Metal Injection Molding Defect Modes: Knit Lines, Voids And Lamination

SEP 16, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

MIM Technology Background and Objectives

Metal Injection Molding (MIM) emerged in the 1970s as an innovative manufacturing process combining the versatility of plastic injection molding with the material properties of powder metallurgy. This technology evolved from earlier powder metallurgy techniques, offering a revolutionary approach to producing complex, high-precision metal components with excellent mechanical properties. The development of MIM has been driven by increasing demands across industries for miniaturization, complex geometries, and cost-effective production of metal parts.

The evolution of MIM technology has seen significant advancements in material science, equipment precision, and process control. Early implementations faced challenges with dimensional accuracy and material properties, but continuous refinement has established MIM as a mature manufacturing technology. Modern MIM processes typically achieve tolerances of ±0.3% of the dimension, significantly outperforming traditional powder metallurgy methods while maintaining competitive production costs for medium to high-volume manufacturing.

Despite its maturity, MIM continues to face technical challenges, particularly in the area of defect control. Knit lines, voids, and lamination represent three critical defect modes that significantly impact product quality, reliability, and performance. These defects arise from complex interactions between material properties, mold design, and processing parameters, making their prediction and prevention particularly challenging.

The primary objective of current MIM technology research is to develop comprehensive understanding and control strategies for these defect modes. This includes establishing predictive models for defect formation, optimizing process parameters to minimize defect occurrence, and developing in-line quality control methods for early defect detection. Additionally, research aims to expand the range of applicable materials and improve the consistency of material properties across complex geometries.

Industry trends indicate growing adoption of MIM technology in critical applications such as medical devices, aerospace components, and automotive systems, where defect-free production is paramount. This expansion into high-reliability sectors has intensified focus on defect elimination strategies and quality assurance methodologies specific to MIM processes.

The technological trajectory suggests integration with digital manufacturing concepts, including real-time process monitoring, machine learning for defect prediction, and automated parameter optimization. These advancements aim to transform MIM from a primarily experience-based process to a data-driven manufacturing technology with predictable outcomes and minimized defect rates, particularly addressing persistent challenges like knit lines, voids, and lamination defects.

The evolution of MIM technology has seen significant advancements in material science, equipment precision, and process control. Early implementations faced challenges with dimensional accuracy and material properties, but continuous refinement has established MIM as a mature manufacturing technology. Modern MIM processes typically achieve tolerances of ±0.3% of the dimension, significantly outperforming traditional powder metallurgy methods while maintaining competitive production costs for medium to high-volume manufacturing.

Despite its maturity, MIM continues to face technical challenges, particularly in the area of defect control. Knit lines, voids, and lamination represent three critical defect modes that significantly impact product quality, reliability, and performance. These defects arise from complex interactions between material properties, mold design, and processing parameters, making their prediction and prevention particularly challenging.

The primary objective of current MIM technology research is to develop comprehensive understanding and control strategies for these defect modes. This includes establishing predictive models for defect formation, optimizing process parameters to minimize defect occurrence, and developing in-line quality control methods for early defect detection. Additionally, research aims to expand the range of applicable materials and improve the consistency of material properties across complex geometries.

Industry trends indicate growing adoption of MIM technology in critical applications such as medical devices, aerospace components, and automotive systems, where defect-free production is paramount. This expansion into high-reliability sectors has intensified focus on defect elimination strategies and quality assurance methodologies specific to MIM processes.

The technological trajectory suggests integration with digital manufacturing concepts, including real-time process monitoring, machine learning for defect prediction, and automated parameter optimization. These advancements aim to transform MIM from a primarily experience-based process to a data-driven manufacturing technology with predictable outcomes and minimized defect rates, particularly addressing persistent challenges like knit lines, voids, and lamination defects.

