Metal Injection Molding Mechanical Properties: Strength, Fatigue And Fracture

SEP 16, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

MIM Technology Background and Objectives

Metal Injection Molding (MIM) emerged in the 1970s as an innovative manufacturing process combining the versatility of plastic injection molding with the superior mechanical properties of traditional powder metallurgy. This technology has evolved significantly over the past five decades, transitioning from experimental applications to a mainstream manufacturing method for complex metal components across various industries including automotive, aerospace, medical, and consumer electronics.

The evolution of MIM technology has been characterized by continuous improvements in feedstock formulations, debinding techniques, and sintering processes. Early MIM applications were limited by inconsistent mechanical properties and high production costs. However, advancements in binder systems during the 1980s and 1990s significantly improved green part strength and dimensional stability. The development of catalytic and solvent debinding methods in the late 1990s further enhanced process efficiency and part quality.

Recent technological trends in MIM focus on expanding the range of applicable materials beyond traditional stainless steels and iron-based alloys to include high-performance metals such as titanium, tungsten, and specialized superalloys. This material diversification has been accompanied by innovations in multi-material MIM, allowing for components with gradient properties and complex material compositions.

The primary technical objective in MIM development is achieving mechanical properties comparable to or exceeding those of conventionally manufactured metal components. Specifically, enhancing strength, fatigue resistance, and fracture toughness remains a central focus. Current research aims to optimize microstructural characteristics through precise control of powder characteristics, sintering parameters, and post-processing treatments.

Another critical objective is improving process reliability and reproducibility to ensure consistent mechanical properties across production batches. This includes developing advanced simulation tools for predicting material flow, sintering behavior, and resultant mechanical properties, thereby reducing the empirical nature of process parameter optimization.

The industry also seeks to address the limitations in component size, which has traditionally been restricted due to debinding and sintering challenges in larger parts. Innovations in debinding technologies and sintering equipment are gradually expanding the dimensional capabilities of MIM processes.

Looking forward, the technology roadmap for MIM includes integration with additive manufacturing techniques to create hybrid manufacturing processes, development of nano-reinforced MIM feedstocks for enhanced mechanical properties, and implementation of in-situ monitoring systems for real-time quality control. These advancements aim to position MIM as a versatile, cost-effective solution for producing complex metal components with superior mechanical performance.

The evolution of MIM technology has been characterized by continuous improvements in feedstock formulations, debinding techniques, and sintering processes. Early MIM applications were limited by inconsistent mechanical properties and high production costs. However, advancements in binder systems during the 1980s and 1990s significantly improved green part strength and dimensional stability. The development of catalytic and solvent debinding methods in the late 1990s further enhanced process efficiency and part quality.

Recent technological trends in MIM focus on expanding the range of applicable materials beyond traditional stainless steels and iron-based alloys to include high-performance metals such as titanium, tungsten, and specialized superalloys. This material diversification has been accompanied by innovations in multi-material MIM, allowing for components with gradient properties and complex material compositions.

The primary technical objective in MIM development is achieving mechanical properties comparable to or exceeding those of conventionally manufactured metal components. Specifically, enhancing strength, fatigue resistance, and fracture toughness remains a central focus. Current research aims to optimize microstructural characteristics through precise control of powder characteristics, sintering parameters, and post-processing treatments.

Another critical objective is improving process reliability and reproducibility to ensure consistent mechanical properties across production batches. This includes developing advanced simulation tools for predicting material flow, sintering behavior, and resultant mechanical properties, thereby reducing the empirical nature of process parameter optimization.

The industry also seeks to address the limitations in component size, which has traditionally been restricted due to debinding and sintering challenges in larger parts. Innovations in debinding technologies and sintering equipment are gradually expanding the dimensional capabilities of MIM processes.

Looking forward, the technology roadmap for MIM includes integration with additive manufacturing techniques to create hybrid manufacturing processes, development of nano-reinforced MIM feedstocks for enhanced mechanical properties, and implementation of in-situ monitoring systems for real-time quality control. These advancements aim to position MIM as a versatile, cost-effective solution for producing complex metal components with superior mechanical performance.

Market Demand Analysis for MIM Components

The global market for Metal Injection Molding (MIM) components has been experiencing robust growth, driven primarily by increasing demand for complex, high-precision metal parts across multiple industries. The current market size is estimated at $3.5 billion and is projected to grow at a compound annual growth rate of 11.8% through 2028, reflecting the expanding applications of MIM technology.

