Metal Injection Molding Simulation: Viscous Flow, Weld Lines And Packing Pressure

SEP 16, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

MIM Technology Evolution and Simulation Objectives

Metal Injection Molding (MIM) has evolved significantly since its inception in the 1970s, transforming from an experimental manufacturing technique to a sophisticated industrial process. Initially developed as an extension of powder metallurgy, MIM has progressively incorporated advanced material science principles and engineering methodologies to enhance production efficiency and component quality. The technology's evolution can be traced through several distinct phases, beginning with rudimentary mixing and molding techniques, advancing to more precise feedstock formulations, and culminating in today's highly controlled processes that yield complex geometries with exceptional material properties.

The simulation of MIM processes represents a critical advancement in this technological trajectory. Early MIM manufacturing relied heavily on empirical knowledge and trial-and-error approaches, resulting in significant material waste, quality inconsistencies, and extended development cycles. As computational capabilities expanded in the 1990s and 2000s, preliminary simulation tools emerged, though these were limited in their ability to accurately model the multiphysics nature of MIM processes.

Current technological trends indicate a growing emphasis on high-fidelity simulation capabilities that can precisely predict material behavior during the injection, debinding, and sintering phases. Particular attention is being directed toward viscous flow dynamics, as the non-Newtonian behavior of MIM feedstocks presents substantial modeling challenges. The accurate prediction of weld line formation—where separate flow fronts meet during the injection process—has become increasingly important due to their significant impact on final part integrity and mechanical properties.

Packing pressure simulation has emerged as another critical focus area, as this phase directly influences dimensional accuracy, internal stress distribution, and defect formation. The complex interplay between pressure, temperature, and material rheology during packing requires sophisticated simulation approaches that can account for time-dependent material behavior and phase transitions.

The primary objectives of modern MIM simulation technology center on developing comprehensive models that can accurately predict the entire manufacturing process chain. This includes capturing the rheological behavior of feedstock materials under varying processing conditions, predicting defect formation mechanisms with high precision, and optimizing process parameters to achieve desired material properties and dimensional specifications. Additionally, there is a growing emphasis on reducing computational requirements while maintaining simulation accuracy, enabling more widespread adoption of simulation tools across the industry.

Looking forward, the integration of machine learning algorithms with physics-based models represents a promising direction for MIM simulation, potentially enabling real-time process optimization and adaptive manufacturing approaches that can respond dynamically to variations in material properties or processing conditions.

The simulation of MIM processes represents a critical advancement in this technological trajectory. Early MIM manufacturing relied heavily on empirical knowledge and trial-and-error approaches, resulting in significant material waste, quality inconsistencies, and extended development cycles. As computational capabilities expanded in the 1990s and 2000s, preliminary simulation tools emerged, though these were limited in their ability to accurately model the multiphysics nature of MIM processes.

Current technological trends indicate a growing emphasis on high-fidelity simulation capabilities that can precisely predict material behavior during the injection, debinding, and sintering phases. Particular attention is being directed toward viscous flow dynamics, as the non-Newtonian behavior of MIM feedstocks presents substantial modeling challenges. The accurate prediction of weld line formation—where separate flow fronts meet during the injection process—has become increasingly important due to their significant impact on final part integrity and mechanical properties.

Packing pressure simulation has emerged as another critical focus area, as this phase directly influences dimensional accuracy, internal stress distribution, and defect formation. The complex interplay between pressure, temperature, and material rheology during packing requires sophisticated simulation approaches that can account for time-dependent material behavior and phase transitions.

The primary objectives of modern MIM simulation technology center on developing comprehensive models that can accurately predict the entire manufacturing process chain. This includes capturing the rheological behavior of feedstock materials under varying processing conditions, predicting defect formation mechanisms with high precision, and optimizing process parameters to achieve desired material properties and dimensional specifications. Additionally, there is a growing emphasis on reducing computational requirements while maintaining simulation accuracy, enabling more widespread adoption of simulation tools across the industry.

Looking forward, the integration of machine learning algorithms with physics-based models represents a promising direction for MIM simulation, potentially enabling real-time process optimization and adaptive manufacturing approaches that can respond dynamically to variations in material properties or processing conditions.