Market Analysis for MIM Components

The global Metal Injection Molding (MIM) components market has been experiencing robust growth, valued at approximately $2.7 billion in 2022 and projected to reach $4.5 billion by 2028, representing a compound annual growth rate (CAGR) of 8.9%. This growth is primarily driven by increasing demand from automotive, aerospace, medical, and consumer electronics industries seeking complex, precision metal parts with cost-effective production methods.

The automotive sector currently dominates the MIM components market, accounting for nearly 35% of the total market share. The industry's push toward lightweight components for fuel efficiency and the growing complexity of engine and transmission parts have significantly boosted MIM adoption. Additionally, the medical device industry represents the fastest-growing segment with a CAGR of 11.2%, fueled by the need for biocompatible, precision components in surgical instruments and implantable devices.

Regionally, Asia-Pacific leads the market with approximately 45% share, with China and India emerging as manufacturing hubs due to lower production costs and increasing industrial capabilities. North America and Europe follow with 28% and 22% market shares respectively, where high-end applications in aerospace and medical sectors drive demand for premium MIM components.

The market for defect-free MIM components is particularly significant, as quality issues directly impact product performance and reliability. Industry reports indicate that manufacturers lose between 5-8% of production value due to defects such as knit lines, voids, and lamination issues. This translates to approximately $135-215 million in annual losses globally, creating substantial market opportunity for improved processes and technologies that address these specific defect modes.

Consumer electronics represents an emerging high-growth segment for MIM components, with smartphone manufacturers increasingly adopting MIM for intricate internal components and aesthetic external features. This segment is expected to grow at 10.5% CAGR through 2028, creating new demand for defect-free, high-finish MIM parts.

Market analysis reveals a growing premium segment for high-performance MIM components with near-zero defect rates, commanding price premiums of 30-40% over standard components. This trend is particularly evident in aerospace and medical applications where component failure risks are unacceptable, creating a lucrative niche market estimated at $450 million annually for manufacturers who can consistently deliver defect-free parts.

The automotive sector currently dominates the MIM components market, accounting for nearly 35% of the total market share. The industry's push toward lightweight components for fuel efficiency and the growing complexity of engine and transmission parts have significantly boosted MIM adoption. Additionally, the medical device industry represents the fastest-growing segment with a CAGR of 11.2%, fueled by the need for biocompatible, precision components in surgical instruments and implantable devices.

Regionally, Asia-Pacific leads the market with approximately 45% share, with China and India emerging as manufacturing hubs due to lower production costs and increasing industrial capabilities. North America and Europe follow with 28% and 22% market shares respectively, where high-end applications in aerospace and medical sectors drive demand for premium MIM components.

The market for defect-free MIM components is particularly significant, as quality issues directly impact product performance and reliability. Industry reports indicate that manufacturers lose between 5-8% of production value due to defects such as knit lines, voids, and lamination issues. This translates to approximately $135-215 million in annual losses globally, creating substantial market opportunity for improved processes and technologies that address these specific defect modes.

Consumer electronics represents an emerging high-growth segment for MIM components, with smartphone manufacturers increasingly adopting MIM for intricate internal components and aesthetic external features. This segment is expected to grow at 10.5% CAGR through 2028, creating new demand for defect-free, high-finish MIM parts.

Market analysis reveals a growing premium segment for high-performance MIM components with near-zero defect rates, commanding price premiums of 30-40% over standard components. This trend is particularly evident in aerospace and medical applications where component failure risks are unacceptable, creating a lucrative niche market estimated at $450 million annually for manufacturers who can consistently deliver defect-free parts.

Current Challenges in MIM Defect Control

Metal Injection Molding (MIM) technology faces several persistent defect control challenges that impede quality production and limit broader industry adoption. The most prevalent defects—knit lines, voids, and lamination—continue to plague manufacturers despite advancements in process technology. These defects significantly impact mechanical properties, dimensional accuracy, and surface finish of final components.

