Anodized aluminum with nanostructured sealing layers

OCT 11, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Anodized Aluminum Nanostructured Sealing Technology Background

Anodized aluminum has been widely utilized across various industries for decades due to its excellent corrosion resistance, enhanced surface hardness, and aesthetic appeal. The anodization process, discovered in the early 20th century, involves an electrochemical procedure that converts the aluminum surface into a durable, porous aluminum oxide layer. This porous structure, while providing initial protection, requires sealing to achieve optimal performance characteristics.

Traditional sealing methods developed in the mid-20th century primarily involved hot water or steam treatments, which formed hydrated aluminum oxide (boehmite) to close the pores. As industrial demands evolved, nickel acetate and sodium dichromate sealing techniques emerged in the 1960s and 1970s, offering improved corrosion resistance but introducing environmental concerns due to heavy metal content.

The technological evolution of sealing processes has been driven by increasingly stringent performance requirements across aerospace, architectural, automotive, and consumer electronics sectors. Each industry demands specific surface properties, including wear resistance, electrical insulation, and decorative finishes, pushing research toward more sophisticated sealing solutions.

Nanostructured sealing represents the cutting edge of this technological progression. Beginning in the early 2000s, researchers started exploring nanoscale materials and processes to enhance the sealing efficiency of anodized aluminum. This approach aims to address the limitations of conventional sealing methods, including incomplete pore closure, surface degradation under extreme conditions, and environmental impact.

The fundamental goal of nanostructured sealing technology is to create a more robust barrier against environmental factors while maintaining or improving the beneficial properties of anodized aluminum. This involves the precise control of nanoscale structures within the pores of the anodic oxide layer, creating a more complete and resilient seal.

Recent technological trends indicate a shift toward multi-functional nanostructured sealing layers that not only provide superior corrosion protection but also impart additional properties such as self-cleaning capabilities, antimicrobial activity, and enhanced thermal stability. These advancements align with broader industry trends toward sustainable manufacturing processes and multifunctional materials.

The development trajectory suggests that future nanostructured sealing technologies will likely focus on environmentally friendly formulations, reduced energy consumption during application, and enhanced durability under extreme conditions. The integration of smart materials that can respond to environmental changes represents another promising direction in this evolving technological landscape.

Traditional sealing methods developed in the mid-20th century primarily involved hot water or steam treatments, which formed hydrated aluminum oxide (boehmite) to close the pores. As industrial demands evolved, nickel acetate and sodium dichromate sealing techniques emerged in the 1960s and 1970s, offering improved corrosion resistance but introducing environmental concerns due to heavy metal content.

The technological evolution of sealing processes has been driven by increasingly stringent performance requirements across aerospace, architectural, automotive, and consumer electronics sectors. Each industry demands specific surface properties, including wear resistance, electrical insulation, and decorative finishes, pushing research toward more sophisticated sealing solutions.

Nanostructured sealing represents the cutting edge of this technological progression. Beginning in the early 2000s, researchers started exploring nanoscale materials and processes to enhance the sealing efficiency of anodized aluminum. This approach aims to address the limitations of conventional sealing methods, including incomplete pore closure, surface degradation under extreme conditions, and environmental impact.

The fundamental goal of nanostructured sealing technology is to create a more robust barrier against environmental factors while maintaining or improving the beneficial properties of anodized aluminum. This involves the precise control of nanoscale structures within the pores of the anodic oxide layer, creating a more complete and resilient seal.

Recent technological trends indicate a shift toward multi-functional nanostructured sealing layers that not only provide superior corrosion protection but also impart additional properties such as self-cleaning capabilities, antimicrobial activity, and enhanced thermal stability. These advancements align with broader industry trends toward sustainable manufacturing processes and multifunctional materials.

The development trajectory suggests that future nanostructured sealing technologies will likely focus on environmentally friendly formulations, reduced energy consumption during application, and enhanced durability under extreme conditions. The integration of smart materials that can respond to environmental changes represents another promising direction in this evolving technological landscape.

Market Applications and Demand Analysis

The global market for anodized aluminum with nanostructured sealing layers has been experiencing significant growth, driven by increasing demand across multiple industries seeking enhanced material performance. The automotive sector represents one of the largest application areas, where these advanced materials offer superior corrosion resistance and aesthetic durability for exterior components, contributing to longer vehicle lifespans and reduced maintenance costs. Market research indicates that automotive manufacturers are increasingly specifying these materials to meet consumer expectations for quality and appearance retention.