Market Analysis for MIM Simulation Software

The global market for Metal Injection Molding (MIM) simulation software is experiencing robust growth, driven by increasing adoption of MIM technology across various high-value manufacturing sectors. Current market valuation stands at approximately $120 million, with projections indicating a compound annual growth rate of 7.8% through 2028, potentially reaching $175 million by that time.

The automotive industry represents the largest market segment, accounting for roughly 32% of total demand. This is primarily due to the growing need for complex, lightweight metal components in modern vehicles, particularly in electric and hybrid models where weight reduction is critical. The medical device sector follows closely at 28% market share, where MIM processes enable the production of intricate surgical instruments and implantable devices.

Aerospace and consumer electronics industries collectively contribute about 25% to the overall market demand, with particular emphasis on components requiring high precision and complex geometries. The remaining market share is distributed among various industries including industrial equipment, defense, and luxury goods manufacturing.

Geographically, North America and Europe currently dominate the market with approximately 35% and 30% market share respectively, owing to their established manufacturing bases and early adoption of simulation technologies. However, the Asia-Pacific region is witnessing the fastest growth rate at 9.5% annually, driven by rapid industrialization in China, Japan, and South Korea.

Customer segmentation reveals that large enterprises with dedicated R&D departments constitute about 60% of end-users, while small and medium enterprises represent the remaining 40%. This distribution is gradually shifting as more affordable cloud-based simulation solutions enter the market, making advanced simulation capabilities accessible to smaller manufacturers.

Key market drivers include increasing pressure to reduce production costs, minimize material waste, and shorten time-to-market. The ability of simulation software to predict and prevent manufacturing defects such as weld lines, voids, and warpage is particularly valued, as these capabilities directly translate to cost savings and quality improvements.

Market challenges primarily revolve around the high initial investment required for comprehensive simulation packages and the technical expertise needed to effectively utilize these tools. Additionally, the complexity of accurately modeling the rheological behavior of MIM feedstock materials presents ongoing technical challenges that software developers continue to address through research and development efforts.

The automotive industry represents the largest market segment, accounting for roughly 32% of total demand. This is primarily due to the growing need for complex, lightweight metal components in modern vehicles, particularly in electric and hybrid models where weight reduction is critical. The medical device sector follows closely at 28% market share, where MIM processes enable the production of intricate surgical instruments and implantable devices.

Aerospace and consumer electronics industries collectively contribute about 25% to the overall market demand, with particular emphasis on components requiring high precision and complex geometries. The remaining market share is distributed among various industries including industrial equipment, defense, and luxury goods manufacturing.

Geographically, North America and Europe currently dominate the market with approximately 35% and 30% market share respectively, owing to their established manufacturing bases and early adoption of simulation technologies. However, the Asia-Pacific region is witnessing the fastest growth rate at 9.5% annually, driven by rapid industrialization in China, Japan, and South Korea.

Customer segmentation reveals that large enterprises with dedicated R&D departments constitute about 60% of end-users, while small and medium enterprises represent the remaining 40%. This distribution is gradually shifting as more affordable cloud-based simulation solutions enter the market, making advanced simulation capabilities accessible to smaller manufacturers.

Key market drivers include increasing pressure to reduce production costs, minimize material waste, and shorten time-to-market. The ability of simulation software to predict and prevent manufacturing defects such as weld lines, voids, and warpage is particularly valued, as these capabilities directly translate to cost savings and quality improvements.

Market challenges primarily revolve around the high initial investment required for comprehensive simulation packages and the technical expertise needed to effectively utilize these tools. Additionally, the complexity of accurately modeling the rheological behavior of MIM feedstock materials presents ongoing technical challenges that software developers continue to address through research and development efforts.

Current Challenges in MIM Flow Simulation

Despite significant advancements in Metal Injection Molding (MIM) simulation technology, several critical challenges persist in accurately modeling the complex flow behavior during the injection process. Current simulation tools struggle to fully capture the non-Newtonian rheological properties of metal-polymer feedstocks, which exhibit both shear-thinning and yield stress behaviors. The temperature and pressure-dependent viscosity models often fail to account for the complex phase separation phenomena that occur during actual molding operations.

