How Metal Injection Molding Controls Carbon/Oxygen To Meet Mechanical Targets?

SEP 16, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

MIM Technology Background and Objectives

Metal Injection Molding (MIM) emerged in the 1970s as a revolutionary manufacturing process combining the design flexibility of plastic injection molding with the superior material properties of powder metallurgy. This technology has evolved significantly over the past five decades, transitioning from experimental applications to a mainstream manufacturing method for complex metal components across various industries including automotive, medical, aerospace, and consumer electronics.

The fundamental principle of MIM involves mixing fine metal powders with polymer binders to create a feedstock that can be injected into molds using conventional injection molding equipment. Following the molding process, the binder is removed through thermal or chemical processes, and the resulting "brown part" undergoes sintering at high temperatures to achieve final densification and desired mechanical properties.

A critical aspect of MIM technology development has been the progressive understanding and control of interstitial elements, particularly carbon and oxygen. These elements significantly influence the microstructure and mechanical properties of MIM components. Historically, early MIM processes struggled with inconsistent carbon and oxygen levels, resulting in unpredictable mechanical performance and limiting widespread industrial adoption.

The technological evolution trajectory shows a clear trend toward more precise control of the entire MIM process chain, with particular emphasis on feedstock formulation, debinding parameters, and sintering profiles. Recent advancements in analytical techniques and process monitoring have enabled real-time adjustment of processing parameters to maintain optimal carbon and oxygen concentrations throughout manufacturing.

The primary technical objective in modern MIM processing is achieving precise control over carbon and oxygen content to consistently meet specific mechanical property targets. This includes developing robust processes that can accommodate variations in raw materials while still delivering components with predictable strength, ductility, hardness, and fatigue resistance properties.

Secondary objectives include reducing cycle times, minimizing post-processing requirements, expanding the range of compatible alloys, and scaling production capabilities while maintaining quality. The industry is increasingly focused on developing closed-loop control systems that can automatically adjust processing parameters based on real-time measurements of carbon and oxygen levels.

The significance of carbon and oxygen control extends beyond mechanical properties to include dimensional stability, surface finish, and overall part quality. As MIM technology continues to mature, the emphasis has shifted from simply achieving basic functionality to optimizing performance characteristics for specific applications, with carbon and oxygen management being central to this precision engineering approach.

The fundamental principle of MIM involves mixing fine metal powders with polymer binders to create a feedstock that can be injected into molds using conventional injection molding equipment. Following the molding process, the binder is removed through thermal or chemical processes, and the resulting "brown part" undergoes sintering at high temperatures to achieve final densification and desired mechanical properties.

A critical aspect of MIM technology development has been the progressive understanding and control of interstitial elements, particularly carbon and oxygen. These elements significantly influence the microstructure and mechanical properties of MIM components. Historically, early MIM processes struggled with inconsistent carbon and oxygen levels, resulting in unpredictable mechanical performance and limiting widespread industrial adoption.

The technological evolution trajectory shows a clear trend toward more precise control of the entire MIM process chain, with particular emphasis on feedstock formulation, debinding parameters, and sintering profiles. Recent advancements in analytical techniques and process monitoring have enabled real-time adjustment of processing parameters to maintain optimal carbon and oxygen concentrations throughout manufacturing.

The primary technical objective in modern MIM processing is achieving precise control over carbon and oxygen content to consistently meet specific mechanical property targets. This includes developing robust processes that can accommodate variations in raw materials while still delivering components with predictable strength, ductility, hardness, and fatigue resistance properties.

Secondary objectives include reducing cycle times, minimizing post-processing requirements, expanding the range of compatible alloys, and scaling production capabilities while maintaining quality. The industry is increasingly focused on developing closed-loop control systems that can automatically adjust processing parameters based on real-time measurements of carbon and oxygen levels.

The significance of carbon and oxygen control extends beyond mechanical properties to include dimensional stability, surface finish, and overall part quality. As MIM technology continues to mature, the emphasis has shifted from simply achieving basic functionality to optimizing performance characteristics for specific applications, with carbon and oxygen management being central to this precision engineering approach.

Market Demand Analysis for MIM Components

The global Metal Injection Molding (MIM) components market has been experiencing robust growth, driven primarily by increasing demand across automotive, aerospace, medical, and consumer electronics sectors. The market was valued at approximately $2.7 billion in 2022 and is projected to reach $4.5 billion by 2028, representing a compound annual growth rate (CAGR) of 8.9% during the forecast period.