Aerospace applications constitute another critical market segment, where the exceptional wear resistance and weight-to-performance ratio of nanostructured sealed anodized aluminum provides crucial advantages. The ability to withstand extreme environmental conditions while maintaining structural integrity makes these materials particularly valuable for aircraft components exposed to varying altitudes, temperatures, and atmospheric conditions.

The architectural and construction industry demonstrates growing adoption rates, particularly in high-end commercial and institutional buildings where facade longevity and reduced maintenance intervals translate to substantial lifecycle cost benefits. The enhanced color stability and resistance to environmental degradation have positioned these materials as premium solutions for exterior applications in challenging environments.

Consumer electronics manufacturers have embraced nanostructured sealed anodized aluminum for premium device enclosures, where tactile quality, scratch resistance, and visual appeal directly influence consumer purchasing decisions. The material's ability to maintain appearance through years of handling provides manufacturers with a competitive advantage in the high-end device market.

Marine applications represent an emerging growth sector, where the superior salt water corrosion resistance of these materials addresses a persistent industry challenge. Boat hardware, structural components, and decorative elements benefit from extended service life even under constant exposure to highly corrosive environments.

Market analysis reveals that regional demand patterns vary significantly, with North America and Europe currently leading adoption rates due to stricter environmental regulations and higher consumer willingness to pay for premium materials. However, the Asia-Pacific region is projected to demonstrate the fastest growth rate as manufacturing sophistication increases and environmental standards become more stringent.

The overall market trajectory indicates a shift from price-sensitive purchasing toward value-based decision-making, where the total cost of ownership increasingly favors these advanced materials despite higher initial investment. This trend is reinforced by growing sustainability concerns, as the extended service life and reduced replacement frequency align with circular economy principles and waste reduction initiatives.

Aerospace applications constitute another critical market segment, where the exceptional wear resistance and weight-to-performance ratio of nanostructured sealed anodized aluminum provides crucial advantages. The ability to withstand extreme environmental conditions while maintaining structural integrity makes these materials particularly valuable for aircraft components exposed to varying altitudes, temperatures, and atmospheric conditions.

The architectural and construction industry demonstrates growing adoption rates, particularly in high-end commercial and institutional buildings where facade longevity and reduced maintenance intervals translate to substantial lifecycle cost benefits. The enhanced color stability and resistance to environmental degradation have positioned these materials as premium solutions for exterior applications in challenging environments.

Consumer electronics manufacturers have embraced nanostructured sealed anodized aluminum for premium device enclosures, where tactile quality, scratch resistance, and visual appeal directly influence consumer purchasing decisions. The material's ability to maintain appearance through years of handling provides manufacturers with a competitive advantage in the high-end device market.

Marine applications represent an emerging growth sector, where the superior salt water corrosion resistance of these materials addresses a persistent industry challenge. Boat hardware, structural components, and decorative elements benefit from extended service life even under constant exposure to highly corrosive environments.

Market analysis reveals that regional demand patterns vary significantly, with North America and Europe currently leading adoption rates due to stricter environmental regulations and higher consumer willingness to pay for premium materials. However, the Asia-Pacific region is projected to demonstrate the fastest growth rate as manufacturing sophistication increases and environmental standards become more stringent.

The overall market trajectory indicates a shift from price-sensitive purchasing toward value-based decision-making, where the total cost of ownership increasingly favors these advanced materials despite higher initial investment. This trend is reinforced by growing sustainability concerns, as the extended service life and reduced replacement frequency align with circular economy principles and waste reduction initiatives.

Current Challenges in Aluminum Surface Treatment

Despite significant advancements in aluminum surface treatment technologies, several persistent challenges continue to impede optimal performance and durability of anodized aluminum products. The conventional sealing methods, including hot water, nickel acetate, and sodium dichromate sealing, often fail to provide comprehensive protection against aggressive environmental conditions, particularly in marine and industrial settings where exposure to corrosive elements is severe.

