How Solenoid Valves Drive Innovation in Modular Construction Techniques

JUL 23, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Solenoid Valve Evolution in Construction

The evolution of solenoid valves in construction has been a journey of continuous innovation and adaptation. Initially developed for industrial applications, these electromechanical devices have found their way into the construction industry, revolutionizing fluid control systems in buildings and infrastructure projects.

In the early stages, solenoid valves were primarily used in basic on/off control applications within construction sites, such as water supply management and simple pneumatic systems. As construction techniques advanced, so did the demands placed on these valves, leading to significant improvements in their design and functionality.

The 1980s and 1990s saw a shift towards more sophisticated solenoid valve designs, incorporating materials that could withstand harsh construction environments. This period marked the introduction of corrosion-resistant alloys and high-performance polymers, extending the lifespan and reliability of these components in challenging conditions.

The turn of the millennium brought about a new era for solenoid valves in construction. With the rise of smart building technologies, these valves evolved to include electronic controls and sensors. This integration allowed for more precise fluid management and remote operation capabilities, aligning with the growing trend of building automation systems.

As modular construction techniques gained traction in the 2010s, solenoid valves adapted to meet the unique requirements of prefabricated building elements. Manufacturers developed compact, lightweight valve designs that could be easily integrated into modular units during the factory assembly process. This evolution significantly reduced on-site installation time and improved overall construction efficiency.

Recent years have seen further advancements in solenoid valve technology for construction applications. The introduction of energy-efficient designs, such as latching solenoid valves, has addressed the industry's growing focus on sustainability. These valves consume power only during state changes, contributing to reduced energy consumption in buildings.

Moreover, the integration of IoT (Internet of Things) capabilities has transformed solenoid valves into smart devices capable of real-time monitoring and predictive maintenance. This development has enhanced the reliability and performance of fluid control systems in modern construction projects, aligning with the industry's shift towards data-driven decision-making and proactive maintenance strategies.

The ongoing evolution of solenoid valves continues to drive innovation in modular construction techniques. As the industry moves towards more sustainable and efficient building practices, these valves are expected to play an increasingly critical role in optimizing resource management and enhancing the overall performance of constructed environments.

In the early stages, solenoid valves were primarily used in basic on/off control applications within construction sites, such as water supply management and simple pneumatic systems. As construction techniques advanced, so did the demands placed on these valves, leading to significant improvements in their design and functionality.

The 1980s and 1990s saw a shift towards more sophisticated solenoid valve designs, incorporating materials that could withstand harsh construction environments. This period marked the introduction of corrosion-resistant alloys and high-performance polymers, extending the lifespan and reliability of these components in challenging conditions.

The turn of the millennium brought about a new era for solenoid valves in construction. With the rise of smart building technologies, these valves evolved to include electronic controls and sensors. This integration allowed for more precise fluid management and remote operation capabilities, aligning with the growing trend of building automation systems.

As modular construction techniques gained traction in the 2010s, solenoid valves adapted to meet the unique requirements of prefabricated building elements. Manufacturers developed compact, lightweight valve designs that could be easily integrated into modular units during the factory assembly process. This evolution significantly reduced on-site installation time and improved overall construction efficiency.

Recent years have seen further advancements in solenoid valve technology for construction applications. The introduction of energy-efficient designs, such as latching solenoid valves, has addressed the industry's growing focus on sustainability. These valves consume power only during state changes, contributing to reduced energy consumption in buildings.

Moreover, the integration of IoT (Internet of Things) capabilities has transformed solenoid valves into smart devices capable of real-time monitoring and predictive maintenance. This development has enhanced the reliability and performance of fluid control systems in modern construction projects, aligning with the industry's shift towards data-driven decision-making and proactive maintenance strategies.

The ongoing evolution of solenoid valves continues to drive innovation in modular construction techniques. As the industry moves towards more sustainable and efficient building practices, these valves are expected to play an increasingly critical role in optimizing resource management and enhancing the overall performance of constructed environments.

Market Demand Analysis

The market demand for solenoid valves in modular construction techniques has been experiencing significant growth in recent years. This surge is primarily driven by the increasing adoption of prefabricated and modular construction methods across various sectors, including residential, commercial, and industrial buildings. The global modular construction market is projected to expand at a compound annual growth rate (CAGR) of over 6% from 2021 to 2026, with solenoid valves playing a crucial role in this growth.