Weld line prediction remains particularly problematic in MIM simulation. While conventional plastic injection molding simulations can reasonably predict weld line locations, the unique characteristics of metal powders suspended in binder systems create additional complexities. The high solid loading (typically 60-65% by volume) significantly alters flow dynamics, making traditional weld line prediction algorithms less reliable for MIM applications. Furthermore, the correlation between simulated weld lines and actual mechanical properties in sintered parts remains poorly understood.

Packing pressure simulation presents another significant challenge. Current models inadequately address the compressibility of MIM feedstocks during the packing phase, leading to discrepancies between simulated and actual part dimensions. The pressure transmission through partially solidified gates is particularly difficult to model accurately, resulting in unreliable predictions of residual stresses and dimensional stability in final components.

Computational limitations further compound these challenges. The multi-scale nature of MIM processes—from powder particle interactions at the microscale to bulk flow behavior at the macroscale—demands enormous computational resources. Most commercial software packages employ simplified models that sacrifice accuracy for computational efficiency, creating a significant gap between simulation results and real-world outcomes.

Powder-binder separation during flow represents another poorly modeled phenomenon. Current simulations typically treat the feedstock as a homogeneous material, whereas actual MIM processes often experience phase separation, particularly in regions of high shear or complex geometry. This separation leads to density variations in the green part that cannot be accurately predicted by existing simulation tools.

Validation methodologies for MIM simulations also remain underdeveloped. Unlike conventional plastic injection molding, where in-mold sensors can provide real-time data for validation, the high temperatures and abrasive nature of metal powders limit the application of similar instrumentation in MIM processes. This creates a fundamental disconnect between simulation development and experimental validation, slowing the advancement of more accurate predictive models.

Weld line prediction remains particularly problematic in MIM simulation. While conventional plastic injection molding simulations can reasonably predict weld line locations, the unique characteristics of metal powders suspended in binder systems create additional complexities. The high solid loading (typically 60-65% by volume) significantly alters flow dynamics, making traditional weld line prediction algorithms less reliable for MIM applications. Furthermore, the correlation between simulated weld lines and actual mechanical properties in sintered parts remains poorly understood.

Packing pressure simulation presents another significant challenge. Current models inadequately address the compressibility of MIM feedstocks during the packing phase, leading to discrepancies between simulated and actual part dimensions. The pressure transmission through partially solidified gates is particularly difficult to model accurately, resulting in unreliable predictions of residual stresses and dimensional stability in final components.

Computational limitations further compound these challenges. The multi-scale nature of MIM processes—from powder particle interactions at the microscale to bulk flow behavior at the macroscale—demands enormous computational resources. Most commercial software packages employ simplified models that sacrifice accuracy for computational efficiency, creating a significant gap between simulation results and real-world outcomes.

Powder-binder separation during flow represents another poorly modeled phenomenon. Current simulations typically treat the feedstock as a homogeneous material, whereas actual MIM processes often experience phase separation, particularly in regions of high shear or complex geometry. This separation leads to density variations in the green part that cannot be accurately predicted by existing simulation tools.

Validation methodologies for MIM simulations also remain underdeveloped. Unlike conventional plastic injection molding, where in-mold sensors can provide real-time data for validation, the high temperatures and abrasive nature of metal powders limit the application of similar instrumentation in MIM processes. This creates a fundamental disconnect between simulation development and experimental validation, slowing the advancement of more accurate predictive models.

State-of-the-Art MIM Simulation Approaches

01 Simulation of viscous flow in metal injection molding

Computer-based simulation models are used to predict and analyze the viscous flow behavior of metal-polymer mixtures during the injection molding process. These simulations help optimize mold design and process parameters by calculating flow patterns, pressure distributions, and temperature profiles. Advanced algorithms account for the non-Newtonian behavior of MIM feedstocks and can predict potential defects before actual production.- Simulation of viscous flow in metal injection molding: Computer-based simulation models are used to predict and analyze the viscous flow behavior of metal-polymer mixtures during the injection molding process. These simulations help optimize the flow parameters, including temperature, pressure, and injection speed, to ensure complete filling of the mold cavity. Advanced algorithms account for the non-Newtonian behavior of the feedstock material, allowing for accurate prediction of flow patterns and potential defects.