A primary challenge lies in achieving uniform sealing across complex geometries and varying surface topographies. Current industrial processes struggle to maintain consistent sealing quality on components with intricate designs, leading to localized weaknesses that become failure initiation points. This non-uniformity issue becomes particularly pronounced when dealing with large-scale architectural applications or precision components for aerospace and automotive industries.

The environmental impact of traditional sealing processes represents another significant concern. Many conventional sealing methods utilize hexavalent chromium compounds and other environmentally hazardous substances that face increasing regulatory restrictions worldwide. The industry is under mounting pressure to develop eco-friendly alternatives without compromising performance characteristics, creating a technical dilemma that requires innovative solutions.

Durability under extreme conditions remains problematic, with current sealing technologies showing limitations in withstanding thermal cycling, UV exposure, and chemical attack simultaneously. The multi-factorial degradation mechanisms often lead to premature failure of sealed surfaces, particularly in applications where anodized aluminum is exposed to fluctuating environmental conditions over extended periods.

The microscale and nanoscale control of pore sealing presents technical difficulties that conventional methods cannot adequately address. The inherent variability in pore size, depth, and distribution across anodized surfaces creates inconsistencies in sealing effectiveness. Current technologies lack the precision to selectively target and completely seal pores of varying dimensions, leaving partially sealed structures vulnerable to environmental ingress.

Energy consumption during the sealing process constitutes another challenge, with traditional hot sealing methods requiring significant thermal energy input, contributing to high operational costs and carbon footprint. The industry seeks more energy-efficient alternatives that can deliver equivalent or superior sealing performance while reducing resource consumption.

The integration of multifunctional properties into sealed surfaces represents an emerging challenge. Modern applications increasingly demand anodized surfaces that not only resist corrosion but also provide additional functionalities such as antimicrobial properties, self-cleaning capabilities, enhanced wear resistance, or electrical conductivity—requirements that conventional sealing approaches cannot satisfy simultaneously.

A primary challenge lies in achieving uniform sealing across complex geometries and varying surface topographies. Current industrial processes struggle to maintain consistent sealing quality on components with intricate designs, leading to localized weaknesses that become failure initiation points. This non-uniformity issue becomes particularly pronounced when dealing with large-scale architectural applications or precision components for aerospace and automotive industries.

The environmental impact of traditional sealing processes represents another significant concern. Many conventional sealing methods utilize hexavalent chromium compounds and other environmentally hazardous substances that face increasing regulatory restrictions worldwide. The industry is under mounting pressure to develop eco-friendly alternatives without compromising performance characteristics, creating a technical dilemma that requires innovative solutions.

Durability under extreme conditions remains problematic, with current sealing technologies showing limitations in withstanding thermal cycling, UV exposure, and chemical attack simultaneously. The multi-factorial degradation mechanisms often lead to premature failure of sealed surfaces, particularly in applications where anodized aluminum is exposed to fluctuating environmental conditions over extended periods.

The microscale and nanoscale control of pore sealing presents technical difficulties that conventional methods cannot adequately address. The inherent variability in pore size, depth, and distribution across anodized surfaces creates inconsistencies in sealing effectiveness. Current technologies lack the precision to selectively target and completely seal pores of varying dimensions, leaving partially sealed structures vulnerable to environmental ingress.

Energy consumption during the sealing process constitutes another challenge, with traditional hot sealing methods requiring significant thermal energy input, contributing to high operational costs and carbon footprint. The industry seeks more energy-efficient alternatives that can deliver equivalent or superior sealing performance while reducing resource consumption.

The integration of multifunctional properties into sealed surfaces represents an emerging challenge. Modern applications increasingly demand anodized surfaces that not only resist corrosion but also provide additional functionalities such as antimicrobial properties, self-cleaning capabilities, enhanced wear resistance, or electrical conductivity—requirements that conventional sealing approaches cannot satisfy simultaneously.

Current Nanostructured Sealing Solutions

01 Nanostructured sealing methods for anodized aluminum

Various methods can be used to create nanostructured sealing layers on anodized aluminum surfaces. These methods include sol-gel processes, hydrothermal treatments, and chemical vapor deposition techniques that form nanoscale structures within the pores of anodized aluminum. The nanostructured sealing enhances corrosion resistance, wear resistance, and overall durability of the anodized layer by effectively closing the pores with nanomaterials that form a protective barrier.- Nanostructured sealing methods for anodized aluminum: Various methods can be employed to create nanostructured sealing layers on anodized aluminum surfaces. These methods include sol-gel processes, hydrothermal treatments, and chemical vapor deposition techniques that form nanoscale structures within the pores of anodized aluminum. The nanostructured sealing enhances corrosion resistance, wear resistance, and overall durability of the anodized layer by effectively closing the pores with nanomaterials that bond chemically with the aluminum oxide surface.

