Metal Injection Molding Feedstock: Powder Size, Binder Systems And Stability

SEP 16, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

MIM Feedstock Evolution and Objectives

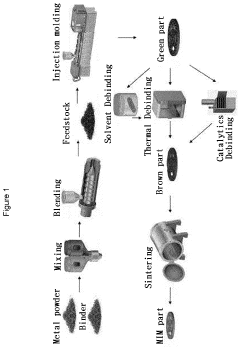

Metal Injection Molding (MIM) technology has evolved significantly since its inception in the 1970s, transforming from an experimental manufacturing process to a sophisticated industrial technique. The evolution of MIM feedstock—the critical mixture of metal powder and binder system—has been central to this transformation. Initially, MIM feedstock formulations were rudimentary, utilizing basic thermoplastic polymers with relatively coarse metal powders, resulting in products with limited mechanical properties and dimensional accuracy.

The 1980s marked a pivotal shift with the introduction of multi-component binder systems, enabling better flow characteristics and debinding processes. By the 1990s, advancements in powder metallurgy facilitated the production of finer metal powders, dramatically improving sintered density and mechanical properties of MIM components. The early 2000s witnessed significant improvements in feedstock homogeneity and stability, addressing persistent issues of separation during molding operations.

Recent developments have focused on nano-sized metal powders, which offer enhanced sintering behavior and superior mechanical properties. Concurrently, environmentally friendly binder systems have emerged, reducing the ecological footprint of MIM operations while maintaining or improving performance characteristics. The integration of computational modeling has further refined feedstock formulations, optimizing rheological properties for increasingly complex geometries.

The current technical landscape presents several challenges, including the need for feedstock stability during extended production runs, consistent rheological behavior across varying temperature ranges, and uniform powder distribution throughout the molded component. These challenges are particularly pronounced when working with ultrafine powders, which exhibit increased surface area and reactivity.

The primary objectives for MIM feedstock development include enhancing the stability of powder-binder mixtures to prevent separation during molding and storage, optimizing binder systems for more efficient debinding without compromising structural integrity, and developing universal methodologies for characterizing feedstock properties across different material systems. Additionally, there is a growing emphasis on reducing variability in feedstock performance between batches, which remains a significant obstacle to wider industrial adoption.

Future research aims to establish standardized protocols for feedstock preparation and quality control, develop novel binder systems compatible with a broader range of metal powders, and create predictive models for feedstock behavior under various processing conditions. The ultimate goal is to enable MIM technology to reliably produce components with complex geometries, tight tolerances, and exceptional mechanical properties across diverse industrial applications.

The 1980s marked a pivotal shift with the introduction of multi-component binder systems, enabling better flow characteristics and debinding processes. By the 1990s, advancements in powder metallurgy facilitated the production of finer metal powders, dramatically improving sintered density and mechanical properties of MIM components. The early 2000s witnessed significant improvements in feedstock homogeneity and stability, addressing persistent issues of separation during molding operations.

Recent developments have focused on nano-sized metal powders, which offer enhanced sintering behavior and superior mechanical properties. Concurrently, environmentally friendly binder systems have emerged, reducing the ecological footprint of MIM operations while maintaining or improving performance characteristics. The integration of computational modeling has further refined feedstock formulations, optimizing rheological properties for increasingly complex geometries.

The current technical landscape presents several challenges, including the need for feedstock stability during extended production runs, consistent rheological behavior across varying temperature ranges, and uniform powder distribution throughout the molded component. These challenges are particularly pronounced when working with ultrafine powders, which exhibit increased surface area and reactivity.

The primary objectives for MIM feedstock development include enhancing the stability of powder-binder mixtures to prevent separation during molding and storage, optimizing binder systems for more efficient debinding without compromising structural integrity, and developing universal methodologies for characterizing feedstock properties across different material systems. Additionally, there is a growing emphasis on reducing variability in feedstock performance between batches, which remains a significant obstacle to wider industrial adoption.

Future research aims to establish standardized protocols for feedstock preparation and quality control, develop novel binder systems compatible with a broader range of metal powders, and create predictive models for feedstock behavior under various processing conditions. The ultimate goal is to enable MIM technology to reliably produce components with complex geometries, tight tolerances, and exceptional mechanical properties across diverse industrial applications.

