How Virtual Reality Environments Simulate Solenoid Valve Operation for Training

JUL 23, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

VR Solenoid Simulation Background and Objectives

Virtual Reality (VR) technology has rapidly evolved over the past decade, transforming various industries and educational sectors. In the context of industrial training, particularly for complex mechanical systems like solenoid valves, VR offers unprecedented opportunities for immersive and interactive learning experiences. This technological advancement addresses the longstanding challenges in traditional training methods for intricate machinery operations.

The development of VR simulations for solenoid valve operation training stems from the increasing demand for more efficient, safe, and cost-effective training solutions in industrial settings. Solenoid valves, being critical components in numerous hydraulic and pneumatic systems, require precise understanding and handling. Traditional training methods often fall short in providing hands-on experience without risking equipment damage or compromising safety.

The evolution of VR technology in this domain can be traced back to early computer-aided design (CAD) visualizations, progressing through augmented reality applications, and finally culminating in fully immersive VR environments. This progression has been driven by advancements in computer graphics, motion tracking, and haptic feedback technologies, enabling increasingly realistic and interactive simulations.

The primary objective of VR solenoid valve simulations is to create a virtual environment that accurately replicates the physical characteristics, operational mechanics, and troubleshooting scenarios of real-world solenoid valves. This includes simulating various valve types, sizes, and configurations, as well as different operating conditions and potential failure modes.

Key goals of these VR simulations include enhancing trainee understanding of internal valve mechanisms, improving spatial awareness of valve components, and developing muscle memory for maintenance procedures. Additionally, these simulations aim to reduce training costs, minimize equipment downtime, and eliminate safety risks associated with hands-on training on actual equipment.

The technology also seeks to address the scalability issues in traditional training methods. VR simulations can be easily replicated and distributed, allowing for simultaneous training of multiple individuals across different locations. This aspect is particularly valuable for large-scale industrial operations with geographically dispersed teams.

Looking forward, the trajectory of VR solenoid valve simulations is expected to align with broader trends in VR technology. This includes the integration of artificial intelligence for adaptive learning experiences, enhanced haptic feedback for more realistic tactile sensations, and the incorporation of collaborative features for team-based training scenarios.

The development of VR simulations for solenoid valve operation training stems from the increasing demand for more efficient, safe, and cost-effective training solutions in industrial settings. Solenoid valves, being critical components in numerous hydraulic and pneumatic systems, require precise understanding and handling. Traditional training methods often fall short in providing hands-on experience without risking equipment damage or compromising safety.

The evolution of VR technology in this domain can be traced back to early computer-aided design (CAD) visualizations, progressing through augmented reality applications, and finally culminating in fully immersive VR environments. This progression has been driven by advancements in computer graphics, motion tracking, and haptic feedback technologies, enabling increasingly realistic and interactive simulations.

The primary objective of VR solenoid valve simulations is to create a virtual environment that accurately replicates the physical characteristics, operational mechanics, and troubleshooting scenarios of real-world solenoid valves. This includes simulating various valve types, sizes, and configurations, as well as different operating conditions and potential failure modes.

Key goals of these VR simulations include enhancing trainee understanding of internal valve mechanisms, improving spatial awareness of valve components, and developing muscle memory for maintenance procedures. Additionally, these simulations aim to reduce training costs, minimize equipment downtime, and eliminate safety risks associated with hands-on training on actual equipment.

The technology also seeks to address the scalability issues in traditional training methods. VR simulations can be easily replicated and distributed, allowing for simultaneous training of multiple individuals across different locations. This aspect is particularly valuable for large-scale industrial operations with geographically dispersed teams.

Looking forward, the trajectory of VR solenoid valve simulations is expected to align with broader trends in VR technology. This includes the integration of artificial intelligence for adaptive learning experiences, enhanced haptic feedback for more realistic tactile sensations, and the incorporation of collaborative features for team-based training scenarios.

