Metal Injection Molding Cost Drivers: Tooling Life, Yield And Inline Inspection

SEP 16, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

MIM Technology Background and Objectives

Metal Injection Molding (MIM) emerged in the 1970s as a revolutionary manufacturing process combining the design flexibility of plastic injection molding with the superior material properties of powder metallurgy. This technology has evolved significantly over the past five decades, transitioning from experimental applications to a mainstream manufacturing method for complex metal components across various industries including automotive, medical, aerospace, and consumer electronics.

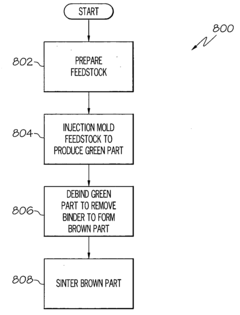

The fundamental principle of MIM involves mixing fine metal powders with polymer binders to create a feedstock that can be injection molded into complex shapes. After molding, the binder is removed through debinding processes, and the remaining metal particles are sintered at high temperatures to achieve near full density. This process enables the production of intricate metal parts with excellent mechanical properties that would be difficult or cost-prohibitive to manufacture using conventional methods.

Recent technological advancements have focused on improving process efficiency, material versatility, and component quality. The development of new binder systems, optimization of debinding techniques, and refinement of sintering parameters have collectively enhanced the capabilities of MIM technology. Additionally, computational modeling and simulation tools have enabled more precise prediction of material behavior during the molding and sintering stages, reducing development time and costs.

The global MIM market has experienced robust growth, with a compound annual growth rate exceeding 11% in recent years. This expansion is driven by increasing demand for complex, high-precision metal components in miniaturized devices and systems. The technology's ability to produce near-net-shape parts with minimal material waste aligns well with modern sustainability objectives and lean manufacturing principles.

The primary technical objectives in MIM development currently center around three critical cost drivers: tooling life, production yield, and inline inspection capabilities. Extended tooling life is essential for amortizing the significant initial investment in mold design and fabrication across larger production volumes. Improving yield rates directly impacts unit economics by reducing scrap and rework. Meanwhile, advanced inline inspection technologies enable real-time quality control, preventing defective parts from progressing through the production cycle.

Looking forward, the MIM industry is poised for further innovation through integration with digital manufacturing technologies, development of novel material compositions, and implementation of advanced process control systems. These developments aim to address persistent challenges related to dimensional accuracy, surface finish, and batch-to-batch consistency while expanding the application scope of MIM technology into new markets and product categories.

The fundamental principle of MIM involves mixing fine metal powders with polymer binders to create a feedstock that can be injection molded into complex shapes. After molding, the binder is removed through debinding processes, and the remaining metal particles are sintered at high temperatures to achieve near full density. This process enables the production of intricate metal parts with excellent mechanical properties that would be difficult or cost-prohibitive to manufacture using conventional methods.

Recent technological advancements have focused on improving process efficiency, material versatility, and component quality. The development of new binder systems, optimization of debinding techniques, and refinement of sintering parameters have collectively enhanced the capabilities of MIM technology. Additionally, computational modeling and simulation tools have enabled more precise prediction of material behavior during the molding and sintering stages, reducing development time and costs.

The global MIM market has experienced robust growth, with a compound annual growth rate exceeding 11% in recent years. This expansion is driven by increasing demand for complex, high-precision metal components in miniaturized devices and systems. The technology's ability to produce near-net-shape parts with minimal material waste aligns well with modern sustainability objectives and lean manufacturing principles.

The primary technical objectives in MIM development currently center around three critical cost drivers: tooling life, production yield, and inline inspection capabilities. Extended tooling life is essential for amortizing the significant initial investment in mold design and fabrication across larger production volumes. Improving yield rates directly impacts unit economics by reducing scrap and rework. Meanwhile, advanced inline inspection technologies enable real-time quality control, preventing defective parts from progressing through the production cycle.

Looking forward, the MIM industry is poised for further innovation through integration with digital manufacturing technologies, development of novel material compositions, and implementation of advanced process control systems. These developments aim to address persistent challenges related to dimensional accuracy, surface finish, and batch-to-batch consistency while expanding the application scope of MIM technology into new markets and product categories.