The automotive industry remains the largest consumer of MIM components, accounting for nearly 35% of the total market share. This dominance is attributed to the growing need for lightweight, high-strength parts that can withstand extreme operating conditions while maintaining precise carbon and oxygen levels for optimal mechanical performance. As vehicle manufacturers continue to focus on fuel efficiency and emissions reduction, the demand for complex MIM components with controlled carbon-oxygen ratios is expected to surge.

Medical and healthcare applications represent the fastest-growing segment for MIM components, with a projected CAGR of 11.2% through 2028. The sector's demand is primarily driven by the need for biocompatible materials with specific mechanical properties that can only be achieved through precise carbon and oxygen control during the MIM process. Surgical instruments, orthopedic implants, and dental applications are particularly significant growth areas.

Consumer electronics manufacturers are increasingly adopting MIM technology for producing intricate components with excellent mechanical properties. The miniaturization trend in electronics has created substantial demand for small, complex metal parts with tight tolerances and specific strength-to-weight ratios that depend heavily on carbon-oxygen content management.

Regional analysis indicates that Asia-Pacific dominates the MIM components market, accounting for approximately 45% of global demand, with China, Japan, and South Korea being the major contributors. North America and Europe follow with market shares of 28% and 22% respectively, where advanced applications requiring precise carbon-oxygen control for enhanced mechanical properties are particularly prevalent.

Industry surveys reveal that end-users are increasingly prioritizing MIM suppliers who can demonstrate consistent carbon and oxygen control capabilities, as these directly impact mechanical properties such as tensile strength, hardness, and fatigue resistance. Nearly 78% of procurement managers in high-performance industries cite material property consistency as a critical selection factor for MIM component suppliers.

The market is also witnessing a shift toward customized MIM solutions with tailored carbon-oxygen specifications to meet specific mechanical targets for specialized applications. This trend is expected to create new market opportunities for MIM providers with advanced material science capabilities and precise process control technologies.

The automotive industry remains the largest consumer of MIM components, accounting for nearly 35% of the total market share. This dominance is attributed to the growing need for lightweight, high-strength parts that can withstand extreme operating conditions while maintaining precise carbon and oxygen levels for optimal mechanical performance. As vehicle manufacturers continue to focus on fuel efficiency and emissions reduction, the demand for complex MIM components with controlled carbon-oxygen ratios is expected to surge.

Medical and healthcare applications represent the fastest-growing segment for MIM components, with a projected CAGR of 11.2% through 2028. The sector's demand is primarily driven by the need for biocompatible materials with specific mechanical properties that can only be achieved through precise carbon and oxygen control during the MIM process. Surgical instruments, orthopedic implants, and dental applications are particularly significant growth areas.

Consumer electronics manufacturers are increasingly adopting MIM technology for producing intricate components with excellent mechanical properties. The miniaturization trend in electronics has created substantial demand for small, complex metal parts with tight tolerances and specific strength-to-weight ratios that depend heavily on carbon-oxygen content management.

Regional analysis indicates that Asia-Pacific dominates the MIM components market, accounting for approximately 45% of global demand, with China, Japan, and South Korea being the major contributors. North America and Europe follow with market shares of 28% and 22% respectively, where advanced applications requiring precise carbon-oxygen control for enhanced mechanical properties are particularly prevalent.

Industry surveys reveal that end-users are increasingly prioritizing MIM suppliers who can demonstrate consistent carbon and oxygen control capabilities, as these directly impact mechanical properties such as tensile strength, hardness, and fatigue resistance. Nearly 78% of procurement managers in high-performance industries cite material property consistency as a critical selection factor for MIM component suppliers.

The market is also witnessing a shift toward customized MIM solutions with tailored carbon-oxygen specifications to meet specific mechanical targets for specialized applications. This trend is expected to create new market opportunities for MIM providers with advanced material science capabilities and precise process control technologies.

Current C/O Control Challenges in MIM

Metal Injection Molding (MIM) processes face significant challenges in controlling carbon and oxygen levels, which directly impact the mechanical properties of final components. The primary challenge lies in the complex interplay between carbon and oxygen during the debinding and sintering stages. During debinding, residual carbon from binder materials can remain trapped within the metal matrix, while oxygen contamination can occur through exposure to atmospheric conditions or from oxide layers on powder surfaces.

