Thermal Expansion Control in Solenoid Valves for Solar Thermal Systems

JUL 23, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Solenoid Valve Thermal Challenges

Solenoid valves play a crucial role in solar thermal systems, regulating fluid flow and pressure. However, these components face significant thermal challenges that can impact their performance and longevity. The primary issue stems from the extreme temperature variations inherent in solar thermal applications, which can range from sub-zero temperatures during cold nights to well over 100°C during peak solar exposure.

Thermal expansion is a major concern in solenoid valves used in solar thermal systems. As temperatures fluctuate, materials within the valve expand and contract, potentially leading to misalignment, leakage, or even complete failure. The valve body, typically made of metal or high-temperature plastics, may expand at a different rate than internal components such as springs, seals, and plungers. This differential expansion can cause gaps to form, compromising the valve's sealing ability and overall functionality.

Another thermal challenge is the degradation of materials under prolonged exposure to high temperatures. Elastomeric seals and gaskets, crucial for maintaining a tight seal, can harden, crack, or lose their elasticity over time when subjected to extreme heat. This degradation can result in fluid leakage and reduced system efficiency. Similarly, lubricants used in the valve mechanism may break down or evaporate at high temperatures, leading to increased friction and wear on moving parts.

The solenoid coil itself is also susceptible to thermal issues. As the coil heats up during operation, its electrical resistance increases, potentially affecting the valve's response time and overall performance. In extreme cases, excessive heat can cause insulation breakdown, leading to short circuits or coil burnout. This risk is particularly high in solar thermal systems where valves may be required to operate continuously for extended periods during peak sunlight hours.

Thermal cycling, the repeated heating and cooling of the valve, presents another significant challenge. This constant temperature fluctuation can lead to material fatigue, particularly at joints and interfaces between different materials. Over time, this can result in micro-cracks, loosening of components, and eventual valve failure. The thermal cycling also puts stress on electrical connections within the valve, potentially causing intermittent electrical faults or complete circuit breaks.

Addressing these thermal challenges requires a multifaceted approach. Engineers must carefully select materials that can withstand the expected temperature range while maintaining dimensional stability. Advanced thermal management techniques, such as heat sinks or active cooling systems, may be necessary for valves in particularly demanding applications. Additionally, innovative designs that accommodate thermal expansion without compromising functionality are crucial for ensuring reliable operation in solar thermal systems.

Thermal expansion is a major concern in solenoid valves used in solar thermal systems. As temperatures fluctuate, materials within the valve expand and contract, potentially leading to misalignment, leakage, or even complete failure. The valve body, typically made of metal or high-temperature plastics, may expand at a different rate than internal components such as springs, seals, and plungers. This differential expansion can cause gaps to form, compromising the valve's sealing ability and overall functionality.

Another thermal challenge is the degradation of materials under prolonged exposure to high temperatures. Elastomeric seals and gaskets, crucial for maintaining a tight seal, can harden, crack, or lose their elasticity over time when subjected to extreme heat. This degradation can result in fluid leakage and reduced system efficiency. Similarly, lubricants used in the valve mechanism may break down or evaporate at high temperatures, leading to increased friction and wear on moving parts.

The solenoid coil itself is also susceptible to thermal issues. As the coil heats up during operation, its electrical resistance increases, potentially affecting the valve's response time and overall performance. In extreme cases, excessive heat can cause insulation breakdown, leading to short circuits or coil burnout. This risk is particularly high in solar thermal systems where valves may be required to operate continuously for extended periods during peak sunlight hours.

Thermal cycling, the repeated heating and cooling of the valve, presents another significant challenge. This constant temperature fluctuation can lead to material fatigue, particularly at joints and interfaces between different materials. Over time, this can result in micro-cracks, loosening of components, and eventual valve failure. The thermal cycling also puts stress on electrical connections within the valve, potentially causing intermittent electrical faults or complete circuit breaks.