- Weld line prediction and prevention strategies: Weld lines occur when separate flow fronts meet during the injection molding process, creating potential weak points in the final part. Simulation tools can predict the location and severity of weld lines based on mold geometry and process parameters. Prevention strategies include optimizing gate locations, adjusting injection speed profiles, implementing proper venting, and controlling material temperature to improve the fusion between flow fronts, thereby enhancing the mechanical properties of the final component.

- Packing pressure optimization techniques: Packing pressure applied after the mold cavity is filled compensates for material shrinkage and ensures dimensional accuracy of the molded part. Simulation tools help determine optimal packing pressure profiles by analyzing material compressibility, thermal behavior, and part geometry. Advanced algorithms can predict the effects of different packing parameters on part density, internal stress distribution, and final dimensions, allowing for process optimization to minimize defects such as sink marks and warpage.

- Material behavior modeling for MIM feedstock: Accurate simulation of metal injection molding requires sophisticated material models that capture the complex rheological behavior of metal-polymer feedstock. These models incorporate temperature-dependent viscosity, shear thinning effects, wall slip phenomena, and powder-binder interaction characteristics. Advanced simulation software uses these material models to predict flow behavior under various processing conditions, enabling optimization of process parameters for specific feedstock formulations.

- Integrated simulation approaches for multi-stage MIM process: Comprehensive simulation approaches integrate multiple stages of the metal injection molding process, including injection, debinding, and sintering. These holistic simulations account for the interdependencies between process stages, allowing engineers to predict how decisions made during the injection phase affect subsequent processing steps. By considering the entire manufacturing chain, these integrated approaches help optimize overall process efficiency and final part quality, reducing development time and production costs.

02 Weld line prediction and prevention strategies

Weld lines occur when separate flow fronts meet during the injection molding process, creating potential weak points in the final part. Simulation tools can predict the location and severity of weld lines based on gate locations, part geometry, and process conditions. Techniques to minimize weld line defects include optimizing gate placement, adjusting injection speed, implementing proper venting, and controlling melt temperature and pressure to improve material fusion at weld line interfaces.Expand Specific Solutions03 Packing pressure optimization techniques

Packing pressure is critical in metal injection molding to compensate for material shrinkage and ensure dimensional accuracy of the final parts. Simulation tools can determine optimal packing pressure profiles by analyzing material compressibility, thermal behavior, and part geometry. Advanced algorithms can predict the effects of different packing parameters on part density, internal stress, and dimensional stability, allowing for process optimization before production.Expand Specific Solutions04 Integrated simulation approaches for multi-phase MIM processes

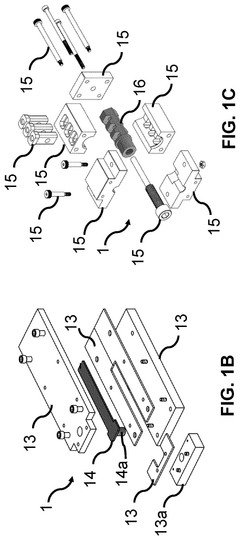

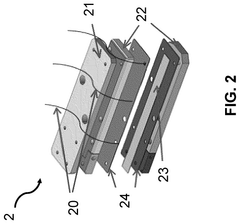

Comprehensive simulation systems model the entire metal injection molding process, including mixing, injection, debinding, and sintering phases. These integrated approaches account for the interactions between different process stages and material transformations. By simulating the complete process chain, manufacturers can predict final part properties more accurately and identify potential issues that might arise from the combination of process parameters across different stages.Expand Specific Solutions05 Equipment and mold design optimization for MIM

Specialized equipment and mold designs are developed based on simulation results to improve metal injection molding processes. These designs incorporate features that address flow-related challenges such as optimized runner systems, balanced gate configurations, and strategic venting. Advanced cooling channel designs help control solidification patterns and reduce cycle times, while specialized injection mechanisms provide precise control over flow rates and pressure profiles to minimize defects.Expand Specific Solutions

