Metal Injection Molding Vs CNC Machining: Complexity, Tolerance And Cost At Scale

SEP 16, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

MIM vs CNC: Historical Development and Objectives

Metal Injection Molding (MIM) and Computer Numerical Control (CNC) machining represent two distinct manufacturing approaches that have evolved along different technological trajectories. MIM emerged in the 1970s as an offshoot of powder metallurgy and plastic injection molding technologies. The process was developed to combine the material advantages of powder metallurgy with the complex shaping capabilities of plastic injection molding. Early MIM applications were primarily focused on small, complex parts for firearms and medical devices where traditional manufacturing methods proved either too costly or technically unfeasible.

CNC machining, by contrast, has a longer industrial history, with numerical control concepts dating back to the 1940s and 1950s. The technology saw significant advancement in the 1970s and 1980s with the integration of computer systems, transforming manual machining processes into highly automated operations. This evolution enabled manufacturers to achieve unprecedented precision and repeatability in subtractive manufacturing processes.

The technological evolution of both methods has been driven by increasing demands for precision, complexity, and cost-effectiveness in component manufacturing. MIM has progressively improved in material options, dimensional accuracy, and surface finish capabilities. Modern MIM processes can achieve near-net-shape components with minimal secondary operations, significantly reducing production costs for complex geometries at high volumes.

Similarly, CNC technology has advanced through enhanced machine capabilities, multi-axis operations, and sophisticated CAM software development. These improvements have expanded the range of achievable geometries while reducing setup times and increasing production efficiency. The integration of automation and robotics has further enhanced CNC's position in modern manufacturing ecosystems.

The primary objective in comparing these technologies is to establish a comprehensive framework for manufacturing decision-making based on part complexity requirements, dimensional tolerance specifications, and production volume considerations. This analysis aims to identify the optimal manufacturing approach for specific applications, recognizing that each technology offers distinct advantages depending on the particular combination of these factors.

Understanding the historical context and technological trajectory of both MIM and CNC machining provides essential insights into their current capabilities and limitations. This historical perspective also informs predictions about future developments in these technologies, particularly as they adapt to emerging materials, sustainability requirements, and evolving market demands for increasingly sophisticated components across industries including aerospace, automotive, medical, and consumer electronics.

CNC machining, by contrast, has a longer industrial history, with numerical control concepts dating back to the 1940s and 1950s. The technology saw significant advancement in the 1970s and 1980s with the integration of computer systems, transforming manual machining processes into highly automated operations. This evolution enabled manufacturers to achieve unprecedented precision and repeatability in subtractive manufacturing processes.

The technological evolution of both methods has been driven by increasing demands for precision, complexity, and cost-effectiveness in component manufacturing. MIM has progressively improved in material options, dimensional accuracy, and surface finish capabilities. Modern MIM processes can achieve near-net-shape components with minimal secondary operations, significantly reducing production costs for complex geometries at high volumes.

Similarly, CNC technology has advanced through enhanced machine capabilities, multi-axis operations, and sophisticated CAM software development. These improvements have expanded the range of achievable geometries while reducing setup times and increasing production efficiency. The integration of automation and robotics has further enhanced CNC's position in modern manufacturing ecosystems.

The primary objective in comparing these technologies is to establish a comprehensive framework for manufacturing decision-making based on part complexity requirements, dimensional tolerance specifications, and production volume considerations. This analysis aims to identify the optimal manufacturing approach for specific applications, recognizing that each technology offers distinct advantages depending on the particular combination of these factors.

Understanding the historical context and technological trajectory of both MIM and CNC machining provides essential insights into their current capabilities and limitations. This historical perspective also informs predictions about future developments in these technologies, particularly as they adapt to emerging materials, sustainability requirements, and evolving market demands for increasingly sophisticated components across industries including aerospace, automotive, medical, and consumer electronics.

Market Demand Analysis for Precision Manufacturing Technologies

The precision manufacturing market is experiencing robust growth driven by increasing demand for complex components with tight tolerances across multiple industries. The global precision manufacturing market was valued at $212 billion in 2022 and is projected to reach $341 billion by 2030, growing at a CAGR of 6.1% during the forecast period.