Automotive and aerospace sectors represent the largest market segments for MIM components, collectively accounting for approximately 45% of total demand. These industries particularly value MIM's ability to produce components with excellent mechanical properties, including high strength-to-weight ratios and superior fatigue resistance. The trend toward vehicle lightweighting and fuel efficiency has significantly boosted demand for MIM parts that can replace heavier traditional components while maintaining or improving mechanical performance.

Medical device manufacturing has emerged as the fastest-growing application segment, with demand increasing at nearly 14% annually. This growth is fueled by the need for biocompatible, high-strength components with complex geometries for surgical instruments, orthopedic implants, and dental applications. The ability of MIM to produce parts with consistent mechanical properties and excellent surface finish makes it particularly valuable in this highly regulated sector.

Consumer electronics represents another significant market, where miniaturization trends drive demand for small, complex metal components with reliable mechanical properties. The need for components that can withstand repeated stress cycles without failure has positioned MIM as a preferred manufacturing method for smartphone frames, connectors, and other high-stress electronic components.

Regional analysis reveals Asia-Pacific as the dominant market, accounting for over 40% of global MIM component consumption. This is primarily due to the concentration of electronics manufacturing and automotive production in countries like China, Japan, and South Korea. North America and Europe follow with approximately 30% and 25% market share respectively, with particular strength in aerospace and medical applications.

Customer requirements are increasingly focused on enhanced mechanical properties, with particular emphasis on fatigue resistance for dynamic applications and fracture toughness for safety-critical components. Market research indicates that over 70% of MIM component buyers cite mechanical property reliability as their primary selection criterion, ahead of cost considerations.

The market is also witnessing growing demand for MIM components made from advanced alloys, including titanium, cobalt-chrome, and specialized stainless steels, which can deliver superior strength and fatigue resistance in challenging operating environments. This trend is expected to continue as industries push the performance boundaries of metal components in next-generation products.

Automotive and aerospace sectors represent the largest market segments for MIM components, collectively accounting for approximately 45% of total demand. These industries particularly value MIM's ability to produce components with excellent mechanical properties, including high strength-to-weight ratios and superior fatigue resistance. The trend toward vehicle lightweighting and fuel efficiency has significantly boosted demand for MIM parts that can replace heavier traditional components while maintaining or improving mechanical performance.

Medical device manufacturing has emerged as the fastest-growing application segment, with demand increasing at nearly 14% annually. This growth is fueled by the need for biocompatible, high-strength components with complex geometries for surgical instruments, orthopedic implants, and dental applications. The ability of MIM to produce parts with consistent mechanical properties and excellent surface finish makes it particularly valuable in this highly regulated sector.

Consumer electronics represents another significant market, where miniaturization trends drive demand for small, complex metal components with reliable mechanical properties. The need for components that can withstand repeated stress cycles without failure has positioned MIM as a preferred manufacturing method for smartphone frames, connectors, and other high-stress electronic components.

Regional analysis reveals Asia-Pacific as the dominant market, accounting for over 40% of global MIM component consumption. This is primarily due to the concentration of electronics manufacturing and automotive production in countries like China, Japan, and South Korea. North America and Europe follow with approximately 30% and 25% market share respectively, with particular strength in aerospace and medical applications.

Customer requirements are increasingly focused on enhanced mechanical properties, with particular emphasis on fatigue resistance for dynamic applications and fracture toughness for safety-critical components. Market research indicates that over 70% of MIM component buyers cite mechanical property reliability as their primary selection criterion, ahead of cost considerations.

The market is also witnessing growing demand for MIM components made from advanced alloys, including titanium, cobalt-chrome, and specialized stainless steels, which can deliver superior strength and fatigue resistance in challenging operating environments. This trend is expected to continue as industries push the performance boundaries of metal components in next-generation products.

Current State and Challenges in MIM Mechanical Properties

Metal Injection Molding (MIM) has emerged as a significant manufacturing process for complex metal components across various industries. Currently, the mechanical properties of MIM parts have reached impressive levels, with tensile strengths ranging from 400 to 1400 MPa depending on the alloy system used. This places MIM components in direct competition with traditionally manufactured counterparts in many applications.