- Metal oxide nanoparticles for sealing anodized aluminum: Metal oxide nanoparticles, such as titanium dioxide, zinc oxide, and silicon dioxide, can be incorporated into sealing solutions for anodized aluminum. These nanoparticles penetrate the porous structure of the anodized layer and form a dense, protective nanostructured sealing layer. The metal oxide nanoparticles enhance the mechanical properties, corrosion resistance, and UV stability of the sealed anodized aluminum surface, making it suitable for various industrial applications.

- Self-assembled nanostructured sealing layers: Self-assembly techniques can be used to create ordered nanostructured sealing layers on anodized aluminum. These methods involve the controlled deposition of molecules or nanoparticles that spontaneously organize into well-defined structures. The self-assembled nanostructured sealing layers provide enhanced barrier properties, improved aesthetic appearance, and can incorporate functional properties such as hydrophobicity, optical effects, or antimicrobial activity while maintaining the integrity of the anodized layer.

- Polymer-based nanocomposite sealing for anodized aluminum: Polymer-based nanocomposite materials can be used to create effective sealing layers for anodized aluminum. These nanocomposites typically consist of polymer matrices embedded with nanoscale fillers such as clay, carbon nanotubes, or graphene. When applied to anodized aluminum, these materials penetrate the porous structure and form a flexible yet durable sealing layer that provides excellent chemical resistance, thermal stability, and mechanical protection while maintaining the lightweight properties of aluminum.

- Environmentally friendly nanostructured sealing technologies: Environmentally friendly approaches to creating nanostructured sealing layers for anodized aluminum focus on eliminating toxic chemicals and reducing energy consumption. These methods include water-based sealing solutions containing biodegradable nanoparticles, low-temperature sealing processes, and the use of naturally derived compounds. These green technologies provide effective sealing of anodized aluminum while minimizing environmental impact and meeting increasingly stringent regulatory requirements for industrial processes.

02 Metal oxide nanoparticles for sealing anodized aluminum

Metal oxide nanoparticles, such as titanium dioxide, zinc oxide, and aluminum oxide, can be incorporated into sealing solutions to create nanostructured sealing layers on anodized aluminum. These nanoparticles penetrate the pores of the anodized layer and form a dense, protective barrier that enhances corrosion resistance and mechanical properties. The nanoparticle-based sealing can also provide additional functionalities such as photocatalytic properties or enhanced thermal stability.Expand Specific Solutions03 Polymer-based nanocomposite sealing layers

Polymer-based nanocomposite materials can be used to create effective sealing layers on anodized aluminum surfaces. These composites typically consist of polymeric materials embedded with nanoparticles or nanostructures that enhance the barrier properties of the sealing layer. The polymer matrix provides flexibility and adhesion, while the nanostructures improve mechanical strength, chemical resistance, and durability. These nanocomposite sealing layers can be applied through various methods including dip-coating, spray coating, or electrodeposition.Expand Specific Solutions04 Self-healing nanostructured sealing layers

Advanced self-healing nanostructured sealing layers can be developed for anodized aluminum surfaces. These innovative sealing systems incorporate nanocontainers or nanocapsules filled with healing agents that are released when the sealing layer is damaged. The self-healing mechanism helps to maintain the integrity of the protective barrier over time, extending the service life of the anodized aluminum components. These systems may also include stimuli-responsive materials that can react to environmental changes such as pH, temperature, or mechanical stress.Expand Specific Solutions05 Functional nanostructured sealing layers for enhanced properties

Functional nanostructured sealing layers can be engineered to provide additional properties beyond basic protection. These specialized sealing layers can incorporate nanomaterials that impart properties such as hydrophobicity, optical effects, electrical conductivity, or antimicrobial activity. For example, incorporating silica nanoparticles can create superhydrophobic surfaces, while silver nanoparticles can provide antimicrobial properties. These functional sealing layers expand the application range of anodized aluminum in various industries including electronics, architecture, and medical devices.Expand Specific Solutions