Market Analysis for MIM Components

The Metal Injection Molding (MIM) components market has experienced significant growth over the past decade, driven by increasing demand across various industries including automotive, medical, consumer electronics, and aerospace. Currently valued at approximately $2.7 billion globally, the market is projected to grow at a CAGR of 11.3% through 2028, reaching over $5 billion by the end of the forecast period.

The automotive sector represents the largest application segment, accounting for roughly 35% of the total MIM components market. This dominance is attributed to the growing need for lightweight, complex-shaped metal parts that enhance fuel efficiency while maintaining structural integrity. The medical devices segment follows closely, representing about 28% of the market, with demand primarily driven by the need for precision components in surgical instruments, orthopedic implants, and dental applications.

Geographically, Asia Pacific leads the global MIM market with approximately 45% market share, with China and Japan being the primary contributors. North America and Europe follow with 30% and 20% market shares respectively, while the rest of the world accounts for the remaining 5%. The Asia Pacific region's dominance can be attributed to the presence of a robust manufacturing infrastructure, lower production costs, and increasing adoption of advanced manufacturing technologies.

The market is witnessing several notable trends that are reshaping demand dynamics. First, there is increasing preference for MIM over traditional manufacturing methods due to its ability to produce complex geometries with tight tolerances while minimizing material waste. Second, miniaturization trends across electronics and medical devices are driving demand for micro-MIM components. Third, the push toward sustainable manufacturing is positioning MIM favorably due to its relatively lower energy consumption compared to conventional machining processes.

Key customer segments demonstrate varying priorities regarding MIM components. The automotive industry prioritizes cost-effectiveness and durability, while the medical sector emphasizes biocompatibility, precision, and surface finish quality. The aerospace industry, though smaller in market share (approximately 8%), places premium value on high-performance alloys and stringent quality control measures.

Market research indicates that customers are increasingly concerned about total cost of ownership rather than just unit prices. This shift has placed greater emphasis on tooling life, production yields, and inline inspection capabilities as critical factors influencing purchasing decisions. Companies that can demonstrate superior performance in these areas are gaining competitive advantage and commanding premium pricing in the marketplace.

The automotive sector represents the largest application segment, accounting for roughly 35% of the total MIM components market. This dominance is attributed to the growing need for lightweight, complex-shaped metal parts that enhance fuel efficiency while maintaining structural integrity. The medical devices segment follows closely, representing about 28% of the market, with demand primarily driven by the need for precision components in surgical instruments, orthopedic implants, and dental applications.

Geographically, Asia Pacific leads the global MIM market with approximately 45% market share, with China and Japan being the primary contributors. North America and Europe follow with 30% and 20% market shares respectively, while the rest of the world accounts for the remaining 5%. The Asia Pacific region's dominance can be attributed to the presence of a robust manufacturing infrastructure, lower production costs, and increasing adoption of advanced manufacturing technologies.

The market is witnessing several notable trends that are reshaping demand dynamics. First, there is increasing preference for MIM over traditional manufacturing methods due to its ability to produce complex geometries with tight tolerances while minimizing material waste. Second, miniaturization trends across electronics and medical devices are driving demand for micro-MIM components. Third, the push toward sustainable manufacturing is positioning MIM favorably due to its relatively lower energy consumption compared to conventional machining processes.

Key customer segments demonstrate varying priorities regarding MIM components. The automotive industry prioritizes cost-effectiveness and durability, while the medical sector emphasizes biocompatibility, precision, and surface finish quality. The aerospace industry, though smaller in market share (approximately 8%), places premium value on high-performance alloys and stringent quality control measures.

Market research indicates that customers are increasingly concerned about total cost of ownership rather than just unit prices. This shift has placed greater emphasis on tooling life, production yields, and inline inspection capabilities as critical factors influencing purchasing decisions. Companies that can demonstrate superior performance in these areas are gaining competitive advantage and commanding premium pricing in the marketplace.

Technical Challenges in MIM Production

Metal Injection Molding (MIM) faces several significant technical challenges that impact production efficiency and cost-effectiveness. The complexity of the MIM process, which combines powder metallurgy with plastic injection molding techniques, introduces multiple variables that must be carefully controlled to ensure consistent quality.

