Metal Injection Molding Sintering: Shrinkage Mapping, Distortion And Grain Growth

SEP 16, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

MIM Sintering Technology Background and Objectives

Metal Injection Molding (MIM) has evolved significantly since its inception in the 1970s, transforming from an experimental manufacturing technique to a sophisticated industrial process. This technology combines the design flexibility of plastic injection molding with the material properties of powder metallurgy, enabling the production of complex metal components with exceptional mechanical properties. The sintering phase represents the critical stage where the molded "green parts" are transformed into fully dense metal components through controlled thermal processing.

The evolution of MIM sintering technology has been marked by continuous improvements in process control, material science, and computational modeling. Early MIM processes suffered from unpredictable shrinkage rates, significant part distortion, and inconsistent microstructural development. These challenges limited the adoption of MIM technology to applications with relatively loose dimensional tolerances and moderate mechanical requirements.

Recent technological advancements have focused on developing more precise sintering profiles, enhanced atmosphere control systems, and advanced monitoring capabilities. The introduction of computer-controlled sintering furnaces has enabled more precise temperature management throughout the thermal cycle, significantly improving dimensional consistency and reducing distortion in final parts.

The primary objective of current MIM sintering research is to establish predictable relationships between processing parameters and final part characteristics, particularly focusing on shrinkage mapping, distortion control, and grain growth management. Understanding these relationships is essential for expanding MIM applications into high-precision industries such as aerospace, medical devices, and advanced electronics.

Shrinkage mapping aims to create comprehensive models that can accurately predict dimensional changes during sintering across different geometries and material compositions. This capability would enable manufacturers to design molds with precise compensation factors, significantly reducing post-sintering machining requirements and improving overall process economics.

Distortion control research focuses on identifying and mitigating the factors that cause non-uniform dimensional changes during sintering. These factors include gravity effects, thermal gradients, density variations in green parts, and material composition inconsistencies. Advanced simulation tools are being developed to predict distortion patterns and optimize part orientation and support structures during sintering.

Grain growth management represents another critical research area, as the microstructural development during sintering directly impacts the mechanical properties of final components. Controlling grain size and distribution is essential for achieving desired strength, hardness, and fatigue resistance in MIM parts.

The convergence of these research directions aims to transform MIM sintering from an experience-based art to a predictable science, enabling broader adoption across industries requiring high-precision metal components with complex geometries.

The evolution of MIM sintering technology has been marked by continuous improvements in process control, material science, and computational modeling. Early MIM processes suffered from unpredictable shrinkage rates, significant part distortion, and inconsistent microstructural development. These challenges limited the adoption of MIM technology to applications with relatively loose dimensional tolerances and moderate mechanical requirements.

Recent technological advancements have focused on developing more precise sintering profiles, enhanced atmosphere control systems, and advanced monitoring capabilities. The introduction of computer-controlled sintering furnaces has enabled more precise temperature management throughout the thermal cycle, significantly improving dimensional consistency and reducing distortion in final parts.

The primary objective of current MIM sintering research is to establish predictable relationships between processing parameters and final part characteristics, particularly focusing on shrinkage mapping, distortion control, and grain growth management. Understanding these relationships is essential for expanding MIM applications into high-precision industries such as aerospace, medical devices, and advanced electronics.

Shrinkage mapping aims to create comprehensive models that can accurately predict dimensional changes during sintering across different geometries and material compositions. This capability would enable manufacturers to design molds with precise compensation factors, significantly reducing post-sintering machining requirements and improving overall process economics.

Distortion control research focuses on identifying and mitigating the factors that cause non-uniform dimensional changes during sintering. These factors include gravity effects, thermal gradients, density variations in green parts, and material composition inconsistencies. Advanced simulation tools are being developed to predict distortion patterns and optimize part orientation and support structures during sintering.

Grain growth management represents another critical research area, as the microstructural development during sintering directly impacts the mechanical properties of final components. Controlling grain size and distribution is essential for achieving desired strength, hardness, and fatigue resistance in MIM parts.

The convergence of these research directions aims to transform MIM sintering from an experience-based art to a predictable science, enabling broader adoption across industries requiring high-precision metal components with complex geometries.

Market Analysis for MIM Precision Components

The Metal Injection Molding (MIM) precision components market has experienced substantial growth over the past decade, driven by increasing demand for complex, high-precision metal parts across multiple industries. The global MIM market is currently valued at approximately 3.5 billion USD, with a compound annual growth rate of 11.8% projected through 2028, significantly outpacing traditional metal forming technologies.