Leading Companies and Research Institutions

The anodized aluminum with nanostructured sealing layers market is in a growth phase, driven by increasing demand for corrosion-resistant materials across aerospace, automotive, and electronics industries. The global market size is estimated to exceed $5 billion, with projected annual growth of 6-8%. Technologically, the field shows moderate maturity with ongoing innovation. Leading players include Henkel AG, demonstrating advanced sealing technologies; Canon and FUJIFILM developing proprietary coating processes; and RTX Corp. focusing on aerospace applications. Academic institutions like Fudan University and University of Notre Dame are advancing fundamental research, while specialized companies such as InRedox LLC are pioneering nanostructured solutions. The competitive landscape features both established industrial giants and emerging specialized technology providers.

Henkel AG & Co. KGaA

Technical Solution: Henkel has pioneered advanced sealing technologies for anodized aluminum through their BONDERITE® product line. Their approach involves a two-step process: first, creating a controlled nanoporous anodic layer, then applying proprietary nanostructured sealants containing silicate/polymer hybrid nanoparticles. These nanoparticles (20-50 nm) penetrate the porous structure and form chemical bonds with the aluminum oxide substrate. The technology employs room-temperature sealing processes that reduce energy consumption by up to 30% compared to traditional hot water sealing methods. Henkel's research has demonstrated that their nanostructured sealing layers provide superior corrosion protection (>1000 hours in salt spray testing) while maintaining the aesthetic qualities of the anodized surface. The company has also developed environmentally friendly formulations that eliminate heavy metals and reduce water consumption in the sealing process.

Strengths: Energy-efficient room-temperature sealing process; excellent corrosion resistance; environmentally friendly formulations without heavy metals; compatible with existing anodizing lines. Weaknesses: May require specific pre-treatment processes; performance might vary depending on the initial anodizing quality; potentially higher material costs than conventional sealants.

Consejo Superior de Investigaciones Científicas

Technical Solution: The Consejo Superior de Investigaciones Científicas (CSIC) has developed innovative nanostructured sealing technologies for anodized aluminum through their Institute of Materials Science. Their research focuses on sol-gel derived nanocomposite sealing layers incorporating cerium oxide nanoparticles (5-20 nm) and functionalized silica. The process involves controlled hydrolysis and condensation reactions to form a dense network of Si-O-Al bonds within the anodic pores. CSIC researchers have demonstrated that these nanostructured sealing layers provide exceptional barrier properties, with electrochemical impedance spectroscopy showing impedance values exceeding 10^9 Ω·cm² after prolonged exposure to corrosive environments. The technology also enables the incorporation of self-healing capabilities through the controlled release of corrosion inhibitors from nanocontainers embedded in the sealing matrix. This approach has shown particular promise for aerospace and architectural applications where long-term durability under extreme conditions is required.

Strengths: Exceptional barrier properties with high impedance values; self-healing capabilities through controlled release of corrosion inhibitors; strong chemical bonding with the anodic substrate. Weaknesses: Complex multi-step synthesis process; may require specialized equipment and expertise; potential scalability challenges for industrial implementation.

Key Patents and Innovations in Nano-Sealing Technology

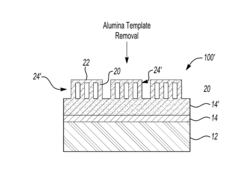

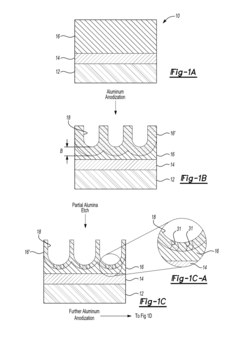

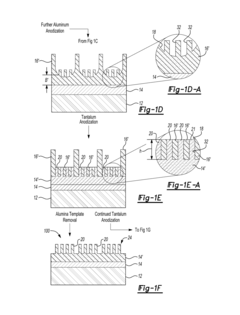

Nano-structure and method of making the same

PatentInactiveUS20170159194A1

Innovation

- The development of super nano-pillars formed by splitting larger nano-pillars into smaller clusters, which are amorphous oxide and share the same material as the underlying support, allowing them to bend rather than break under mechanical pressure, and increasing the active surface area and mechanical flexibility.