Tooling wear represents a primary challenge in MIM production. The highly abrasive nature of metal powders mixed with binders causes accelerated tool degradation compared to conventional plastic injection molding. This wear affects critical dimensions and surface finish of components, leading to increased rejection rates as tools age. The high replacement cost of precision tooling significantly impacts overall production economics, particularly for smaller production runs where these costs cannot be amortized over large volumes.

Feedstock homogeneity presents another substantial challenge. Inconsistent mixing of metal powders with binder systems creates variations in flow behavior during injection and subsequent dimensional control issues. These variations can lead to defects such as voids, cracks, or density gradients that may only become apparent after sintering, resulting in costly scrap rates at late production stages.

Debinding and sintering processes introduce additional technical complexities. The removal of binder components must occur at precisely controlled rates to prevent defects such as blistering or cracking. Similarly, sintering requires exact temperature profiles to achieve desired densification without distortion. Both processes contribute significantly to cycle time and energy consumption, affecting overall production costs.

Quality control and inspection present unique challenges in MIM production. Unlike conventional manufacturing methods, many critical defects in MIM parts cannot be detected until after sintering, when significant value has already been added to the components. The development of effective in-line inspection techniques remains technically challenging due to the complex shape changes that occur during processing.

Process parameter optimization represents an ongoing challenge. The interdependence of numerous variables—including injection pressure, temperature, feedstock composition, debinding rates, and sintering profiles—creates a multidimensional optimization problem. Small variations in these parameters can have compounding effects on final part quality, necessitating sophisticated process control systems and extensive experience.

Environmental and safety considerations add further complexity. The handling of fine metal powders presents explosion and health hazards, while certain debinding processes may involve hazardous chemicals requiring specialized containment and treatment systems. These safety requirements add to facility costs and operational complexity.

Tooling wear represents a primary challenge in MIM production. The highly abrasive nature of metal powders mixed with binders causes accelerated tool degradation compared to conventional plastic injection molding. This wear affects critical dimensions and surface finish of components, leading to increased rejection rates as tools age. The high replacement cost of precision tooling significantly impacts overall production economics, particularly for smaller production runs where these costs cannot be amortized over large volumes.

Feedstock homogeneity presents another substantial challenge. Inconsistent mixing of metal powders with binder systems creates variations in flow behavior during injection and subsequent dimensional control issues. These variations can lead to defects such as voids, cracks, or density gradients that may only become apparent after sintering, resulting in costly scrap rates at late production stages.

Debinding and sintering processes introduce additional technical complexities. The removal of binder components must occur at precisely controlled rates to prevent defects such as blistering or cracking. Similarly, sintering requires exact temperature profiles to achieve desired densification without distortion. Both processes contribute significantly to cycle time and energy consumption, affecting overall production costs.

Quality control and inspection present unique challenges in MIM production. Unlike conventional manufacturing methods, many critical defects in MIM parts cannot be detected until after sintering, when significant value has already been added to the components. The development of effective in-line inspection techniques remains technically challenging due to the complex shape changes that occur during processing.

Process parameter optimization represents an ongoing challenge. The interdependence of numerous variables—including injection pressure, temperature, feedstock composition, debinding rates, and sintering profiles—creates a multidimensional optimization problem. Small variations in these parameters can have compounding effects on final part quality, necessitating sophisticated process control systems and extensive experience.

Environmental and safety considerations add further complexity. The handling of fine metal powders presents explosion and health hazards, while certain debinding processes may involve hazardous chemicals requiring specialized containment and treatment systems. These safety requirements add to facility costs and operational complexity.

Current Cost Optimization Solutions

01 Tooling life optimization in MIM processes

Tooling life is a significant cost driver in metal injection molding. Various approaches can extend tool lifespan, including advanced materials for mold construction, optimized cooling systems, and specialized coatings that reduce wear. Proper maintenance protocols and monitoring systems can detect early signs of tool degradation. Extending tooling life directly reduces per-part costs by distributing tooling investment across more production units.- Tooling life optimization in MIM processes: Tooling life is a significant cost driver in metal injection molding. Various approaches can extend the lifespan of molds and tooling components, including advanced materials selection, surface treatments, and optimized design. Proper maintenance protocols and monitoring systems can detect early signs of wear, allowing for timely interventions. Temperature control during the molding process also plays a crucial role in preventing premature tool degradation and ensuring consistent part quality throughout the tool's lifecycle.