Metal Injection Molding (MIM) and CNC machining represent two distinct approaches to precision manufacturing, each addressing different market segments and requirements. The MIM market specifically is expanding rapidly, with particular strength in automotive, aerospace, medical devices, and consumer electronics sectors where complex geometries and high-volume production are essential.

The automotive industry remains the largest consumer of precision manufacturing technologies, accounting for approximately 28% of the market share. This sector demands both MIM and CNC solutions for different applications - MIM for complex internal engine components and CNC for larger precision parts requiring exceptional tolerances.

Medical device manufacturing represents the fastest-growing segment, with a projected growth rate of 8.7% through 2030. This sector increasingly favors MIM for small, intricate components like surgical instruments and implantable devices, where complexity and biocompatibility are paramount concerns.

Consumer electronics manufacturers are shifting toward MIM for miniaturized components, driven by the continuous trend toward smaller, more feature-rich devices. This segment values MIM's ability to produce complex geometries at scale while maintaining tight tolerances.

Regional analysis reveals Asia-Pacific as the dominant market for precision manufacturing technologies, accounting for 41% of global demand. This is primarily due to the concentration of electronics manufacturing and automotive production facilities in countries like China, Japan, and South Korea. North America and Europe follow with 27% and 24% market shares respectively, with stronger emphasis on high-precision CNC applications for aerospace and medical devices.

Market research indicates a growing preference for manufacturing technologies that can balance complexity, tolerance, and cost-effectiveness at scale. While CNC machining continues to dominate applications requiring extremely tight tolerances (±0.0005 inches or better), MIM is rapidly gaining market share in applications requiring medium tolerances (±0.003 inches) with complex geometries produced at high volumes.

The market is increasingly demanding hybrid manufacturing approaches that leverage the strengths of both technologies, creating opportunities for manufacturers who can offer integrated solutions that optimize for complexity, tolerance, and cost based on specific application requirements.

Metal Injection Molding (MIM) and CNC machining represent two distinct approaches to precision manufacturing, each addressing different market segments and requirements. The MIM market specifically is expanding rapidly, with particular strength in automotive, aerospace, medical devices, and consumer electronics sectors where complex geometries and high-volume production are essential.

The automotive industry remains the largest consumer of precision manufacturing technologies, accounting for approximately 28% of the market share. This sector demands both MIM and CNC solutions for different applications - MIM for complex internal engine components and CNC for larger precision parts requiring exceptional tolerances.

Medical device manufacturing represents the fastest-growing segment, with a projected growth rate of 8.7% through 2030. This sector increasingly favors MIM for small, intricate components like surgical instruments and implantable devices, where complexity and biocompatibility are paramount concerns.

Consumer electronics manufacturers are shifting toward MIM for miniaturized components, driven by the continuous trend toward smaller, more feature-rich devices. This segment values MIM's ability to produce complex geometries at scale while maintaining tight tolerances.

Regional analysis reveals Asia-Pacific as the dominant market for precision manufacturing technologies, accounting for 41% of global demand. This is primarily due to the concentration of electronics manufacturing and automotive production facilities in countries like China, Japan, and South Korea. North America and Europe follow with 27% and 24% market shares respectively, with stronger emphasis on high-precision CNC applications for aerospace and medical devices.

Market research indicates a growing preference for manufacturing technologies that can balance complexity, tolerance, and cost-effectiveness at scale. While CNC machining continues to dominate applications requiring extremely tight tolerances (±0.0005 inches or better), MIM is rapidly gaining market share in applications requiring medium tolerances (±0.003 inches) with complex geometries produced at high volumes.

The market is increasingly demanding hybrid manufacturing approaches that leverage the strengths of both technologies, creating opportunities for manufacturers who can offer integrated solutions that optimize for complexity, tolerance, and cost based on specific application requirements.

Technical Limitations and Challenges in Metal Forming Processes

Metal Injection Molding (MIM) and CNC machining represent two distinct approaches to metal forming, each with inherent technical limitations that impact their applicability across different manufacturing scenarios. MIM processes face significant challenges in material selection, as not all metal alloys are suitable for the powder metallurgy approach required. The binder systems used in MIM can introduce impurities that affect the final material properties, potentially compromising structural integrity in high-stress applications.