Addressing these thermal challenges requires a multifaceted approach. Engineers must carefully select materials that can withstand the expected temperature range while maintaining dimensional stability. Advanced thermal management techniques, such as heat sinks or active cooling systems, may be necessary for valves in particularly demanding applications. Additionally, innovative designs that accommodate thermal expansion without compromising functionality are crucial for ensuring reliable operation in solar thermal systems.

Solar Thermal System Market Trends

The solar thermal system market has been experiencing significant growth and transformation in recent years, driven by increasing environmental awareness, government incentives, and technological advancements. This market segment is part of the broader renewable energy sector, which has seen substantial expansion globally.

One of the key trends in the solar thermal system market is the increasing adoption of these systems in residential and commercial buildings. As energy costs continue to rise and consumers become more environmentally conscious, there is a growing demand for sustainable heating solutions. Solar thermal systems offer an attractive option for reducing energy bills and carbon footprints, particularly in regions with high solar irradiation.

The industrial sector is also emerging as a significant market for solar thermal systems. Many industries require large amounts of heat for their processes, and solar thermal technology can provide a cost-effective and sustainable alternative to traditional fossil fuel-based heating methods. This trend is particularly evident in sectors such as food processing, textiles, and chemical manufacturing.

Technological advancements are playing a crucial role in shaping the solar thermal system market. Improvements in collector efficiency, storage technologies, and system integration are making these systems more effective and reliable. For instance, the development of high-performance evacuated tube collectors and advanced flat plate collectors has significantly increased the overall system efficiency.

Geographically, the market is showing varied growth patterns. Europe has been a leader in solar thermal system adoption, with countries like Germany, Austria, and Greece at the forefront. However, emerging markets in Asia-Pacific, particularly China and India, are experiencing rapid growth due to supportive government policies and increasing energy demands.

The integration of solar thermal systems with other renewable technologies is another notable trend. Hybrid systems that combine solar thermal with heat pumps or biomass boilers are gaining popularity, offering increased efficiency and reliability. This trend towards integrated renewable energy solutions is expected to continue, driving further innovation in the sector.

Despite the positive outlook, the solar thermal system market faces challenges. The relatively high initial investment costs and competition from other renewable technologies, such as photovoltaics, pose significant hurdles. However, ongoing research and development efforts are focused on reducing costs and improving system performance, which is expected to address these challenges in the coming years.

One of the key trends in the solar thermal system market is the increasing adoption of these systems in residential and commercial buildings. As energy costs continue to rise and consumers become more environmentally conscious, there is a growing demand for sustainable heating solutions. Solar thermal systems offer an attractive option for reducing energy bills and carbon footprints, particularly in regions with high solar irradiation.

The industrial sector is also emerging as a significant market for solar thermal systems. Many industries require large amounts of heat for their processes, and solar thermal technology can provide a cost-effective and sustainable alternative to traditional fossil fuel-based heating methods. This trend is particularly evident in sectors such as food processing, textiles, and chemical manufacturing.

Technological advancements are playing a crucial role in shaping the solar thermal system market. Improvements in collector efficiency, storage technologies, and system integration are making these systems more effective and reliable. For instance, the development of high-performance evacuated tube collectors and advanced flat plate collectors has significantly increased the overall system efficiency.

Geographically, the market is showing varied growth patterns. Europe has been a leader in solar thermal system adoption, with countries like Germany, Austria, and Greece at the forefront. However, emerging markets in Asia-Pacific, particularly China and India, are experiencing rapid growth due to supportive government policies and increasing energy demands.

The integration of solar thermal systems with other renewable technologies is another notable trend. Hybrid systems that combine solar thermal with heat pumps or biomass boilers are gaining popularity, offering increased efficiency and reliability. This trend towards integrated renewable energy solutions is expected to continue, driving further innovation in the sector.