- Yield improvement strategies: Yield is a critical cost factor in metal injection molding operations. Enhancing yield involves minimizing defects through precise control of process parameters such as temperature, pressure, and material flow. Advanced feedstock formulations with optimized binder systems can reduce part rejection rates. Statistical process control methods help identify and eliminate sources of variation. Additionally, proper debinding and sintering protocols are essential to prevent warping, cracking, and dimensional inconsistencies that would otherwise reduce production yield.

- Inline inspection technologies and quality control: Inline inspection systems are increasingly important for cost control in metal injection molding. Advanced vision systems, sensors, and real-time monitoring equipment can detect defects during production rather than at final inspection. Machine learning algorithms can analyze inspection data to predict potential issues before they occur. Automated dimensional verification ensures parts meet specifications without manual intervention. These technologies reduce scrap rates and rework costs while enabling faster production cycles and consistent quality.

- Material selection and feedstock optimization: The selection and optimization of metal powders and binder systems significantly impact MIM production costs. Particle size distribution, powder morphology, and binder compatibility affect flowability during injection and dimensional stability during sintering. Recycling and reuse strategies for feedstock materials can reduce raw material costs. Advanced feedstock formulations can lower processing temperatures and times, reducing energy consumption. The right material selection also influences debinding efficiency and sintering behavior, which directly affects production cycle time and yield.

- Process automation and equipment efficiency: Automation and equipment efficiency are major cost drivers in metal injection molding operations. Implementing robotic handling systems reduces labor costs and improves consistency. Advanced process control systems optimize cycle times and reduce energy consumption. Predictive maintenance approaches minimize unplanned downtime. Integration of digital manufacturing principles enables real-time adjustments to process parameters based on production data. Equipment modifications that improve heating efficiency, material flow, and cooling can significantly reduce cycle times and energy costs.

02 Yield improvement strategies

Yield optimization is critical for MIM cost efficiency. This includes minimizing material waste during feedstock preparation, optimizing runner systems to reduce scrap, and implementing process controls to decrease defect rates. Advanced simulation tools can predict and prevent common defects like warping, cracking, and incomplete filling. Higher yields directly translate to lower per-part costs by maximizing the number of acceptable parts from raw material inputs.Expand Specific Solutions03 Inline inspection technologies

Inline inspection systems represent a critical cost control measure in MIM production. These include automated vision systems, dimensional scanning, and non-destructive testing methods that can detect defects during production rather than after completion. Real-time monitoring allows for immediate process adjustments, reducing scrap rates and preventing downstream processing of defective parts. While implementing inspection systems requires initial investment, they significantly reduce overall costs by minimizing waste and rework.Expand Specific Solutions04 Material and feedstock optimization

Material selection and feedstock preparation significantly impact MIM costs. This includes optimizing binder systems for better flowability and debinding characteristics, precise control of powder particle size distribution, and development of feedstock formulations that minimize segregation during molding. Advanced mixing techniques ensure homogeneous feedstock, while recycling strategies for runners and rejected parts can recover valuable metal powders. These optimizations reduce material costs while improving part quality and process reliability.Expand Specific Solutions05 Process automation and monitoring systems

Automation and advanced monitoring systems play a crucial role in controlling MIM costs. These include robotic handling systems, automated parameter adjustment based on real-time data, and integrated production management systems that optimize machine utilization. Sensors throughout the production line collect data on temperature, pressure, flow rates, and other critical parameters. This information enables predictive maintenance, reduces labor costs, and ensures consistent quality, all contributing to lower overall production costs.Expand Specific Solutions

Leading MIM Industry Players

Metal Injection Molding (MIM) is currently in a growth phase, with the global market expected to reach significant expansion due to increasing demand in automotive, medical, and consumer electronics sectors. The technology has matured considerably, with key players demonstrating varying levels of expertise. Autodesk offers advanced simulation software for optimizing MIM processes, while specialized manufacturers like Husky Injection Molding Systems and iMFLUX (Procter & Gamble) focus on innovative tooling solutions to extend life and improve yields. Japanese companies including Sumitomo Heavy Industries, Nissei Plastic, and Japan Steel Works have established strong positions in equipment manufacturing with integrated inspection capabilities. The competitive landscape is characterized by increasing focus on automation, real-time monitoring, and quality control systems to address the primary cost drivers of tooling life and production yield.