Solenoid valves are essential components in modular construction, particularly in plumbing and HVAC systems. They offer precise control over fluid flow, which is critical in maintaining the efficiency and reliability of these systems in prefabricated modules. The demand for solenoid valves is further amplified by the need for smart building solutions, where automated control systems are becoming increasingly prevalent.

In the residential sector, the rising demand for affordable housing and the trend towards sustainable construction practices are driving the adoption of modular construction techniques. This, in turn, is boosting the market for solenoid valves, as they are integral to the plumbing and heating systems in prefabricated housing modules. The commercial sector, including offices and hotels, is also witnessing a shift towards modular construction, further expanding the market for solenoid valves.

The industrial sector presents another significant market opportunity for solenoid valves in modular construction. As industries seek to optimize their operations and reduce construction time, modular construction techniques are gaining traction in the development of manufacturing facilities, warehouses, and data centers. Solenoid valves are crucial in these applications for controlling various fluid systems, including cooling and process control.

The healthcare sector is emerging as a promising market for solenoid valves in modular construction. The need for rapid deployment of healthcare facilities, especially in light of recent global health crises, has accelerated the adoption of modular construction in this sector. Solenoid valves are essential in these applications for controlling water supply, medical gas systems, and HVAC systems in prefabricated hospital modules.

Geographically, North America and Europe are currently the largest markets for solenoid valves in modular construction, owing to the advanced state of their construction industries and the high adoption rate of innovative building techniques. However, the Asia-Pacific region is expected to witness the fastest growth in this market, driven by rapid urbanization, increasing infrastructure development, and government initiatives promoting modular construction methods.

As the modular construction industry continues to evolve, the demand for more sophisticated and efficient solenoid valves is likely to increase. Manufacturers are focusing on developing smart, energy-efficient valves that can integrate seamlessly with building automation systems. This trend aligns with the growing emphasis on sustainability and energy efficiency in the construction sector, further driving the market demand for advanced solenoid valve solutions in modular construction techniques.

Solenoid valves are essential components in modular construction, particularly in plumbing and HVAC systems. They offer precise control over fluid flow, which is critical in maintaining the efficiency and reliability of these systems in prefabricated modules. The demand for solenoid valves is further amplified by the need for smart building solutions, where automated control systems are becoming increasingly prevalent.

In the residential sector, the rising demand for affordable housing and the trend towards sustainable construction practices are driving the adoption of modular construction techniques. This, in turn, is boosting the market for solenoid valves, as they are integral to the plumbing and heating systems in prefabricated housing modules. The commercial sector, including offices and hotels, is also witnessing a shift towards modular construction, further expanding the market for solenoid valves.

The industrial sector presents another significant market opportunity for solenoid valves in modular construction. As industries seek to optimize their operations and reduce construction time, modular construction techniques are gaining traction in the development of manufacturing facilities, warehouses, and data centers. Solenoid valves are crucial in these applications for controlling various fluid systems, including cooling and process control.

The healthcare sector is emerging as a promising market for solenoid valves in modular construction. The need for rapid deployment of healthcare facilities, especially in light of recent global health crises, has accelerated the adoption of modular construction in this sector. Solenoid valves are essential in these applications for controlling water supply, medical gas systems, and HVAC systems in prefabricated hospital modules.

Geographically, North America and Europe are currently the largest markets for solenoid valves in modular construction, owing to the advanced state of their construction industries and the high adoption rate of innovative building techniques. However, the Asia-Pacific region is expected to witness the fastest growth in this market, driven by rapid urbanization, increasing infrastructure development, and government initiatives promoting modular construction methods.

As the modular construction industry continues to evolve, the demand for more sophisticated and efficient solenoid valves is likely to increase. Manufacturers are focusing on developing smart, energy-efficient valves that can integrate seamlessly with building automation systems. This trend aligns with the growing emphasis on sustainability and energy efficiency in the construction sector, further driving the market demand for advanced solenoid valve solutions in modular construction techniques.

Technical Challenges

The integration of solenoid valves in modular construction techniques faces several technical challenges that need to be addressed for successful implementation. One of the primary obstacles is the miniaturization of valve systems while maintaining their efficiency and reliability. As modular construction aims to maximize space utilization, compact valve designs are essential. However, reducing the size of solenoid valves without compromising their performance requires advanced materials and precision engineering.