Market Analysis for MIM Technology Applications

The Metal Injection Molding (MIM) market has experienced significant growth over the past decade, driven by increasing demand for complex, precision metal components across various industries. The global MIM market was valued at approximately 2.9 billion USD in 2021 and is projected to reach 5.4 billion USD by 2028, growing at a CAGR of around 9.3% during the forecast period.

The automotive sector represents the largest application segment for MIM technology, accounting for roughly 35% of the total market share. This dominance is attributed to the automotive industry's continuous pursuit of lightweight, high-performance components that can withstand extreme conditions while reducing overall vehicle weight and improving fuel efficiency. MIM components are widely used in fuel injection systems, turbochargers, transmission systems, and various engine components.

The consumer electronics industry has emerged as the fastest-growing application segment for MIM technology, with a growth rate exceeding 12% annually. The miniaturization trend in electronic devices has created substantial demand for small, complex metal components that can be efficiently produced using MIM processes. Smartphone components, laptop hinges, and wearable device parts are increasingly manufactured using MIM technology.

Medical and healthcare applications represent another significant market segment, accounting for approximately 18% of the global MIM market. The sector's demand is driven by the need for biocompatible, high-precision components for surgical instruments, dental implants, orthopedic devices, and drug delivery systems. The ability of MIM to produce complex geometries with excellent material properties makes it particularly valuable in medical applications.

The aerospace and defense sectors collectively contribute about 15% to the global MIM market. These industries require high-performance components capable of withstanding extreme conditions, where MIM's ability to produce complex parts with superior mechanical properties provides significant advantages over traditional manufacturing methods.

Regional analysis indicates that Asia-Pacific dominates the global MIM market with approximately 45% market share, led by China, Japan, and South Korea. North America and Europe follow with roughly 30% and 20% market shares respectively. The Asia-Pacific region is also expected to witness the highest growth rate due to expanding manufacturing capabilities, increasing industrialization, and growing adoption of advanced manufacturing technologies.

The market analysis clearly indicates that advancements in feedstock technology—specifically in powder size optimization, binder system development, and stability enhancement—will be critical factors driving future market growth and expanding application possibilities for MIM technology across various industries.

The automotive sector represents the largest application segment for MIM technology, accounting for roughly 35% of the total market share. This dominance is attributed to the automotive industry's continuous pursuit of lightweight, high-performance components that can withstand extreme conditions while reducing overall vehicle weight and improving fuel efficiency. MIM components are widely used in fuel injection systems, turbochargers, transmission systems, and various engine components.

The consumer electronics industry has emerged as the fastest-growing application segment for MIM technology, with a growth rate exceeding 12% annually. The miniaturization trend in electronic devices has created substantial demand for small, complex metal components that can be efficiently produced using MIM processes. Smartphone components, laptop hinges, and wearable device parts are increasingly manufactured using MIM technology.

Medical and healthcare applications represent another significant market segment, accounting for approximately 18% of the global MIM market. The sector's demand is driven by the need for biocompatible, high-precision components for surgical instruments, dental implants, orthopedic devices, and drug delivery systems. The ability of MIM to produce complex geometries with excellent material properties makes it particularly valuable in medical applications.

The aerospace and defense sectors collectively contribute about 15% to the global MIM market. These industries require high-performance components capable of withstanding extreme conditions, where MIM's ability to produce complex parts with superior mechanical properties provides significant advantages over traditional manufacturing methods.

Regional analysis indicates that Asia-Pacific dominates the global MIM market with approximately 45% market share, led by China, Japan, and South Korea. North America and Europe follow with roughly 30% and 20% market shares respectively. The Asia-Pacific region is also expected to witness the highest growth rate due to expanding manufacturing capabilities, increasing industrialization, and growing adoption of advanced manufacturing technologies.

The market analysis clearly indicates that advancements in feedstock technology—specifically in powder size optimization, binder system development, and stability enhancement—will be critical factors driving future market growth and expanding application possibilities for MIM technology across various industries.

Current Challenges in Powder-Binder Systems

The metal injection molding (MIM) industry currently faces several significant challenges related to powder-binder systems that limit production efficiency and end-product quality. One primary issue is the inconsistent rheological behavior of feedstock materials, which directly impacts flow characteristics during the injection process. Variations in viscosity and flow properties can lead to defects such as weld lines, voids, and internal stresses in the final components, particularly when processing complex geometries with thin walls or intricate features.