The automotive sector represents the largest application segment, accounting for roughly 35% of the total MIM market. This dominance stems from the automotive industry's continuous pursuit of lightweight, high-strength components for fuel efficiency and emissions reduction. MIM components such as turbocharger vanes, sensor housings, and transmission parts have become standard in modern vehicle manufacturing.

Medical and healthcare applications constitute the second-largest market segment at 28%, with surgical instruments, orthopedic implants, and dental components being primary applications. The biocompatibility of MIM materials like stainless steel and titanium alloys makes them particularly valuable in this sector, where precision and reliability are paramount.

Consumer electronics represents a rapidly growing segment (18% of the market) as manufacturers seek miniaturized metal components with complex geometries for smartphones, wearables, and other portable devices. The aerospace and defense sectors (12%) utilize MIM for specialized components requiring exceptional mechanical properties and dimensional accuracy.

Regional analysis reveals Asia-Pacific as the dominant market (45% share), with China, Japan, and South Korea leading in production capacity. North America follows at 30%, with strong demand from medical device manufacturers and aerospace contractors. Europe accounts for 20% of the market, with Germany and Italy as key manufacturing hubs.

Market demand is increasingly focused on components with tighter tolerances, more complex geometries, and enhanced material properties. This trend directly correlates with advancements in sintering technology, particularly in controlling shrinkage, distortion, and grain growth—the technical challenges addressed in this research.

Industry surveys indicate that manufacturers are willing to pay premium prices (20-35% higher) for MIM components with predictable shrinkage patterns and minimal distortion, as these characteristics significantly reduce post-processing costs and improve final product quality. The ability to control grain growth during sintering also commands market value, as it directly impacts mechanical properties and surface finish quality.

The market outlook remains highly positive, with technological innovations in sintering processes expected to expand MIM applications into new industries and enable the production of larger and more complex components than currently feasible.

The automotive sector represents the largest application segment, accounting for roughly 35% of the total MIM market. This dominance stems from the automotive industry's continuous pursuit of lightweight, high-strength components for fuel efficiency and emissions reduction. MIM components such as turbocharger vanes, sensor housings, and transmission parts have become standard in modern vehicle manufacturing.

Medical and healthcare applications constitute the second-largest market segment at 28%, with surgical instruments, orthopedic implants, and dental components being primary applications. The biocompatibility of MIM materials like stainless steel and titanium alloys makes them particularly valuable in this sector, where precision and reliability are paramount.

Consumer electronics represents a rapidly growing segment (18% of the market) as manufacturers seek miniaturized metal components with complex geometries for smartphones, wearables, and other portable devices. The aerospace and defense sectors (12%) utilize MIM for specialized components requiring exceptional mechanical properties and dimensional accuracy.

Regional analysis reveals Asia-Pacific as the dominant market (45% share), with China, Japan, and South Korea leading in production capacity. North America follows at 30%, with strong demand from medical device manufacturers and aerospace contractors. Europe accounts for 20% of the market, with Germany and Italy as key manufacturing hubs.

Market demand is increasingly focused on components with tighter tolerances, more complex geometries, and enhanced material properties. This trend directly correlates with advancements in sintering technology, particularly in controlling shrinkage, distortion, and grain growth—the technical challenges addressed in this research.

Industry surveys indicate that manufacturers are willing to pay premium prices (20-35% higher) for MIM components with predictable shrinkage patterns and minimal distortion, as these characteristics significantly reduce post-processing costs and improve final product quality. The ability to control grain growth during sintering also commands market value, as it directly impacts mechanical properties and surface finish quality.

The market outlook remains highly positive, with technological innovations in sintering processes expected to expand MIM applications into new industries and enable the production of larger and more complex components than currently feasible.

Current Challenges in Shrinkage Control and Grain Growth

Despite significant advancements in Metal Injection Molding (MIM) technology, shrinkage control and grain growth management remain persistent challenges that impede broader industrial adoption. The fundamental issue stems from the complex thermodynamic processes during sintering, where components typically experience 15-20% volumetric shrinkage. This shrinkage is rarely uniform across the entire component, leading to dimensional inaccuracies and geometric distortions that compromise final part quality.

