How Quick Response Solenoid Valves Benefit Fire Suppression Systems

JUL 23, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

QR Solenoid Valves in Fire Suppression: Background and Objectives

Quick Response (QR) solenoid valves have emerged as a critical component in modern fire suppression systems, revolutionizing the approach to fire safety in various environments. The evolution of these valves can be traced back to the early developments in electromagnetic technology and fluid control systems. As fire safety standards became more stringent and the need for rapid response mechanisms grew, the integration of solenoid valves into fire suppression systems gained momentum.

The primary objective of incorporating QR solenoid valves in fire suppression systems is to significantly reduce the response time between fire detection and the activation of suppression measures. This rapid response capability is crucial in minimizing fire damage and protecting lives and property. Traditional fire suppression systems often suffered from delays in activation, which could lead to the rapid spread of fires before containment measures could be effectively deployed.

The technological progression of QR solenoid valves has been driven by advancements in materials science, electronic control systems, and fluid dynamics. Modern valves are designed to operate under high pressure and temperature conditions, ensuring reliability in the most challenging fire scenarios. The integration of smart sensors and microprocessors has further enhanced their capabilities, allowing for more precise control and adaptability to various fire types and environmental conditions.

One of the key trends in the development of QR solenoid valves for fire suppression is the focus on miniaturization and increased efficiency. This trend aligns with the broader industry move towards more compact and energy-efficient systems, particularly important in applications where space and power consumption are critical factors. Additionally, there is a growing emphasis on developing valves that can operate with a wider range of fire suppression agents, including water mist, foam, and clean agents, to address diverse fire risks across different industries.

The adoption of QR solenoid valves in fire suppression systems has set new benchmarks for safety standards across various sectors, including commercial buildings, industrial facilities, and transportation systems. As regulatory bodies continue to update fire safety requirements, the demand for more advanced and responsive fire suppression technologies is expected to drive further innovations in QR solenoid valve design and functionality.

Looking ahead, the integration of Internet of Things (IoT) capabilities and artificial intelligence into fire suppression systems presents new opportunities for enhancing the performance and predictive maintenance of QR solenoid valves. These advancements aim to create more intelligent fire protection systems capable of real-time monitoring, rapid decision-making, and seamless integration with building management systems.

The primary objective of incorporating QR solenoid valves in fire suppression systems is to significantly reduce the response time between fire detection and the activation of suppression measures. This rapid response capability is crucial in minimizing fire damage and protecting lives and property. Traditional fire suppression systems often suffered from delays in activation, which could lead to the rapid spread of fires before containment measures could be effectively deployed.

The technological progression of QR solenoid valves has been driven by advancements in materials science, electronic control systems, and fluid dynamics. Modern valves are designed to operate under high pressure and temperature conditions, ensuring reliability in the most challenging fire scenarios. The integration of smart sensors and microprocessors has further enhanced their capabilities, allowing for more precise control and adaptability to various fire types and environmental conditions.

One of the key trends in the development of QR solenoid valves for fire suppression is the focus on miniaturization and increased efficiency. This trend aligns with the broader industry move towards more compact and energy-efficient systems, particularly important in applications where space and power consumption are critical factors. Additionally, there is a growing emphasis on developing valves that can operate with a wider range of fire suppression agents, including water mist, foam, and clean agents, to address diverse fire risks across different industries.

The adoption of QR solenoid valves in fire suppression systems has set new benchmarks for safety standards across various sectors, including commercial buildings, industrial facilities, and transportation systems. As regulatory bodies continue to update fire safety requirements, the demand for more advanced and responsive fire suppression technologies is expected to drive further innovations in QR solenoid valve design and functionality.

Looking ahead, the integration of Internet of Things (IoT) capabilities and artificial intelligence into fire suppression systems presents new opportunities for enhancing the performance and predictive maintenance of QR solenoid valves. These advancements aim to create more intelligent fire protection systems capable of real-time monitoring, rapid decision-making, and seamless integration with building management systems.