The precise control of carbon content presents a particular difficulty as it must be maintained within extremely narrow specifications—often between 0.1% and 0.8% depending on the alloy system. Deviations as small as 0.05% can dramatically alter mechanical properties, especially in high-performance applications where strength, hardness, and ductility requirements are stringent. Similarly, oxygen content typically needs to be kept below 0.2% to prevent embrittlement and ensure optimal mechanical performance.

Current production environments struggle with batch-to-batch consistency in carbon and oxygen levels. Variations in feedstock composition, processing parameters, and environmental conditions contribute to this inconsistency. The heterogeneous nature of powder-binder mixtures further complicates uniform carbon distribution throughout complex geometries, leading to localized variations in mechanical properties within the same component.

Temperature control during thermal debinding and sintering represents another significant challenge. The narrow processing windows required for optimal carbon/oxygen control demand precise temperature management throughout the entire component volume. Thermal gradients within larger or geometrically complex parts can result in non-uniform carbon extraction or oxygen absorption, creating zones with varying mechanical properties.

Measurement and monitoring limitations compound these challenges. Real-time monitoring of carbon and oxygen levels during processing remains difficult, with most manufacturers relying on post-production testing. This reactive approach leads to higher rejection rates and increased production costs. Current analytical methods often require destructive testing, preventing 100% inspection of production components.

The industry also faces challenges related to the trade-off between processing speed and carbon/oxygen control. Faster debinding and sintering cycles are economically desirable but can compromise the precision of carbon/oxygen management. This creates a constant tension between production efficiency and quality control, particularly for high-volume manufacturing operations.

Addressing these challenges requires advancements in process monitoring technologies, feedstock formulations with more predictable carbon yield, and improved atmospheric control systems for sintering furnaces. The development of computational models that can accurately predict carbon and oxygen behavior during processing would also significantly improve manufacturers' ability to meet mechanical property targets consistently.

The precise control of carbon content presents a particular difficulty as it must be maintained within extremely narrow specifications—often between 0.1% and 0.8% depending on the alloy system. Deviations as small as 0.05% can dramatically alter mechanical properties, especially in high-performance applications where strength, hardness, and ductility requirements are stringent. Similarly, oxygen content typically needs to be kept below 0.2% to prevent embrittlement and ensure optimal mechanical performance.

Current production environments struggle with batch-to-batch consistency in carbon and oxygen levels. Variations in feedstock composition, processing parameters, and environmental conditions contribute to this inconsistency. The heterogeneous nature of powder-binder mixtures further complicates uniform carbon distribution throughout complex geometries, leading to localized variations in mechanical properties within the same component.

Temperature control during thermal debinding and sintering represents another significant challenge. The narrow processing windows required for optimal carbon/oxygen control demand precise temperature management throughout the entire component volume. Thermal gradients within larger or geometrically complex parts can result in non-uniform carbon extraction or oxygen absorption, creating zones with varying mechanical properties.

Measurement and monitoring limitations compound these challenges. Real-time monitoring of carbon and oxygen levels during processing remains difficult, with most manufacturers relying on post-production testing. This reactive approach leads to higher rejection rates and increased production costs. Current analytical methods often require destructive testing, preventing 100% inspection of production components.

The industry also faces challenges related to the trade-off between processing speed and carbon/oxygen control. Faster debinding and sintering cycles are economically desirable but can compromise the precision of carbon/oxygen management. This creates a constant tension between production efficiency and quality control, particularly for high-volume manufacturing operations.

Addressing these challenges requires advancements in process monitoring technologies, feedstock formulations with more predictable carbon yield, and improved atmospheric control systems for sintering furnaces. The development of computational models that can accurately predict carbon and oxygen behavior during processing would also significantly improve manufacturers' ability to meet mechanical property targets consistently.

Current C/O Management Solutions

01 Carbon and oxygen content control methods in MIM feedstock

Various methods are employed to control carbon and oxygen content in metal injection molding feedstock. These include using specific binder compositions, controlling the atmosphere during processing, and implementing precise debinding procedures. Proper control of carbon and oxygen levels is crucial for achieving desired mechanical properties in the final sintered parts and preventing defects such as oxidation or carbon contamination.- Carbon and oxygen content control methods in MIM feedstock: Various methods are employed to control carbon and oxygen content in metal injection molding feedstock. These include using specific binder compositions, controlled atmosphere processing, and precise temperature regulation during debinding. Proper carbon and oxygen control is essential for achieving desired mechanical properties in the final sintered parts, as excessive carbon or oxygen can lead to embrittlement or reduced strength.