Another significant challenge lies in the development of robust control systems for solenoid valves in modular construction. These valves often need to operate in diverse environmental conditions, from extreme temperatures to high-pressure situations. Ensuring consistent and accurate valve operation across various scenarios demands sophisticated control algorithms and sensor technologies. The integration of these control systems with existing building management systems also presents interoperability issues that need to be resolved.

Energy efficiency is a critical concern in modular construction, and solenoid valves are no exception. Designing valves that consume minimal power while maintaining rapid response times and high flow rates is a complex engineering task. This challenge is further compounded by the need for long-term reliability, as accessing and replacing components in modular structures can be difficult and costly.

The durability and lifespan of solenoid valves in modular construction environments pose another technical hurdle. These valves must withstand frequent cycling, vibrations, and potential exposure to corrosive substances. Developing materials and coatings that can endure these conditions without degradation or failure is crucial for the long-term success of modular construction projects.

Standardization and compatibility issues also present significant challenges. With various manufacturers and designs in the market, ensuring that solenoid valves can be seamlessly integrated into different modular construction systems requires the development of universal standards and interfaces. This standardization effort must balance the need for innovation with the practical requirements of interchangeability and ease of maintenance.

Lastly, the challenge of real-time monitoring and predictive maintenance for solenoid valves in modular construction cannot be overlooked. Implementing sensors and diagnostic systems that can detect early signs of valve wear or malfunction, without adding significant complexity or cost to the overall system, is a critical area of development. This proactive approach to maintenance is essential for minimizing downtime and ensuring the longevity of modular structures.

Another significant challenge lies in the development of robust control systems for solenoid valves in modular construction. These valves often need to operate in diverse environmental conditions, from extreme temperatures to high-pressure situations. Ensuring consistent and accurate valve operation across various scenarios demands sophisticated control algorithms and sensor technologies. The integration of these control systems with existing building management systems also presents interoperability issues that need to be resolved.

Energy efficiency is a critical concern in modular construction, and solenoid valves are no exception. Designing valves that consume minimal power while maintaining rapid response times and high flow rates is a complex engineering task. This challenge is further compounded by the need for long-term reliability, as accessing and replacing components in modular structures can be difficult and costly.

The durability and lifespan of solenoid valves in modular construction environments pose another technical hurdle. These valves must withstand frequent cycling, vibrations, and potential exposure to corrosive substances. Developing materials and coatings that can endure these conditions without degradation or failure is crucial for the long-term success of modular construction projects.

Standardization and compatibility issues also present significant challenges. With various manufacturers and designs in the market, ensuring that solenoid valves can be seamlessly integrated into different modular construction systems requires the development of universal standards and interfaces. This standardization effort must balance the need for innovation with the practical requirements of interchangeability and ease of maintenance.

Lastly, the challenge of real-time monitoring and predictive maintenance for solenoid valves in modular construction cannot be overlooked. Implementing sensors and diagnostic systems that can detect early signs of valve wear or malfunction, without adding significant complexity or cost to the overall system, is a critical area of development. This proactive approach to maintenance is essential for minimizing downtime and ensuring the longevity of modular structures.

Current Solenoid Solutions

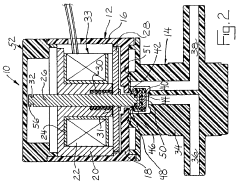

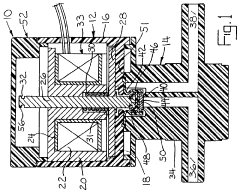

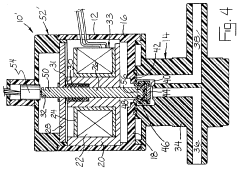

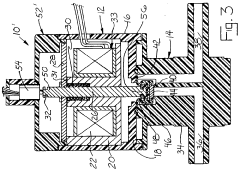

01 Solenoid valve design and structure

Solenoid valves are electromechanical devices that control the flow of fluids. Their design typically includes a coil, plunger, and valve body. When energized, the coil creates a magnetic field that moves the plunger, opening or closing the valve. Various structural improvements focus on enhancing efficiency, reliability, and response time.- Solenoid valve design and structure: Solenoid valves are electromechanical devices that control the flow of fluids. They consist of a solenoid coil, plunger, and valve body. When energized, the coil creates a magnetic field that moves the plunger, opening or closing the valve. Various designs exist to optimize performance, efficiency, and reliability for different applications.