Knit lines remain particularly problematic in complex geometries where multiple flow fronts meet during injection. Current process controls struggle to eliminate these structural weaknesses, which can reduce tensile strength by up to 30% in affected areas. The industry lacks reliable predictive models that accurately account for powder-binder interaction at flow front interfaces, making knit line prevention largely dependent on trial-and-error approaches.

Void formation presents another significant challenge, with internal porosity often remaining undetected until final sintering stages. Contemporary non-destructive testing methods lack sufficient resolution to identify micro-voids in green parts, resulting in costly quality issues discovered late in production. The relationship between feedstock rheology, molding parameters, and void formation remains incompletely characterized, hampering systematic prevention strategies.

Lamination defects, characterized by layer separation within components, continue to challenge manufacturers, particularly when processing highly filled feedstocks. Current mixing technologies struggle to achieve homogeneous dispersion of powder particles in binder systems above certain loading thresholds, creating inherent vulnerabilities to lamination. The industry lacks standardized methods for quantifying feedstock homogeneity that correlate reliably with lamination risk.

Process monitoring capabilities represent another significant gap. Real-time detection systems for defect formation during injection remain underdeveloped, with most quality control occurring post-molding. This reactive approach increases production costs and waste rates. Advanced sensor technologies that can withstand the harsh processing environment while providing meaningful data on material flow behavior are still in early development stages.

Simulation tools present additional limitations. Current modeling software inadequately captures the complex multiphase flow behavior of MIM feedstocks, particularly regarding phase separation phenomena that contribute to defect formation. The computational requirements for accurate simulation often exceed practical industrial implementation, forcing manufacturers to rely on simplified models with limited predictive value.

Material inconsistency further complicates defect control efforts. Batch-to-batch variations in powder characteristics and binder properties introduce unpredictable processing behavior that current quality systems struggle to accommodate. The industry lacks robust feedstock qualification protocols that can effectively predict processing performance based on measurable material properties.

Knit lines remain particularly problematic in complex geometries where multiple flow fronts meet during injection. Current process controls struggle to eliminate these structural weaknesses, which can reduce tensile strength by up to 30% in affected areas. The industry lacks reliable predictive models that accurately account for powder-binder interaction at flow front interfaces, making knit line prevention largely dependent on trial-and-error approaches.

Void formation presents another significant challenge, with internal porosity often remaining undetected until final sintering stages. Contemporary non-destructive testing methods lack sufficient resolution to identify micro-voids in green parts, resulting in costly quality issues discovered late in production. The relationship between feedstock rheology, molding parameters, and void formation remains incompletely characterized, hampering systematic prevention strategies.

Lamination defects, characterized by layer separation within components, continue to challenge manufacturers, particularly when processing highly filled feedstocks. Current mixing technologies struggle to achieve homogeneous dispersion of powder particles in binder systems above certain loading thresholds, creating inherent vulnerabilities to lamination. The industry lacks standardized methods for quantifying feedstock homogeneity that correlate reliably with lamination risk.

Process monitoring capabilities represent another significant gap. Real-time detection systems for defect formation during injection remain underdeveloped, with most quality control occurring post-molding. This reactive approach increases production costs and waste rates. Advanced sensor technologies that can withstand the harsh processing environment while providing meaningful data on material flow behavior are still in early development stages.

Simulation tools present additional limitations. Current modeling software inadequately captures the complex multiphase flow behavior of MIM feedstocks, particularly regarding phase separation phenomena that contribute to defect formation. The computational requirements for accurate simulation often exceed practical industrial implementation, forcing manufacturers to rely on simplified models with limited predictive value.

Material inconsistency further complicates defect control efforts. Batch-to-batch variations in powder characteristics and binder properties introduce unpredictable processing behavior that current quality systems struggle to accommodate. The industry lacks robust feedstock qualification protocols that can effectively predict processing performance based on measurable material properties.