Sumitomo Heavy Industries, Ltd.

Technical Solution: Sumitomo Heavy Industries has developed the "SE-DUO" system specifically targeting MIM cost efficiency through tooling life extension and yield improvement. Their approach combines dual-material tooling inserts that place high-performance tool steels only in high-wear areas, reducing overall tooling costs while extending service life. The company's proprietary coating technology, applied through a plasma-enhanced chemical vapor deposition process, creates ultra-hard surfaces with friction coefficients approximately 40% lower than conventional treatments. Sumitomo's process monitoring system integrates cavity pressure sensors with thermal imaging to create comprehensive mold condition maps, enabling early detection of potential failure points. Their inline inspection technology incorporates multi-spectrum imaging that can detect both surface and subsurface defects at production speeds exceeding 10,000 parts per hour. The company has also pioneered adaptive cooling channel designs that maintain more consistent temperature distributions across complex tool geometries, reducing thermal stress and extending tool life while improving dimensional stability of finished parts.

Strengths: Excellent cost-performance balance through strategic use of premium materials only where needed; sophisticated thermal management that reduces cycle times while extending tool life; highly automated inspection systems requiring minimal operator intervention. Weaknesses: Complex tooling designs can extend initial manufacturing lead times; specialized maintenance requirements; system optimization requires extensive process knowledge.

Nissei Plastic Industrial Co., Ltd.

Technical Solution: Nissei has developed the "X-MIM" platform specifically addressing cost drivers in metal injection molding operations. Their system features a hybrid tooling approach that combines conventional tool steels with ceramic inserts at critical wear points, extending overall tool life by approximately 45% for abrasive feedstock materials. The company's proprietary control system monitors injection parameters with millisecond precision, allowing for real-time adjustments that maintain consistent part quality despite gradual tool wear. Nissei's approach to yield improvement includes a patented venting system that reduces gas trapping defects by approximately 30% compared to conventional designs. Their inline inspection technology combines structured light scanning with thermal imaging to detect both dimensional and internal defects without interrupting production flow. The company has also developed specialized feedstock formulations with improved flow characteristics that reduce tool wear while maintaining final part properties. Nissei's integrated production management system connects quality data directly to process parameters, enabling automated optimization routines that maintain yield rates even as tooling approaches end-of-life conditions.

Strengths: Exceptional tool life extension through innovative material combinations; sophisticated process control capabilities that compensate for gradual tool wear; excellent yield stability throughout the tooling lifecycle. Weaknesses: Higher initial tooling costs; system requires specialized maintenance expertise; technology implementation requires substantial process reengineering.

Key Innovations in Tooling Materials

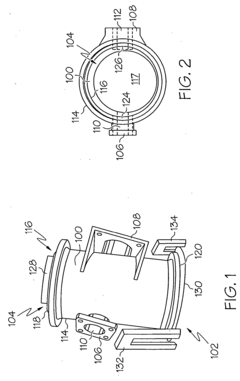

Advanced sintering process and tools for use in metal injection molding of large parts

PatentInactiveUS20070003426A1

Innovation

- A tool assembly comprising an insert and endcap with an adjustable slot and a stand to support side housings, made from materials that maintain structural integrity at high temperatures, preventing deformation and allowing for the sintering of larger parts by controlling shrinkage and providing support during the process.