Leading Providers in MIM Simulation Software

Metal Injection Molding (MIM) simulation technology is currently in a growth phase, with the global market expected to reach significant expansion due to increasing demand for complex metal components across automotive, aerospace, and medical industries. The technological landscape shows varying degrees of maturity, with companies like Autodesk and CoreTech System (Moldex3D) leading in comprehensive simulation solutions that address viscous flow, weld line prediction, and packing pressure optimization. ENGEL AUSTRIA and Nissei Plastic Industrial focus on machine-specific simulation integration, while research institutions like Hefei University of Technology and Northwestern Polytechnical University contribute to fundamental flow dynamics advancements. RJG and Beaumont Technologies have developed specialized tools for process monitoring and optimization, creating a competitive environment where software capabilities and industry-specific expertise determine market positioning.

CoreTech System Co. Ltd.

Technical Solution: CoreTech System's Moldex3D software offers comprehensive MIM simulation capabilities with specialized modules for metal powder-binder systems. Their solution employs a multi-physics approach that couples computational fluid dynamics with heat transfer and structural mechanics to simulate the entire MIM process. The software incorporates advanced material models that account for the non-Newtonian behavior of metal-polymer mixtures, powder loading effects on viscosity, and phase separation tendencies. Moldex3D's high-resolution mesh technology enables accurate prediction of weld line formation by tracking flow fronts with precision down to microscopic levels. Their packing simulation module calculates pressure distribution throughout the mold cavity and predicts volumetric shrinkage based on PVT (Pressure-Volume-Temperature) data specific to MIM feedstocks. Recent updates include machine learning algorithms that optimize process parameters to minimize defects while maintaining dimensional accuracy.

Strengths: Comprehensive simulation platform covering the entire MIM process; extensive material database for various metal powder-binder systems; powerful visualization tools for analyzing flow patterns and weld lines. Weaknesses: Steep learning curve; requires significant computational resources for complex simulations; accuracy depends heavily on material characterization data quality.

Autodesk, Inc.

Technical Solution: Autodesk's Moldflow simulation technology has been extended to address the unique challenges of Metal Injection Molding through specialized material models and process parameters. Their approach integrates computational fluid dynamics with thermal analysis to simulate the complex rheological behavior of metal-polymer feedstock materials. The software employs adaptive meshing techniques that provide higher resolution in critical areas such as gates, thin walls, and potential weld line locations. Autodesk's solution incorporates a dual-domain approach that balances computational efficiency with accuracy, allowing for rapid iteration during design phases. Their weld line prediction algorithms account for flow front temperature, pressure, and velocity to assess weld line strength and visibility. The packing phase simulation includes models for compressibility of the feedstock material and pressure-dependent viscosity changes. Autodesk has recently enhanced their MIM simulation capabilities with machine learning algorithms that optimize process parameters based on historical data and simulation results.

Strengths: Seamless integration with CAD systems; user-friendly interface accessible to non-specialists; cloud computing options for handling complex simulations. Weaknesses: General-purpose simulation tool adapted for MIM rather than purpose-built; may lack some specialized features for metal powder behavior modeling.

Critical Patents in Viscous Flow and Weld Line Prediction

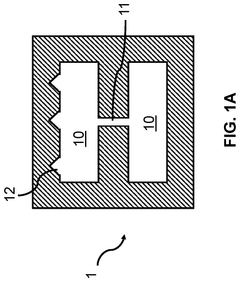

Metal powder injection molding material and metal powder injection molding method

PatentInactiveUS20060099103A1

Innovation

- A metal injection molding process using a material composition with 40-70% volume of metal powder, at least 50% of which is iron-containing powder with an effective diameter of 40 micrometers or larger, combined with 30-60% thermoplastic binder and up to 5% dispersant or assistants, allowing for the production of complex geometries with improved handling and cost reduction.