Technical Solutions for MIM Defect Mitigation

01 Knit line formation and prevention in MIM

Knit lines occur when two or more flow fronts meet during the metal injection molding process, creating weak points in the final product. These defects can be prevented by optimizing injection parameters such as temperature, pressure, and gate location. Proper mold design with strategically placed gates and vents helps ensure uniform material flow, reducing the formation of knit lines. Additionally, adjusting the feedstock composition and rheological properties can improve flow characteristics and minimize these defects.- Knit line formation and prevention in metal injection molding: Knit lines occur in metal injection molding when two or more flow fronts meet but do not completely fuse together, creating a weak point or visible line in the final part. These defects typically form around holes or inserts, or when material flows around obstacles. Prevention methods include optimizing gate locations, increasing injection pressure and temperature, improving mold venting, and using appropriate binder systems that promote better flow characteristics. Proper control of molding parameters such as injection speed and pressure can significantly reduce knit line formation.

- Void formation mechanisms and reduction strategies: Voids in metal injection molded parts are internal cavities or bubbles that form due to trapped gases, incomplete filling, or shrinkage during cooling. These defects compromise the structural integrity and mechanical properties of the final component. Strategies to reduce void formation include proper feedstock preparation to minimize air entrapment, optimized debinding cycles to allow gases to escape, controlled cooling rates to minimize shrinkage, and application of appropriate holding pressure during the molding process. Advanced simulation techniques can help predict and prevent void formation by optimizing process parameters.

- Lamination defects and interlayer adhesion improvement: Lamination defects in metal injection molding appear as layers or sheets that fail to properly bond together, resulting in delamination or separation in the final part. These defects often occur due to improper flow patterns, temperature variations across the part, or inconsistent material properties. Improving interlayer adhesion can be achieved through optimized feedstock formulation with appropriate binder systems, controlled injection parameters to ensure uniform temperature distribution, and proper mixing of metal powders with binders to achieve homogeneous feedstock. Post-processing techniques such as specialized sintering profiles can also help mitigate lamination issues.

- Process parameter optimization for defect reduction: Optimizing process parameters is crucial for minimizing defects in metal injection molding. Key parameters include injection pressure, temperature, speed, holding time, and cooling rate. Advanced monitoring systems can detect variations in these parameters that might lead to defects. Statistical process control methods help identify optimal processing windows for specific materials and geometries. Simulation tools enable prediction of potential defect formation based on process parameters, allowing for preemptive adjustments. Systematic optimization approaches like design of experiments can efficiently determine ideal parameter combinations for defect-free production.

- Feedstock formulation impact on defect prevention: The composition and quality of metal injection molding feedstock significantly influence defect formation. Proper powder characteristics (size, shape, distribution), binder selection, and powder-to-binder ratio are critical factors. Homogeneous mixing ensures uniform flow behavior and reduces the risk of segregation that can lead to defects. Additives can be incorporated to improve flowability, reduce friction, and enhance part quality. Feedstock rheology must be carefully controlled to achieve consistent flow behavior under processing conditions. Advanced feedstock formulations may include specialized components that specifically address common defect mechanisms.

02 Void formation mechanisms and reduction strategies

Voids in metal injection molded parts result from trapped gases, incomplete filling, or uneven shrinkage during sintering. These defects compromise structural integrity and surface quality. Effective void reduction strategies include proper debinding cycles to allow gradual binder removal, controlled sintering profiles to manage densification, and optimized powder-binder ratios. Vacuum-assisted molding techniques can also help eliminate trapped air pockets. Implementing pressure holding times during injection helps compensate for material shrinkage and reduces void formation.Expand Specific Solutions03 Lamination defects and interlayer adhesion improvement

Lamination defects occur when layers of the molded material fail to properly bond, creating separation between layers. These defects are often caused by temperature variations, improper flow patterns, or contamination at the interface. Improving interlayer adhesion requires optimizing feedstock homogeneity, ensuring consistent temperature distribution throughout the mold, and controlling cooling rates. Specialized binder systems with enhanced cohesive properties can also help prevent layer separation. Post-processing treatments may be employed to strengthen interlayer bonds in affected components.Expand Specific Solutions04 Process parameter optimization for defect reduction