- Debinding techniques for carbon/oxygen management: Specialized debinding techniques are crucial for managing carbon and oxygen levels in MIM parts. These include thermal debinding under controlled atmospheres, catalytic debinding, and multi-stage debinding processes. The debinding stage is particularly critical as it removes the organic binder components while preventing oxidation or carbon contamination of the metal powder, which would affect the final part properties.

- Sintering atmosphere control for carbon/oxygen regulation: The sintering atmosphere plays a vital role in controlling carbon and oxygen levels in MIM parts. Various gas compositions including hydrogen, nitrogen, argon, or vacuum environments are used depending on the metal alloy. Precise control of the sintering atmosphere helps prevent oxidation while allowing for controlled carbon diffusion, ensuring optimal mechanical and physical properties in the final components.

- Feedstock formulations for optimized carbon/oxygen levels: Specialized feedstock formulations are developed to achieve optimal carbon and oxygen levels in MIM parts. These formulations include specific metal powders with controlled surface chemistry, tailored binder systems, and additives that can act as oxygen getters or carbon sources. The precise composition of the feedstock significantly influences the final carbon and oxygen content in the sintered components.

- Analytical methods for carbon/oxygen monitoring in MIM: Various analytical techniques are employed to monitor and control carbon and oxygen levels throughout the MIM process. These include gas analysis, thermal analysis, mass spectrometry, and microstructural examination. Real-time monitoring allows for process adjustments to maintain optimal carbon and oxygen levels, ensuring consistent quality in the final sintered parts.

02 Thermal debinding techniques for carbon/oxygen management

Thermal debinding techniques are specifically designed to manage carbon and oxygen levels during the MIM process. These techniques involve carefully controlled heating profiles to remove organic binders while minimizing carbon residue and preventing oxidation. The process may include multiple temperature stages and specific atmospheric conditions to ensure optimal carbon and oxygen control before the sintering stage.Expand Specific Solutions03 Atmosphere control systems for MIM processing

Specialized atmosphere control systems are implemented during metal injection molding to regulate carbon and oxygen levels. These systems may utilize inert gases, reducing atmospheres, or vacuum conditions at different stages of the process. The controlled atmosphere prevents oxidation of metal powders and helps maintain the desired carbon content, particularly during debinding and sintering phases.Expand Specific Solutions04 Powder composition and treatment for carbon/oxygen optimization

The composition and pre-treatment of metal powders significantly impact carbon and oxygen control in MIM. Specific powder characteristics such as particle size distribution, surface area, and pre-alloying can affect carbon pickup and oxygen sensitivity. Various powder treatments including reduction processes, surface modifications, and specialized handling techniques are employed to optimize carbon and oxygen levels before and during the MIM process.Expand Specific Solutions05 Analytical methods for carbon/oxygen monitoring in MIM

Advanced analytical techniques are utilized to monitor and control carbon and oxygen levels throughout the metal injection molding process. These include gas analysis, thermal analysis, spectroscopy, and various in-process monitoring systems. Real-time measurement and feedback control mechanisms help maintain optimal carbon and oxygen concentrations, ensuring consistent quality of the final sintered components.Expand Specific Solutions

Key MIM Industry Players and Competitors

Metal Injection Molding (MIM) technology is currently in a growth phase, with the market expected to reach $4.5 billion by 2025. The competitive landscape is characterized by established industrial players like Sumitomo Heavy Industries and Robert Bosch GmbH focusing on carbon/oxygen control to achieve superior mechanical properties. The technology has reached moderate maturity, with companies like iMFLUX and Shibaura Machine developing proprietary processes for precise carbon/oxygen ratio management. Honda Motor and JFE Steel are advancing material science applications, while research institutions like Korea Institute of Machinery & Materials are pushing boundaries in powder metallurgy optimization. The industry is transitioning from experimental approaches to standardized methodologies for controlling interstitial elements to consistently meet mechanical targets across automotive, aerospace, and medical applications.

Sumitomo Heavy Industries, Ltd.