Current prediction models for shrinkage behavior exhibit limitations in accuracy, particularly for complex geometries with varying cross-sectional thicknesses. The industry lacks comprehensive shrinkage mapping tools that can reliably predict dimensional changes across different material compositions and sintering profiles. Existing simulation software often fails to account for the interaction between powder characteristics, binder systems, and sintering parameters, resulting in significant deviations between predicted and actual outcomes.

Anisotropic shrinkage presents another major challenge, occurring when different sections of a component shrink at varying rates due to density gradients introduced during the injection molding phase. These gradients create internal stresses during sintering that manifest as warping, cracking, or dimensional instability. The industry has yet to develop robust methodologies for controlling density distribution during the molding stage to ensure more uniform shrinkage patterns.

Grain growth control represents a parallel challenge that directly impacts mechanical properties and surface finish quality. During the high-temperature sintering phase, excessive grain growth can occur, particularly in components with fine features or thin walls. This phenomenon reduces mechanical strength, compromises wear resistance, and degrades surface finish. Current sintering protocols struggle to balance the competing requirements of achieving full densification while limiting detrimental grain growth.

The relationship between sintering parameters and resultant microstructure remains inadequately characterized across different material systems. Temperature ramp rates, holding times, and atmosphere composition all influence grain boundary mobility and growth kinetics, yet predictive models for these interactions lack sufficient accuracy for production environments. This knowledge gap forces manufacturers to rely heavily on empirical approaches and extensive trial-and-error testing.

Advanced materials and multi-material components present additional complications, as different materials exhibit varying shrinkage behaviors and grain growth tendencies. The industry lacks standardized approaches for co-sintering dissimilar materials while maintaining dimensional accuracy and desired microstructural characteristics. This limitation restricts the design freedom and material selection options available to engineers working with MIM technology.

Current prediction models for shrinkage behavior exhibit limitations in accuracy, particularly for complex geometries with varying cross-sectional thicknesses. The industry lacks comprehensive shrinkage mapping tools that can reliably predict dimensional changes across different material compositions and sintering profiles. Existing simulation software often fails to account for the interaction between powder characteristics, binder systems, and sintering parameters, resulting in significant deviations between predicted and actual outcomes.

Anisotropic shrinkage presents another major challenge, occurring when different sections of a component shrink at varying rates due to density gradients introduced during the injection molding phase. These gradients create internal stresses during sintering that manifest as warping, cracking, or dimensional instability. The industry has yet to develop robust methodologies for controlling density distribution during the molding stage to ensure more uniform shrinkage patterns.

Grain growth control represents a parallel challenge that directly impacts mechanical properties and surface finish quality. During the high-temperature sintering phase, excessive grain growth can occur, particularly in components with fine features or thin walls. This phenomenon reduces mechanical strength, compromises wear resistance, and degrades surface finish. Current sintering protocols struggle to balance the competing requirements of achieving full densification while limiting detrimental grain growth.

The relationship between sintering parameters and resultant microstructure remains inadequately characterized across different material systems. Temperature ramp rates, holding times, and atmosphere composition all influence grain boundary mobility and growth kinetics, yet predictive models for these interactions lack sufficient accuracy for production environments. This knowledge gap forces manufacturers to rely heavily on empirical approaches and extensive trial-and-error testing.

Advanced materials and multi-material components present additional complications, as different materials exhibit varying shrinkage behaviors and grain growth tendencies. The industry lacks standardized approaches for co-sintering dissimilar materials while maintaining dimensional accuracy and desired microstructural characteristics. This limitation restricts the design freedom and material selection options available to engineers working with MIM technology.

Existing Methods for Shrinkage Prediction and Distortion Control

01 Controlling sintering shrinkage in MIM

Various methods can be employed to control and predict sintering shrinkage in metal injection molding processes. These include optimizing powder characteristics, binder formulations, and processing parameters. By carefully controlling these factors, manufacturers can achieve more predictable shrinkage rates, which is crucial for maintaining dimensional accuracy in final parts. Techniques such as using specific powder particle sizes and distributions, adjusting sintering temperatures and times, and implementing controlled cooling rates can significantly reduce uneven shrinkage.- Control of sintering shrinkage in MIM: Sintering shrinkage is a critical factor in metal injection molding that affects the final dimensions of the part. Various techniques can be employed to control shrinkage, including adjusting the powder loading in the feedstock, optimizing binder composition, and controlling sintering parameters such as temperature and time. Proper control of these factors can help achieve predictable and uniform shrinkage, resulting in more accurate final dimensions of the sintered parts.