Powder characteristics present another major challenge, specifically regarding particle size distribution and morphology. While finer powders (typically <20 μm) enable better sintering and higher final densities, they simultaneously increase surface area, leading to higher binder requirements and more challenging debinding processes. The industry struggles to establish optimal powder loading thresholds that balance moldability against final part density and dimensional accuracy.

Binder system stability remains problematic across varying production conditions. Temperature fluctuations during processing can cause phase separation between powder and binder components, resulting in powder-binder segregation that creates density gradients in molded parts. This segregation issue becomes particularly pronounced during extended production runs or when feedstock is subjected to multiple reprocessing cycles, significantly affecting batch-to-batch consistency.

Environmental and regulatory constraints have intensified challenges in binder formulation. Traditional binder systems often contain components like paraffin wax, polyethylene, and stearic acid, but increasing restrictions on volatile organic compounds (VOCs) and hazardous substances are forcing manufacturers to develop alternative formulations with comparable performance characteristics but reduced environmental impact.

The debinding process presents technical difficulties that directly correlate with binder system design. Multi-component binder systems require precisely controlled sequential debinding steps, where incomplete removal of primary binders before thermal debinding can cause defects like blistering or cracking. The industry lacks standardized protocols for optimizing debinding cycles across different powder-binder combinations.

Shelf life limitations of prepared feedstock materials create logistical challenges for manufacturers. Oxidation of metal powders, moisture absorption, and binder degradation over time can significantly alter feedstock properties, necessitating strict storage conditions and potentially limiting production flexibility. This issue becomes particularly critical for specialized applications requiring small production volumes with intermittent manufacturing schedules.

Compatibility issues between different powder types and binder systems further complicate material selection. Novel metal alloys or specialized powders often require customized binder formulations to achieve optimal rheological properties and debinding characteristics, creating barriers to rapid implementation of new materials in existing production processes.

Powder characteristics present another major challenge, specifically regarding particle size distribution and morphology. While finer powders (typically <20 μm) enable better sintering and higher final densities, they simultaneously increase surface area, leading to higher binder requirements and more challenging debinding processes. The industry struggles to establish optimal powder loading thresholds that balance moldability against final part density and dimensional accuracy.

Binder system stability remains problematic across varying production conditions. Temperature fluctuations during processing can cause phase separation between powder and binder components, resulting in powder-binder segregation that creates density gradients in molded parts. This segregation issue becomes particularly pronounced during extended production runs or when feedstock is subjected to multiple reprocessing cycles, significantly affecting batch-to-batch consistency.

Environmental and regulatory constraints have intensified challenges in binder formulation. Traditional binder systems often contain components like paraffin wax, polyethylene, and stearic acid, but increasing restrictions on volatile organic compounds (VOCs) and hazardous substances are forcing manufacturers to develop alternative formulations with comparable performance characteristics but reduced environmental impact.

The debinding process presents technical difficulties that directly correlate with binder system design. Multi-component binder systems require precisely controlled sequential debinding steps, where incomplete removal of primary binders before thermal debinding can cause defects like blistering or cracking. The industry lacks standardized protocols for optimizing debinding cycles across different powder-binder combinations.

Shelf life limitations of prepared feedstock materials create logistical challenges for manufacturers. Oxidation of metal powders, moisture absorption, and binder degradation over time can significantly alter feedstock properties, necessitating strict storage conditions and potentially limiting production flexibility. This issue becomes particularly critical for specialized applications requiring small production volumes with intermittent manufacturing schedules.

Compatibility issues between different powder types and binder systems further complicate material selection. Novel metal alloys or specialized powders often require customized binder formulations to achieve optimal rheological properties and debinding characteristics, creating barriers to rapid implementation of new materials in existing production processes.

State-of-the-Art Feedstock Formulations

01 Optimal powder size for metal injection molding

The size of metal powders used in injection molding significantly impacts the quality of the final product. Typically, fine powders with particle sizes ranging from 1-20 microns are preferred as they provide better flowability and higher packing density. Smaller particles also result in reduced shrinkage during sintering and improved mechanical properties of the final component. However, extremely fine powders may cause handling issues and increased viscosity in the feedstock.- Optimal powder size distributions for MIM feedstock: Metal injection molding feedstock requires specific powder size distributions to achieve optimal flow properties and final part density. Typically, fine metal powders with particle sizes ranging from 0.5 to 20 microns are preferred, with many formulations focusing on 2-10 micron ranges. Bimodal or multimodal distributions can improve packing density and reduce viscosity during injection. The powder size directly impacts sintering behavior, surface finish quality, and mechanical properties of the final parts.