Market Analysis for VR Training Solutions

The market for Virtual Reality (VR) training solutions has been experiencing significant growth in recent years, driven by the increasing demand for immersive and interactive learning experiences across various industries. The global VR training market is expected to reach substantial value by 2025, with a compound annual growth rate (CAGR) exceeding 40% during the forecast period.

The adoption of VR training solutions for simulating solenoid valve operations is part of a broader trend in industrial and technical training. Industries such as manufacturing, oil and gas, aerospace, and automotive are increasingly turning to VR technologies to enhance their training programs. These sectors recognize the potential of VR to provide safe, cost-effective, and highly engaging training environments for complex technical operations.

One of the key drivers for the market growth is the ability of VR training solutions to reduce training costs and improve safety. Traditional training methods for solenoid valve operations often require expensive physical equipment and can pose safety risks. VR simulations eliminate these concerns while providing a highly realistic and interactive learning experience. This has led to a growing interest from both large corporations and small to medium-sized enterprises in implementing VR training solutions.

The market for VR training solutions is also benefiting from advancements in hardware and software technologies. The development of more powerful and affordable VR headsets, along with improvements in graphics and haptic feedback systems, has made VR training more accessible and effective. This technological progress has expanded the potential applications of VR in simulating complex mechanical systems like solenoid valves.

Geographically, North America currently leads the market for VR training solutions, followed by Europe and Asia-Pacific. However, the Asia-Pacific region is expected to witness the highest growth rate in the coming years, driven by rapid industrialization and increasing investments in advanced training technologies.

The competitive landscape of the VR training market is characterized by a mix of established technology companies and specialized VR training solution providers. Major players are investing heavily in research and development to enhance their offerings and gain a competitive edge. Partnerships between VR technology companies and industry-specific training providers are becoming increasingly common, leading to more tailored and effective solutions for simulating solenoid valve operations and other technical processes.

Despite the positive outlook, the market faces some challenges. These include the initial high cost of implementing VR training systems, concerns about the long-term effectiveness of VR training compared to traditional methods, and the need for continuous content updates to keep pace with evolving industrial technologies. However, as the technology matures and more case studies demonstrate its effectiveness, these barriers are expected to diminish, further driving market growth.

The adoption of VR training solutions for simulating solenoid valve operations is part of a broader trend in industrial and technical training. Industries such as manufacturing, oil and gas, aerospace, and automotive are increasingly turning to VR technologies to enhance their training programs. These sectors recognize the potential of VR to provide safe, cost-effective, and highly engaging training environments for complex technical operations.

One of the key drivers for the market growth is the ability of VR training solutions to reduce training costs and improve safety. Traditional training methods for solenoid valve operations often require expensive physical equipment and can pose safety risks. VR simulations eliminate these concerns while providing a highly realistic and interactive learning experience. This has led to a growing interest from both large corporations and small to medium-sized enterprises in implementing VR training solutions.

The market for VR training solutions is also benefiting from advancements in hardware and software technologies. The development of more powerful and affordable VR headsets, along with improvements in graphics and haptic feedback systems, has made VR training more accessible and effective. This technological progress has expanded the potential applications of VR in simulating complex mechanical systems like solenoid valves.

Geographically, North America currently leads the market for VR training solutions, followed by Europe and Asia-Pacific. However, the Asia-Pacific region is expected to witness the highest growth rate in the coming years, driven by rapid industrialization and increasing investments in advanced training technologies.

The competitive landscape of the VR training market is characterized by a mix of established technology companies and specialized VR training solution providers. Major players are investing heavily in research and development to enhance their offerings and gain a competitive edge. Partnerships between VR technology companies and industry-specific training providers are becoming increasingly common, leading to more tailored and effective solutions for simulating solenoid valve operations and other technical processes.

Despite the positive outlook, the market faces some challenges. These include the initial high cost of implementing VR training systems, concerns about the long-term effectiveness of VR training compared to traditional methods, and the need for continuous content updates to keep pace with evolving industrial technologies. However, as the technology matures and more case studies demonstrate its effectiveness, these barriers are expected to diminish, further driving market growth.