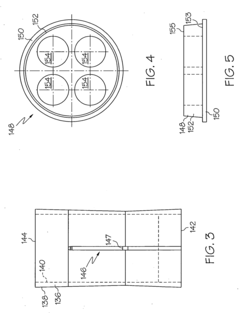

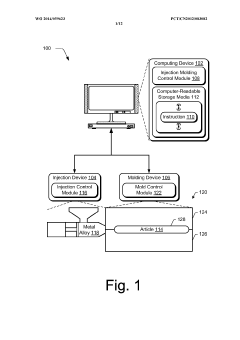

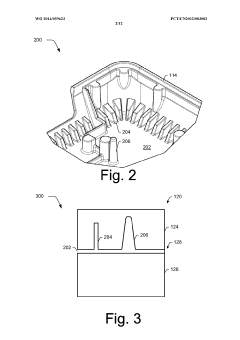

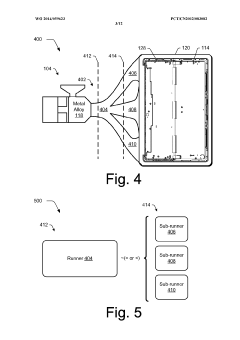

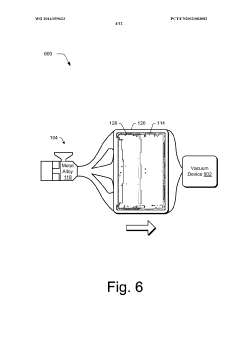

Metal alloy injection molding

PatentWO2014059623A1

Innovation

- The techniques involve adjusting injection pressure, configuring runners and using vacuum pressure to enhance metal alloy flow, employing protrusions to counteract thermal expansion, and utilizing radii to reduce voids, allowing for the successful molding of larger metal alloy articles with complex features.

Quality Control Systems Integration

Quality control systems integration represents a critical component in optimizing Metal Injection Molding (MIM) processes, directly impacting key cost drivers including tooling life, yield rates, and inspection efficiency. Modern MIM facilities are increasingly implementing integrated quality management systems that connect various inspection points throughout the production workflow.

Advanced sensor technologies now enable real-time monitoring of critical process parameters during the injection molding phase. These systems can detect variations in pressure, temperature, and material flow characteristics that may indicate potential defects or tooling wear. By establishing digital connections between these sensors and central quality management platforms, manufacturers can implement predictive maintenance protocols that significantly extend tooling life.

Statistical Process Control (SPC) software integration has emerged as a fundamental approach for MIM quality assurance. These systems collect and analyze data from multiple inspection points, establishing control limits that help identify process drift before it results in defective parts. The integration of SPC with production equipment allows for automated adjustments when parameters approach control limits, maintaining optimal yield rates without human intervention.

Machine vision systems integrated at critical inspection points provide non-contact measurement capabilities that can detect surface defects, dimensional variations, and material inconsistencies. These systems are increasingly being connected to central databases that store historical quality data, enabling comparative analysis and continuous improvement initiatives. The integration of these vision systems with production equipment control systems allows for immediate corrective actions when defects are detected.

Cloud-based quality management platforms now enable the integration of quality data across multiple production facilities. This enterprise-level integration provides valuable insights into regional variations in quality performance and facilitates the standardization of best practices across global operations. Such systems typically incorporate machine learning algorithms that can identify subtle patterns in quality data that might escape human analysis.

The financial impact of integrated quality systems in MIM operations is substantial. Industry studies indicate that comprehensive quality system integration can reduce scrap rates by 15-25%, extend tooling life by 30-40%, and decrease quality-related labor costs by up to 50%. These improvements directly address the primary cost drivers in MIM production, making quality system integration a strategic investment rather than merely an operational expense.

Advanced sensor technologies now enable real-time monitoring of critical process parameters during the injection molding phase. These systems can detect variations in pressure, temperature, and material flow characteristics that may indicate potential defects or tooling wear. By establishing digital connections between these sensors and central quality management platforms, manufacturers can implement predictive maintenance protocols that significantly extend tooling life.

Statistical Process Control (SPC) software integration has emerged as a fundamental approach for MIM quality assurance. These systems collect and analyze data from multiple inspection points, establishing control limits that help identify process drift before it results in defective parts. The integration of SPC with production equipment allows for automated adjustments when parameters approach control limits, maintaining optimal yield rates without human intervention.

Machine vision systems integrated at critical inspection points provide non-contact measurement capabilities that can detect surface defects, dimensional variations, and material inconsistencies. These systems are increasingly being connected to central databases that store historical quality data, enabling comparative analysis and continuous improvement initiatives. The integration of these vision systems with production equipment control systems allows for immediate corrective actions when defects are detected.

Cloud-based quality management platforms now enable the integration of quality data across multiple production facilities. This enterprise-level integration provides valuable insights into regional variations in quality performance and facilitates the standardization of best practices across global operations. Such systems typically incorporate machine learning algorithms that can identify subtle patterns in quality data that might escape human analysis.