The sintering phase in MIM introduces dimensional control challenges, with typical tolerances ranging from ±0.3% to ±0.5% of the nominal dimension. This limitation becomes particularly problematic for precision components where tight tolerances below ±0.05mm are required. Additionally, MIM exhibits anisotropic shrinkage during sintering, creating inconsistent dimensional changes across different axes of the component.

Surface finish quality in MIM depends heavily on powder characteristics and mold surface quality. While capable of producing good surface finishes (1.6-3.2 μm Ra), achieving mirror-like finishes often requires secondary operations, adding complexity and cost to the manufacturing process. MIM also struggles with large components (typically limited to under 100g) due to difficulties in maintaining uniform density during injection and consistent shrinkage during sintering.

CNC machining, while offering superior precision (tolerances as tight as ±0.01mm), faces its own set of technical constraints. Complex internal geometries present significant challenges, as tool accessibility limitations restrict the creation of certain features. The subtractive nature of CNC machining results in substantial material waste, particularly problematic with expensive alloys or materials with high embodied energy.

Tool wear represents another significant challenge in CNC operations, especially when machining hardened materials or superalloys. Progressive tool degradation can lead to dimensional inconsistencies across production runs and increased production costs due to frequent tool replacements. Additionally, CNC machining struggles with thin-walled structures (below 0.5mm) due to workpiece deflection during cutting operations.

The economic viability threshold between these technologies shifts dramatically with production volume. MIM typically becomes cost-effective at volumes exceeding 10,000 units, while CNC machining maintains cost advantages at lower production quantities. This crossover point varies significantly based on part complexity, material selection, and tolerance requirements, creating a complex decision matrix for manufacturing engineers.

The sintering phase in MIM introduces dimensional control challenges, with typical tolerances ranging from ±0.3% to ±0.5% of the nominal dimension. This limitation becomes particularly problematic for precision components where tight tolerances below ±0.05mm are required. Additionally, MIM exhibits anisotropic shrinkage during sintering, creating inconsistent dimensional changes across different axes of the component.

Surface finish quality in MIM depends heavily on powder characteristics and mold surface quality. While capable of producing good surface finishes (1.6-3.2 μm Ra), achieving mirror-like finishes often requires secondary operations, adding complexity and cost to the manufacturing process. MIM also struggles with large components (typically limited to under 100g) due to difficulties in maintaining uniform density during injection and consistent shrinkage during sintering.

CNC machining, while offering superior precision (tolerances as tight as ±0.01mm), faces its own set of technical constraints. Complex internal geometries present significant challenges, as tool accessibility limitations restrict the creation of certain features. The subtractive nature of CNC machining results in substantial material waste, particularly problematic with expensive alloys or materials with high embodied energy.

Tool wear represents another significant challenge in CNC operations, especially when machining hardened materials or superalloys. Progressive tool degradation can lead to dimensional inconsistencies across production runs and increased production costs due to frequent tool replacements. Additionally, CNC machining struggles with thin-walled structures (below 0.5mm) due to workpiece deflection during cutting operations.

The economic viability threshold between these technologies shifts dramatically with production volume. MIM typically becomes cost-effective at volumes exceeding 10,000 units, while CNC machining maintains cost advantages at lower production quantities. This crossover point varies significantly based on part complexity, material selection, and tolerance requirements, creating a complex decision matrix for manufacturing engineers.

Current Technical Solutions for Complex Metal Components

01 Complexity comparison between MIM and CNC machining

Metal Injection Molding (MIM) allows for the production of complex geometries that would be difficult or impossible to achieve with traditional CNC machining. MIM can create intricate internal features, undercuts, and complex 3D structures in a single process, whereas CNC machining may require multiple setups and operations for similar complexity. MIM is particularly advantageous for small, complex parts with detailed features, while CNC machining excels at larger components with simpler geometries or where specific surface finishes are required.- Complexity comparison between MIM and CNC machining: Metal Injection Molding (MIM) allows for the production of complex geometries that would be difficult or impossible to achieve with traditional CNC machining. MIM can create intricate internal features, undercuts, and complex 3D structures in a single process, whereas CNC machining may require multiple setups and operations for similar complexity. MIM is particularly advantageous for small, complex parts with detailed features, while CNC machining excels at larger components with simpler geometries or when high precision is required for specific features.