Despite these achievements, the industry faces several critical challenges in consistently achieving optimal mechanical properties. Density variations remain a persistent issue, with typical MIM parts reaching 95-98% of theoretical density. These residual porosities, particularly when concentrated or interconnected, act as stress concentrators that significantly impact fatigue performance and fracture behavior. Research indicates that even a 2% increase in porosity can result in up to 15% reduction in fatigue strength.

The sintering process presents another major challenge, as temperature control and sintering atmosphere must be precisely managed to achieve desired microstructures. Variations as small as ±10°C can lead to substantial differences in grain size and phase distribution, directly affecting mechanical properties. Carbon control is particularly problematic in steel MIM parts, where carbon content variations of just 0.1% can shift tensile strength by 50-100 MPa.

Globally, research efforts show geographical concentration, with significant advancements coming from East Asia (particularly Japan and China), Europe (especially Germany), and North America. Japanese researchers have made notable progress in developing high-performance stainless steel MIM components with enhanced fatigue resistance, while German institutions lead in fundamental understanding of microstructure-property relationships.

The fatigue performance of MIM components remains substantially below that of wrought counterparts, with endurance limits typically 20-30% lower. This gap represents one of the most significant barriers to MIM adoption in highly demanding applications such as aerospace components and medical implants. Recent studies have demonstrated that post-processing treatments like hot isostatic pressing can narrow this gap to 10-15%, but at considerable additional cost.

Fracture toughness values for MIM parts also show greater variability compared to conventional manufacturing, with standard deviations up to three times higher. This inconsistency creates challenges for design engineers attempting to establish reliable safety factors. The industry currently lacks standardized testing protocols specifically optimized for MIM materials, further complicating property prediction and quality assurance.

Despite these achievements, the industry faces several critical challenges in consistently achieving optimal mechanical properties. Density variations remain a persistent issue, with typical MIM parts reaching 95-98% of theoretical density. These residual porosities, particularly when concentrated or interconnected, act as stress concentrators that significantly impact fatigue performance and fracture behavior. Research indicates that even a 2% increase in porosity can result in up to 15% reduction in fatigue strength.

The sintering process presents another major challenge, as temperature control and sintering atmosphere must be precisely managed to achieve desired microstructures. Variations as small as ±10°C can lead to substantial differences in grain size and phase distribution, directly affecting mechanical properties. Carbon control is particularly problematic in steel MIM parts, where carbon content variations of just 0.1% can shift tensile strength by 50-100 MPa.

Globally, research efforts show geographical concentration, with significant advancements coming from East Asia (particularly Japan and China), Europe (especially Germany), and North America. Japanese researchers have made notable progress in developing high-performance stainless steel MIM components with enhanced fatigue resistance, while German institutions lead in fundamental understanding of microstructure-property relationships.

The fatigue performance of MIM components remains substantially below that of wrought counterparts, with endurance limits typically 20-30% lower. This gap represents one of the most significant barriers to MIM adoption in highly demanding applications such as aerospace components and medical implants. Recent studies have demonstrated that post-processing treatments like hot isostatic pressing can narrow this gap to 10-15%, but at considerable additional cost.

Fracture toughness values for MIM parts also show greater variability compared to conventional manufacturing, with standard deviations up to three times higher. This inconsistency creates challenges for design engineers attempting to establish reliable safety factors. The industry currently lacks standardized testing protocols specifically optimized for MIM materials, further complicating property prediction and quality assurance.

Current Solutions for Enhancing MIM Mechanical Performance

01 Material composition effects on MIM strength properties

The composition of materials used in metal injection molding significantly affects the strength, fatigue resistance, and fracture behavior of the final parts. By carefully selecting and optimizing metal powders, binders, and additives, manufacturers can enhance mechanical properties. Various alloying elements and their proportions can be tailored to achieve specific strength requirements, while maintaining good moldability and dimensional stability during the sintering process.- Material composition effects on MIM strength properties: The composition of materials used in Metal Injection Molding significantly affects the mechanical properties including strength, fatigue resistance, and fracture behavior. Various metal powders and binder systems can be optimized to enhance mechanical performance. Specific alloying elements and their proportions can be tailored to improve tensile strength, yield strength, and overall durability of MIM parts.