- Solenoid valve control systems: Control systems for solenoid valves include electronic circuits and microcontrollers that regulate valve operation. These systems can incorporate sensors, feedback mechanisms, and advanced algorithms to ensure precise timing, pressure control, and flow regulation. Some designs feature adaptive control to optimize performance under varying conditions.

- Solenoid valve applications in automotive systems: Solenoid valves are widely used in automotive systems for fuel injection, transmission control, and engine management. They play a crucial role in regulating fluid flow and pressure in various vehicle subsystems, contributing to improved engine performance, fuel efficiency, and emissions control.

- Miniaturization and integration of solenoid valves: Advancements in solenoid valve technology focus on miniaturization and integration with other components. This trend enables the development of compact, multi-functional valve assemblies that can be easily incorporated into space-constrained systems. Miniaturized solenoid valves find applications in medical devices, robotics, and portable equipment.

- Energy-efficient solenoid valve designs: Innovative solenoid valve designs aim to improve energy efficiency and reduce power consumption. These designs may incorporate low-power actuators, energy recovery mechanisms, or alternative materials to minimize heat generation and power losses. Energy-efficient solenoid valves are particularly important in battery-powered systems and applications requiring continuous operation.

02 Application in fuel injection systems

Solenoid valves play a crucial role in fuel injection systems for internal combustion engines. They control the precise timing and amount of fuel delivered to the engine, improving fuel efficiency and reducing emissions. Advancements in this area focus on faster response times and more accurate fuel metering.Expand Specific Solutions03 Integration with electronic control systems

Modern solenoid valves are often integrated with electronic control systems for enhanced precision and automation. This integration allows for real-time adjustments based on various parameters, improving overall system performance. Developments in this area include smart valves with built-in sensors and communication capabilities.Expand Specific Solutions04 Energy efficiency and power consumption optimization

Improving the energy efficiency of solenoid valves is a key focus area. This includes developing low-power designs, optimizing coil configurations, and implementing energy-saving control strategies. These advancements aim to reduce power consumption without compromising valve performance.Expand Specific Solutions05 Miniaturization and specialized applications

There is a trend towards miniaturization of solenoid valves for use in compact systems and specialized applications. This includes developing micro-solenoid valves for medical devices, aerospace applications, and other fields requiring precise fluid control in limited spaces. These miniature valves often require innovative designs to maintain performance at a smaller scale.Expand Specific Solutions

Key Industry Players

The solenoid valve market in modular construction is in a growth phase, driven by increasing demand for efficient and automated building systems. The market size is expanding as modular construction techniques gain traction globally. Technologically, solenoid valves are mature but continue to evolve with smart features and IoT integration. Key players like Robert Bosch GmbH, Eaton Corp., and Mitsubishi Electric Corp. are leading innovation, focusing on miniaturization, energy efficiency, and precision control. Emerging companies such as Xiamen Lota Industrial Co., Ltd. are also contributing to market dynamism. The competitive landscape is characterized by a mix of established industrial giants and specialized valve manufacturers, all vying to meet the unique demands of modular construction applications.

Robert Bosch GmbH

Technical Solution: Bosch has developed advanced solenoid valve systems for modular construction, focusing on precision control and energy efficiency. Their innovative approach includes the integration of smart sensors and IoT connectivity, allowing for real-time monitoring and adjustment of fluid flow in modular building systems[1]. The company's solenoid valves feature compact designs suitable for prefabricated construction elements, with high-speed switching capabilities that enable rapid response to changing environmental conditions[3]. Bosch's valves incorporate advanced materials and coatings to enhance durability and reduce maintenance requirements in harsh construction environments[5].

Strengths: Industry-leading precision control, IoT integration, and energy efficiency. Weaknesses: Potentially higher initial costs compared to traditional systems, and reliance on proprietary software platforms.

Eaton Corp.

Technical Solution: Eaton has pioneered the development of modular hydraulic systems incorporating advanced solenoid valves for construction applications. Their technology focuses on creating scalable, plug-and-play solutions that significantly reduce on-site assembly time and complexity[2]. Eaton's solenoid valves feature adaptive control algorithms that optimize performance based on real-time load conditions, improving energy efficiency and reducing wear[4]. The company has also introduced a series of compact, multi-function valve blocks that integrate multiple solenoid valves into a single unit, ideal for space-constrained modular construction projects[6].