Optimizing process parameters is crucial for minimizing defects in metal injection molding. Key parameters include injection speed, pressure profiles, mold and feedstock temperatures, cooling rates, and holding times. Computer simulation and modeling help predict material flow behavior and identify potential defect-prone areas before production. Statistical process control methods enable continuous monitoring and adjustment of parameters to maintain quality. Advanced sensing technologies can detect variations in process conditions that might lead to defects, allowing for real-time adjustments to prevent their occurrence.Expand Specific Solutions05 Feedstock formulation for improved molding quality

The composition and quality of MIM feedstock significantly impact the occurrence of defects. Optimal powder characteristics (size, shape, distribution) combined with appropriate binder systems enhance flowability and reduce defects. Additives such as surfactants and flow modifiers can improve the rheological properties of the feedstock, promoting uniform filling and reducing the likelihood of knit lines and voids. Proper mixing techniques ensure homogeneous distribution of metal powders within the binder, preventing agglomerations that could lead to defects. Advanced feedstock preparation methods, including granulation and pelletizing, can further enhance moldability.Expand Specific Solutions

Leading MIM Industry Players

Metal Injection Molding (MIM) defect modes represent a critical challenge in the evolving precision manufacturing landscape. The industry is currently in a growth phase, with the global MIM market expected to expand significantly due to increasing demand for complex, high-precision metal components. Key players like Husky Injection Molding Systems and Nissei Plastic Industrial are advancing technical solutions for common defects such as knit lines, voids, and lamination issues. Automotive manufacturers including Ford, Toyota, and Mazda are driving innovation in this space, while specialized companies like Sodick and Applied Materials are developing enhanced process control technologies. The technology is approaching maturity in traditional applications but continues to evolve for advanced materials and complex geometries, with research institutions like Tohoku University collaborating with industry to address persistent quality challenges.

Husky Injection Molding Systems Ltd.

Technical Solution: Husky has developed advanced hot runner systems specifically designed to address metal injection molding (MIM) defects. Their technology utilizes precise temperature control throughout the injection process to prevent knit lines and voids. The company's valve gate technology ensures optimal gate location and controlled filling patterns, minimizing the formation of knit lines at material flow fronts. Their proprietary UltraSync-E technology provides electric servo-driven valve gate control with synchronization accuracy to 0.002 seconds, allowing for precise pressure control during the injection phase. Husky's systems incorporate specialized nozzle designs with optimized geometry to maintain consistent material temperature and prevent premature cooling that leads to lamination defects. Additionally, their process monitoring systems use real-time data analytics to detect potential defect-causing conditions before they manifest in finished parts.

Strengths: Superior precision in gate timing control, advanced temperature management across the mold, and comprehensive process monitoring capabilities. Weaknesses: Higher initial investment costs compared to conventional systems, requires specialized operator training, and may have limitations with certain metal powder formulations.

Nissei Plastic Industrial Co., Ltd.

Technical Solution: Nissei has pioneered a comprehensive approach to MIM defect prevention through their X-MELT technology platform. This system addresses knit lines through advanced flow front control algorithms that dynamically adjust injection parameters based on real-time feedback. Their technology incorporates specialized venting systems strategically positioned to eliminate trapped air that causes voids. Nissei's process employs a two-stage injection profile with precisely controlled holding pressure transitions to prevent lamination issues. The company has developed specialized screw designs with optimized compression ratios specifically for metal powder feedstocks, ensuring homogeneous mixing and consistent material properties throughout the part. Their TACT (Total Advanced Control Technology) system continuously monitors and adjusts injection speed, pressure, and temperature parameters to maintain optimal processing conditions, reducing defect occurrence rates by up to 40% compared to conventional systems.