- Tolerance capabilities and precision control: CNC machining generally offers superior dimensional accuracy and tighter tolerances compared to Metal Injection Molding. CNC processes can typically achieve tolerances of ±0.025mm or better, while standard MIM processes usually provide tolerances of ±0.3% of the dimension or ±0.08mm. However, advanced MIM techniques with secondary operations can improve precision. CNC machining provides better surface finish and dimensional stability, making it preferred for applications requiring high precision. MIM parts may experience some shrinkage during sintering that must be accounted for in the design phase.

- Cost factors and economic considerations: MIM typically offers cost advantages for high-volume production of small, complex parts due to minimal material waste and high production rates. The initial tooling costs for MIM are high, but unit costs decrease significantly with volume. CNC machining has lower setup costs but higher per-unit costs due to material waste, longer processing times, and skilled labor requirements. The economic crossover point between these technologies depends on part complexity, size, material, and production volume. For low to medium volumes, CNC machining is often more economical, while MIM becomes more cost-effective at higher volumes, typically above 10,000 units.

- Material selection and properties: MIM can process a wide range of metals and alloys including stainless steel, tool steel, titanium, and various alloys, producing parts with 95-99% of theoretical density. The sintering process in MIM can result in uniform material properties throughout the part. CNC machining can work with virtually any machinable material including metals, plastics, and composites, and preserves the original material properties since no phase changes occur during processing. Material selection impacts both processes differently - with MIM requiring specific powder characteristics, while CNC machining considerations include machinability, tool wear, and cutting parameters.

- Hybrid manufacturing approaches: Combining MIM and CNC machining in hybrid manufacturing approaches can leverage the advantages of both technologies. MIM can be used for creating near-net shape parts with complex geometries, followed by selective CNC machining of critical features requiring tighter tolerances. This hybrid approach optimizes production by reducing material waste and machining time while achieving necessary precision where required. Advanced manufacturing facilities are increasingly implementing these complementary processes to optimize production efficiency, particularly for components with varying tolerance requirements across different features.

02 Tolerance capabilities and precision control

CNC machining generally offers superior dimensional accuracy and tighter tolerances compared to MIM. While modern MIM processes have improved significantly, they typically achieve tolerances of ±0.3-0.5% of the dimension, whereas CNC machining can routinely achieve tolerances of ±0.025-0.05mm. The shrinkage that occurs during the sintering phase of MIM can introduce variability that must be accounted for in design. CNC machining provides more consistent results for applications requiring precise dimensions and critical tolerances, though at higher cost for complex geometries.Expand Specific Solutions03 Cost factors and economic considerations

MIM typically offers cost advantages for medium to high-volume production of small, complex parts. The initial tooling investment for MIM is high, but unit costs decrease significantly as production volumes increase. CNC machining has lower setup costs but higher per-unit costs due to material waste, longer processing times, and labor requirements. The economic crossover point between these technologies depends on part complexity, size, material, and production volume. For simple geometries or low volumes, CNC machining is often more economical, while MIM becomes increasingly cost-effective as complexity increases and production volumes rise.Expand Specific Solutions04 Material selection and properties

MIM can process a wide range of metal alloys including stainless steels, tool steels, titanium alloys, and some superalloys. The sintering process in MIM results in near-full density parts with mechanical properties approaching those of wrought materials. CNC machining offers even broader material flexibility, working with virtually any machinable metal, and preserves the original material properties since no phase changes occur during processing. Material selection impacts both cost and performance, with certain specialized alloys being more suitable for one process over the other based on machinability or MIM processability.Expand Specific Solutions05 Hybrid manufacturing approaches