- Polymer-based binder systems and compositions: Effective binder systems for MIM typically consist of multiple components including primary polymers (such as polyethylene, polypropylene, or polyacetal), secondary polymers, waxes, and surfactants. These multi-component binder systems provide balanced rheological properties during molding and controlled removal during debinding. The polymer components provide structural integrity during molding while waxes reduce viscosity and improve flowability. Surfactants improve the interaction between the metal powder and organic components, enhancing homogeneity and stability of the feedstock.

- Environmentally friendly and water-soluble binder systems: Water-soluble and environmentally friendly binder systems have been developed to address environmental concerns in MIM processing. These systems typically incorporate polyethylene glycol (PEG), polyvinyl alcohol (PVA), or other water-soluble polymers as primary components. The water-soluble portion facilitates easier and cleaner primary debinding, reducing the use of hazardous solvents. These binder systems offer advantages including reduced environmental impact, safer handling, faster debinding cycles, and lower processing costs while maintaining adequate mechanical properties during molding.

- Feedstock stability and homogeneity enhancement: Maintaining stability and homogeneity in MIM feedstock is critical for consistent part quality. Techniques to enhance stability include proper selection of dispersants and coupling agents that improve powder-binder interactions, preventing separation during storage and processing. Specialized mixing protocols involving high-shear mixing, temperature control, and vacuum processing help achieve uniform distribution of powder in the binder matrix. Stability testing methods such as rheological measurements over time, thermal cycling tests, and storage stability evaluations are employed to ensure feedstock quality and processability is maintained throughout its shelf life.

- Advanced feedstock formulations for specialized applications: Advanced MIM feedstock formulations have been developed for specialized applications requiring enhanced properties. These include nano-powder reinforced feedstocks for improved mechanical properties, low-viscosity formulations for complex thin-walled components, and custom binder systems for reactive or sensitive metal powders like titanium and aluminum. Additives such as antioxidants and process control agents are incorporated to prevent oxidation and improve processing characteristics. These specialized formulations often require tailored debinding and sintering profiles to achieve optimal results in demanding applications such as aerospace, medical implants, and high-performance consumer electronics.

02 Binder system compositions for MIM feedstock

Binder systems typically consist of multiple components including primary binders (polymers like polyethylene, polypropylene), secondary binders (waxes), and additives (surfactants, plasticizers). Multi-component binder systems offer advantages in terms of processing flexibility and debinding efficiency. The binder composition must provide adequate flowability during injection while maintaining shape retention after molding. Common formulations include combinations of thermoplastic polymers with waxes and surfactants to optimize both processing characteristics and final part properties.Expand Specific Solutions03 Feedstock stability and homogeneity considerations

Maintaining stability and homogeneity of the metal-binder mixture is crucial for consistent part quality. Proper mixing techniques and equipment are essential to ensure uniform distribution of metal particles within the binder matrix. Factors affecting stability include storage conditions, temperature fluctuations, and aging effects. Stabilizers and coupling agents are often incorporated to prevent separation of components and maintain consistent rheological properties over time. Homogeneous feedstock results in uniform shrinkage and minimizes defects in the final sintered parts.Expand Specific Solutions04 Debinding processes and binder removal techniques

Effective debinding is critical in MIM processing and is influenced by binder system design. Sequential debinding approaches are commonly employed, where different components of the binder system are removed in stages. Techniques include solvent debinding, thermal debinding, and catalytic debinding. The binder system must be engineered to allow controlled removal without causing defects like blistering or cracking. Proper debinding parameters and schedules are essential to maintain dimensional stability and structural integrity before sintering.Expand Specific Solutions05 Rheological properties and flow behavior optimization

The rheological properties of MIM feedstock determine its processability during injection molding. Key parameters include viscosity, shear sensitivity, and melt flow index. The powder loading (typically 55-65% by volume) must be optimized to achieve adequate flow while maximizing metal content. Additives such as plasticizers and flow modifiers are used to adjust rheological behavior. Temperature-dependent viscosity characteristics must be carefully controlled to ensure complete mold filling without separation of powder and binder components during the injection process.Expand Specific Solutions