- Prevention of distortion during MIM sintering: Distortion during the sintering process can significantly impact the quality and dimensional accuracy of MIM parts. Methods to prevent distortion include using appropriate support structures during sintering, controlling the heating and cooling rates, ensuring uniform debinding, and optimizing the sintering atmosphere. These approaches help maintain the geometric integrity of complex parts during the high-temperature sintering process, reducing the need for post-sintering operations.

- Grain growth management in MIM sintering: Controlling grain growth during sintering is essential for achieving desired mechanical properties in MIM parts. Techniques include adding grain growth inhibitors to the feedstock, implementing specific heating profiles, using alloying elements that restrict grain boundary movement, and applying pressure-assisted sintering methods. Proper grain size control results in improved strength, hardness, and other mechanical properties of the final sintered components.

- Advanced feedstock formulations for improved sintering behavior: The composition of MIM feedstock significantly influences sintering behavior, including shrinkage, distortion, and grain growth. Advanced formulations incorporate specialized binders, surfactants, and powder treatments to enhance powder packing density and homogeneity. These formulations can include multi-component binder systems, nanoscale additives, and custom-designed powder blends that promote uniform sintering, reduce defects, and improve the overall quality of sintered parts.

- Process optimization and simulation for MIM sintering: Computer simulation and process optimization techniques are increasingly used to predict and control sintering behavior in MIM. These approaches include finite element analysis, computational fluid dynamics, and machine learning algorithms to model shrinkage, distortion, and microstructural evolution during sintering. By simulating the sintering process before actual production, manufacturers can optimize process parameters, predict potential issues, and design appropriate tooling to compensate for dimensional changes, resulting in more efficient production and higher quality parts.

02 Preventing distortion during MIM sintering

Distortion during the sintering phase of metal injection molding can be minimized through several approaches. These include designing appropriate support structures during sintering, optimizing debinding processes to ensure uniform binder removal, and controlling sintering atmosphere composition. Gradual heating rates and proper part orientation during sintering also play significant roles in reducing distortion. Advanced simulation tools can predict potential distortion issues before production, allowing for preemptive design modifications.Expand Specific Solutions03 Managing grain growth during sintering

Controlling grain growth during the sintering process is essential for achieving desired mechanical properties in MIM parts. This can be accomplished through the addition of grain growth inhibitors, precise temperature control during sintering cycles, and the use of specialized sintering atmospheres. Rapid sintering techniques can also be employed to limit the time available for excessive grain growth. The management of grain size directly impacts the strength, hardness, and other mechanical properties of the final component.Expand Specific Solutions04 Advanced materials and additives for improved MIM sintering

The incorporation of specialized additives and advanced material formulations can significantly improve the sintering behavior of MIM parts. These include sintering aids that promote densification at lower temperatures, lubricants that improve powder flow and compaction, and phase stabilizers that maintain desired microstructures during sintering. Nano-sized particles can be added to enhance sintering kinetics and reduce processing temperatures. These advanced materials help achieve better dimensional control, reduced distortion, and improved mechanical properties in the final components.Expand Specific Solutions05 Process monitoring and control systems for MIM sintering

Implementation of sophisticated monitoring and control systems during the sintering process can significantly improve outcomes in metal injection molding. These systems include real-time temperature profiling, atmosphere composition monitoring, and dimensional change tracking during sintering. Computer-aided simulation tools can predict shrinkage patterns and potential distortion issues before production begins. Feedback control mechanisms can make real-time adjustments to sintering parameters based on monitored data, ensuring consistent results across production batches and minimizing defects related to shrinkage and distortion.Expand Specific Solutions

Leading Companies and Research Institutions in MIM Industry

Metal Injection Molding (MIM) sintering technology is currently in a growth phase, with the global market expected to reach significant expansion due to increasing demand in automotive, medical, and consumer electronics sectors. The technology has reached moderate maturity, with key players advancing solutions for critical challenges like shrinkage mapping and distortion control. Companies like Jiangsu Gian Technology and Taiwan Powder Technologies specialize in MIM solutions, while larger corporations such as Höganäs AB and Desktop Metal are driving innovation in powder metallurgy and additive manufacturing integration. Established industrial giants including Seiko Epson, Rolls-Royce, and NIPPON STEEL are incorporating MIM technology into their manufacturing processes, particularly for complex components requiring precise dimensional control and enhanced material properties.