Despite the positive outlook, the solar thermal system market faces challenges. The relatively high initial investment costs and competition from other renewable technologies, such as photovoltaics, pose significant hurdles. However, ongoing research and development efforts are focused on reducing costs and improving system performance, which is expected to address these challenges in the coming years.

Thermal Expansion Issues in Solenoids

Thermal expansion in solenoid valves presents a significant challenge in solar thermal systems, particularly due to the wide temperature ranges these components experience. As solar thermal systems often operate in environments with extreme temperature fluctuations, the materials used in solenoid valves are subjected to repeated cycles of expansion and contraction. This thermal cycling can lead to several issues that affect the performance, reliability, and longevity of the valves.

One of the primary concerns is the potential for valve sticking or seizure. As different materials within the solenoid valve expand at varying rates, misalignments can occur between moving parts. This differential expansion may cause the valve plunger to bind against the valve body, resulting in operational failures or reduced responsiveness. In severe cases, the valve may completely seize, rendering the system inoperable and necessitating costly repairs or replacements.

Another critical issue is the potential for leakage. Thermal expansion can cause gaps to form between sealing surfaces, compromising the valve's ability to maintain a tight seal. This is particularly problematic in solar thermal systems where maintaining system pressure and preventing fluid loss is crucial for efficient operation. Even minor leaks can lead to significant performance degradation over time and may pose safety risks in high-temperature applications.

The electrical components of solenoid valves are also susceptible to thermal expansion issues. Coil windings may expand and contract, potentially leading to short circuits or changes in the valve's magnetic characteristics. This can result in inconsistent valve operation or complete failure of the solenoid mechanism. Additionally, thermal expansion can stress electrical connections, potentially causing intermittent faults or complete electrical failures.

Material fatigue is another long-term consequence of repeated thermal expansion cycles. Over time, the constant expansion and contraction can lead to micro-cracks in valve components, particularly at stress concentration points. This fatigue can ultimately result in component failure, which is especially critical in solar thermal systems that are expected to operate reliably for extended periods with minimal maintenance.

Addressing these thermal expansion issues requires a multifaceted approach. Engineers must carefully select materials with compatible thermal expansion coefficients to minimize differential expansion. Advanced design techniques, such as incorporating expansion joints or flexible components, can help accommodate thermal movement without compromising valve function. Additionally, the use of high-temperature lubricants and coatings can reduce friction and wear caused by thermal expansion, extending the operational life of the valve.

One of the primary concerns is the potential for valve sticking or seizure. As different materials within the solenoid valve expand at varying rates, misalignments can occur between moving parts. This differential expansion may cause the valve plunger to bind against the valve body, resulting in operational failures or reduced responsiveness. In severe cases, the valve may completely seize, rendering the system inoperable and necessitating costly repairs or replacements.

Another critical issue is the potential for leakage. Thermal expansion can cause gaps to form between sealing surfaces, compromising the valve's ability to maintain a tight seal. This is particularly problematic in solar thermal systems where maintaining system pressure and preventing fluid loss is crucial for efficient operation. Even minor leaks can lead to significant performance degradation over time and may pose safety risks in high-temperature applications.

The electrical components of solenoid valves are also susceptible to thermal expansion issues. Coil windings may expand and contract, potentially leading to short circuits or changes in the valve's magnetic characteristics. This can result in inconsistent valve operation or complete failure of the solenoid mechanism. Additionally, thermal expansion can stress electrical connections, potentially causing intermittent faults or complete electrical failures.

Material fatigue is another long-term consequence of repeated thermal expansion cycles. Over time, the constant expansion and contraction can lead to micro-cracks in valve components, particularly at stress concentration points. This fatigue can ultimately result in component failure, which is especially critical in solar thermal systems that are expected to operate reliably for extended periods with minimal maintenance.