Strengths: Exceptional material homogenization capabilities, sophisticated real-time parameter adjustment, and proven reduction in defect rates. Weaknesses: System complexity requires significant technical expertise to operate effectively, higher maintenance requirements, and potential compatibility issues with some specialized metal powder formulations.

Critical Patents in MIM Defect Prevention

Metal injection molding methods and feedstocks

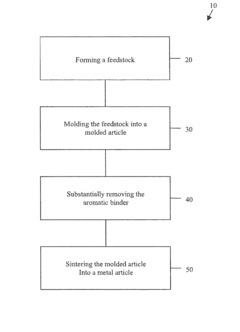

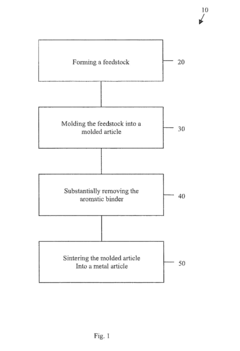

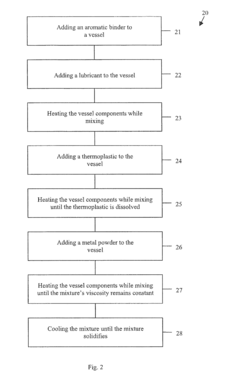

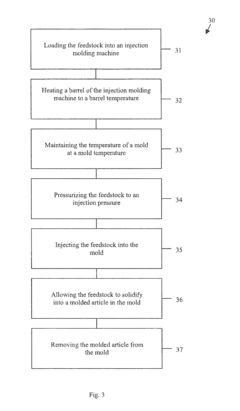

PatentActiveUS7883662B2

Innovation

- The method involves forming a feedstock with a lubricant, thermoplastic, and aromatic binder, followed by molding, binder removal, and sintering, using techniques like alcohol immersion, atmospheric pressure heating, or heated vacuum to produce metal articles with enhanced properties, including oxygen reduction and densification methods to meet specific industry standards.

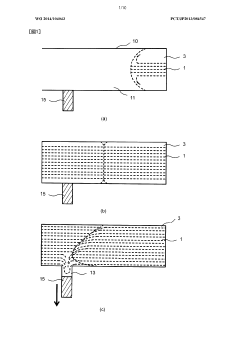

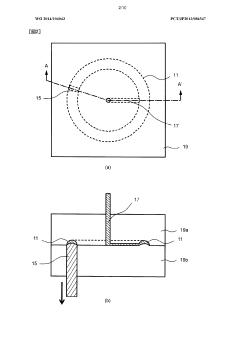

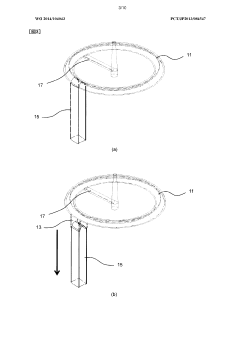

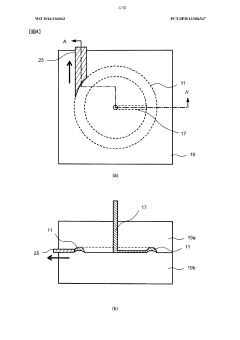

Injection molding method and injection-molded item

PatentWO2014104043A1

Innovation

- An injection molding method utilizing a mold with a retraction mechanism that draws molding material from one direction into a second gap, applying negative pressure to control filler orientation and prevent weld lines, allowing for the formation of ribs or bosses while suppressing flow lines.

Material Science Advancements for MIM

Recent advancements in material science have significantly enhanced Metal Injection Molding (MIM) processes, particularly in addressing common defect modes such as knit lines, voids, and lamination issues. The evolution of feedstock formulations has been a critical area of development, with researchers focusing on optimizing binder systems that provide improved flow characteristics while maintaining structural integrity during the molding phase.

Polymer science contributions have led to the development of multi-component binder systems that exhibit pseudoplastic behavior, reducing the occurrence of knit lines by allowing better material flow convergence at meeting points within complex molds. These advanced binders typically combine backbone polymers with surfactants and plasticizers in precisely controlled ratios, resulting in more homogeneous material distribution throughout the molded part.