Innovative hybrid approaches combine MIM and CNC machining to leverage the advantages of both technologies. These methods typically use MIM to create near-net-shape parts with complex geometries, followed by selective CNC machining of critical surfaces requiring tighter tolerances. This hybrid approach optimizes cost-effectiveness while meeting stringent performance requirements. Advanced process control systems and simulation tools help manufacturers determine the optimal manufacturing strategy for specific components, balancing complexity, tolerance requirements, and cost considerations.Expand Specific Solutions

Industry Leaders in MIM and CNC Manufacturing

Metal Injection Molding (MIM) and CNC Machining are competing in a maturing market with significant growth potential, driven by increasing demand for complex, precision components. The global market is expanding as industries seek cost-effective manufacturing solutions for high-volume production. Technologically, MIM offers advantages for complex geometries and cost efficiency at scale, while CNC provides superior tolerances and flexibility for lower volumes. Leading players like Proto Labs have positioned themselves to offer both technologies, while industrial giants such as Robert Bosch, Schaeffler, and Honeywell leverage these processes in their manufacturing ecosystems. Companies like Sodick and Nissei Plastic are advancing MIM technology, while Stratasys and Autodesk are developing complementary digital design and additive manufacturing solutions that integrate with traditional manufacturing methods.

Proto Labs, Inc.

Technical Solution: Proto Labs has developed a comprehensive manufacturing platform that integrates both Metal Injection Molding (MIM) and CNC machining technologies. Their MIM process utilizes proprietary feedstock formulations with fine metal powders (typically 20 microns or smaller) mixed with thermoplastic binders, allowing for complex geometries with wall thicknesses as thin as 0.5mm. Their automated digital manufacturing system enables rapid transition from CAD models to production parts, with their MIM process achieving tolerances of ±0.3% (with a minimum of ±0.075mm). For high-volume production exceeding 20,000 units, Proto Labs' MIM technology demonstrates significant cost advantages over CNC machining, with per-part costs potentially 60-70% lower at scale. Their proprietary debinding and sintering processes achieve 95-98% theoretical density, providing mechanical properties comparable to wrought materials.

Strengths: Industry-leading digital manufacturing platform integrating both technologies; automated quoting system providing real-time manufacturability feedback; exceptional scaling economics for MIM at volumes >20,000 units. Weaknesses: MIM requires higher initial tooling investment ($10,000-$50,000); longer lead times (15-20 days) compared to CNC for initial production; limited material selection compared to their CNC offerings.

Robert Bosch GmbH

Technical Solution: Bosch has pioneered advanced Metal Injection Molding technology through their MIM2 (Metal Injection Molding Innovation) system, specifically designed for high-precision automotive and industrial components. Their process combines nanoscale metal powders (typically 5-15μm) with multi-component binder systems to achieve near-net-shape components with complex geometries impossible through traditional machining. Bosch's proprietary catalytic debinding technology accelerates production cycles by 40% compared to conventional MIM processes, while their controlled atmosphere sintering achieves dimensional tolerances of ±0.1mm for most dimensions. For high-volume production of complex components like fuel injector parts, sensor housings, and transmission components, Bosch's MIM technology delivers 30-50% cost savings compared to CNC machining at volumes exceeding 100,000 units. Their integrated quality control system employs in-line monitoring with AI-powered defect detection, achieving rejection rates below 50 PPM for critical components.

Strengths: Exceptional material density (98-99% of theoretical) providing superior mechanical properties; proprietary catalytic debinding technology reducing production cycle times; advanced process control systems ensuring consistent quality across massive production volumes. Weaknesses: Limited to smaller components (typically under 100g); significant capital investment required for implementation; less economical for low-volume production compared to their CNC machining capabilities.

Critical Patents and Innovations in Metal Processing

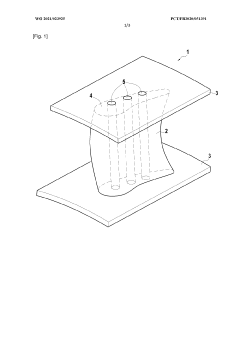

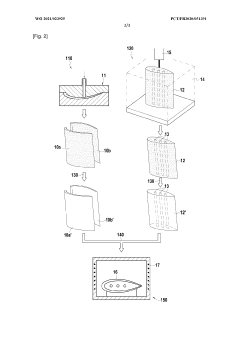

Method for manufacturing a metal part

PatentWO2021023925A1

Innovation

- A hybrid manufacturing process combining additive manufacturing and injection molding, where a first portion with a specific binder and metal powder is formed via additive methods and a second portion via injection molding, followed by debinding and joint sintering to create complex parts efficiently.