Addressing these thermal expansion issues requires a multifaceted approach. Engineers must carefully select materials with compatible thermal expansion coefficients to minimize differential expansion. Advanced design techniques, such as incorporating expansion joints or flexible components, can help accommodate thermal movement without compromising valve function. Additionally, the use of high-temperature lubricants and coatings can reduce friction and wear caused by thermal expansion, extending the operational life of the valve.

Current Thermal Expansion Solutions

01 Thermal expansion compensation in solenoid valves

Solenoid valves are designed with mechanisms to compensate for thermal expansion, ensuring consistent operation across various temperatures. This may include the use of materials with similar thermal expansion coefficients or the incorporation of flexible components that can absorb dimensional changes.- Thermal expansion compensation in solenoid valves: Solenoid valves are designed with mechanisms to compensate for thermal expansion, ensuring consistent performance across various temperature ranges. This may include the use of materials with similar thermal expansion coefficients or the incorporation of flexible components that can absorb dimensional changes caused by temperature fluctuations.

- Temperature-sensitive actuation mechanisms: Some solenoid valves incorporate temperature-sensitive actuation mechanisms that respond to thermal expansion. These mechanisms can adjust the valve's operation based on temperature changes, maintaining optimal performance and preventing issues such as leakage or sticking.

- Thermal management systems for solenoid valves: Advanced solenoid valve designs may include thermal management systems to control and mitigate the effects of thermal expansion. These systems can involve heat dissipation techniques, insulation, or active cooling mechanisms to maintain stable operating temperatures and prevent thermal-related malfunctions.

- Material selection for thermal stability: The choice of materials used in solenoid valve construction plays a crucial role in managing thermal expansion. Engineers select materials with appropriate thermal properties to ensure dimensional stability and consistent performance across the valve's operating temperature range.

- Thermal expansion in specialized solenoid valve applications: Certain applications, such as refrigeration systems or high-temperature industrial processes, require solenoid valves specifically designed to handle extreme thermal conditions. These valves may incorporate unique features or materials to address the challenges posed by significant thermal expansion or contraction.

02 Temperature-sensitive control systems for solenoid valves

Advanced control systems are implemented to monitor and adjust solenoid valve operation based on temperature changes. These systems may include temperature sensors, microprocessors, and adaptive algorithms to maintain optimal performance under varying thermal conditions.Expand Specific Solutions03 Material selection for thermal stability in solenoid valves

Careful selection of materials is crucial in solenoid valve design to minimize the effects of thermal expansion. This includes using thermally stable alloys, composites, or ceramics for critical components such as valve seats, plungers, and housings.Expand Specific Solutions04 Thermal insulation and heat dissipation in solenoid valves

Solenoid valves incorporate thermal insulation and heat dissipation features to manage temperature-related issues. This may involve the use of insulating materials, heat sinks, or cooling fins to regulate internal temperatures and prevent thermal expansion-related malfunctions.Expand Specific Solutions05 Pressure-balanced designs for thermal expansion mitigation

Solenoid valves utilize pressure-balanced designs to counteract the effects of thermal expansion. These designs may incorporate floating seals, balanced spools, or pressure-equalizing chambers to maintain proper sealing and operation despite temperature-induced dimensional changes.Expand Specific Solutions

Key Solar Thermal Component Manufacturers

The thermal expansion control in solenoid valves for solar thermal systems is in a growth phase, with increasing market size driven by the rising adoption of renewable energy solutions. The global market for solar thermal systems is expanding, creating opportunities for advanced valve technologies. While the technology is relatively mature, ongoing innovations focus on improving efficiency and reliability. Companies like Eaton Corp., DENSO Corp., and Robert Bosch GmbH are leading players, leveraging their extensive experience in automotive and industrial applications to develop sophisticated solenoid valve solutions. Emerging players such as Fujikoki Corp. and Stiebel Eltron GmbH & Co. KG are also contributing to technological advancements in this field, particularly in thermal management and control systems for solar applications.

DENSO Corp.