Powder metallurgy has also seen substantial innovation, with the introduction of ultra-fine metal powders featuring optimized particle size distributions and morphologies. These powders, often in the sub-5 micron range, facilitate tighter packing densities and reduce the likelihood of void formation during the sintering process. Surface-modified metal powders with enhanced wettability characteristics have demonstrated particular promise in minimizing lamination defects by improving the cohesion between powder particles and binder components.

Computational materials science has enabled the development of predictive models that can simulate the rheological behavior of MIM feedstocks under various processing conditions. These models incorporate parameters such as shear rate sensitivity, thermal conductivity, and viscoelastic properties to predict potential defect formation zones before actual production, allowing for preemptive adjustments to mold design or process parameters.

Nanomaterial integration represents another frontier in MIM material science. The incorporation of nanoparticles as reinforcing agents or flow modifiers has shown potential in reducing defect occurrence. For instance, certain nanosilica additives can improve the flow behavior of feedstock while simultaneously strengthening the green part, reducing the likelihood of lamination during handling and debinding stages.

Hybrid material systems combining different metal alloys or metal-ceramic compositions have emerged as solutions for applications requiring gradient properties. These systems utilize controlled diffusion mechanisms during sintering to create seamless transitions between different material zones, effectively eliminating traditional knit line weaknesses while expanding the functional capabilities of MIM components.

The development of environmentally friendly binder systems represents another significant advancement, with water-soluble or catalytically debinding options replacing traditional solvent-based systems. These newer binders not only reduce environmental impact but often demonstrate superior flow characteristics and fewer defect tendencies due to their more uniform debinding behavior.

Polymer science contributions have led to the development of multi-component binder systems that exhibit pseudoplastic behavior, reducing the occurrence of knit lines by allowing better material flow convergence at meeting points within complex molds. These advanced binders typically combine backbone polymers with surfactants and plasticizers in precisely controlled ratios, resulting in more homogeneous material distribution throughout the molded part.

Powder metallurgy has also seen substantial innovation, with the introduction of ultra-fine metal powders featuring optimized particle size distributions and morphologies. These powders, often in the sub-5 micron range, facilitate tighter packing densities and reduce the likelihood of void formation during the sintering process. Surface-modified metal powders with enhanced wettability characteristics have demonstrated particular promise in minimizing lamination defects by improving the cohesion between powder particles and binder components.

Computational materials science has enabled the development of predictive models that can simulate the rheological behavior of MIM feedstocks under various processing conditions. These models incorporate parameters such as shear rate sensitivity, thermal conductivity, and viscoelastic properties to predict potential defect formation zones before actual production, allowing for preemptive adjustments to mold design or process parameters.

Nanomaterial integration represents another frontier in MIM material science. The incorporation of nanoparticles as reinforcing agents or flow modifiers has shown potential in reducing defect occurrence. For instance, certain nanosilica additives can improve the flow behavior of feedstock while simultaneously strengthening the green part, reducing the likelihood of lamination during handling and debinding stages.

Hybrid material systems combining different metal alloys or metal-ceramic compositions have emerged as solutions for applications requiring gradient properties. These systems utilize controlled diffusion mechanisms during sintering to create seamless transitions between different material zones, effectively eliminating traditional knit line weaknesses while expanding the functional capabilities of MIM components.

The development of environmentally friendly binder systems represents another significant advancement, with water-soluble or catalytically debinding options replacing traditional solvent-based systems. These newer binders not only reduce environmental impact but often demonstrate superior flow characteristics and fewer defect tendencies due to their more uniform debinding behavior.

Environmental Impact of MIM Manufacturing

Metal Injection Molding (MIM) processes, while offering significant advantages in manufacturing complex metal parts, present several environmental challenges that warrant careful consideration. The environmental footprint of MIM manufacturing encompasses multiple dimensions, from resource consumption to waste generation and energy usage.