Technical Challenges in VR Solenoid Simulation

Simulating solenoid valve operation in virtual reality (VR) environments presents several significant technical challenges. One of the primary difficulties lies in accurately replicating the complex electromagnetic interactions within the solenoid valve. The precise modeling of magnetic fields and their effects on the valve's moving components requires sophisticated physics engines and computational resources.

Another major challenge is achieving real-time performance while maintaining high fidelity in the simulation. VR applications demand low latency and high frame rates to provide a seamless user experience. Balancing the computational demands of accurate solenoid simulation with the need for responsive VR interactions poses a significant technical hurdle.

Haptic feedback represents a crucial aspect of realistic solenoid valve simulation in VR. Replicating the tactile sensations associated with valve operation, such as the resistance felt when actuating the valve or the vibrations during operation, requires advanced haptic technologies. Current haptic devices often struggle to provide the nuanced force feedback necessary for authentic solenoid valve interaction.

Visual fidelity is another area of technical difficulty. Rendering detailed 3D models of solenoid valves with accurate material properties, reflections, and shadows in a VR environment can be computationally intensive. Achieving photorealistic visuals while maintaining performance is a delicate balancing act.

Simulating fluid dynamics within and around the solenoid valve adds another layer of complexity. Accurately representing the flow of liquids or gases through the valve, including pressure changes and turbulence, requires advanced computational fluid dynamics (CFD) models. Integrating these models into a real-time VR simulation presents significant technical challenges.

User interaction and input precision pose additional hurdles. Ensuring that users can manipulate virtual solenoid valves with the same level of control and accuracy as their real-world counterparts requires sophisticated hand tracking and gesture recognition technologies. The limitations of current VR input devices can impact the realism and effectiveness of the simulation.

Lastly, creating a comprehensive training environment that accurately simulates various operational scenarios, fault conditions, and maintenance procedures for solenoid valves in VR requires extensive domain knowledge and complex scenario modeling. Developing adaptive training algorithms that can assess user performance and provide appropriate feedback in real-time adds further technical complexity to the simulation.

Another major challenge is achieving real-time performance while maintaining high fidelity in the simulation. VR applications demand low latency and high frame rates to provide a seamless user experience. Balancing the computational demands of accurate solenoid simulation with the need for responsive VR interactions poses a significant technical hurdle.

Haptic feedback represents a crucial aspect of realistic solenoid valve simulation in VR. Replicating the tactile sensations associated with valve operation, such as the resistance felt when actuating the valve or the vibrations during operation, requires advanced haptic technologies. Current haptic devices often struggle to provide the nuanced force feedback necessary for authentic solenoid valve interaction.

Visual fidelity is another area of technical difficulty. Rendering detailed 3D models of solenoid valves with accurate material properties, reflections, and shadows in a VR environment can be computationally intensive. Achieving photorealistic visuals while maintaining performance is a delicate balancing act.

Simulating fluid dynamics within and around the solenoid valve adds another layer of complexity. Accurately representing the flow of liquids or gases through the valve, including pressure changes and turbulence, requires advanced computational fluid dynamics (CFD) models. Integrating these models into a real-time VR simulation presents significant technical challenges.

User interaction and input precision pose additional hurdles. Ensuring that users can manipulate virtual solenoid valves with the same level of control and accuracy as their real-world counterparts requires sophisticated hand tracking and gesture recognition technologies. The limitations of current VR input devices can impact the realism and effectiveness of the simulation.

Lastly, creating a comprehensive training environment that accurately simulates various operational scenarios, fault conditions, and maintenance procedures for solenoid valves in VR requires extensive domain knowledge and complex scenario modeling. Developing adaptive training algorithms that can assess user performance and provide appropriate feedback in real-time adds further technical complexity to the simulation.