Höganäs AB

Technical Solution: Höganäs AB has developed advanced sintering technologies for Metal Injection Molding (MIM) that focus on shrinkage prediction and control. Their proprietary Digital Metal® technology incorporates sophisticated simulation models that predict shrinkage patterns during the sintering process with accuracy rates of up to 95%. The company employs a multi-stage sintering approach where initial debinding occurs at lower temperatures (around 450°C) followed by controlled sintering at higher temperatures (1200-1380°C) with precisely managed heating rates of 5-10°C/minute to minimize distortion. Their technology includes real-time monitoring systems that track dimensional changes during sintering, allowing for adaptive process control. Höganäs has also developed specialized powder formulations with tailored particle size distributions (typically 5-25μm) and morphologies that exhibit more uniform shrinkage characteristics, reducing overall part distortion by up to 30% compared to conventional powders. Their research has established correlations between powder characteristics, sintering parameters, and final part dimensions, enabling predictive modeling of shrinkage across complex geometries.

Strengths: Industry-leading powder metallurgy expertise with specialized formulations that provide more predictable shrinkage behavior. Their Digital Metal® technology offers superior dimensional accuracy for complex parts. Weaknesses: Their solutions may require more expensive equipment and specialized powders, potentially increasing production costs compared to conventional MIM approaches.

Honeywell International Technologies Ltd.

Technical Solution: Honeywell has developed an integrated approach to MIM sintering that focuses on predictive modeling and process control to manage shrinkage and distortion. Their technology incorporates finite element analysis (FEA) models that simulate the entire sintering process, accounting for thermal gradients, gravitational effects, and material-specific behavior. These models achieve shrinkage prediction accuracy within 3% across complex geometries. The company employs a multi-stage sintering protocol with precisely controlled temperature ramps and holds at critical transformation points to manage densification rates and minimize internal stresses. Their approach includes specialized sintering atmospheres with controlled oxygen partial pressures that inhibit abnormal grain growth while promoting uniform densification. Honeywell has developed proprietary feedback control systems that monitor key process parameters in real-time and make adjustments to maintain optimal sintering conditions throughout the thermal cycle. Their research has established correlations between powder characteristics, green part density distributions, and final sintering behavior, allowing them to optimize the entire MIM process chain for dimensional accuracy. The company employs post-sintering characterization techniques including 3D scanning and advanced metallography to continuously refine their predictive models and process parameters.

Strengths: Comprehensive approach that integrates material science, process engineering, and advanced simulation to achieve superior dimensional control. Their real-time monitoring and feedback systems provide exceptional process consistency across production runs. Weaknesses: Their technology likely requires significant capital investment and specialized expertise to implement effectively. The approach may be overly complex for simpler applications where extreme precision is not required.

Critical Patents and Research on Grain Growth Management

Sintering process and tools for use in metal injection molding of large parts

PatentInactiveEP1414605A2

Innovation

- A two-stage sintering process combined with specialized sintering tools, including ceramic inserts, to control deformation and maintain geometric stability, involving a first stage to fix the shape at 60-80% density and a second stage near the melting point for maximum densification, along with a four-stage drying process to prevent cracking.

Metal injection molding methods and feedstocks

PatentActiveUS7883662B2

Innovation

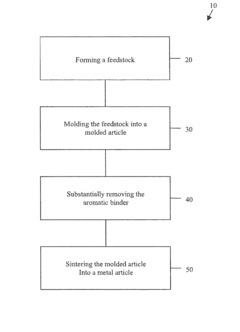

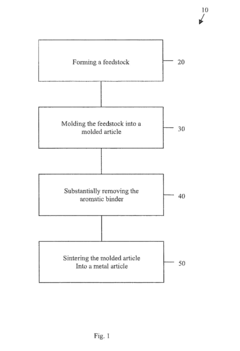

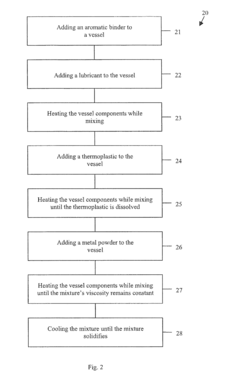

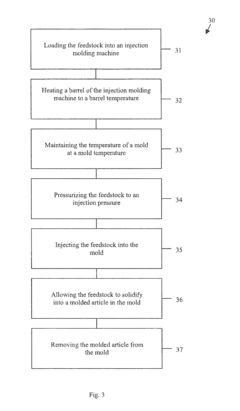

- The method involves forming a feedstock with a lubricant, thermoplastic, and aromatic binder, followed by molding, binder removal, and sintering, using techniques like alcohol immersion, atmospheric pressure heating, or heated vacuum to produce metal articles with enhanced properties, including oxygen reduction and densification methods to meet specific industry standards.