The financial impact of integrated quality systems in MIM operations is substantial. Industry studies indicate that comprehensive quality system integration can reduce scrap rates by 15-25%, extend tooling life by 30-40%, and decrease quality-related labor costs by up to 50%. These improvements directly address the primary cost drivers in MIM production, making quality system integration a strategic investment rather than merely an operational expense.

Material Science Advancements

Recent advancements in material science have significantly impacted the Metal Injection Molding (MIM) industry, particularly in addressing cost drivers related to tooling life, yield, and inspection processes. The development of novel feedstock formulations has been at the forefront of these innovations, with researchers creating optimized binder systems that facilitate better flow characteristics while reducing wear on tooling components.

Advanced ceramic-metal composite materials have emerged as game-changers for tooling applications in MIM processes. These materials exhibit exceptional hardness and wear resistance while maintaining dimensional stability under the high-pressure and temperature conditions typical in injection molding operations. Studies indicate that tools manufactured with these advanced composites can achieve up to 40% longer service life compared to conventional tool steels, directly impacting production economics.

Nanomaterial integration into metal powders has revolutionized the sintering behavior of MIM parts. By incorporating carefully engineered nanoparticles, manufacturers have achieved more uniform shrinkage during sintering, resulting in higher dimensional accuracy and significantly improved yields. This advancement has been particularly valuable for complex geometries where traditional MIM processes often struggled with inconsistent densification.

Surface modification technologies have evolved to create more resilient tooling surfaces. Techniques such as Physical Vapor Deposition (PVD) and Chemical Vapor Deposition (CVD) coatings with specialized formulations have demonstrated remarkable resistance to abrasive wear from metal powders. These coatings, often just a few microns thick, can extend tool life by 25-35% while maintaining precise dimensional tolerances throughout production runs.

Computational materials science has enabled the development of predictive models for material behavior during the MIM process. These models account for rheological properties, thermal gradients, and phase transformations, allowing engineers to optimize material formulations specifically for improved flow characteristics that reduce tool wear while maintaining excellent part quality. This approach has reduced the empirical trial-and-error traditionally required when developing new MIM materials.

Biodegradable binder systems represent another significant advancement, addressing both environmental concerns and yield improvements. These new binder formulations decompose more uniformly during debinding, reducing the risk of defects while minimizing hazardous waste. Studies have shown that these environmentally friendly alternatives can achieve comparable or superior performance to traditional petroleum-based binders while reducing the environmental footprint of MIM operations.

Advanced ceramic-metal composite materials have emerged as game-changers for tooling applications in MIM processes. These materials exhibit exceptional hardness and wear resistance while maintaining dimensional stability under the high-pressure and temperature conditions typical in injection molding operations. Studies indicate that tools manufactured with these advanced composites can achieve up to 40% longer service life compared to conventional tool steels, directly impacting production economics.

Nanomaterial integration into metal powders has revolutionized the sintering behavior of MIM parts. By incorporating carefully engineered nanoparticles, manufacturers have achieved more uniform shrinkage during sintering, resulting in higher dimensional accuracy and significantly improved yields. This advancement has been particularly valuable for complex geometries where traditional MIM processes often struggled with inconsistent densification.

Surface modification technologies have evolved to create more resilient tooling surfaces. Techniques such as Physical Vapor Deposition (PVD) and Chemical Vapor Deposition (CVD) coatings with specialized formulations have demonstrated remarkable resistance to abrasive wear from metal powders. These coatings, often just a few microns thick, can extend tool life by 25-35% while maintaining precise dimensional tolerances throughout production runs.

Computational materials science has enabled the development of predictive models for material behavior during the MIM process. These models account for rheological properties, thermal gradients, and phase transformations, allowing engineers to optimize material formulations specifically for improved flow characteristics that reduce tool wear while maintaining excellent part quality. This approach has reduced the empirical trial-and-error traditionally required when developing new MIM materials.

Biodegradable binder systems represent another significant advancement, addressing both environmental concerns and yield improvements. These new binder formulations decompose more uniformly during debinding, reducing the risk of defects while minimizing hazardous waste. Studies have shown that these environmentally friendly alternatives can achieve comparable or superior performance to traditional petroleum-based binders while reducing the environmental footprint of MIM operations.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!