Current VR Solenoid Simulation Techniques

01 Immersive VR environment creation

This involves developing techniques for creating highly realistic and immersive virtual reality environments. These methods focus on generating detailed 3D models, realistic textures, and accurate lighting to simulate real-world or imaginary settings. The goal is to provide users with a sense of presence and believability within the virtual space.- Immersive VR environment creation: This involves developing techniques for creating highly realistic and immersive virtual reality environments. These methods focus on generating detailed 3D models, realistic textures, and accurate lighting to simulate real-world or imaginary settings. The goal is to provide users with a sense of presence and believability within the virtual space.

- Interactive elements in VR simulations: This aspect deals with incorporating interactive elements into virtual reality simulations. It includes developing responsive objects, physics-based interactions, and user input mechanisms. These features allow users to manipulate and engage with the virtual environment, enhancing the overall experience and making it more dynamic and engaging.

- Multi-user VR experiences: This focuses on creating shared virtual reality experiences where multiple users can interact within the same simulated environment. It involves developing networking protocols, avatar systems, and synchronization techniques to ensure a seamless and collaborative experience for all participants, regardless of their physical locations.

- Haptic feedback in VR simulations: This area involves integrating haptic feedback technologies into virtual reality simulations to provide users with tactile sensations. It includes developing hardware and software solutions that can simulate touch, pressure, and texture, enhancing the realism and immersion of the virtual experience.

- AI-driven VR environment generation: This involves using artificial intelligence and machine learning techniques to automatically generate and adapt virtual reality environments. These methods can create diverse and dynamic virtual worlds, potentially infinite in scope, that can change based on user interactions or predefined parameters, reducing the manual effort required in environment creation.

02 Interactive elements in VR simulations

This aspect deals with incorporating interactive elements into virtual reality simulations. It includes developing responsive objects, AI-driven characters, and user-manipulable items within the virtual environment. The focus is on creating engaging and dynamic experiences that allow users to interact meaningfully with the virtual world.Expand Specific Solutions03 Multi-sensory feedback in VR

This involves integrating various sensory feedback mechanisms into virtual reality simulations. It includes haptic feedback, spatial audio, and even olfactory cues to enhance the immersive experience. The aim is to engage multiple senses, making the virtual environment feel more realistic and tangible to the user.Expand Specific Solutions04 Real-time rendering and performance optimization

This focuses on techniques for real-time rendering of complex virtual environments and optimizing performance. It includes methods for efficient graphics processing, load balancing, and data streaming to ensure smooth and responsive VR experiences, even with limited computational resources.Expand Specific Solutions05 Collaborative and shared VR experiences

This aspect deals with creating virtual reality environments that support multiple users simultaneously. It involves developing networking protocols, synchronization methods, and avatar systems to enable collaborative interactions within the virtual space. The goal is to facilitate shared experiences and social interactions in VR simulations.Expand Specific Solutions

Key Players in VR Industrial Training

The virtual reality (VR) simulation of solenoid valve operation for training is an emerging technology in an early growth stage. The market size is expanding as industries recognize the potential of VR for enhancing technical training. While the technology is still evolving, it shows promise in improving learning outcomes and reducing training costs. Companies like State Grid Corp. of China, Immersion Corp., and Street Smarts VR are at the forefront of developing VR training solutions, with varying levels of technological maturity. As the field advances, we can expect increased competition and innovation from both established players and startups entering this space.

Immersion Corp.

Technical Solution: Immersion Corporation has developed a sophisticated haptic feedback system specifically designed for simulating solenoid valve operations in virtual reality environments. Their technology, known as TouchSense Force, provides precise force feedback that mimics the physical sensations experienced when operating real solenoid valves[4]. The system integrates with VR headsets and controllers to create a multi-sensory training experience. Immersion's solution includes a library of pre-programmed haptic effects that accurately represent different valve states, such as opening, closing, and various fault conditions[5]. The company has also developed custom APIs that allow for easy integration of their haptic technology into existing VR training platforms, enabling rapid deployment across various industries[6].

Strengths: Industry-leading haptic feedback technology, extensive library of pre-programmed effects, and easy integration with existing VR systems. Weaknesses: Primarily focused on haptic technology, may require partnerships for complete VR training solutions.