Environmental Impact and Sustainability Considerations

The environmental impact of anodized aluminum with nanostructured sealing layers represents a critical consideration in the broader adoption of this technology. Traditional anodizing processes typically involve heavy metal compounds and generate significant wastewater containing chromium, nickel, and other potentially harmful substances. In contrast, nanostructured sealing technologies offer promising alternatives that can substantially reduce environmental footprint while maintaining or enhancing performance characteristics.

Water consumption represents one of the most significant environmental concerns in conventional anodizing operations. The implementation of nanostructured sealing layers has demonstrated potential for reducing water usage by 30-45% compared to traditional hot water or dichromate sealing methods. This reduction stems from more efficient sealing mechanisms that require fewer rinse cycles and shorter processing times, contributing to overall resource conservation.

Energy efficiency constitutes another important sustainability advantage of nanostructured sealing technologies. Conventional sealing processes often require elevated temperatures (90-100°C) maintained for extended periods, whereas many nano-sealing approaches can operate at lower temperatures (40-60°C) or even at ambient conditions. Research indicates potential energy savings of 25-60% depending on the specific nanostructured sealing system employed.

Chemical waste reduction represents perhaps the most significant environmental benefit. Nanostructured sealing layers typically utilize benign materials such as silica, titanium dioxide, or organic polymers rather than hexavalent chromium or nickel acetate. Studies have documented 50-80% reductions in hazardous waste generation when implementing these advanced sealing technologies, substantially decreasing the environmental burden associated with waste treatment and disposal.

Life cycle assessment (LCA) studies comparing conventional and nanostructured sealing technologies have consistently demonstrated favorable environmental profiles for the latter. Carbon footprint reductions of 15-40% have been documented, primarily due to lower energy requirements and reduced chemical inputs. Additionally, the enhanced corrosion resistance provided by nanostructured sealing layers extends product lifespans, further improving sustainability metrics through reduced replacement frequency.

Regulatory compliance represents an increasingly important driver for adoption of nanostructured sealing technologies. With stricter environmental regulations worldwide, particularly regarding hexavalent chromium and other hazardous substances, these advanced sealing approaches offer manufacturers a pathway to meet or exceed compliance requirements while maintaining product performance. This regulatory alignment positions nanostructured sealing as a forward-looking technology with significant potential for sustainable industrial implementation.

Water consumption represents one of the most significant environmental concerns in conventional anodizing operations. The implementation of nanostructured sealing layers has demonstrated potential for reducing water usage by 30-45% compared to traditional hot water or dichromate sealing methods. This reduction stems from more efficient sealing mechanisms that require fewer rinse cycles and shorter processing times, contributing to overall resource conservation.

Energy efficiency constitutes another important sustainability advantage of nanostructured sealing technologies. Conventional sealing processes often require elevated temperatures (90-100°C) maintained for extended periods, whereas many nano-sealing approaches can operate at lower temperatures (40-60°C) or even at ambient conditions. Research indicates potential energy savings of 25-60% depending on the specific nanostructured sealing system employed.

Chemical waste reduction represents perhaps the most significant environmental benefit. Nanostructured sealing layers typically utilize benign materials such as silica, titanium dioxide, or organic polymers rather than hexavalent chromium or nickel acetate. Studies have documented 50-80% reductions in hazardous waste generation when implementing these advanced sealing technologies, substantially decreasing the environmental burden associated with waste treatment and disposal.

Life cycle assessment (LCA) studies comparing conventional and nanostructured sealing technologies have consistently demonstrated favorable environmental profiles for the latter. Carbon footprint reductions of 15-40% have been documented, primarily due to lower energy requirements and reduced chemical inputs. Additionally, the enhanced corrosion resistance provided by nanostructured sealing layers extends product lifespans, further improving sustainability metrics through reduced replacement frequency.

Regulatory compliance represents an increasingly important driver for adoption of nanostructured sealing technologies. With stricter environmental regulations worldwide, particularly regarding hexavalent chromium and other hazardous substances, these advanced sealing approaches offer manufacturers a pathway to meet or exceed compliance requirements while maintaining product performance. This regulatory alignment positions nanostructured sealing as a forward-looking technology with significant potential for sustainable industrial implementation.