Industry Leaders and Competitive Landscape

Metal Injection Molding (MIM) feedstock technology is currently in a growth phase, with the global market expected to reach $4.5 billion by 2025. The industry is characterized by increasing technical maturity, particularly in powder size optimization and binder system development. Leading companies like Höganäs AB, BASF Corp., and Headmade Materials GmbH are driving innovation in powder metallurgy, while Jiangsu Gian Technology and Advanced Materials Technologies focus on application-specific solutions. The competitive landscape shows a mix of established materials giants and specialized MIM providers, with recent advancements in nano-sized powders and environmentally friendly binder systems improving component stability and performance. Research collaborations between industry leaders and institutions like Korea Institute of Industrial Technology are accelerating technical refinements in feedstock formulations.

Höganäs AB

Technical Solution: Höganäs AB has developed advanced metal injection molding (MIM) feedstock systems focusing on optimized powder size distribution and innovative binder formulations. Their technology utilizes fine metal powders (typically 2-20 μm) with carefully controlled particle morphology to achieve high packing density. Their proprietary multi-component binder system combines primary polymers (typically polyethylene or polypropylene) with secondary components like waxes and surfactants to create a balanced rheological profile. Höganäs has pioneered temperature-sensitive binder systems that maintain stability during molding but allow efficient debinding through staged thermal processes. Their feedstock formulations typically contain 60-65% metal powder by volume, optimized for minimal viscosity fluctuation across processing temperatures. The company has also developed specialized additives that enhance powder-binder interaction, reducing separation issues during high-pressure injection and improving green strength of molded components.

Strengths: Superior powder metallurgy expertise with exceptional particle size control leading to higher density finished parts and reduced shrinkage variability. Their binder systems demonstrate excellent thermal stability and consistent rheological properties. Weaknesses: Their premium feedstock systems typically command higher prices than competitors, and some formulations may require more specialized debinding equipment.

BASF Corp.

Technical Solution: BASF Corp. has developed the Catamold® system, a revolutionary approach to metal injection molding feedstock that addresses key challenges in powder size optimization and binder stability. Their technology utilizes ultra-fine metal powders (typically 1-20 μm) combined with their proprietary polyacetal-based binder system. This catalytic debinding approach allows for rapid removal of the binder through a chemical reaction rather than traditional thermal processes. BASF's feedstock maintains exceptional stability through precise control of powder surface chemistry and specialized coupling agents that create strong interfaces between the metal particles and polymer matrix. Their formulations typically contain metal loadings of 60-65% by volume, carefully balanced to maintain flow properties while maximizing final density. The company has engineered their feedstock to minimize powder-binder separation during molding by incorporating rheology modifiers that create thixotropic behavior - allowing the material to flow under injection pressure but resist separation at rest. This technology enables complex geometries with wall thicknesses down to 0.3mm while maintaining dimensional stability.

Strengths: Catamold's catalytic debinding technology significantly reduces processing time compared to conventional thermal debinding methods. Their feedstock demonstrates exceptional batch-to-batch consistency and long shelf life. Weaknesses: The catalytic debinding process requires specialized equipment and handling of nitric acid catalysts, creating additional safety considerations. The system is less flexible for custom formulations compared to some competitors.

Critical Patents in Powder-Binder Compatibility

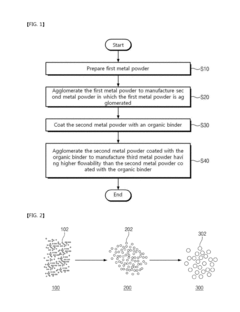

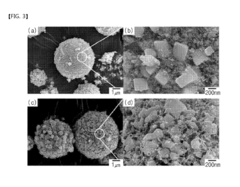

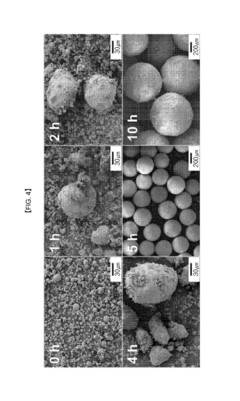

Metal powder, feedstock, and preparation method therefor

PatentActiveUS20170326641A1

Innovation

- The method involves agglomerating and coating metal powders to increase their size and flowability, using a low-melting-point binder and surfactant in feedstock for powder injection molding, allowing for improved handling and moldability, and enabling the production of high-strength, dense molded products at low temperatures and pressures.