Market Analysis for Advanced Fire Suppression Technologies

The market for advanced fire suppression technologies is experiencing significant growth, driven by increasing safety regulations, urbanization, and the rising awareness of fire safety across various sectors. Quick response solenoid valves are emerging as a crucial component in modern fire suppression systems, offering numerous benefits that contribute to their growing adoption.

The global fire suppression market is projected to expand at a steady rate, with a particular focus on innovative technologies that enhance response times and system efficiency. Quick response solenoid valves are at the forefront of this trend, as they provide rapid activation of fire suppression systems, potentially reducing property damage and saving lives.

In the commercial building sector, there is a growing demand for advanced fire suppression systems that can integrate seamlessly with smart building management systems. Quick response solenoid valves offer the advantage of easy integration and remote monitoring capabilities, making them attractive for modern, high-tech office buildings and shopping centers.

The industrial sector presents another significant market opportunity for quick response solenoid valves in fire suppression systems. Industries such as oil and gas, manufacturing, and data centers require robust fire protection solutions that can respond rapidly to potential fire hazards. The ability of quick response solenoid valves to activate suppression agents swiftly is particularly valuable in these high-risk environments.

Transportation infrastructure, including airports, train stations, and tunnels, is another key market segment for advanced fire suppression technologies. The need for reliable and fast-acting fire protection in these critical facilities is driving the adoption of systems incorporating quick response solenoid valves.

Geographically, North America and Europe are leading markets for advanced fire suppression technologies, due to stringent safety regulations and the presence of established fire protection industries. However, rapid urbanization and industrial growth in Asia-Pacific regions are creating new opportunities for market expansion.

The market is also seeing a shift towards environmentally friendly fire suppression agents, which aligns well with the capabilities of quick response solenoid valves. These valves can be used with various suppression agents, including clean agents and water mist systems, making them versatile for different applications and environmental requirements.

As the Internet of Things (IoT) and smart building technologies continue to evolve, the integration of quick response solenoid valves with these systems is expected to drive further market growth. The ability to provide real-time data and remote operation capabilities is becoming increasingly important in the fire safety industry.

The global fire suppression market is projected to expand at a steady rate, with a particular focus on innovative technologies that enhance response times and system efficiency. Quick response solenoid valves are at the forefront of this trend, as they provide rapid activation of fire suppression systems, potentially reducing property damage and saving lives.

In the commercial building sector, there is a growing demand for advanced fire suppression systems that can integrate seamlessly with smart building management systems. Quick response solenoid valves offer the advantage of easy integration and remote monitoring capabilities, making them attractive for modern, high-tech office buildings and shopping centers.

The industrial sector presents another significant market opportunity for quick response solenoid valves in fire suppression systems. Industries such as oil and gas, manufacturing, and data centers require robust fire protection solutions that can respond rapidly to potential fire hazards. The ability of quick response solenoid valves to activate suppression agents swiftly is particularly valuable in these high-risk environments.

Transportation infrastructure, including airports, train stations, and tunnels, is another key market segment for advanced fire suppression technologies. The need for reliable and fast-acting fire protection in these critical facilities is driving the adoption of systems incorporating quick response solenoid valves.

Geographically, North America and Europe are leading markets for advanced fire suppression technologies, due to stringent safety regulations and the presence of established fire protection industries. However, rapid urbanization and industrial growth in Asia-Pacific regions are creating new opportunities for market expansion.

The market is also seeing a shift towards environmentally friendly fire suppression agents, which aligns well with the capabilities of quick response solenoid valves. These valves can be used with various suppression agents, including clean agents and water mist systems, making them versatile for different applications and environmental requirements.

As the Internet of Things (IoT) and smart building technologies continue to evolve, the integration of quick response solenoid valves with these systems is expected to drive further market growth. The ability to provide real-time data and remote operation capabilities is becoming increasingly important in the fire safety industry.