- Processing parameters influence on mechanical properties: Processing parameters during metal injection molding, including injection pressure, temperature, sintering conditions, and cooling rates, have significant impacts on the final mechanical properties. Optimizing these parameters can enhance strength characteristics, reduce fatigue failure, and improve fracture toughness. Controlled cooling and specific sintering profiles can minimize internal stresses and defects that would otherwise lead to premature failure.

- Post-processing treatments for enhanced mechanical performance: Various post-processing treatments can significantly improve the mechanical properties of MIM parts. Heat treatments, surface modifications, and secondary operations like hot isostatic pressing can enhance strength, fatigue resistance, and fracture toughness. These treatments can optimize microstructure, reduce porosity, and create beneficial surface characteristics that extend component life under mechanical stress.

- Testing and evaluation methods for MIM mechanical properties: Specialized testing methodologies and evaluation techniques are essential for accurately assessing the strength, fatigue resistance, and fracture behavior of MIM components. These include tensile testing, fatigue cycling, impact testing, and fracture mechanics approaches. Advanced analytical techniques like finite element analysis and microstructural characterization help predict performance and identify potential failure modes in MIM parts under various loading conditions.

- Design considerations for optimizing MIM part performance: Design strategies specifically tailored for metal injection molded components can significantly improve mechanical performance. Considerations include wall thickness uniformity, elimination of sharp corners, proper gate location, and reinforcement features. Designs that account for the unique characteristics of the MIM process can minimize stress concentrations, enhance load distribution, and improve overall strength and fatigue resistance while reducing fracture risks.

02 Processing parameters optimization for improved mechanical properties

Processing parameters during metal injection molding significantly impact the mechanical properties of the final components. Factors such as injection pressure, temperature, holding time, cooling rate, debinding methods, and sintering profiles all affect the microstructure development and consequently the strength, fatigue resistance, and fracture behavior. Optimizing these parameters can minimize defects like porosity and internal stresses, leading to improved mechanical performance and reliability of MIM parts.Expand Specific Solutions03 Microstructure control and defect minimization

Controlling the microstructure and minimizing defects in metal injection molded parts is crucial for achieving optimal strength and fatigue resistance. Techniques to reduce porosity, eliminate internal voids, control grain size, and ensure uniform density distribution throughout the part can significantly enhance mechanical properties. Advanced sintering techniques and post-processing treatments can further refine the microstructure, leading to improved fracture toughness and fatigue life of MIM components.Expand Specific Solutions04 Testing and characterization methods for MIM parts

Various testing and characterization methods are employed to evaluate the strength, fatigue resistance, and fracture behavior of metal injection molded parts. These include tensile testing, fatigue testing, impact testing, hardness measurements, and microstructural analysis. Advanced techniques such as X-ray tomography, scanning electron microscopy, and finite element analysis help in understanding failure mechanisms and predicting the mechanical performance of MIM components under different loading conditions.Expand Specific Solutions05 Post-processing treatments for enhanced mechanical properties

Various post-processing treatments can be applied to metal injection molded parts to enhance their mechanical properties. Heat treatments such as annealing, quenching, and tempering can optimize the microstructure for improved strength and toughness. Surface treatments like shot peening, nitriding, and carburizing can introduce compressive residual stresses that enhance fatigue resistance. Hot isostatic pressing (HIP) can eliminate residual porosity, significantly improving strength and fatigue performance of MIM components.Expand Specific Solutions

Key Industry Players and Manufacturers in MIM

Metal Injection Molding (MIM) technology is currently in a growth phase, with the global market expected to reach significant expansion due to increasing demand for complex, high-precision metal components. The technology has matured considerably, achieving mechanical properties comparable to conventional manufacturing methods while offering cost advantages for complex geometries. Leading players like JSR Corp., NSK Ltd., and Proterial Ltd. have developed proprietary MIM formulations enhancing strength and fatigue resistance. US Synthetic Corp. and Kobe Steel have advanced fracture-resistant MIM materials, while companies like Husky Injection Molding Systems focus on equipment optimization. Academic institutions including Stevens Institute of Technology and Louisiana State University contribute fundamental research on microstructural improvements. The competitive landscape features both specialized MIM providers and diversified materials companies developing application-specific solutions.

Przedsiebiorstwo Innowacyjne Odlewnictwa Specodlew Sp. Z O.O.