Verb Surgical, Inc.

Technical Solution: Verb Surgical has developed a virtual reality simulation platform specifically designed for training medical professionals in the operation of solenoid valves used in surgical robots and medical devices. Their system combines high-fidelity 3D models of medical-grade solenoid valves with accurate representations of surgical environments[13]. The VR simulation incorporates realistic haptic feedback that mimics the tactile sensations experienced during actual surgical procedures involving solenoid valve manipulation. Verb Surgical's platform includes a range of scenarios that cover both routine operations and rare failure modes, ensuring comprehensive training for medical staff[14]. The system also features real-time performance metrics and error detection algorithms to provide immediate feedback to trainees, helping to improve their skills and decision-making abilities in critical situations[15].

Strengths: Specialized focus on medical applications, integration of surgical environments, and real-time performance feedback. Weaknesses: Narrow focus on medical field may limit applicability in other industries.

Innovations in Haptic Feedback for VR

Enhancement of virtual reality effect using fragrance

PatentInactiveEP0665039A1

Innovation

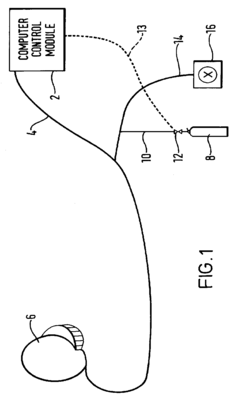

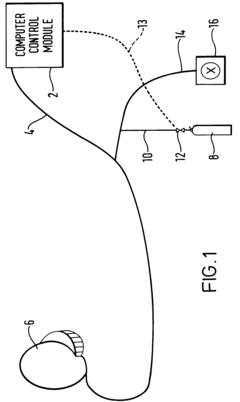

- A simulation apparatus that integrates a means to deliver controlled aromas, known as aromagas, to a headset by using a gas cylinder, solenoid valve, and air line system, where the computer control module signals the solenoid valve to release preselected fragrances at specific intervals and durations, ensuring safety through timed boluses and purging with compressed air.

Virtual environment navigation device and system

PatentInactiveUS20060139317A1

Innovation

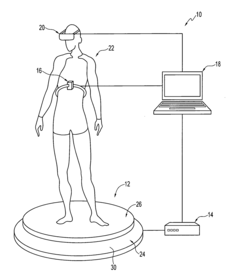

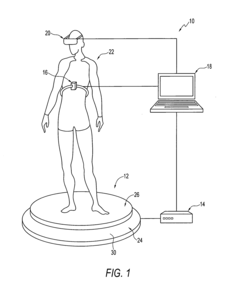

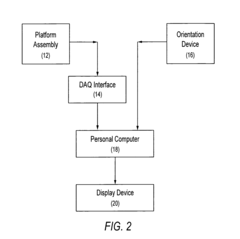

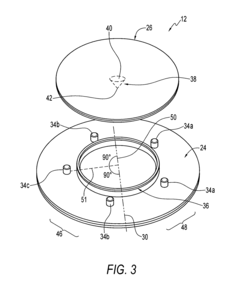

- A Virtual Environment Navigation Pad (VENP) system with an impact platform and odd-numbered sensors evenly spaced around its circumference, coupled with an orientation device and software subsystem, allows users to navigate through physical assertions by detecting impacts and predicting navigation intentions, enabling real-time movement and orientation control in virtual environments.

Safety Considerations in VR Industrial Training

Virtual Reality (VR) training for industrial applications, particularly in simulating solenoid valve operations, presents unique safety considerations that must be addressed to ensure a secure and effective learning environment. The immersive nature of VR technology, while beneficial for skill acquisition, introduces potential physical and psychological risks that require careful management.

One primary safety concern is the risk of physical injury due to disorientation or loss of spatial awareness. Users immersed in VR environments may inadvertently collide with real-world objects or lose balance, potentially resulting in falls or other accidents. To mitigate this risk, training areas should be cleared of obstacles, and users should be supervised during VR sessions. Additionally, implementing virtual boundaries or chaperone systems within the VR software can alert users when they approach physical limits of the safe training space.