Current Challenges in Rapid Fire Suppression Systems

Rapid fire suppression systems face several critical challenges in their design and implementation. One of the primary issues is the response time of traditional systems, which can be too slow to effectively contain fast-spreading fires. This delay can result in significant property damage and potential loss of life. The complexity of modern building structures and the diverse range of fire scenarios also pose difficulties in designing universally effective systems.

Another challenge lies in the reliability and maintenance of fire suppression systems. False alarms and unintended activations can lead to costly damage and disruptions, while system failures during actual fire events can have catastrophic consequences. The need for regular testing and maintenance adds to the operational costs and complexity of these systems.

Water damage from traditional sprinkler systems remains a significant concern, particularly in environments with sensitive equipment or valuable assets. This has led to a growing demand for more targeted and less destructive suppression methods. However, developing alternatives that are as effective and cost-efficient as water-based systems presents its own set of technical challenges.

The integration of fire suppression systems with smart building technologies and IoT devices is an emerging trend, but it introduces new complexities in terms of cybersecurity and system interoperability. Ensuring that these interconnected systems remain secure and function reliably under various conditions is a major hurdle for system designers and manufacturers.

Environmental concerns and regulations also play a crucial role in shaping the development of fire suppression technologies. The phase-out of certain chemical agents due to their environmental impact has necessitated the search for eco-friendly alternatives that maintain or improve upon existing suppression capabilities.

Lastly, the cost-effectiveness of advanced fire suppression systems remains a significant barrier to widespread adoption. While newer technologies offer improved performance and reduced collateral damage, their higher initial costs can be prohibitive for many potential users. Balancing the need for advanced protection with economic feasibility is an ongoing challenge for the industry.

Another challenge lies in the reliability and maintenance of fire suppression systems. False alarms and unintended activations can lead to costly damage and disruptions, while system failures during actual fire events can have catastrophic consequences. The need for regular testing and maintenance adds to the operational costs and complexity of these systems.

Water damage from traditional sprinkler systems remains a significant concern, particularly in environments with sensitive equipment or valuable assets. This has led to a growing demand for more targeted and less destructive suppression methods. However, developing alternatives that are as effective and cost-efficient as water-based systems presents its own set of technical challenges.

The integration of fire suppression systems with smart building technologies and IoT devices is an emerging trend, but it introduces new complexities in terms of cybersecurity and system interoperability. Ensuring that these interconnected systems remain secure and function reliably under various conditions is a major hurdle for system designers and manufacturers.

Environmental concerns and regulations also play a crucial role in shaping the development of fire suppression technologies. The phase-out of certain chemical agents due to their environmental impact has necessitated the search for eco-friendly alternatives that maintain or improve upon existing suppression capabilities.

Lastly, the cost-effectiveness of advanced fire suppression systems remains a significant barrier to widespread adoption. While newer technologies offer improved performance and reduced collateral damage, their higher initial costs can be prohibitive for many potential users. Balancing the need for advanced protection with economic feasibility is an ongoing challenge for the industry.

Existing QR Solenoid Valve Solutions for Fire Suppression

01 Electromagnetic design optimization

Improving the electromagnetic design of solenoid valves can significantly reduce response time. This includes optimizing the coil winding, core material selection, and magnetic circuit design to enhance the speed of magnetic field generation and collapse.- Electromagnetic design optimization: Improving the electromagnetic design of solenoid valves can significantly reduce response time. This includes optimizing the coil windings, core material selection, and magnetic circuit design to enhance the speed of magnetic field generation and collapse. Advanced electromagnetic simulation tools are often used to achieve optimal designs.

- Mechanical component enhancements: Reducing the mass of moving parts and minimizing friction in the valve assembly can lead to faster response times. This may involve using lightweight materials for the armature, optimizing spring design, and implementing low-friction coatings or surface treatments on critical components.