Technical Solution: DENSO has engineered an innovative thermal expansion control system for solenoid valves used in solar thermal applications. Their solution incorporates a dual-material valve stem that provides inherent thermal compensation[1]. The stem consists of two materials with different thermal expansion coefficients, carefully selected to counteract each other's expansion over the operating temperature range. DENSO has also developed a proprietary magnetic circuit design that maintains consistent solenoid force output across varying temperatures, ensuring reliable valve actuation[2]. The valve housing features an advanced thermal management system with integrated heat pipes to distribute heat evenly and prevent localized thermal expansion. Additionally, DENSO's electronic control unit employs machine learning algorithms to adapt valve timing and positioning based on historical performance data and current operating conditions[3], optimizing efficiency and reducing wear over time.

Strengths: Self-compensating mechanical design, consistent performance across temperature ranges, and adaptive control for long-term optimization. Weaknesses: Complex manufacturing process for dual-material components and potential for increased cost due to advanced materials and control systems.

Robert Bosch GmbH

Technical Solution: Bosch has developed an advanced thermal expansion control system for solenoid valves in solar thermal systems. Their solution incorporates a bimetallic compensator that adjusts valve position based on temperature changes[1]. This compensator is integrated into the valve stem, allowing for automatic adjustment as the system heats up or cools down. The valve design also includes a high-performance thermal insulation layer to minimize heat transfer to sensitive components[2]. Bosch's system utilizes smart sensors and adaptive control algorithms to optimize valve operation across varying temperature ranges, ensuring consistent performance in diverse climatic conditions[3]. The company has implemented this technology in their latest generation of solar thermal controllers, which can manage multiple valves simultaneously for complex system configurations.

Strengths: Precise temperature compensation, energy-efficient operation, and adaptability to various system sizes. Weaknesses: Higher initial cost and potential complexity in maintenance for advanced electronic components.

Innovative Materials for Thermal Control

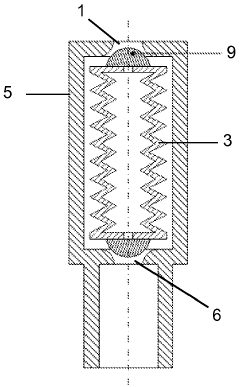

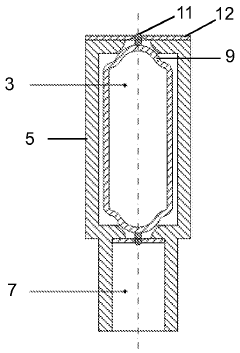

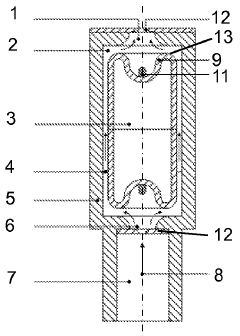

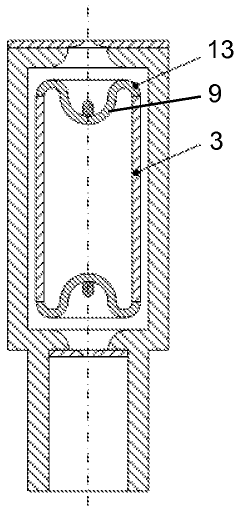

Thermally controlled expansion valve and arrangement comprising the same

PatentActiveEP2368062A1

Innovation

- A thermally controlled expansion valve that integrates 'intelligent' passive actuators, utilizing a floating body with thermal expansion behavior to automatically control the outlet and inlet openings, combining the functions of a float valve and ball valve, allowing for automatic venting without additional energy supply.

Thermally controlled expansion valve and arrangement comprising the same

PatentWO2010063703A1

Innovation

- A thermally controlled expansion valve that integrates 'intelligent' passive actuators, combining the functions of a float valve and shut-off valve, utilizing a closure body with thermal expansion behavior to automatically vent the system by sealing and unsealing openings based on temperature changes, simplifying design and reducing production costs.