Technical Solution: Specodlew has developed specialized MIM technologies focusing on high-performance alloys with enhanced mechanical properties. Their research centers on optimizing powder characteristics and sintering parameters to achieve near-theoretical densities (>98%), critical for maximizing strength and fatigue resistance. The company employs proprietary binder systems designed to minimize contamination during debinding, preserving the intrinsic mechanical properties of the base alloys. Their process innovations include controlled cooling protocols that optimize microstructural development, resulting in improved fracture toughness. Specodlew's research has demonstrated significant improvements in high-cycle fatigue performance through careful control of surface finish and internal defect populations. Their testing protocols include advanced non-destructive evaluation techniques to correlate processing parameters with mechanical performance. The company has also developed specialized post-sintering treatments that induce beneficial residual stress states, enhancing fatigue resistance in cyclically loaded components. Their work includes comprehensive fracture mechanics studies that have established relationships between processing parameters and fracture toughness in various alloy systems.

Strengths: Specialized expertise in high-performance alloys; excellent density control capabilities; advanced mechanical property optimization techniques. Weaknesses: Limited production capacity compared to larger manufacturers; higher unit costs for specialized materials; longer development cycles for new material systems.

Zoltrix Material (Guangzhou) Ltd.

Technical Solution: Zoltrix Material has developed comprehensive MIM technologies focused on optimizing mechanical properties through innovative powder formulations and processing techniques. Their research includes development of custom alloy systems with tailored mechanical properties, achieved through precise control of particle size distribution and morphology. The company employs advanced computational modeling to predict and optimize sintering behavior, resulting in enhanced density and reduced defect populations that could compromise mechanical performance. Zoltrix's proprietary binder systems are designed to facilitate uniform shrinkage during sintering, minimizing internal stresses that could reduce fatigue resistance. Their research has demonstrated significant improvements in fracture toughness through controlled introduction of secondary phases that impede crack propagation. The company utilizes advanced characterization techniques, including high-resolution tomography, to correlate microstructural features with mechanical performance. Zoltrix has also developed specialized surface treatments that induce compressive residual stresses, enhancing fatigue resistance in critical applications. Their integrated approach to process optimization has yielded MIM components with mechanical properties approaching those of wrought materials in several alloy systems.

Strengths: Strong materials science foundation; excellent process optimization capabilities; comprehensive testing and characterization facilities. Weaknesses: Less established global presence compared to industry leaders; more limited application experience in certain sectors; higher costs for specialized material formulations.

Critical Research on MIM Strength and Fatigue Resistance

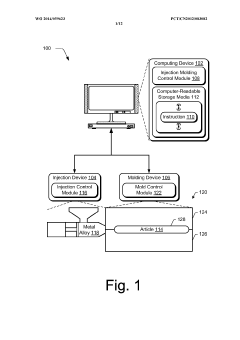

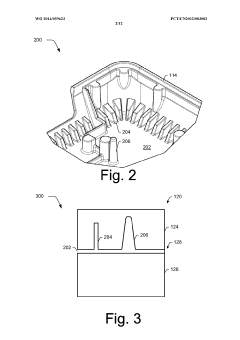

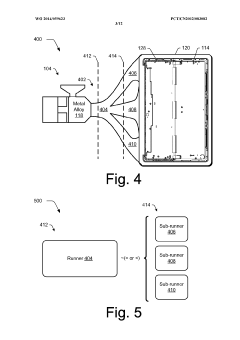

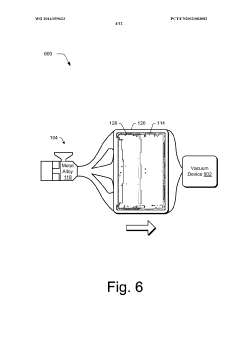

Metal alloy injection molding

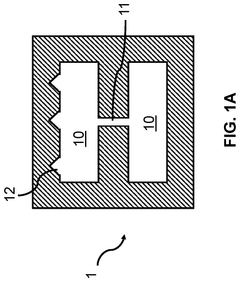

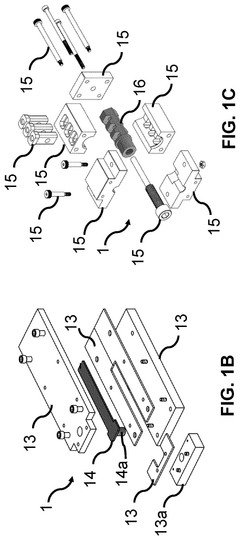

PatentWO2014059623A1

Innovation

- The techniques involve adjusting injection pressure, configuring runners and using vacuum pressure to enhance metal alloy flow, employing protrusions to counteract thermal expansion, and utilizing radii to reduce voids, allowing for the successful molding of larger metal alloy articles with complex features.