Strengths: Highly scalable and adaptable systems, reduced on-site assembly time. Weaknesses: May require specialized training for installation and maintenance, potential compatibility issues with non-Eaton components.

Innovative Valve Technologies

Solenoid valve in modular design

PatentInactiveDE4135993A1

Innovation

- A modular solenoid valve design with three basic components - a valve part, a magnet part, and a cap part - allowing reversible assembly in two orientations to function as either a regularly open or closed valve, simplifying assembly and manufacturing.

Modular valve system for flowing media

PatentInactiveEP0719395A1

Innovation

- A modular valve design featuring a magnetically non-conductive intermediate plate between the valve housing and electromagnetic drive, allowing the electromagnetic drive to act on one leg of the rocker switch symmetrically, enabling easy adaptation to different electrical and media connections by rotating the intermediate plate and rocker switch by 180°, while maintaining a uniform basic structure.

Regulatory Framework

The regulatory framework surrounding solenoid valves in modular construction techniques is a complex and evolving landscape that significantly impacts innovation and implementation. As these valves play a crucial role in controlling fluid flow and pressure within modular systems, they are subject to various standards and regulations across different jurisdictions.

In the United States, the primary regulatory body overseeing the use of solenoid valves in construction is the Occupational Safety and Health Administration (OSHA). OSHA sets forth guidelines for the safe installation and operation of these valves, particularly in relation to worker safety and system integrity. Additionally, the American Society of Mechanical Engineers (ASME) provides specific codes and standards for pressure vessels and piping systems, which often incorporate solenoid valves.

The European Union has established the Machinery Directive 2006/42/EC, which outlines essential health and safety requirements for machinery and components, including solenoid valves used in modular construction. This directive is complemented by harmonized standards such as EN ISO 13849-1, which focuses on the safety of control systems.

In the context of modular construction, building codes play a significant role in shaping the regulatory landscape. The International Building Code (IBC) and its regional adaptations provide guidelines for the use of prefabricated components, including those incorporating solenoid valves. These codes often reference industry standards such as those set by the National Electrical Manufacturers Association (NEMA) for electrical components.

Environmental regulations also impact the use of solenoid valves in modular construction. The Restriction of Hazardous Substances (RoHS) directive in the EU and similar regulations worldwide restrict the use of certain hazardous materials in electrical and electronic equipment, affecting the manufacturing of solenoid valves.

As modular construction techniques continue to evolve, regulatory bodies are adapting to keep pace with technological advancements. This includes the development of new standards for smart building systems and the Internet of Things (IoT), which often incorporate advanced solenoid valve technologies. The challenge for innovators lies in navigating this complex regulatory landscape while pushing the boundaries of what is possible in modular construction.

Compliance with these regulations is crucial for manufacturers and construction companies. It not only ensures safety and reliability but also facilitates market access and acceptance of innovative modular construction techniques. As such, staying abreast of regulatory changes and actively participating in standards development processes has become an integral part of driving innovation in this field.

In the United States, the primary regulatory body overseeing the use of solenoid valves in construction is the Occupational Safety and Health Administration (OSHA). OSHA sets forth guidelines for the safe installation and operation of these valves, particularly in relation to worker safety and system integrity. Additionally, the American Society of Mechanical Engineers (ASME) provides specific codes and standards for pressure vessels and piping systems, which often incorporate solenoid valves.

The European Union has established the Machinery Directive 2006/42/EC, which outlines essential health and safety requirements for machinery and components, including solenoid valves used in modular construction. This directive is complemented by harmonized standards such as EN ISO 13849-1, which focuses on the safety of control systems.

In the context of modular construction, building codes play a significant role in shaping the regulatory landscape. The International Building Code (IBC) and its regional adaptations provide guidelines for the use of prefabricated components, including those incorporating solenoid valves. These codes often reference industry standards such as those set by the National Electrical Manufacturers Association (NEMA) for electrical components.

Environmental regulations also impact the use of solenoid valves in modular construction. The Restriction of Hazardous Substances (RoHS) directive in the EU and similar regulations worldwide restrict the use of certain hazardous materials in electrical and electronic equipment, affecting the manufacturing of solenoid valves.

As modular construction techniques continue to evolve, regulatory bodies are adapting to keep pace with technological advancements. This includes the development of new standards for smart building systems and the Internet of Things (IoT), which often incorporate advanced solenoid valve technologies. The challenge for innovators lies in navigating this complex regulatory landscape while pushing the boundaries of what is possible in modular construction.