Binder composition for metal powder injection molding

PatentPendingUS20220372282A1

Innovation

- A binder composition for metal powder injection molding comprising 10 to 50 wt % high-viscosity polyoxymethylene polymer and 50 to 90 wt % low-viscosity polyoxymethylene polymer, without the use of additional monomers, is developed, along with a feedstock composition including a sinterable inorganic material, to enhance injection and debinding characteristics.

Material Characterization Techniques

Effective characterization of Metal Injection Molding (MIM) feedstock components is crucial for process optimization and quality control. Particle size analysis of metal powders typically employs laser diffraction techniques, which provide rapid and accurate size distribution measurements ranging from nanometers to millimeters. This method is particularly valuable for MIM applications where powder size directly impacts packing density and sintering behavior. Complementary techniques include scanning electron microscopy (SEM) for visual confirmation of particle morphology and dynamic light scattering for nanoscale particles.

Rheological characterization represents another essential aspect of feedstock analysis, typically conducted using capillary rheometers and rotational viscometers. These instruments measure viscosity as a function of shear rate, temperature, and time—critical parameters for predicting flow behavior during injection molding. Thermal analysis techniques, particularly differential scanning calorimetry (DSC) and thermogravimetric analysis (TGA), provide valuable insights into binder melting points, decomposition temperatures, and phase transitions.

For binder system characterization, Fourier Transform Infrared Spectroscopy (FTIR) enables identification of organic components through their characteristic absorption bands. Gas chromatography-mass spectrometry (GC-MS) offers complementary information on binder composition, especially useful for proprietary formulations. X-ray diffraction (XRD) primarily characterizes the crystalline structure of metal powders but can also detect crystalline components in certain binder systems.

Stability assessment of MIM feedstock requires specialized techniques such as accelerated aging tests under controlled temperature and humidity conditions. Melt flow index (MFI) measurements before and after aging provide quantitative data on rheological stability. Thermomechanical analysis (TMA) can detect dimensional changes during thermal cycling, indicating potential issues during processing.

Advanced characterization methods include micro-computed tomography (micro-CT) for non-destructive 3D visualization of powder distribution within the binder matrix. This technique reveals internal defects such as agglomerations or voids that may compromise part quality. Nuclear magnetic resonance (NMR) spectroscopy offers detailed structural information about polymer-based binders, while dynamic mechanical analysis (DMA) evaluates viscoelastic properties across temperature ranges relevant to processing conditions.

Surface analysis techniques such as X-ray photoelectron spectroscopy (XPS) and time-of-flight secondary ion mass spectrometry (ToF-SIMS) provide information about surface chemistry and potential contamination that might affect binder-powder interactions. These sophisticated methods are particularly valuable when troubleshooting adhesion issues or unexpected feedstock behavior.

Rheological characterization represents another essential aspect of feedstock analysis, typically conducted using capillary rheometers and rotational viscometers. These instruments measure viscosity as a function of shear rate, temperature, and time—critical parameters for predicting flow behavior during injection molding. Thermal analysis techniques, particularly differential scanning calorimetry (DSC) and thermogravimetric analysis (TGA), provide valuable insights into binder melting points, decomposition temperatures, and phase transitions.

For binder system characterization, Fourier Transform Infrared Spectroscopy (FTIR) enables identification of organic components through their characteristic absorption bands. Gas chromatography-mass spectrometry (GC-MS) offers complementary information on binder composition, especially useful for proprietary formulations. X-ray diffraction (XRD) primarily characterizes the crystalline structure of metal powders but can also detect crystalline components in certain binder systems.

Stability assessment of MIM feedstock requires specialized techniques such as accelerated aging tests under controlled temperature and humidity conditions. Melt flow index (MFI) measurements before and after aging provide quantitative data on rheological stability. Thermomechanical analysis (TMA) can detect dimensional changes during thermal cycling, indicating potential issues during processing.

Advanced characterization methods include micro-computed tomography (micro-CT) for non-destructive 3D visualization of powder distribution within the binder matrix. This technique reveals internal defects such as agglomerations or voids that may compromise part quality. Nuclear magnetic resonance (NMR) spectroscopy offers detailed structural information about polymer-based binders, while dynamic mechanical analysis (DMA) evaluates viscoelastic properties across temperature ranges relevant to processing conditions.