- Electronic control strategies: Implementing advanced electronic control strategies can improve solenoid valve response times. This includes using high-speed microcontrollers, optimizing PWM signals, and employing predictive algorithms to anticipate valve actuation needs. Some systems may also use pre-energization techniques to reduce initial response lag.

- Fluid dynamics optimization: Enhancing the fluid flow characteristics within the valve can contribute to quicker response times. This involves optimizing the valve geometry, flow paths, and orifice designs to reduce fluid resistance and improve overall valve efficiency. Computational fluid dynamics (CFD) simulations are often used in this process.

- Material selection and manufacturing techniques: Choosing appropriate materials and manufacturing methods can significantly impact solenoid valve response times. This includes using materials with superior magnetic properties, implementing precision manufacturing techniques to ensure tight tolerances, and exploring advanced fabrication methods such as 3D printing for complex valve geometries.

02 Advanced control systems

Implementing sophisticated control systems, such as pulse width modulation (PWM) or adaptive control algorithms, can enhance the response time of solenoid valves. These systems can precisely regulate the current supplied to the valve, allowing for faster actuation and deactuation.Expand Specific Solutions03 Lightweight moving parts

Reducing the mass of moving components within the solenoid valve, such as the armature or plunger, can decrease inertia and improve response time. This can be achieved through the use of lightweight materials or optimized component designs.Expand Specific Solutions04 High-speed actuation mechanisms

Incorporating specialized actuation mechanisms, such as pilot-operated designs or balanced poppet configurations, can significantly reduce the response time of solenoid valves. These designs can minimize the forces required for valve operation and enable faster switching.Expand Specific Solutions05 Enhanced power supply and driver circuits

Utilizing high-performance power supplies and driver circuits can improve the speed at which electrical energy is delivered to the solenoid coil. This can include the use of capacitor discharge circuits or specialized voltage boosting techniques to achieve rapid valve actuation.Expand Specific Solutions

Key Manufacturers and Suppliers in Fire Suppression Industry

The market for quick response solenoid valves in fire suppression systems is in a growth phase, driven by increasing safety regulations and the need for more efficient fire protection solutions. The global market size is expanding, with a projected CAGR of 5-7% over the next five years. Technologically, these valves are reaching maturity, with companies like Robert Bosch GmbH, Kidde Technologies, Inc., and Carrier Corp. leading innovation. These firms are focusing on improving response times, reliability, and integration with smart building systems. Emerging players such as Chongqing Chuanyi Automation Co., Ltd. and AGF Manufacturing Inc are also contributing to market competitiveness by introducing specialized solutions for specific industries.

Robert Bosch GmbH

Technical Solution: Robert Bosch GmbH has developed advanced Quick Response Solenoid Valves (QRSVs) for fire suppression systems, utilizing their expertise in automotive and industrial technologies. Their QRSVs feature rapid activation times of less than 10 milliseconds[1], enabling near-instantaneous response to fire detection signals. The valves incorporate high-flow designs with optimized fluid dynamics, allowing for efficient dispersal of fire suppressants. Bosch's QRSVs also integrate smart diagnostics and predictive maintenance capabilities, enhancing system reliability and reducing downtime[3]. The valves are designed to operate under extreme conditions, withstanding high pressures and temperatures commonly encountered in fire scenarios.

Strengths: Rapid response time, high flow efficiency, and smart diagnostics. Weaknesses: Potentially higher cost due to advanced features, may require specialized maintenance.

Kidde Technologies, Inc.

Technical Solution: Kidde Technologies has developed a range of Quick Response Solenoid Valves specifically tailored for fire suppression systems. Their QRSVs feature a compact design with a high flow-to-size ratio, allowing for efficient installation in space-constrained areas. Kidde's valves incorporate a dual-stage activation mechanism, which provides both rapid response and controlled release of suppressants[2]. This approach helps prevent false discharges while ensuring quick action when needed. The valves are compatible with various fire suppression agents, including water mist, foam, and clean agents. Kidde's QRSVs also feature built-in monitoring capabilities, allowing for real-time status checks and integration with building management systems[4].