Motion sickness and cybersickness are common issues in VR experiences, particularly for novice users or during extended training sessions. These conditions can manifest as nausea, dizziness, or headaches, potentially compromising the user's well-being and learning effectiveness. To address this, VR training programs should incorporate gradual acclimation periods, allow for frequent breaks, and optimize visual and motion cues to reduce sensory conflicts.

Ergonomic considerations are crucial in VR industrial training. Prolonged use of VR headsets and controllers can lead to eye strain, neck fatigue, and repetitive stress injuries. Proper adjustment of VR equipment, ergonomic design of virtual interfaces, and guidelines for optimal posture and movement should be integrated into the training protocol to minimize these risks.

Psychological safety is another critical aspect of VR industrial training. Realistic simulations of hazardous scenarios, such as valve failures or industrial accidents, may induce stress or anxiety in some users. While this realism is valuable for training purposes, it's essential to provide proper psychological preparation and debriefing sessions. Implementing gradual exposure techniques and offering opt-out options for particularly sensitive scenarios can help maintain a psychologically safe learning environment.

Data privacy and security concerns also arise in VR training systems. As these platforms often collect user performance data and potentially sensitive industrial information, robust data protection measures must be implemented. This includes secure data storage, encryption of transmitted information, and clear policies on data usage and retention.

Lastly, the integration of emergency protocols within the VR training environment is crucial. Users should be trained on how to quickly exit the VR simulation in case of real-world emergencies, and systems should be in place to alert users of actual hazards in their physical surroundings. Regular safety drills and clear communication channels between trainers and trainees are essential components of a comprehensive safety strategy in VR industrial training.

One primary safety concern is the risk of physical injury due to disorientation or loss of spatial awareness. Users immersed in VR environments may inadvertently collide with real-world objects or lose balance, potentially resulting in falls or other accidents. To mitigate this risk, training areas should be cleared of obstacles, and users should be supervised during VR sessions. Additionally, implementing virtual boundaries or chaperone systems within the VR software can alert users when they approach physical limits of the safe training space.

Motion sickness and cybersickness are common issues in VR experiences, particularly for novice users or during extended training sessions. These conditions can manifest as nausea, dizziness, or headaches, potentially compromising the user's well-being and learning effectiveness. To address this, VR training programs should incorporate gradual acclimation periods, allow for frequent breaks, and optimize visual and motion cues to reduce sensory conflicts.

Ergonomic considerations are crucial in VR industrial training. Prolonged use of VR headsets and controllers can lead to eye strain, neck fatigue, and repetitive stress injuries. Proper adjustment of VR equipment, ergonomic design of virtual interfaces, and guidelines for optimal posture and movement should be integrated into the training protocol to minimize these risks.

Psychological safety is another critical aspect of VR industrial training. Realistic simulations of hazardous scenarios, such as valve failures or industrial accidents, may induce stress or anxiety in some users. While this realism is valuable for training purposes, it's essential to provide proper psychological preparation and debriefing sessions. Implementing gradual exposure techniques and offering opt-out options for particularly sensitive scenarios can help maintain a psychologically safe learning environment.

Data privacy and security concerns also arise in VR training systems. As these platforms often collect user performance data and potentially sensitive industrial information, robust data protection measures must be implemented. This includes secure data storage, encryption of transmitted information, and clear policies on data usage and retention.

Lastly, the integration of emergency protocols within the VR training environment is crucial. Users should be trained on how to quickly exit the VR simulation in case of real-world emergencies, and systems should be in place to alert users of actual hazards in their physical surroundings. Regular safety drills and clear communication channels between trainers and trainees are essential components of a comprehensive safety strategy in VR industrial training.

Cost-Benefit Analysis of VR Training Systems

The implementation of Virtual Reality (VR) training systems for solenoid valve operation presents a significant opportunity for cost savings and improved training outcomes. When conducting a cost-benefit analysis, it is crucial to consider both the initial investment and long-term financial implications.

