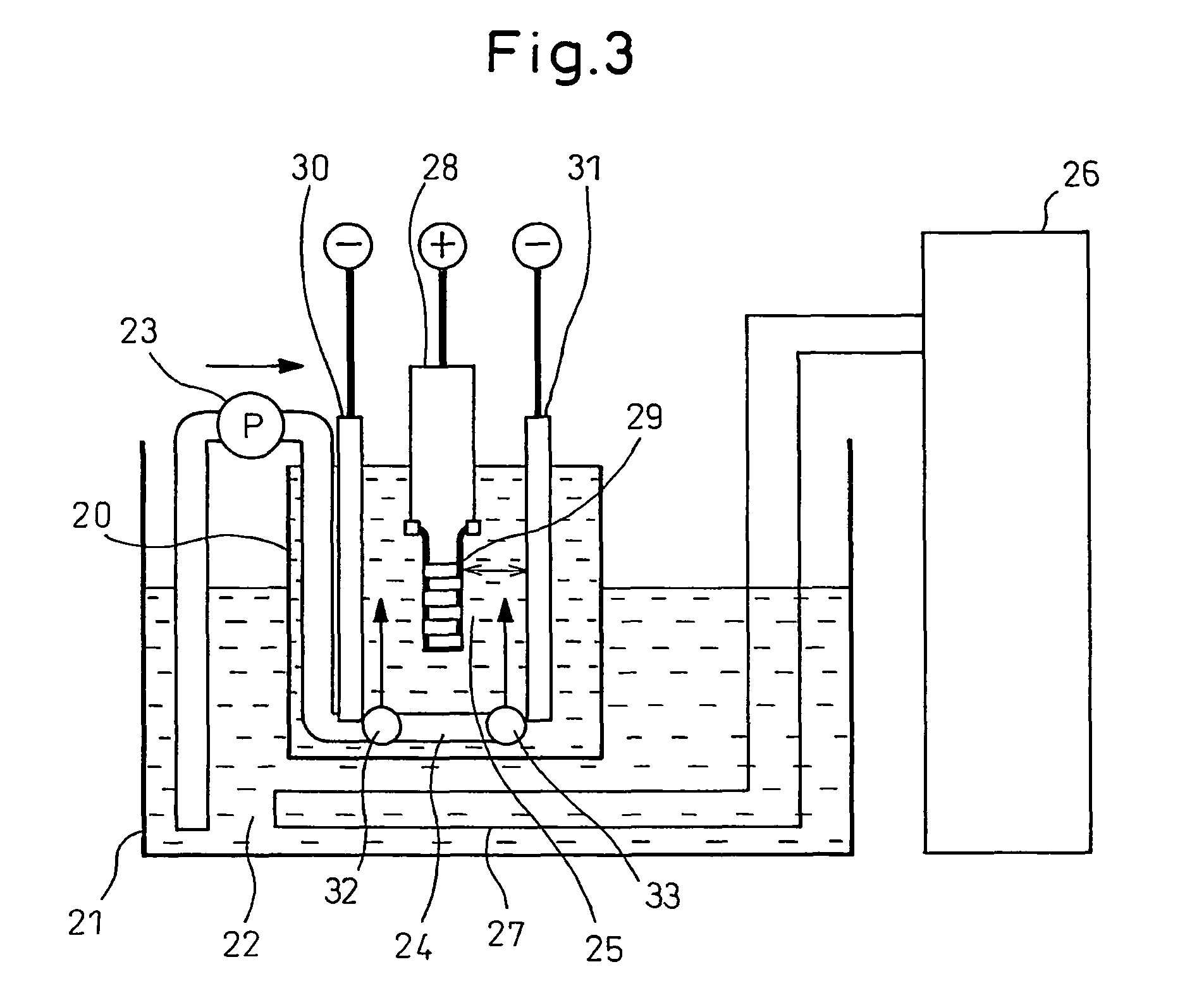

Technical Solution: Applied Materials has developed advanced anodization process control systems that precisely regulate current density to achieve specific pore morphologies in aluminum oxide layers. Their technology utilizes proprietary pulse modulation techniques that allow for dynamic adjustment of current density during the anodization process, enabling the formation of highly ordered nanoporous structures with controlled pore diameter, interpore distance, and pore depth. Their research demonstrates that by maintaining precise current density profiles (typically between 1-50 mA/cm²), they can produce self-ordered porous alumina with hexagonal cell arrangements and aspect ratios exceeding 1000:1. Their systems incorporate real-time monitoring of electrolyte temperature, pH, and agitation to ensure uniform current distribution across the aluminum substrate, which is critical for consistent pore formation and growth kinetics.