Technical Solution: Sumitomo Heavy Industries has developed an advanced Metal Injection Molding system that precisely controls carbon and oxygen content through a proprietary feedstock formulation and sintering process. Their technology utilizes a two-stage debinding process: first a solvent debinding step that removes primary binders while maintaining structural integrity, followed by thermal debinding in a controlled atmosphere furnace. The sintering phase employs variable atmosphere control systems that can dynamically adjust hydrogen/nitrogen ratios and dew points to achieve optimal carbon content (typically 0.1-0.8%) and oxygen levels below 0.2%. Their process incorporates real-time monitoring with oxygen sensors and carbon analyzers that provide feedback to atmosphere control systems, allowing for precise adjustments during the critical sintering phase. This enables production of high-density (>98%) components with consistent mechanical properties.

Strengths: Superior atmosphere control systems allow for precise carbon/oxygen ratio management, resulting in highly consistent mechanical properties across production batches. Their real-time monitoring technology minimizes defects and optimizes resource usage. Weaknesses: The sophisticated control systems require significant capital investment and specialized technical expertise to operate effectively, potentially limiting accessibility for smaller manufacturers.

Robert Bosch GmbH

Technical Solution: Bosch has pioneered a Metal Injection Molding technology that focuses on precise carbon/oxygen control through their patented "Controlled Atmosphere Processing" (CAP) system. This technology utilizes specialized binder formulations containing dispersed carbon sources that can be precisely activated during thermal processing. Their process begins with highly homogenized feedstock preparation using high-shear mixers that ensure uniform distribution of metal powders and binder components. The debinding phase employs a proprietary catalytic debinding process that removes polymer binders while minimizing carbon contamination. During sintering, Bosch's CAP system maintains oxygen partial pressure within 10^-15 to 10^-20 atm range while simultaneously controlling carbon activity through programmed introduction of methane/hydrogen mixtures. This allows for precise targeting of carbon content between 0.2-0.6% depending on the desired mechanical properties. The system also incorporates in-situ oxygen sensors that provide continuous feedback to atmosphere control systems.

Strengths: Their catalytic debinding technology significantly reduces processing time while maintaining excellent carbon control. The CAP system allows for tailored mechanical properties through precise atmosphere manipulation. Weaknesses: The process requires specialized equipment and gases that may increase operational costs, and the technology is more suited for medium to high volume production runs rather than small batches.

Critical Patents in MIM Carbon/Oxygen Control

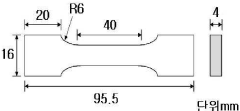

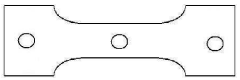

Method of controlling carbon content in sintered body made by metal injection molding

PatentInactiveKR1020120009622A

Innovation

- A method involving the mixing of two or more carbonyl iron powders (CIPs) with different carbon contents to control the carbon content in the sintered body through a neutral atmosphere in the degreasing and sintering processes, eliminating the need for expensive raw materials and toxic gases, and ensuring homogeneous carbon distribution.

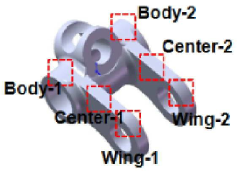

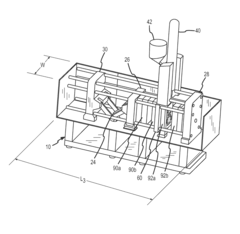

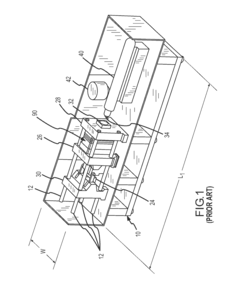

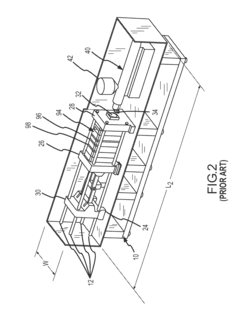

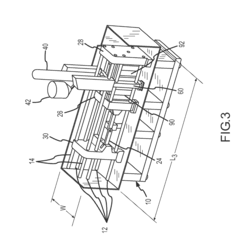

Injection molding machine with melt distributing platen

PatentInactiveUS8123516B1

Innovation

- The implementation of a center platen with opposing mold mounting surfaces allows for the use of multiple conventional molds during a single cycle, utilizing a vertical injection unit to distribute molten material efficiently between molds, reducing the overall length and footprint of the machine while maintaining or increasing production capacity.