Mold for metal injection molding

PatentPendingUS20250010368A1

Innovation

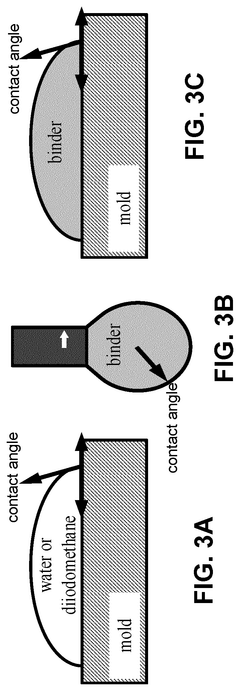

- A polymer mold with a metallic layer coating, specifically 100-200 nm thick, is used to reduce adhesion and improve moldability, allowing for the production of complex parts without significant thermal conductivity increases, using metals like chromium, silver, or gold, and polymers such as polytetrafluoroethylene or polycarbonate, with controlled pressure and temperature conditions.

Material Science Considerations for MIM Simulation

Material science fundamentals play a critical role in the accuracy and reliability of Metal Injection Molding (MIM) simulations. The feedstock material in MIM processes consists of metal powders dispersed in a polymeric binder system, creating a complex rheological behavior that significantly differs from conventional thermoplastics used in injection molding.

The binder system typically comprises multiple components including waxes, polymers, and surfactants, each serving specific functions during the molding process. Understanding the interaction between these components and metal particles is essential for accurate simulation of viscous flow behavior. The metal powder characteristics—including particle size distribution, shape, and surface properties—directly influence the feedstock's rheological properties.

Temperature-dependent viscosity models must account for the non-Newtonian behavior of MIM feedstocks, which typically exhibit pseudoplastic flow with yield stress. The powder loading, typically ranging from 55-65% by volume, dramatically affects viscosity and flow behavior. Higher powder loadings increase viscosity exponentially, necessitating precise characterization for simulation accuracy.

Thermal properties of MIM feedstocks present another critical consideration. The thermal conductivity of these materials is significantly higher than conventional plastics due to the metal content, affecting cooling rates and temperature distribution during molding. This impacts flow behavior prediction, particularly in thin-walled sections where rapid cooling occurs.

The formation of weld lines in MIM parts requires special material science considerations in simulation models. Unlike conventional plastics, the presence of metal particles affects the healing behavior at flow fronts. Particle migration and orientation near weld lines can create localized variations in density and mechanical properties, potentially leading to defects during sintering.

During the packing phase, material compressibility becomes a key factor. The PVT (Pressure-Volume-Temperature) behavior of MIM feedstocks differs significantly from standard polymers due to the presence of incompressible metal particles. Accurate PVT data is essential for predicting volumetric shrinkage and residual stresses in the molded component.

Powder-binder separation during high-pressure injection represents another material science challenge for simulation. This phenomenon, known as phase separation, can lead to inhomogeneous distribution of metal particles, affecting the final part quality after debinding and sintering. Advanced simulation models must incorporate these separation mechanisms to predict potential defects accurately.

The binder system typically comprises multiple components including waxes, polymers, and surfactants, each serving specific functions during the molding process. Understanding the interaction between these components and metal particles is essential for accurate simulation of viscous flow behavior. The metal powder characteristics—including particle size distribution, shape, and surface properties—directly influence the feedstock's rheological properties.

Temperature-dependent viscosity models must account for the non-Newtonian behavior of MIM feedstocks, which typically exhibit pseudoplastic flow with yield stress. The powder loading, typically ranging from 55-65% by volume, dramatically affects viscosity and flow behavior. Higher powder loadings increase viscosity exponentially, necessitating precise characterization for simulation accuracy.

Thermal properties of MIM feedstocks present another critical consideration. The thermal conductivity of these materials is significantly higher than conventional plastics due to the metal content, affecting cooling rates and temperature distribution during molding. This impacts flow behavior prediction, particularly in thin-walled sections where rapid cooling occurs.

The formation of weld lines in MIM parts requires special material science considerations in simulation models. Unlike conventional plastics, the presence of metal particles affects the healing behavior at flow fronts. Particle migration and orientation near weld lines can create localized variations in density and mechanical properties, potentially leading to defects during sintering.