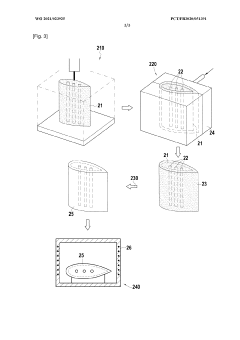

Automated total profile machining of parts

PatentInactiveGB2455679A

Innovation

- A method and apparatus for total profile machining using a CNC machine, where a block of material is machined to define a registration recess, a potting fixture is used to pack and solidify support material, allowing the part to be machined in multiple orientations without the need for custom fixturing, reducing waste and production time.

Material Science Considerations for MIM and CNC Applications

Material selection represents a critical factor in determining the suitability of either Metal Injection Molding (MIM) or CNC machining for specific applications. MIM technology demonstrates exceptional versatility with a wide range of metal powders, including stainless steels (17-4PH, 316L), tool steels, titanium alloys, and various ferrous metals. The material science behind MIM involves creating a feedstock by mixing fine metal powders with thermoplastic binders, resulting in unique microstructural characteristics after sintering.

The sintering process in MIM creates distinctive material properties that differ from wrought materials used in CNC machining. MIM parts typically exhibit isotropic properties with uniform grain structures throughout complex geometries, though they may have slightly lower density (95-99%) compared to wrought materials. This minor porosity can affect mechanical properties, with MIM parts generally achieving 95-98% of the strength of their wrought counterparts.

CNC machining, conversely, utilizes a broader spectrum of materials including high-performance alloys, superalloys, and specialized metals that may be unsuitable for MIM due to sintering challenges. The material integrity in CNC-machined components remains unaltered from the original stock, preserving all engineered properties of the source material. This preservation of material characteristics makes CNC particularly valuable for applications requiring specific material certifications or properties.

Surface finish considerations also differ significantly between these technologies. MIM components typically achieve surface finishes of 1-4 μm Ra without secondary operations, while CNC machining can produce finishes ranging from 0.8-3.2 μm Ra depending on tooling and parameters. For applications requiring superior surface characteristics, both technologies may require additional finishing processes.

Material waste represents another important consideration. MIM demonstrates exceptional material efficiency with utilization rates exceeding 97% in many applications, as excess feedstock can be recycled. CNC machining, particularly when creating complex geometries, may generate substantial waste with material utilization sometimes below 30% for intricate components machined from solid stock.

The thermal and mechanical behavior of materials processed through these different methods also warrants consideration. MIM parts may exhibit slightly different thermal expansion coefficients and fatigue resistance compared to wrought materials due to their microstructural characteristics. These differences become particularly relevant in applications involving thermal cycling or high mechanical stress environments.

The sintering process in MIM creates distinctive material properties that differ from wrought materials used in CNC machining. MIM parts typically exhibit isotropic properties with uniform grain structures throughout complex geometries, though they may have slightly lower density (95-99%) compared to wrought materials. This minor porosity can affect mechanical properties, with MIM parts generally achieving 95-98% of the strength of their wrought counterparts.

CNC machining, conversely, utilizes a broader spectrum of materials including high-performance alloys, superalloys, and specialized metals that may be unsuitable for MIM due to sintering challenges. The material integrity in CNC-machined components remains unaltered from the original stock, preserving all engineered properties of the source material. This preservation of material characteristics makes CNC particularly valuable for applications requiring specific material certifications or properties.

Surface finish considerations also differ significantly between these technologies. MIM components typically achieve surface finishes of 1-4 μm Ra without secondary operations, while CNC machining can produce finishes ranging from 0.8-3.2 μm Ra depending on tooling and parameters. For applications requiring superior surface characteristics, both technologies may require additional finishing processes.

Material waste represents another important consideration. MIM demonstrates exceptional material efficiency with utilization rates exceeding 97% in many applications, as excess feedstock can be recycled. CNC machining, particularly when creating complex geometries, may generate substantial waste with material utilization sometimes below 30% for intricate components machined from solid stock.