Performance Testing and Quality Standards

Performance testing and quality standards for anodized aluminum with nanostructured sealing layers require comprehensive evaluation protocols to ensure consistent product performance. The industry has established several standardized testing methods to assess the durability, corrosion resistance, and overall quality of these advanced materials.

The American Society for Testing and Materials (ASTM) and International Organization for Standardization (ISO) have developed specific standards for anodized aluminum, including ASTM B117 for salt spray testing and ISO 9227 for corrosion tests. These standards have been adapted to address the unique properties of nanostructured sealing layers, with particular emphasis on evaluating the integrity of the nano-scale structures after exposure to various environmental conditions.

Accelerated weathering tests, such as those outlined in ASTM G154 and ISO 16474, provide valuable data on the long-term performance of nanostructured seals under UV exposure, temperature fluctuations, and moisture cycles. These tests typically run for 1,000 to 5,000 hours, simulating years of environmental exposure in controlled laboratory conditions.

Mechanical performance testing includes adhesion tests (ASTM D3359), hardness measurements (ISO 6272), and abrasion resistance evaluations (ASTM D4060). For nanostructured sealing layers, specialized nano-indentation techniques have been developed to assess the mechanical properties at the nanoscale, providing insights into the material's resistance to wear and physical damage.

Electrochemical impedance spectroscopy (EIS) has emerged as a critical analytical tool for evaluating the corrosion protection capabilities of nanostructured seals. This non-destructive technique measures the electrical impedance of the coating system at different frequencies, allowing researchers to quantify the barrier properties and predict long-term performance without extended exposure testing.

Quality control protocols for production environments typically include thickness measurements (ASTM B244), seal quality tests (ISO 3210), and color consistency evaluations (ASTM D2244). Advanced imaging techniques such as scanning electron microscopy (SEM) and atomic force microscopy (AFM) are employed for detailed characterization of the nanostructured sealing layers, though these are generally limited to research and development settings rather than routine quality control.

Recent developments in quality standards include the introduction of sustainability metrics, evaluating the environmental impact of nanostructured sealing processes. These standards assess factors such as energy consumption, water usage, and the potential release of nanomaterials during the product lifecycle, reflecting growing industry concerns about environmental responsibility and regulatory compliance.

The American Society for Testing and Materials (ASTM) and International Organization for Standardization (ISO) have developed specific standards for anodized aluminum, including ASTM B117 for salt spray testing and ISO 9227 for corrosion tests. These standards have been adapted to address the unique properties of nanostructured sealing layers, with particular emphasis on evaluating the integrity of the nano-scale structures after exposure to various environmental conditions.

Accelerated weathering tests, such as those outlined in ASTM G154 and ISO 16474, provide valuable data on the long-term performance of nanostructured seals under UV exposure, temperature fluctuations, and moisture cycles. These tests typically run for 1,000 to 5,000 hours, simulating years of environmental exposure in controlled laboratory conditions.

Mechanical performance testing includes adhesion tests (ASTM D3359), hardness measurements (ISO 6272), and abrasion resistance evaluations (ASTM D4060). For nanostructured sealing layers, specialized nano-indentation techniques have been developed to assess the mechanical properties at the nanoscale, providing insights into the material's resistance to wear and physical damage.

Electrochemical impedance spectroscopy (EIS) has emerged as a critical analytical tool for evaluating the corrosion protection capabilities of nanostructured seals. This non-destructive technique measures the electrical impedance of the coating system at different frequencies, allowing researchers to quantify the barrier properties and predict long-term performance without extended exposure testing.

Quality control protocols for production environments typically include thickness measurements (ASTM B244), seal quality tests (ISO 3210), and color consistency evaluations (ASTM D2244). Advanced imaging techniques such as scanning electron microscopy (SEM) and atomic force microscopy (AFM) are employed for detailed characterization of the nanostructured sealing layers, though these are generally limited to research and development settings rather than routine quality control.

Recent developments in quality standards include the introduction of sustainability metrics, evaluating the environmental impact of nanostructured sealing processes. These standards assess factors such as energy consumption, water usage, and the potential release of nanomaterials during the product lifecycle, reflecting growing industry concerns about environmental responsibility and regulatory compliance.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!