Efficiency Standards for Solar Systems

Efficiency standards for solar thermal systems play a crucial role in ensuring optimal performance and energy conservation. These standards are designed to maximize the utilization of solar energy while minimizing heat losses and system inefficiencies. In the context of solar thermal systems, efficiency is typically measured by the ratio of useful heat output to the total solar radiation incident on the collector surface.

The development of efficiency standards for solar thermal systems involves a comprehensive approach that considers various factors affecting system performance. These factors include collector design, heat transfer mechanisms, insulation quality, and overall system integration. Standards often specify minimum requirements for thermal insulation, heat exchanger effectiveness, and collector efficiency to ensure that solar thermal systems meet acceptable performance levels.

One key aspect of efficiency standards is the Solar Keymark certification, widely recognized in Europe. This certification ensures that solar thermal products comply with specific quality and performance criteria. It includes rigorous testing procedures to evaluate collector efficiency, durability, and reliability under various operating conditions. The Solar Keymark certification has become a benchmark for quality assurance in the solar thermal industry.

In the United States, the Solar Rating and Certification Corporation (SRCC) provides similar standards and certifications for solar thermal systems. The SRCC's OG-300 certification, for instance, evaluates the entire solar water heating system, including collectors, storage tanks, and controls, to ensure they meet minimum efficiency and performance requirements.

Efficiency standards also address the importance of proper system sizing and integration. Oversized or undersized systems can lead to reduced efficiency and increased operational costs. Therefore, standards often include guidelines for appropriate system sizing based on factors such as local climate, hot water demand, and available roof space.

Furthermore, efficiency standards for solar thermal systems are continually evolving to incorporate advancements in technology and materials. For example, the development of high-performance selective coatings for absorber surfaces has significantly improved collector efficiency. Standards are updated to reflect these improvements and encourage the adoption of more efficient technologies.

As the global focus on renewable energy intensifies, efficiency standards for solar thermal systems are becoming increasingly stringent. This trend is driven by the need to maximize energy savings, reduce carbon emissions, and improve the overall cost-effectiveness of solar thermal installations. Compliance with these standards not only ensures better system performance but also helps in building consumer confidence in solar thermal technology.

The development of efficiency standards for solar thermal systems involves a comprehensive approach that considers various factors affecting system performance. These factors include collector design, heat transfer mechanisms, insulation quality, and overall system integration. Standards often specify minimum requirements for thermal insulation, heat exchanger effectiveness, and collector efficiency to ensure that solar thermal systems meet acceptable performance levels.

One key aspect of efficiency standards is the Solar Keymark certification, widely recognized in Europe. This certification ensures that solar thermal products comply with specific quality and performance criteria. It includes rigorous testing procedures to evaluate collector efficiency, durability, and reliability under various operating conditions. The Solar Keymark certification has become a benchmark for quality assurance in the solar thermal industry.

In the United States, the Solar Rating and Certification Corporation (SRCC) provides similar standards and certifications for solar thermal systems. The SRCC's OG-300 certification, for instance, evaluates the entire solar water heating system, including collectors, storage tanks, and controls, to ensure they meet minimum efficiency and performance requirements.

Efficiency standards also address the importance of proper system sizing and integration. Oversized or undersized systems can lead to reduced efficiency and increased operational costs. Therefore, standards often include guidelines for appropriate system sizing based on factors such as local climate, hot water demand, and available roof space.

Furthermore, efficiency standards for solar thermal systems are continually evolving to incorporate advancements in technology and materials. For example, the development of high-performance selective coatings for absorber surfaces has significantly improved collector efficiency. Standards are updated to reflect these improvements and encourage the adoption of more efficient technologies.

As the global focus on renewable energy intensifies, efficiency standards for solar thermal systems are becoming increasingly stringent. This trend is driven by the need to maximize energy savings, reduce carbon emissions, and improve the overall cost-effectiveness of solar thermal installations. Compliance with these standards not only ensures better system performance but also helps in building consumer confidence in solar thermal technology.