The thermal and mechanical behavior of materials processed through these different methods also warrants consideration. MIM parts may exhibit slightly different thermal expansion coefficients and fatigue resistance compared to wrought materials due to their microstructural characteristics. These differences become particularly relevant in applications involving thermal cycling or high mechanical stress environments.

Sustainability and Environmental Impact Assessment

When comparing Metal Injection Molding (MIM) and CNC machining from a sustainability perspective, several critical environmental factors must be considered across the entire lifecycle of these manufacturing processes.

MIM demonstrates significant environmental advantages in material utilization, with powder metallurgy approaches typically achieving 97-99% material efficiency. The minimal waste generation stands in stark contrast to CNC machining, where material removal can result in 70-90% of the original stock becoming waste in complex geometries. While CNC waste is recyclable, the energy required for recycling represents additional environmental impact.

Energy consumption patterns differ substantially between these technologies. MIM requires high energy input during the sintering phase, with furnaces operating at 1200-1400°C for extended periods. However, CNC machining consumes considerable energy during the actual cutting operations, particularly when machining harder materials or performing complex operations requiring multiple setups and tool changes.

Carbon footprint analysis reveals that MIM may offer advantages for high-volume production scenarios. Once tooling is established, the incremental environmental impact per additional part is relatively low. CNC operations maintain a more linear environmental impact relationship with production volume, with each part requiring similar energy and generating comparable waste.

Chemical usage presents another environmental consideration. MIM processes involve binders and debinding agents that may contain potentially hazardous substances requiring careful handling and disposal. CNC operations utilize cutting fluids and coolants that similarly require proper environmental management systems to prevent contamination.

From a lifecycle perspective, MIM parts often demonstrate superior durability due to their homogeneous material structure, potentially extending product lifespans. Additionally, the ability to produce near-net-shape components reduces secondary processing requirements, further decreasing the overall environmental footprint.

Regulatory compliance is increasingly influencing manufacturing decisions, with stricter environmental regulations in many regions favoring processes with lower emissions and waste generation. Companies must consider these evolving standards when selecting manufacturing technologies for future production needs.

The environmental impact assessment must ultimately be contextualized within specific application requirements, production volumes, and regional environmental regulations to determine the most sustainable manufacturing approach for a given component.

MIM demonstrates significant environmental advantages in material utilization, with powder metallurgy approaches typically achieving 97-99% material efficiency. The minimal waste generation stands in stark contrast to CNC machining, where material removal can result in 70-90% of the original stock becoming waste in complex geometries. While CNC waste is recyclable, the energy required for recycling represents additional environmental impact.

Energy consumption patterns differ substantially between these technologies. MIM requires high energy input during the sintering phase, with furnaces operating at 1200-1400°C for extended periods. However, CNC machining consumes considerable energy during the actual cutting operations, particularly when machining harder materials or performing complex operations requiring multiple setups and tool changes.

Carbon footprint analysis reveals that MIM may offer advantages for high-volume production scenarios. Once tooling is established, the incremental environmental impact per additional part is relatively low. CNC operations maintain a more linear environmental impact relationship with production volume, with each part requiring similar energy and generating comparable waste.

Chemical usage presents another environmental consideration. MIM processes involve binders and debinding agents that may contain potentially hazardous substances requiring careful handling and disposal. CNC operations utilize cutting fluids and coolants that similarly require proper environmental management systems to prevent contamination.

From a lifecycle perspective, MIM parts often demonstrate superior durability due to their homogeneous material structure, potentially extending product lifespans. Additionally, the ability to produce near-net-shape components reduces secondary processing requirements, further decreasing the overall environmental footprint.

Regulatory compliance is increasingly influencing manufacturing decisions, with stricter environmental regulations in many regions favoring processes with lower emissions and waste generation. Companies must consider these evolving standards when selecting manufacturing technologies for future production needs.

The environmental impact assessment must ultimately be contextualized within specific application requirements, production volumes, and regional environmental regulations to determine the most sustainable manufacturing approach for a given component.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!