Material Selection Impact on MIM Sintering Performance

Material selection plays a critical role in determining the sintering performance of Metal Injection Molding (MIM) components. The choice of metal powder significantly influences shrinkage behavior, distortion patterns, and grain growth characteristics during the sintering process.

Powder particle size distribution directly impacts sintering kinetics and resultant shrinkage. Fine powders (typically <20μm) provide higher surface energy and enhanced sintering activity, leading to more uniform but often greater volumetric shrinkage. Coarser powders (>20μm) exhibit lower shrinkage rates but may result in less predictable dimensional changes and increased porosity.

Alloy composition affects both the sintering temperature requirements and the shrinkage mapping profiles. For instance, stainless steel 316L demonstrates different shrinkage characteristics compared to tungsten heavy alloys or titanium alloys. The presence of alloying elements can create liquid phases during sintering, accelerating densification but potentially introducing anisotropic shrinkage behaviors that complicate distortion prediction.

Powder morphology—spherical versus irregular particles—influences packing density in the green component and subsequent sintering behavior. Spherical powders typically result in more isotropic shrinkage patterns, while irregular powders may lead to directional shrinkage variations that contribute to component distortion.

The carbon content in ferrous alloys deserves special attention, as it significantly impacts grain growth during sintering. Higher carbon levels can promote abnormal grain growth in certain steel compositions, affecting both mechanical properties and dimensional stability. Controlling carbon through precise material selection and processing parameters is essential for managing grain structure.

Oxygen content in metal powders represents another critical factor. Materials with high oxygen affinity (titanium, aluminum alloys) require more stringent atmosphere control during sintering to prevent oxide formation that inhibits proper particle bonding and creates unpredictable shrinkage patterns.

Pre-alloyed versus elemental powder mixes exhibit fundamentally different sintering behaviors. Pre-alloyed powders generally provide more homogeneous shrinkage but may require higher sintering temperatures. Elemental mixes can sinter at lower temperatures due to diffusion effects but often display more complex shrinkage mapping due to the formation of intermetallic compounds during processing.

The binder system interaction with specific metal powders must also be considered, as incompatibilities can lead to contamination that affects grain boundary mobility and subsequent grain growth patterns during the sintering cycle.

Powder particle size distribution directly impacts sintering kinetics and resultant shrinkage. Fine powders (typically <20μm) provide higher surface energy and enhanced sintering activity, leading to more uniform but often greater volumetric shrinkage. Coarser powders (>20μm) exhibit lower shrinkage rates but may result in less predictable dimensional changes and increased porosity.

Alloy composition affects both the sintering temperature requirements and the shrinkage mapping profiles. For instance, stainless steel 316L demonstrates different shrinkage characteristics compared to tungsten heavy alloys or titanium alloys. The presence of alloying elements can create liquid phases during sintering, accelerating densification but potentially introducing anisotropic shrinkage behaviors that complicate distortion prediction.

Powder morphology—spherical versus irregular particles—influences packing density in the green component and subsequent sintering behavior. Spherical powders typically result in more isotropic shrinkage patterns, while irregular powders may lead to directional shrinkage variations that contribute to component distortion.

The carbon content in ferrous alloys deserves special attention, as it significantly impacts grain growth during sintering. Higher carbon levels can promote abnormal grain growth in certain steel compositions, affecting both mechanical properties and dimensional stability. Controlling carbon through precise material selection and processing parameters is essential for managing grain structure.

Oxygen content in metal powders represents another critical factor. Materials with high oxygen affinity (titanium, aluminum alloys) require more stringent atmosphere control during sintering to prevent oxide formation that inhibits proper particle bonding and creates unpredictable shrinkage patterns.

Pre-alloyed versus elemental powder mixes exhibit fundamentally different sintering behaviors. Pre-alloyed powders generally provide more homogeneous shrinkage but may require higher sintering temperatures. Elemental mixes can sinter at lower temperatures due to diffusion effects but often display more complex shrinkage mapping due to the formation of intermetallic compounds during processing.