Mold for metal injection molding

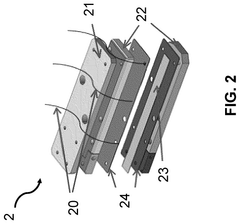

PatentPendingUS20250010368A1

Innovation

- A polymer mold with a metallic layer coating, specifically 100-200 nm thick, is used to reduce adhesion and improve moldability, allowing for the production of complex parts without significant thermal conductivity increases, using metals like chromium, silver, or gold, and polymers such as polytetrafluoroethylene or polycarbonate, with controlled pressure and temperature conditions.

Material Selection Strategies for Optimized MIM Properties

Material selection represents a critical factor in determining the final mechanical properties of Metal Injection Molded (MIM) components. The strategic selection of feedstock materials directly influences strength, fatigue resistance, and fracture behavior of the finished parts. When optimizing MIM properties, engineers must consider several key material characteristics including particle size distribution, powder morphology, and chemical composition.

Fine metal powders with spherical morphology typically yield superior results in MIM applications, as they facilitate better flow characteristics during injection and more uniform shrinkage during sintering. Powders with particle sizes ranging from 5-20 μm have demonstrated optimal balance between moldability and final mechanical properties. The selection of binder systems must complement the metal powder characteristics, with multi-component binders offering advantages in controlled debinding and minimal residual carbon content.

Alloy selection represents another crucial decision point in the MIM process chain. Stainless steels (particularly 17-4PH and 316L) remain industry standards due to their excellent combination of strength and corrosion resistance. However, specialized applications increasingly utilize advanced alloys such as titanium-based materials for biomedical implants, tungsten heavy alloys for high-density applications, and nickel-based superalloys for high-temperature performance.

Material purity significantly impacts mechanical properties, with oxygen and carbon content being particularly critical parameters. Research indicates that oxygen content below 0.2% and carbon content below 0.05% in the final sintered part generally yield optimal mechanical performance for most ferrous alloys. Trace elements must be carefully controlled, as even small variations can dramatically alter grain structure and precipitation behavior during sintering.

Pre-alloyed powders versus elemental powder mixes present another important consideration. While pre-alloyed powders typically offer more homogeneous microstructures and consistent properties, elemental mixes may provide cost advantages and flexibility in composition adjustment. The decision between these options should be guided by specific application requirements and property targets.

Recent innovations in powder metallurgy have introduced nano-scale reinforcements and composite formulations that can significantly enhance mechanical properties. For instance, incorporation of ceramic nanoparticles or carbon nanotubes at concentrations of 0.5-2% has demonstrated improvements in tensile strength by 15-30% and fatigue resistance by up to 40% in certain alloy systems, while maintaining acceptable moldability characteristics.

Fine metal powders with spherical morphology typically yield superior results in MIM applications, as they facilitate better flow characteristics during injection and more uniform shrinkage during sintering. Powders with particle sizes ranging from 5-20 μm have demonstrated optimal balance between moldability and final mechanical properties. The selection of binder systems must complement the metal powder characteristics, with multi-component binders offering advantages in controlled debinding and minimal residual carbon content.

Alloy selection represents another crucial decision point in the MIM process chain. Stainless steels (particularly 17-4PH and 316L) remain industry standards due to their excellent combination of strength and corrosion resistance. However, specialized applications increasingly utilize advanced alloys such as titanium-based materials for biomedical implants, tungsten heavy alloys for high-density applications, and nickel-based superalloys for high-temperature performance.

Material purity significantly impacts mechanical properties, with oxygen and carbon content being particularly critical parameters. Research indicates that oxygen content below 0.2% and carbon content below 0.05% in the final sintered part generally yield optimal mechanical performance for most ferrous alloys. Trace elements must be carefully controlled, as even small variations can dramatically alter grain structure and precipitation behavior during sintering.

Pre-alloyed powders versus elemental powder mixes present another important consideration. While pre-alloyed powders typically offer more homogeneous microstructures and consistent properties, elemental mixes may provide cost advantages and flexibility in composition adjustment. The decision between these options should be guided by specific application requirements and property targets.