Strengths: Exceptional precision in current density control allowing for reproducible nanopore architectures; integrated monitoring systems that compensate for process variations. Weaknesses: Their high-end equipment requires significant capital investment; the technology is primarily optimized for semiconductor and electronics applications rather than general industrial anodizing.

Aluminum Corp. of China Ltd.

Technical Solution: Aluminum Corporation of China (Chalco) has pioneered research in high-field anodization techniques where current density serves as the primary control parameter for tailoring aluminum oxide morphology. Their proprietary process employs carefully calibrated current density gradients (ranging from 5-100 mA/cm²) to create functional anodic films with varying porosity profiles through the oxide thickness. Chalco's research has established that higher current densities (>50 mA/cm²) promote faster oxide growth but can lead to localized heating and "burning" effects that create distinctive morphological features. Their technology incorporates specialized cooling systems and electrolyte formulations that enable stable anodization at elevated current densities, producing oxide layers with enhanced hardness and wear resistance. Chalco has demonstrated that by precisely controlling current density transitions during the anodization process, they can create multi-layered oxide structures with distinct functional properties in each layer.

Strengths: Extensive practical experience in large-scale industrial anodization; proprietary electrolyte formulations optimized for high current density operations. Weaknesses: Their techniques often require more energy consumption compared to conventional methods; some of their high current density processes have limited applicability for precision electronic applications.

Critical Patents in Anodization Current Density Control

A lithographic printing plate support

PatentInactiveBRPI0715078A2

Innovation

- A method involving an aluminum support treated in an aqueous solution with an electrolyte solution, where an alternating voltage is applied to induce a local current density that follows a specific equation, preventing chattermarks by maintaining the current density below a defined limit curve in the J/Q diagram.