Material Science Advancements for MIM

Material science has undergone significant transformations in the Metal Injection Molding (MIM) industry, particularly in controlling carbon and oxygen levels to achieve desired mechanical properties. Recent advancements have focused on developing precise methodologies for manipulating these elements during the sintering process, which directly impacts the final product's strength, ductility, and overall performance.

The evolution of powder metallurgy has enabled manufacturers to create specialized metal powders with controlled particle size distributions and chemical compositions. These innovations allow for more predictable carbon and oxygen content throughout the MIM process. Advanced analytical techniques, including thermogravimetric analysis and gas chromatography, now provide real-time monitoring of carbon and oxygen levels during debinding and sintering stages.

Researchers have developed novel binder systems that minimize oxygen contamination during the debinding phase. Traditional polymer-based binders often introduced excess oxygen, but newer formulations incorporate oxygen scavengers and carbon-stabilizing compounds. These advanced binders facilitate more precise control over the carbon-to-oxygen ratio, which is critical for achieving target mechanical properties in the final component.

Sintering atmosphere control has seen remarkable improvements through the implementation of multi-zone furnaces with independent gas composition management. These systems can create dynamic sintering profiles that adjust hydrogen, nitrogen, and carbon-containing gas ratios throughout the thermal cycle. This capability allows manufacturers to fine-tune the carbon content while simultaneously managing oxygen reduction at different temperature stages.

Computational modeling has revolutionized the prediction of carbon and oxygen behavior during the MIM process. Simulation tools now incorporate thermodynamic databases specific to various metal alloy systems, enabling engineers to forecast how carbon and oxygen will interact with base metals and alloying elements during sintering. These models help optimize process parameters before physical production begins.

Post-processing treatments have also advanced significantly, with specialized heat treatments designed to stabilize carbon content and remove residual oxygen. Techniques such as vacuum heat treatment and controlled atmosphere annealing provide additional mechanisms for fine-tuning the carbon-to-oxygen ratio to meet specific mechanical requirements for high-performance applications in aerospace, medical, and automotive industries.

The integration of in-line quality control systems using spectroscopic methods has enabled real-time adjustments to process parameters, ensuring consistent carbon and oxygen levels across production batches. This advancement has significantly improved the reliability and reproducibility of MIM components with precise mechanical properties.

The evolution of powder metallurgy has enabled manufacturers to create specialized metal powders with controlled particle size distributions and chemical compositions. These innovations allow for more predictable carbon and oxygen content throughout the MIM process. Advanced analytical techniques, including thermogravimetric analysis and gas chromatography, now provide real-time monitoring of carbon and oxygen levels during debinding and sintering stages.

Researchers have developed novel binder systems that minimize oxygen contamination during the debinding phase. Traditional polymer-based binders often introduced excess oxygen, but newer formulations incorporate oxygen scavengers and carbon-stabilizing compounds. These advanced binders facilitate more precise control over the carbon-to-oxygen ratio, which is critical for achieving target mechanical properties in the final component.

Sintering atmosphere control has seen remarkable improvements through the implementation of multi-zone furnaces with independent gas composition management. These systems can create dynamic sintering profiles that adjust hydrogen, nitrogen, and carbon-containing gas ratios throughout the thermal cycle. This capability allows manufacturers to fine-tune the carbon content while simultaneously managing oxygen reduction at different temperature stages.

Computational modeling has revolutionized the prediction of carbon and oxygen behavior during the MIM process. Simulation tools now incorporate thermodynamic databases specific to various metal alloy systems, enabling engineers to forecast how carbon and oxygen will interact with base metals and alloying elements during sintering. These models help optimize process parameters before physical production begins.

Post-processing treatments have also advanced significantly, with specialized heat treatments designed to stabilize carbon content and remove residual oxygen. Techniques such as vacuum heat treatment and controlled atmosphere annealing provide additional mechanisms for fine-tuning the carbon-to-oxygen ratio to meet specific mechanical requirements for high-performance applications in aerospace, medical, and automotive industries.

The integration of in-line quality control systems using spectroscopic methods has enabled real-time adjustments to process parameters, ensuring consistent carbon and oxygen levels across production batches. This advancement has significantly improved the reliability and reproducibility of MIM components with precise mechanical properties.