Surface analysis techniques such as X-ray photoelectron spectroscopy (XPS) and time-of-flight secondary ion mass spectrometry (ToF-SIMS) provide information about surface chemistry and potential contamination that might affect binder-powder interactions. These sophisticated methods are particularly valuable when troubleshooting adhesion issues or unexpected feedstock behavior.

Environmental Impact and Sustainability Considerations

The environmental impact of Metal Injection Molding (MIM) processes has become increasingly significant as industries strive for more sustainable manufacturing methods. The feedstock composition, particularly the powder size and binder systems, directly influences the ecological footprint of MIM operations. Smaller powder particles typically require more energy-intensive production methods, contributing to higher carbon emissions during the manufacturing phase. However, they also enable more efficient sintering processes, potentially reducing overall energy consumption in subsequent production stages.

Binder systems present complex environmental considerations. Traditional petroleum-based binders contribute to resource depletion and generate harmful emissions during debinding. Water-soluble binders offer improved environmental profiles but may introduce water contamination risks if effluent treatment is inadequate. Recent developments in bio-based binders derived from renewable resources show promise in reducing the carbon footprint of MIM processes, though their stability and performance characteristics still require optimization for widespread industrial adoption.

Waste generation throughout the MIM lifecycle presents another critical environmental concern. Material losses during mixing, injection, and post-processing contribute to resource inefficiency. The stability of MIM feedstock directly impacts waste generation—unstable feedstocks lead to higher rejection rates and increased material consumption. Implementing closed-loop recycling systems for metal powders and developing biodegradable binder components can significantly reduce waste volumes and associated environmental impacts.

Energy consumption patterns in MIM processes vary considerably based on feedstock properties. Finer powder sizes generally require lower sintering temperatures but may necessitate more precise temperature control systems. The thermal decomposition profiles of different binder systems also influence energy requirements during debinding. Optimizing these parameters can lead to substantial energy savings and reduced greenhouse gas emissions.

Regulatory frameworks increasingly address the environmental aspects of MIM production. REACH regulations in Europe and similar initiatives globally have placed restrictions on certain binder components with adverse environmental or health effects. Forward-thinking manufacturers are proactively reformulating feedstocks to eliminate potentially harmful substances before regulatory intervention, gaining competitive advantages through environmental compliance.

Life cycle assessment (LCA) studies comparing MIM with conventional manufacturing techniques generally demonstrate environmental advantages for MIM in complex component production, particularly when considering material efficiency and energy consumption across the entire product lifecycle. However, these benefits depend heavily on feedstock formulation and process optimization, highlighting the importance of environmentally conscious design decisions in MIM feedstock development.

Binder systems present complex environmental considerations. Traditional petroleum-based binders contribute to resource depletion and generate harmful emissions during debinding. Water-soluble binders offer improved environmental profiles but may introduce water contamination risks if effluent treatment is inadequate. Recent developments in bio-based binders derived from renewable resources show promise in reducing the carbon footprint of MIM processes, though their stability and performance characteristics still require optimization for widespread industrial adoption.

Waste generation throughout the MIM lifecycle presents another critical environmental concern. Material losses during mixing, injection, and post-processing contribute to resource inefficiency. The stability of MIM feedstock directly impacts waste generation—unstable feedstocks lead to higher rejection rates and increased material consumption. Implementing closed-loop recycling systems for metal powders and developing biodegradable binder components can significantly reduce waste volumes and associated environmental impacts.

Energy consumption patterns in MIM processes vary considerably based on feedstock properties. Finer powder sizes generally require lower sintering temperatures but may necessitate more precise temperature control systems. The thermal decomposition profiles of different binder systems also influence energy requirements during debinding. Optimizing these parameters can lead to substantial energy savings and reduced greenhouse gas emissions.

Regulatory frameworks increasingly address the environmental aspects of MIM production. REACH regulations in Europe and similar initiatives globally have placed restrictions on certain binder components with adverse environmental or health effects. Forward-thinking manufacturers are proactively reformulating feedstocks to eliminate potentially harmful substances before regulatory intervention, gaining competitive advantages through environmental compliance.

Life cycle assessment (LCA) studies comparing MIM with conventional manufacturing techniques generally demonstrate environmental advantages for MIM in complex component production, particularly when considering material efficiency and energy consumption across the entire product lifecycle. However, these benefits depend heavily on feedstock formulation and process optimization, highlighting the importance of environmentally conscious design decisions in MIM feedstock development.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!