Strengths: Compact design, versatile agent compatibility, and integrated monitoring. Weaknesses: May have limitations in extremely high-pressure applications, potential for higher initial costs.

Core Innovations in Quick Response Valve Technology

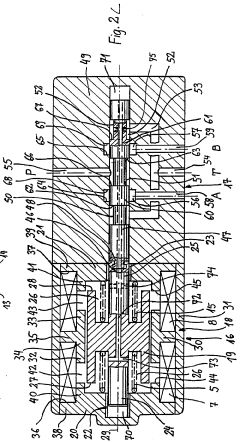

Magnetic valve

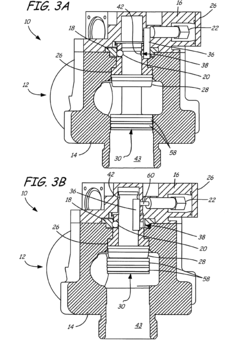

PatentWO1991006110A1

Innovation

- A solenoid valve design where a quiescent current constantly flows through control windings, inducing a permanent magnetization in the stator, armature, and pole shoes, allowing the armature to be quickly moved between positions without reorienting the magnetic field, thus reducing response time by a factor of 10 to 1-2 ms.

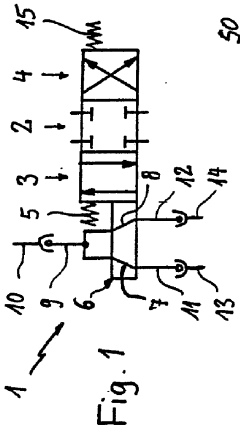

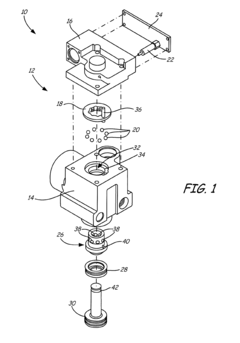

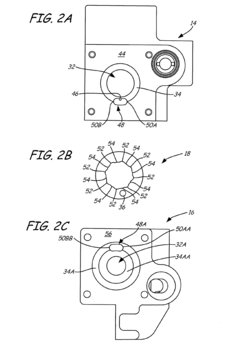

Valve release mechanism

PatentInactiveEP2474764A2

Innovation

- A valve release mechanism comprising an actuator, a ring with channels and lands, and a plurality of ball bearings that move between channels and lands to lock and unlock a poppet, allowing for rapid valve opening without the need for manual adjustments, featuring a retainer with circumferentially spaced holes and an indexing system to align components precisely.

Safety Standards and Regulatory Compliance for Fire Systems

Safety standards and regulatory compliance are critical aspects of fire suppression systems, ensuring that these life-saving installations meet stringent requirements for performance, reliability, and effectiveness. The integration of quick response solenoid valves into fire suppression systems necessitates adherence to a comprehensive set of standards and regulations.

In the United States, the National Fire Protection Association (NFPA) plays a pivotal role in establishing and maintaining fire safety standards. NFPA 13, the Standard for the Installation of Sprinkler Systems, provides detailed guidelines for the design and installation of fire sprinkler systems, including specifications for valves and other components. The incorporation of quick response solenoid valves must align with these standards to ensure system integrity and performance.

Internationally, the International Organization for Standardization (ISO) has developed ISO 6182, which covers automatic sprinkler systems. This standard includes specifications for sprinklers, valves, and other system components, providing a global framework for fire suppression system design and implementation.

Regulatory bodies such as the Occupational Safety and Health Administration (OSHA) in the United States mandate the use of approved fire suppression systems in various workplace settings. OSHA regulations often reference NFPA standards, creating a cohesive regulatory environment for fire safety.