Method for anodizing aluminum and anodized aluminum

PatentActiveUS8691403B2

Innovation

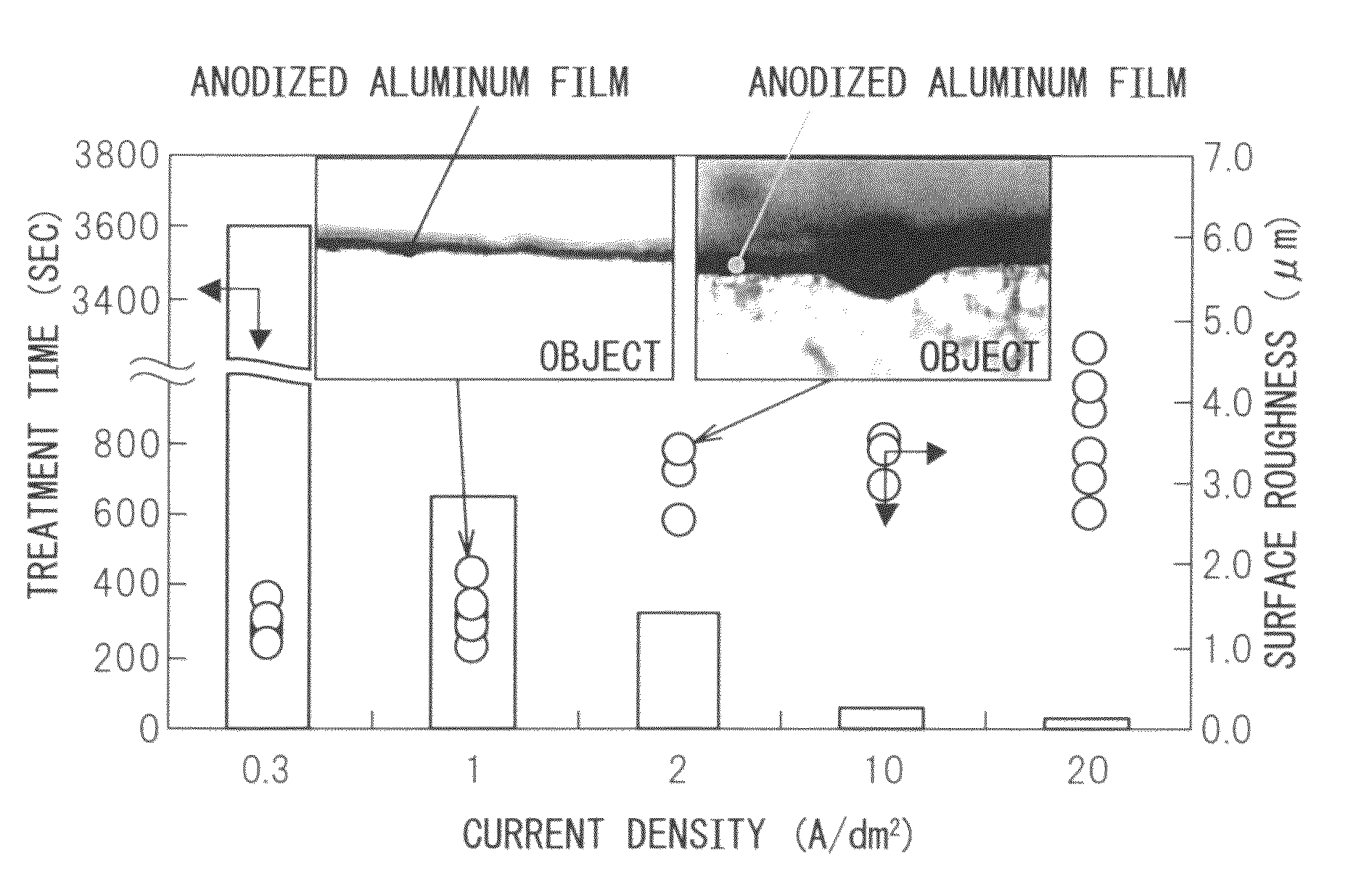

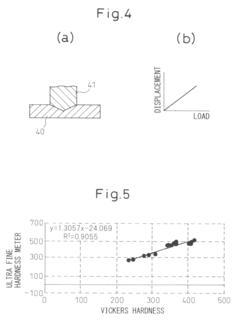

- The method involves using an electrolytic solution with organic acids having two or more carboxylic groups, maintaining a current density between 10 to 170 A/dm², and controlling the flow rate of the electrolytic solution to no more than 15 cm/sec to prevent excessive temperature rise and ensure uniform film formation, thereby reducing anodization time while maintaining desired surface roughness and hardness.

Surface Characterization Techniques for Anodized Aluminum

Surface characterization techniques are essential for understanding the complex relationship between current density and anodized aluminum morphology. Scanning Electron Microscopy (SEM) stands as a primary tool for visualizing the porous structure formed during anodization, allowing researchers to directly observe how varying current densities affect pore diameter, interpore distance, and overall arrangement patterns. The high-resolution imaging capabilities of SEM enable quantitative analysis of these morphological features across different current density conditions.

Atomic Force Microscopy (AFM) complements SEM by providing three-dimensional topographical information with nanometer resolution. This technique is particularly valuable for measuring surface roughness parameters that change with current density variations, offering insights into how current flow influences the nanoscale texture of anodized surfaces. AFM can detect subtle morphological transitions that occur at critical current density thresholds.

X-ray Photoelectron Spectroscopy (XPS) and Energy-Dispersive X-ray Spectroscopy (EDS) provide crucial chemical composition data, revealing how current density affects oxide layer composition and impurity incorporation. These techniques can identify compositional gradients within the anodic film that develop under different current density regimes, explaining certain morphological features observed in microscopy.

Transmission Electron Microscopy (TEM) offers unparalleled resolution for examining the cross-sectional structure of anodic films. By preparing thin sections of anodized aluminum, researchers can visualize how current density influences barrier layer thickness, pore channel straightness, and branching phenomena. TEM analysis has been instrumental in establishing correlations between applied current density and nanoscale structural development.

Electrochemical Impedance Spectroscopy (EIS) provides valuable information about the electrical properties of anodic films formed under different current densities. This non-destructive technique helps researchers understand how current density affects film resistance, capacitance, and overall barrier properties, which directly relate to morphological characteristics.

Advanced 3D characterization methods, including FIB-SEM tomography and X-ray computed tomography, have recently emerged as powerful tools for visualizing the complete three-dimensional architecture of anodic films. These techniques reveal how current density influences not only surface features but also internal pore networking and tortuosity throughout the oxide layer.

Correlative microscopy approaches, combining multiple characterization techniques on the same specimen area, are increasingly being employed to establish direct relationships between current density parameters and resulting morphological features across different length scales.

Atomic Force Microscopy (AFM) complements SEM by providing three-dimensional topographical information with nanometer resolution. This technique is particularly valuable for measuring surface roughness parameters that change with current density variations, offering insights into how current flow influences the nanoscale texture of anodized surfaces. AFM can detect subtle morphological transitions that occur at critical current density thresholds.

X-ray Photoelectron Spectroscopy (XPS) and Energy-Dispersive X-ray Spectroscopy (EDS) provide crucial chemical composition data, revealing how current density affects oxide layer composition and impurity incorporation. These techniques can identify compositional gradients within the anodic film that develop under different current density regimes, explaining certain morphological features observed in microscopy.