Environmental Impact and Sustainability Considerations

Metal Injection Molding (MIM) processes, while offering significant advantages in manufacturing complex metal components, present important environmental and sustainability considerations that must be addressed in modern industrial contexts. The control of carbon and oxygen levels during MIM not only affects mechanical properties but also has substantial environmental implications throughout the product lifecycle.

The energy consumption associated with MIM processes, particularly during sintering which requires high temperatures (typically 1200-1400°C), represents a significant environmental concern. The precise control of carbon and oxygen levels often necessitates specialized equipment and extended processing times, further increasing the energy footprint. Industry data suggests that optimized carbon/oxygen control protocols can reduce energy consumption by 15-20% compared to conventional approaches.

Raw material efficiency presents another critical sustainability dimension. MIM's near-net-shape capabilities minimize material waste compared to traditional manufacturing methods, with material utilization rates often exceeding 95%. However, the feedstock preparation involving fine metal powders and binders requires careful environmental management, as improper handling can lead to particulate emissions and potential health hazards.

The debinding phase of MIM, where organic binders are removed, presents particular environmental challenges. Thermal debinding releases volatile organic compounds (VOCs) and potentially hazardous emissions. Advanced catalytic debinding systems and water-soluble binder technologies have emerged as more environmentally friendly alternatives, reducing harmful emissions by up to 80% compared to conventional solvent-based approaches.

Carbon footprint considerations extend to the entire MIM supply chain. The production of metal powders with precisely controlled oxygen content is energy-intensive, with primary production accounting for approximately 40-60% of the total carbon footprint of MIM components. Recycling initiatives for metal powders and scrap MIM parts can significantly reduce this environmental impact, with closed-loop systems demonstrating carbon footprint reductions of 30-50%.

Regulatory compliance regarding environmental standards is increasingly stringent for MIM operations. Facilities must adhere to emissions standards, waste management protocols, and energy efficiency requirements. Companies implementing advanced carbon/oxygen control technologies often find themselves better positioned to meet these evolving regulations while simultaneously achieving desired mechanical properties in their products.

Looking forward, sustainable innovations in MIM technology are focusing on bio-derived binders, lower-temperature sintering processes, and more efficient carbon/oxygen control methodologies that minimize environmental impact while maintaining or enhancing mechanical performance. These developments represent promising pathways toward more environmentally responsible manufacturing while meeting increasingly demanding mechanical specifications.

The energy consumption associated with MIM processes, particularly during sintering which requires high temperatures (typically 1200-1400°C), represents a significant environmental concern. The precise control of carbon and oxygen levels often necessitates specialized equipment and extended processing times, further increasing the energy footprint. Industry data suggests that optimized carbon/oxygen control protocols can reduce energy consumption by 15-20% compared to conventional approaches.

Raw material efficiency presents another critical sustainability dimension. MIM's near-net-shape capabilities minimize material waste compared to traditional manufacturing methods, with material utilization rates often exceeding 95%. However, the feedstock preparation involving fine metal powders and binders requires careful environmental management, as improper handling can lead to particulate emissions and potential health hazards.

The debinding phase of MIM, where organic binders are removed, presents particular environmental challenges. Thermal debinding releases volatile organic compounds (VOCs) and potentially hazardous emissions. Advanced catalytic debinding systems and water-soluble binder technologies have emerged as more environmentally friendly alternatives, reducing harmful emissions by up to 80% compared to conventional solvent-based approaches.

Carbon footprint considerations extend to the entire MIM supply chain. The production of metal powders with precisely controlled oxygen content is energy-intensive, with primary production accounting for approximately 40-60% of the total carbon footprint of MIM components. Recycling initiatives for metal powders and scrap MIM parts can significantly reduce this environmental impact, with closed-loop systems demonstrating carbon footprint reductions of 30-50%.

Regulatory compliance regarding environmental standards is increasingly stringent for MIM operations. Facilities must adhere to emissions standards, waste management protocols, and energy efficiency requirements. Companies implementing advanced carbon/oxygen control technologies often find themselves better positioned to meet these evolving regulations while simultaneously achieving desired mechanical properties in their products.

Looking forward, sustainable innovations in MIM technology are focusing on bio-derived binders, lower-temperature sintering processes, and more efficient carbon/oxygen control methodologies that minimize environmental impact while maintaining or enhancing mechanical performance. These developments represent promising pathways toward more environmentally responsible manufacturing while meeting increasingly demanding mechanical specifications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!