The use of quick response solenoid valves in fire suppression systems must also comply with electrical safety standards. In the United States, the National Electrical Code (NEC) provides guidelines for the electrical components of fire safety systems. Similarly, the International Electrotechnical Commission (IEC) sets global standards for electrical, electronic, and related technologies.

Certification and testing of fire suppression systems and their components are crucial aspects of regulatory compliance. Organizations such as Underwriters Laboratories (UL) and FM Global conduct rigorous testing to ensure that fire safety products, including quick response solenoid valves, meet established safety standards.

Building codes and local regulations also play a significant role in fire safety compliance. These codes often incorporate national and international standards, adapting them to local conditions and requirements. Designers and installers of fire suppression systems must navigate this complex landscape of regulations to ensure full compliance.

The ongoing development of smart building technologies and the Internet of Things (IoT) is influencing fire safety regulations. Standards are evolving to address the integration of advanced control systems, including those utilizing quick response solenoid valves, with building management systems and emergency response protocols.

As fire suppression technology advances, regulatory bodies continually update their standards to reflect new capabilities and potential risks. This dynamic regulatory environment requires manufacturers, installers, and end-users to stay informed about the latest developments in safety standards and compliance requirements for fire suppression systems incorporating quick response solenoid valves.

In the United States, the National Fire Protection Association (NFPA) plays a pivotal role in establishing and maintaining fire safety standards. NFPA 13, the Standard for the Installation of Sprinkler Systems, provides detailed guidelines for the design and installation of fire sprinkler systems, including specifications for valves and other components. The incorporation of quick response solenoid valves must align with these standards to ensure system integrity and performance.

Internationally, the International Organization for Standardization (ISO) has developed ISO 6182, which covers automatic sprinkler systems. This standard includes specifications for sprinklers, valves, and other system components, providing a global framework for fire suppression system design and implementation.

Regulatory bodies such as the Occupational Safety and Health Administration (OSHA) in the United States mandate the use of approved fire suppression systems in various workplace settings. OSHA regulations often reference NFPA standards, creating a cohesive regulatory environment for fire safety.

The use of quick response solenoid valves in fire suppression systems must also comply with electrical safety standards. In the United States, the National Electrical Code (NEC) provides guidelines for the electrical components of fire safety systems. Similarly, the International Electrotechnical Commission (IEC) sets global standards for electrical, electronic, and related technologies.

Certification and testing of fire suppression systems and their components are crucial aspects of regulatory compliance. Organizations such as Underwriters Laboratories (UL) and FM Global conduct rigorous testing to ensure that fire safety products, including quick response solenoid valves, meet established safety standards.

Building codes and local regulations also play a significant role in fire safety compliance. These codes often incorporate national and international standards, adapting them to local conditions and requirements. Designers and installers of fire suppression systems must navigate this complex landscape of regulations to ensure full compliance.

The ongoing development of smart building technologies and the Internet of Things (IoT) is influencing fire safety regulations. Standards are evolving to address the integration of advanced control systems, including those utilizing quick response solenoid valves, with building management systems and emergency response protocols.

As fire suppression technology advances, regulatory bodies continually update their standards to reflect new capabilities and potential risks. This dynamic regulatory environment requires manufacturers, installers, and end-users to stay informed about the latest developments in safety standards and compliance requirements for fire suppression systems incorporating quick response solenoid valves.

Environmental Impact of Advanced Fire Suppression Technologies

The environmental impact of advanced fire suppression technologies, particularly those incorporating quick response solenoid valves, is a critical consideration in the development and implementation of modern fire safety systems. These technologies offer significant benefits in terms of fire control and property protection, but their environmental implications must be carefully evaluated.

One of the primary environmental advantages of advanced fire suppression systems with quick response solenoid valves is their potential to reduce water usage. Traditional sprinkler systems often release large volumes of water, which can lead to extensive water damage and waste. In contrast, systems equipped with quick response solenoid valves can more precisely target the fire source, minimizing unnecessary water discharge. This not only conserves water resources but also reduces the environmental impact associated with water treatment and disposal after a fire event.