The binder system interaction with specific metal powders must also be considered, as incompatibilities can lead to contamination that affects grain boundary mobility and subsequent grain growth patterns during the sintering cycle.

Quality Control Standards for MIM Components

Quality control standards for Metal Injection Molding (MIM) components have evolved significantly to address the complex challenges associated with shrinkage, distortion, and grain growth during the sintering process. These standards are critical for ensuring consistent product quality and reliability in high-precision applications across various industries.

The primary international standards governing MIM component quality include MPIF Standard 35, ASTM B883, and ISO 22068, which establish comprehensive frameworks for testing, inspection, and acceptance criteria. These standards specifically address dimensional tolerances, surface finish requirements, and mechanical property specifications that are directly impacted by sintering-related phenomena.

For shrinkage mapping, quality control protocols typically require manufacturers to implement statistical process control (SPC) methods to monitor and predict dimensional changes. Advanced manufacturers employ digital mapping technologies that create detailed shrinkage profiles for each component geometry, allowing for precise tooling compensation and process parameter optimization. The acceptable shrinkage variation is typically maintained within ±0.3% for critical dimensions.

Distortion control standards mandate multi-point dimensional verification using coordinate measuring machines (CMM) or optical scanning systems. Quality requirements typically specify maximum allowable warpage values based on component geometry complexity, with high-precision applications permitting no more than 0.05mm deviation per 25mm of length. Process validation protocols require manufacturers to demonstrate statistical capability with Cpk values exceeding 1.33 for critical dimensions.

Regarding microstructural quality, standards specify acceptable grain size distributions and homogeneity requirements. ASTM E112 methods are commonly referenced for grain size measurement, with MIM-specific adaptations to account for the unique sintering dynamics. Advanced components often require average grain sizes below 10μm with minimal variation to ensure consistent mechanical properties.

Porosity standards are particularly stringent for MIM components, with most high-performance applications requiring densities exceeding 97% of theoretical. Quality control procedures mandate regular density testing using Archimedes' principle or image analysis of metallographic samples, with statistical sampling plans based on lot sizes and application criticality.

Non-destructive testing (NDT) requirements have become increasingly important in MIM quality standards, with X-ray computed tomography emerging as the preferred method for detecting internal defects without destroying valuable components. These advanced inspection techniques allow manufacturers to validate internal features and detect subtle sintering anomalies that might compromise component performance.

The primary international standards governing MIM component quality include MPIF Standard 35, ASTM B883, and ISO 22068, which establish comprehensive frameworks for testing, inspection, and acceptance criteria. These standards specifically address dimensional tolerances, surface finish requirements, and mechanical property specifications that are directly impacted by sintering-related phenomena.

For shrinkage mapping, quality control protocols typically require manufacturers to implement statistical process control (SPC) methods to monitor and predict dimensional changes. Advanced manufacturers employ digital mapping technologies that create detailed shrinkage profiles for each component geometry, allowing for precise tooling compensation and process parameter optimization. The acceptable shrinkage variation is typically maintained within ±0.3% for critical dimensions.

Distortion control standards mandate multi-point dimensional verification using coordinate measuring machines (CMM) or optical scanning systems. Quality requirements typically specify maximum allowable warpage values based on component geometry complexity, with high-precision applications permitting no more than 0.05mm deviation per 25mm of length. Process validation protocols require manufacturers to demonstrate statistical capability with Cpk values exceeding 1.33 for critical dimensions.

Regarding microstructural quality, standards specify acceptable grain size distributions and homogeneity requirements. ASTM E112 methods are commonly referenced for grain size measurement, with MIM-specific adaptations to account for the unique sintering dynamics. Advanced components often require average grain sizes below 10μm with minimal variation to ensure consistent mechanical properties.

Porosity standards are particularly stringent for MIM components, with most high-performance applications requiring densities exceeding 97% of theoretical. Quality control procedures mandate regular density testing using Archimedes' principle or image analysis of metallographic samples, with statistical sampling plans based on lot sizes and application criticality.

Non-destructive testing (NDT) requirements have become increasingly important in MIM quality standards, with X-ray computed tomography emerging as the preferred method for detecting internal defects without destroying valuable components. These advanced inspection techniques allow manufacturers to validate internal features and detect subtle sintering anomalies that might compromise component performance.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!