Environmental Impact Assessment

The environmental impact assessment of thermal expansion control in solenoid valves for solar thermal systems reveals both positive and negative implications. On the positive side, improved thermal expansion control enhances the overall efficiency of solar thermal systems, leading to increased renewable energy utilization and reduced reliance on fossil fuels. This contributes to lower greenhouse gas emissions and mitigates climate change impacts.

The use of advanced materials and designs in solenoid valves can result in longer operational lifespans, reducing the frequency of replacements and associated waste generation. Additionally, more precise control over thermal expansion can minimize the risk of leaks and system failures, preventing potential environmental contamination from heat transfer fluids.

However, the manufacturing process of these specialized valves may involve energy-intensive procedures and the use of rare or potentially harmful materials. The production and disposal of these components could contribute to resource depletion and generate electronic waste if not properly managed.

The improved efficiency of solar thermal systems with better thermal expansion control may lead to increased adoption of this technology. While this promotes renewable energy use, it could also result in land use changes for large-scale solar installations, potentially impacting local ecosystems and biodiversity.

Water consumption is another consideration, as some solar thermal systems require significant amounts of water for cooling and cleaning. Enhanced thermal expansion control may reduce water requirements, but the overall impact on water resources should be carefully evaluated, especially in water-scarce regions.

The lifecycle assessment of these valves is crucial, considering the environmental costs of raw material extraction, manufacturing, transportation, operation, and end-of-life disposal. Efforts to develop eco-friendly materials and implement circular economy principles in valve production and recycling could significantly reduce the overall environmental footprint.

Noise pollution from solenoid valve operation is generally minimal, but cumulative effects in large-scale installations should be considered. Electromagnetic emissions from these valves are typically low but may require assessment in sensitive environments or near wildlife habitats.

In conclusion, while thermal expansion control in solenoid valves for solar thermal systems offers significant environmental benefits through improved energy efficiency and renewable energy utilization, a comprehensive approach to design, manufacturing, and lifecycle management is essential to minimize potential negative impacts and maximize the overall environmental benefits of this technology.

The use of advanced materials and designs in solenoid valves can result in longer operational lifespans, reducing the frequency of replacements and associated waste generation. Additionally, more precise control over thermal expansion can minimize the risk of leaks and system failures, preventing potential environmental contamination from heat transfer fluids.

However, the manufacturing process of these specialized valves may involve energy-intensive procedures and the use of rare or potentially harmful materials. The production and disposal of these components could contribute to resource depletion and generate electronic waste if not properly managed.

The improved efficiency of solar thermal systems with better thermal expansion control may lead to increased adoption of this technology. While this promotes renewable energy use, it could also result in land use changes for large-scale solar installations, potentially impacting local ecosystems and biodiversity.

Water consumption is another consideration, as some solar thermal systems require significant amounts of water for cooling and cleaning. Enhanced thermal expansion control may reduce water requirements, but the overall impact on water resources should be carefully evaluated, especially in water-scarce regions.

The lifecycle assessment of these valves is crucial, considering the environmental costs of raw material extraction, manufacturing, transportation, operation, and end-of-life disposal. Efforts to develop eco-friendly materials and implement circular economy principles in valve production and recycling could significantly reduce the overall environmental footprint.

Noise pollution from solenoid valve operation is generally minimal, but cumulative effects in large-scale installations should be considered. Electromagnetic emissions from these valves are typically low but may require assessment in sensitive environments or near wildlife habitats.

In conclusion, while thermal expansion control in solenoid valves for solar thermal systems offers significant environmental benefits through improved energy efficiency and renewable energy utilization, a comprehensive approach to design, manufacturing, and lifecycle management is essential to minimize potential negative impacts and maximize the overall environmental benefits of this technology.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!