Compliance with these regulations is crucial for manufacturers and construction companies. It not only ensures safety and reliability but also facilitates market access and acceptance of innovative modular construction techniques. As such, staying abreast of regulatory changes and actively participating in standards development processes has become an integral part of driving innovation in this field.

Environmental Impact Assessment

The integration of solenoid valves in modular construction techniques presents a significant opportunity for enhancing environmental sustainability in the building sector. These innovative components contribute to more efficient resource utilization and reduced environmental impact throughout the construction process and building lifecycle.

Solenoid valves enable precise control of fluid and gas flow within modular building systems, leading to optimized energy consumption. By regulating heating, cooling, and ventilation systems with greater accuracy, these valves help reduce overall energy usage in completed structures. This improved efficiency translates to lower greenhouse gas emissions associated with building operations, aligning with global efforts to combat climate change.

Furthermore, the incorporation of solenoid valves in modular construction facilitates the implementation of smart building technologies. These systems can adapt to occupancy patterns and environmental conditions, further minimizing energy waste and enhancing the building's ecological footprint. The ability to fine-tune resource consumption based on real-time data contributes to a more sustainable built environment.

The modular construction approach, enhanced by solenoid valve technology, also reduces on-site construction time and associated environmental disturbances. With a significant portion of the building process occurring in controlled factory settings, there is a notable decrease in noise pollution, dust emissions, and local ecosystem disruption typically associated with traditional construction methods. This shift towards off-site fabrication minimizes the environmental impact on construction sites and surrounding communities.

Material efficiency is another key environmental benefit of solenoid valve integration in modular construction. The precise control offered by these valves allows for more accurate material usage, reducing waste generation during the manufacturing and assembly processes. This optimization extends to water usage in plumbing systems, where solenoid valves can prevent leaks and regulate flow more effectively than traditional mechanical valves.

The longevity and maintainability of modular buildings equipped with solenoid valves also contribute to their environmental sustainability. These components are designed for easy replacement and upgrade, extending the lifespan of building systems and reducing the need for extensive renovations or premature demolition. This approach aligns with circular economy principles, minimizing the environmental impact associated with building lifecycle management.

In conclusion, the adoption of solenoid valves in modular construction techniques represents a significant step towards more environmentally friendly building practices. By enhancing energy efficiency, reducing waste, minimizing on-site environmental disturbances, and improving long-term sustainability, this innovation contributes to the overall goal of creating a more eco-conscious construction industry.

Solenoid valves enable precise control of fluid and gas flow within modular building systems, leading to optimized energy consumption. By regulating heating, cooling, and ventilation systems with greater accuracy, these valves help reduce overall energy usage in completed structures. This improved efficiency translates to lower greenhouse gas emissions associated with building operations, aligning with global efforts to combat climate change.

Furthermore, the incorporation of solenoid valves in modular construction facilitates the implementation of smart building technologies. These systems can adapt to occupancy patterns and environmental conditions, further minimizing energy waste and enhancing the building's ecological footprint. The ability to fine-tune resource consumption based on real-time data contributes to a more sustainable built environment.

The modular construction approach, enhanced by solenoid valve technology, also reduces on-site construction time and associated environmental disturbances. With a significant portion of the building process occurring in controlled factory settings, there is a notable decrease in noise pollution, dust emissions, and local ecosystem disruption typically associated with traditional construction methods. This shift towards off-site fabrication minimizes the environmental impact on construction sites and surrounding communities.

Material efficiency is another key environmental benefit of solenoid valve integration in modular construction. The precise control offered by these valves allows for more accurate material usage, reducing waste generation during the manufacturing and assembly processes. This optimization extends to water usage in plumbing systems, where solenoid valves can prevent leaks and regulate flow more effectively than traditional mechanical valves.

The longevity and maintainability of modular buildings equipped with solenoid valves also contribute to their environmental sustainability. These components are designed for easy replacement and upgrade, extending the lifespan of building systems and reducing the need for extensive renovations or premature demolition. This approach aligns with circular economy principles, minimizing the environmental impact associated with building lifecycle management.

In conclusion, the adoption of solenoid valves in modular construction techniques represents a significant step towards more environmentally friendly building practices. By enhancing energy efficiency, reducing waste, minimizing on-site environmental disturbances, and improving long-term sustainability, this innovation contributes to the overall goal of creating a more eco-conscious construction industry.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!