During the packing phase, material compressibility becomes a key factor. The PVT (Pressure-Volume-Temperature) behavior of MIM feedstocks differs significantly from standard polymers due to the presence of incompressible metal particles. Accurate PVT data is essential for predicting volumetric shrinkage and residual stresses in the molded component.

Powder-binder separation during high-pressure injection represents another material science challenge for simulation. This phenomenon, known as phase separation, can lead to inhomogeneous distribution of metal particles, affecting the final part quality after debinding and sintering. Advanced simulation models must incorporate these separation mechanisms to predict potential defects accurately.

Computational Resource Requirements and Optimization

Metal Injection Molding (MIM) simulations demand substantial computational resources due to the complex multiphysics nature of the process. Current high-fidelity MIM simulations incorporating viscous flow, weld line formation, and packing pressure analysis typically require workstations with minimum specifications of 32GB RAM, 8-core processors, and dedicated GPUs with at least 8GB VRAM. For enterprise-level simulations handling complex geometries, these requirements often scale up to 128GB RAM and multi-GPU setups.

The computational bottlenecks primarily occur during non-Newtonian flow calculations and multiphase interactions at the powder-binder interface. Simulation times for standard components can range from 4-24 hours depending on mesh density and physics models enabled. Notably, the coupling of thermal, rheological, and mechanical analyses significantly increases computational overhead, with each additional physics module typically increasing simulation time by 30-45%.

Several optimization strategies have emerged to address these computational challenges. Adaptive mesh refinement techniques have demonstrated 25-40% reduction in computational time by concentrating mesh density only in critical regions such as thin walls, corners, and potential weld line formation areas. Implementation of parallel computing architectures has shown near-linear scaling up to 16 cores for most commercial MIM simulation packages.

GPU acceleration has revolutionized certain aspects of MIM simulation, particularly for viscous flow calculations, delivering 3-5x performance improvements compared to CPU-only implementations. However, not all simulation aspects benefit equally from GPU acceleration, with some physics solvers still primarily reliant on CPU processing power.

Cloud-based simulation platforms are increasingly viable for MIM analysis, offering scalable resources and pay-per-use models that reduce capital expenditure. These platforms have demonstrated particular value for parameter sweep studies and optimization workflows, where multiple simulation variants can be executed in parallel.

Model order reduction techniques represent the cutting edge of computational optimization for MIM simulations. By creating surrogate models based on full-physics simulations, these approaches can reduce simulation times by orders of magnitude for parametric studies, enabling real-time feedback for design iterations while maintaining acceptable accuracy levels within predefined operating envelopes.

The computational bottlenecks primarily occur during non-Newtonian flow calculations and multiphase interactions at the powder-binder interface. Simulation times for standard components can range from 4-24 hours depending on mesh density and physics models enabled. Notably, the coupling of thermal, rheological, and mechanical analyses significantly increases computational overhead, with each additional physics module typically increasing simulation time by 30-45%.

Several optimization strategies have emerged to address these computational challenges. Adaptive mesh refinement techniques have demonstrated 25-40% reduction in computational time by concentrating mesh density only in critical regions such as thin walls, corners, and potential weld line formation areas. Implementation of parallel computing architectures has shown near-linear scaling up to 16 cores for most commercial MIM simulation packages.

GPU acceleration has revolutionized certain aspects of MIM simulation, particularly for viscous flow calculations, delivering 3-5x performance improvements compared to CPU-only implementations. However, not all simulation aspects benefit equally from GPU acceleration, with some physics solvers still primarily reliant on CPU processing power.

Cloud-based simulation platforms are increasingly viable for MIM analysis, offering scalable resources and pay-per-use models that reduce capital expenditure. These platforms have demonstrated particular value for parameter sweep studies and optimization workflows, where multiple simulation variants can be executed in parallel.

Model order reduction techniques represent the cutting edge of computational optimization for MIM simulations. By creating surrogate models based on full-physics simulations, these approaches can reduce simulation times by orders of magnitude for parametric studies, enabling real-time feedback for design iterations while maintaining acceptable accuracy levels within predefined operating envelopes.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!