Recent innovations in powder metallurgy have introduced nano-scale reinforcements and composite formulations that can significantly enhance mechanical properties. For instance, incorporation of ceramic nanoparticles or carbon nanotubes at concentrations of 0.5-2% has demonstrated improvements in tensile strength by 15-30% and fatigue resistance by up to 40% in certain alloy systems, while maintaining acceptable moldability characteristics.

Quality Control and Testing Standards for MIM Components

Quality control and testing standards for Metal Injection Molding (MIM) components are critical to ensuring consistent mechanical properties, particularly strength, fatigue resistance, and fracture behavior. The industry has developed comprehensive testing protocols that address the unique characteristics of MIM parts, which differ significantly from conventionally manufactured components due to their microstructural features.

ASTM B883 serves as the foundational standard for MIM components, outlining specific requirements for material composition, density, dimensional tolerances, and mechanical properties. This standard is complemented by ASTM E8 for tensile testing, which provides methodologies for determining ultimate tensile strength, yield strength, and elongation - properties that directly correlate with component performance under load.

For fatigue testing, ASTM E466 prescribes procedures for axial force-controlled fatigue testing, while ASTM E606 covers strain-controlled testing methods. These standards are particularly relevant for MIM components used in cyclically loaded applications such as automotive and aerospace parts. The S-N curves generated through these tests reveal the relationship between stress amplitude and cycles to failure, critical for predicting component lifespan.

Fracture toughness evaluation follows ASTM E1820, which determines a material's resistance to crack propagation. For MIM components, this testing is especially important due to the potential presence of processing-induced defects that can serve as crack initiation sites. The J-integral and K1C values obtained provide quantitative measures of fracture resistance under different loading conditions.

Microstructural analysis standards, including ASTM E3 for metallographic preparation and ASTM E112 for grain size determination, complement mechanical testing by correlating microstructural features with mechanical behavior. Porosity assessment, following ASTM B311, is particularly crucial for MIM parts as residual porosity significantly impacts mechanical properties.

Non-destructive testing methods have also been standardized for MIM components. These include ASTM E1742 for radiographic testing to detect internal defects, ASTM E1444 for magnetic particle inspection of ferromagnetic materials, and ASTM E1417 for liquid penetrant testing to identify surface discontinuities.

Statistical process control methods, as outlined in ASTM E2281, are increasingly integrated into MIM quality systems to monitor process stability and predict potential deviations before they affect mechanical properties. This approach enables manufacturers to maintain consistent strength, fatigue resistance, and fracture toughness across production batches.

ASTM B883 serves as the foundational standard for MIM components, outlining specific requirements for material composition, density, dimensional tolerances, and mechanical properties. This standard is complemented by ASTM E8 for tensile testing, which provides methodologies for determining ultimate tensile strength, yield strength, and elongation - properties that directly correlate with component performance under load.

For fatigue testing, ASTM E466 prescribes procedures for axial force-controlled fatigue testing, while ASTM E606 covers strain-controlled testing methods. These standards are particularly relevant for MIM components used in cyclically loaded applications such as automotive and aerospace parts. The S-N curves generated through these tests reveal the relationship between stress amplitude and cycles to failure, critical for predicting component lifespan.

Fracture toughness evaluation follows ASTM E1820, which determines a material's resistance to crack propagation. For MIM components, this testing is especially important due to the potential presence of processing-induced defects that can serve as crack initiation sites. The J-integral and K1C values obtained provide quantitative measures of fracture resistance under different loading conditions.

Microstructural analysis standards, including ASTM E3 for metallographic preparation and ASTM E112 for grain size determination, complement mechanical testing by correlating microstructural features with mechanical behavior. Porosity assessment, following ASTM B311, is particularly crucial for MIM parts as residual porosity significantly impacts mechanical properties.

Non-destructive testing methods have also been standardized for MIM components. These include ASTM E1742 for radiographic testing to detect internal defects, ASTM E1444 for magnetic particle inspection of ferromagnetic materials, and ASTM E1417 for liquid penetrant testing to identify surface discontinuities.

Statistical process control methods, as outlined in ASTM E2281, are increasingly integrated into MIM quality systems to monitor process stability and predict potential deviations before they affect mechanical properties. This approach enables manufacturers to maintain consistent strength, fatigue resistance, and fracture toughness across production batches.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!