Transmission Electron Microscopy (TEM) offers unparalleled resolution for examining the cross-sectional structure of anodic films. By preparing thin sections of anodized aluminum, researchers can visualize how current density influences barrier layer thickness, pore channel straightness, and branching phenomena. TEM analysis has been instrumental in establishing correlations between applied current density and nanoscale structural development.

Electrochemical Impedance Spectroscopy (EIS) provides valuable information about the electrical properties of anodic films formed under different current densities. This non-destructive technique helps researchers understand how current density affects film resistance, capacitance, and overall barrier properties, which directly relate to morphological characteristics.

Advanced 3D characterization methods, including FIB-SEM tomography and X-ray computed tomography, have recently emerged as powerful tools for visualizing the complete three-dimensional architecture of anodic films. These techniques reveal how current density influences not only surface features but also internal pore networking and tortuosity throughout the oxide layer.

Correlative microscopy approaches, combining multiple characterization techniques on the same specimen area, are increasingly being employed to establish direct relationships between current density parameters and resulting morphological features across different length scales.

Environmental Impact of Anodization Processes

The anodization process, while providing significant benefits for aluminum products, carries notable environmental implications that warrant careful consideration. The current density parameter, which critically influences anodized aluminum morphology, directly impacts the environmental footprint of these processes. Higher current densities typically accelerate oxide layer formation but simultaneously increase energy consumption and heat generation, leading to greater carbon emissions when non-renewable energy sources power these operations.

Water usage represents another significant environmental concern in anodization processes. The industry consumes substantial volumes of water for rinsing between process steps and for maintaining electrolyte baths. Current density settings affect the frequency of bath replacements and water requirements, with higher densities often necessitating more frequent maintenance cycles and consequently increasing water consumption.

Chemical waste management presents perhaps the most challenging environmental aspect of anodization. The process utilizes various acids, primarily sulfuric, phosphoric, and chromic acids, which require proper treatment before disposal. Higher current densities can accelerate chemical depletion rates and increase the concentration of aluminum and other metals in waste streams. These spent electrolytes and rinse waters contain dissolved metals and acidic compounds that pose significant environmental hazards if improperly managed.

Particularly concerning is the historical use of hexavalent chromium in certain anodizing processes, a known carcinogen with severe environmental persistence. While regulatory pressure has reduced its application, legacy issues remain in older facilities and products. Current density optimization can minimize the need for such hazardous additives by achieving desired surface properties through alternative means.

Recent technological advancements have focused on developing more environmentally sustainable anodization approaches. Closed-loop water systems, energy-efficient rectifiers that optimize current density application, and recovery systems for metals and acids are becoming industry standards. Additionally, research into alternative electrolytes with lower environmental impact shows promising results, potentially allowing similar morphological control with reduced ecological consequences.

The regulatory landscape continues to evolve, with increasingly stringent standards for wastewater discharge, air emissions, and chemical handling in anodization facilities worldwide. Companies must balance technical requirements for specific aluminum morphologies against growing environmental compliance costs and sustainability expectations from consumers and stakeholders.

Water usage represents another significant environmental concern in anodization processes. The industry consumes substantial volumes of water for rinsing between process steps and for maintaining electrolyte baths. Current density settings affect the frequency of bath replacements and water requirements, with higher densities often necessitating more frequent maintenance cycles and consequently increasing water consumption.

Chemical waste management presents perhaps the most challenging environmental aspect of anodization. The process utilizes various acids, primarily sulfuric, phosphoric, and chromic acids, which require proper treatment before disposal. Higher current densities can accelerate chemical depletion rates and increase the concentration of aluminum and other metals in waste streams. These spent electrolytes and rinse waters contain dissolved metals and acidic compounds that pose significant environmental hazards if improperly managed.

Particularly concerning is the historical use of hexavalent chromium in certain anodizing processes, a known carcinogen with severe environmental persistence. While regulatory pressure has reduced its application, legacy issues remain in older facilities and products. Current density optimization can minimize the need for such hazardous additives by achieving desired surface properties through alternative means.

Recent technological advancements have focused on developing more environmentally sustainable anodization approaches. Closed-loop water systems, energy-efficient rectifiers that optimize current density application, and recovery systems for metals and acids are becoming industry standards. Additionally, research into alternative electrolytes with lower environmental impact shows promising results, potentially allowing similar morphological control with reduced ecological consequences.

The regulatory landscape continues to evolve, with increasingly stringent standards for wastewater discharge, air emissions, and chemical handling in anodization facilities worldwide. Companies must balance technical requirements for specific aluminum morphologies against growing environmental compliance costs and sustainability expectations from consumers and stakeholders.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!