The use of advanced fire suppression agents in conjunction with quick response solenoid valves can further mitigate environmental concerns. Many modern systems utilize environmentally friendly suppression agents, such as clean agents or water mist, which have lower environmental impact compared to traditional chemical-based suppressants. These agents typically leave no residue, reducing the need for post-fire cleanup and minimizing the release of potentially harmful substances into the environment.

Energy efficiency is another important environmental aspect of these advanced systems. Quick response solenoid valves often require less energy to operate compared to mechanical alternatives, contributing to reduced overall energy consumption in building fire safety systems. This aligns with broader sustainability goals and can help in achieving green building certifications.

However, the environmental impact of manufacturing and disposing of these advanced components must also be considered. The production of solenoid valves and associated electronic control systems may involve the use of rare earth metals and other materials with significant environmental footprints. End-of-life considerations, including the proper recycling or disposal of electronic components, are crucial to minimizing long-term environmental impact.

The integration of quick response solenoid valves in fire suppression systems also has indirect environmental benefits. By potentially reducing the extent of fire damage, these systems can decrease the need for building repairs and replacements, thereby conserving resources and reducing waste associated with post-fire reconstruction. Additionally, more effective fire suppression can prevent the release of toxic fumes and particulates from burning materials, which can have severe environmental and health consequences.

In conclusion, while advanced fire suppression technologies incorporating quick response solenoid valves offer several environmental benefits, a holistic approach to assessing their environmental impact is necessary. This includes considering the entire lifecycle of the system, from manufacturing to operation and eventual disposal. As these technologies continue to evolve, ongoing research and development efforts should focus on further enhancing their environmental performance, ensuring that fire safety and environmental protection goals are mutually reinforced.

One of the primary environmental advantages of advanced fire suppression systems with quick response solenoid valves is their potential to reduce water usage. Traditional sprinkler systems often release large volumes of water, which can lead to extensive water damage and waste. In contrast, systems equipped with quick response solenoid valves can more precisely target the fire source, minimizing unnecessary water discharge. This not only conserves water resources but also reduces the environmental impact associated with water treatment and disposal after a fire event.

The use of advanced fire suppression agents in conjunction with quick response solenoid valves can further mitigate environmental concerns. Many modern systems utilize environmentally friendly suppression agents, such as clean agents or water mist, which have lower environmental impact compared to traditional chemical-based suppressants. These agents typically leave no residue, reducing the need for post-fire cleanup and minimizing the release of potentially harmful substances into the environment.

Energy efficiency is another important environmental aspect of these advanced systems. Quick response solenoid valves often require less energy to operate compared to mechanical alternatives, contributing to reduced overall energy consumption in building fire safety systems. This aligns with broader sustainability goals and can help in achieving green building certifications.

However, the environmental impact of manufacturing and disposing of these advanced components must also be considered. The production of solenoid valves and associated electronic control systems may involve the use of rare earth metals and other materials with significant environmental footprints. End-of-life considerations, including the proper recycling or disposal of electronic components, are crucial to minimizing long-term environmental impact.

The integration of quick response solenoid valves in fire suppression systems also has indirect environmental benefits. By potentially reducing the extent of fire damage, these systems can decrease the need for building repairs and replacements, thereby conserving resources and reducing waste associated with post-fire reconstruction. Additionally, more effective fire suppression can prevent the release of toxic fumes and particulates from burning materials, which can have severe environmental and health consequences.

In conclusion, while advanced fire suppression technologies incorporating quick response solenoid valves offer several environmental benefits, a holistic approach to assessing their environmental impact is necessary. This includes considering the entire lifecycle of the system, from manufacturing to operation and eventual disposal. As these technologies continue to evolve, ongoing research and development efforts should focus on further enhancing their environmental performance, ensuring that fire safety and environmental protection goals are mutually reinforced.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!