The primary costs associated with VR training systems include hardware acquisition, software development, and ongoing maintenance. High-quality VR headsets, haptic feedback devices, and powerful computing systems are essential components, representing a substantial upfront investment. Custom software development for accurate solenoid valve simulation can also be costly, requiring specialized expertise in both VR technology and industrial processes.

However, these initial expenses are often offset by significant long-term benefits. Traditional training methods for solenoid valve operation typically involve physical equipment, which can be expensive to purchase, maintain, and replace. VR systems eliminate the need for multiple physical valve setups, reducing equipment costs and minimizing the risk of damage during training sessions.

Furthermore, VR training systems offer unparalleled flexibility and scalability. Once developed, the software can be easily distributed to multiple training locations, allowing for simultaneous training of numerous employees without additional hardware costs. This scalability is particularly valuable for large organizations with geographically dispersed workforces.

The efficiency gains provided by VR training are also noteworthy. Trainees can practice valve operations in a safe, controlled environment, reducing the time required for on-site training and minimizing production downtime. The ability to simulate various scenarios and failure modes enhances the breadth of training experiences, potentially reducing the likelihood of costly mistakes in real-world operations.

Additionally, VR training systems can lead to improved retention of knowledge and skills. The immersive nature of VR experiences has been shown to enhance learning outcomes, potentially reducing the need for frequent retraining and associated costs.

When evaluating the return on investment, it is essential to consider the potential reduction in workplace accidents and equipment damage. By providing a risk-free environment for practice, VR training can significantly reduce the incidence of errors in real-world valve operations, leading to substantial cost savings in terms of reduced downtime, repairs, and potential legal liabilities.

In conclusion, while the initial investment in VR training systems for solenoid valve operation may be substantial, the long-term benefits in terms of cost savings, improved training outcomes, and enhanced safety make a compelling case for their implementation. Organizations should carefully assess their specific training needs and operational scale to determine the optimal balance between costs and benefits in their unique context.

The primary costs associated with VR training systems include hardware acquisition, software development, and ongoing maintenance. High-quality VR headsets, haptic feedback devices, and powerful computing systems are essential components, representing a substantial upfront investment. Custom software development for accurate solenoid valve simulation can also be costly, requiring specialized expertise in both VR technology and industrial processes.

However, these initial expenses are often offset by significant long-term benefits. Traditional training methods for solenoid valve operation typically involve physical equipment, which can be expensive to purchase, maintain, and replace. VR systems eliminate the need for multiple physical valve setups, reducing equipment costs and minimizing the risk of damage during training sessions.

Furthermore, VR training systems offer unparalleled flexibility and scalability. Once developed, the software can be easily distributed to multiple training locations, allowing for simultaneous training of numerous employees without additional hardware costs. This scalability is particularly valuable for large organizations with geographically dispersed workforces.

The efficiency gains provided by VR training are also noteworthy. Trainees can practice valve operations in a safe, controlled environment, reducing the time required for on-site training and minimizing production downtime. The ability to simulate various scenarios and failure modes enhances the breadth of training experiences, potentially reducing the likelihood of costly mistakes in real-world operations.

Additionally, VR training systems can lead to improved retention of knowledge and skills. The immersive nature of VR experiences has been shown to enhance learning outcomes, potentially reducing the need for frequent retraining and associated costs.

When evaluating the return on investment, it is essential to consider the potential reduction in workplace accidents and equipment damage. By providing a risk-free environment for practice, VR training can significantly reduce the incidence of errors in real-world valve operations, leading to substantial cost savings in terms of reduced downtime, repairs, and potential legal liabilities.

In conclusion, while the initial investment in VR training systems for solenoid valve operation may be substantial, the long-term benefits in terms of cost savings, improved training outcomes, and enhanced safety make a compelling case for their implementation. Organizations should carefully assess their specific training needs and operational scale to determine the optimal balance between costs and benefits in their unique context.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!