Raw material extraction for MIM feedstock components, particularly metal powders, involves energy-intensive mining and processing operations that contribute to habitat disruption and potential soil and water contamination. The binder systems used in MIM, often containing polymers, waxes, and various chemical additives, frequently incorporate petroleum-derived substances that carry inherent environmental implications throughout their lifecycle.

The manufacturing process itself consumes substantial energy, particularly during the sintering phase where temperatures typically reach 1200-1400°C. This high-temperature requirement translates to significant carbon emissions, especially in regions where electricity generation relies heavily on fossil fuels. Studies indicate that the sintering stage alone can account for approximately 65-75% of the total energy consumption in the MIM production cycle.

Defect modes such as knit lines, voids, and lamination not only affect product quality but also have environmental ramifications. Each defective part represents wasted materials and energy, effectively multiplying the environmental impact per successful unit produced. Industry data suggests that defect rates in MIM can range from 5-15% depending on part complexity and process optimization, creating a substantial environmental burden through material inefficiency.

Water usage presents another environmental concern, particularly in debinding processes that utilize solvent-based systems requiring subsequent wastewater treatment. Chemical debinding methods may introduce potentially hazardous substances into waste streams, necessitating specialized treatment protocols to prevent environmental contamination.

Recent advancements in MIM technology have begun addressing these environmental challenges. Water-based binder systems are reducing dependence on petroleum-derived components, while catalytic debinding processes are minimizing solvent usage. Energy efficiency improvements in sintering furnaces, including better insulation and heat recovery systems, have demonstrated potential energy savings of 15-30% in progressive facilities.

Recycling capabilities for MIM waste streams remain limited but are evolving. Metal powders from rejected parts can be reclaimed through specialized processes, though the mixed-material nature of MIM feedstock complicates comprehensive recycling efforts. The industry is gradually moving toward closed-loop manufacturing systems that minimize waste and maximize resource efficiency.

Raw material extraction for MIM feedstock components, particularly metal powders, involves energy-intensive mining and processing operations that contribute to habitat disruption and potential soil and water contamination. The binder systems used in MIM, often containing polymers, waxes, and various chemical additives, frequently incorporate petroleum-derived substances that carry inherent environmental implications throughout their lifecycle.

The manufacturing process itself consumes substantial energy, particularly during the sintering phase where temperatures typically reach 1200-1400°C. This high-temperature requirement translates to significant carbon emissions, especially in regions where electricity generation relies heavily on fossil fuels. Studies indicate that the sintering stage alone can account for approximately 65-75% of the total energy consumption in the MIM production cycle.

Defect modes such as knit lines, voids, and lamination not only affect product quality but also have environmental ramifications. Each defective part represents wasted materials and energy, effectively multiplying the environmental impact per successful unit produced. Industry data suggests that defect rates in MIM can range from 5-15% depending on part complexity and process optimization, creating a substantial environmental burden through material inefficiency.

Water usage presents another environmental concern, particularly in debinding processes that utilize solvent-based systems requiring subsequent wastewater treatment. Chemical debinding methods may introduce potentially hazardous substances into waste streams, necessitating specialized treatment protocols to prevent environmental contamination.

Recent advancements in MIM technology have begun addressing these environmental challenges. Water-based binder systems are reducing dependence on petroleum-derived components, while catalytic debinding processes are minimizing solvent usage. Energy efficiency improvements in sintering furnaces, including better insulation and heat recovery systems, have demonstrated potential energy savings of 15-30% in progressive facilities.

Recycling capabilities for MIM waste streams remain limited but are evolving. Metal powders from rejected parts can be reclaimed through specialized processes, though the mixed-material nature of MIM feedstock complicates comprehensive recycling efforts. The industry is gradually moving toward closed-loop manufacturing systems that minimize waste and maximize resource efficiency.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!