Role of Solenoid Valves in Enhancing Air Quality Control Systems

JUL 23, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Solenoid Valve Tech Evolution and Objectives

Solenoid valves have played a crucial role in the evolution of air quality control systems, with their development closely tied to the growing need for precise and efficient fluid control mechanisms. The journey of solenoid valve technology in this domain began in the mid-20th century, as industrial processes and environmental concerns necessitated more sophisticated air quality management solutions.

Initially, solenoid valves were primarily used in basic on-off control applications within air handling units and ventilation systems. As environmental regulations became more stringent in the 1970s and 1980s, the demand for more advanced air quality control systems grew, driving innovations in solenoid valve design and functionality.

The 1990s saw a significant leap in solenoid valve technology with the introduction of proportional control capabilities. This advancement allowed for more nuanced regulation of airflow and pressure, enabling air quality control systems to respond more dynamically to changing environmental conditions. Concurrently, the miniaturization of solenoid valves opened up new possibilities for their integration into compact and distributed air quality monitoring and control systems.

The turn of the millennium brought about a focus on energy efficiency and sustainability. Solenoid valve manufacturers responded by developing low-power consumption models and exploring materials that could withstand corrosive environments often encountered in air purification processes. These improvements made solenoid valves more reliable and cost-effective for long-term operation in air quality control applications.

In recent years, the integration of smart technologies has further enhanced the role of solenoid valves in air quality management. IoT-enabled valves with built-in sensors and communication capabilities now allow for real-time monitoring and adjustment of air quality parameters. This has paved the way for predictive maintenance strategies and more sophisticated control algorithms that can optimize air quality while minimizing energy consumption.

Looking ahead, the objectives for solenoid valve technology in air quality control systems are multifaceted. There is a push towards even greater precision and responsiveness, with research focusing on faster actuation times and finer control granularity. Additionally, there is a growing emphasis on developing valves that can handle a wider range of air contaminants and operate effectively in diverse environmental conditions.

Another key objective is the further integration of solenoid valves with artificial intelligence and machine learning systems. This aims to create adaptive air quality control systems that can learn from historical data and anticipate air quality issues before they occur. Sustainability remains a central goal, with ongoing efforts to reduce the environmental footprint of solenoid valves through the use of eco-friendly materials and manufacturing processes.

Initially, solenoid valves were primarily used in basic on-off control applications within air handling units and ventilation systems. As environmental regulations became more stringent in the 1970s and 1980s, the demand for more advanced air quality control systems grew, driving innovations in solenoid valve design and functionality.

The 1990s saw a significant leap in solenoid valve technology with the introduction of proportional control capabilities. This advancement allowed for more nuanced regulation of airflow and pressure, enabling air quality control systems to respond more dynamically to changing environmental conditions. Concurrently, the miniaturization of solenoid valves opened up new possibilities for their integration into compact and distributed air quality monitoring and control systems.

The turn of the millennium brought about a focus on energy efficiency and sustainability. Solenoid valve manufacturers responded by developing low-power consumption models and exploring materials that could withstand corrosive environments often encountered in air purification processes. These improvements made solenoid valves more reliable and cost-effective for long-term operation in air quality control applications.

In recent years, the integration of smart technologies has further enhanced the role of solenoid valves in air quality management. IoT-enabled valves with built-in sensors and communication capabilities now allow for real-time monitoring and adjustment of air quality parameters. This has paved the way for predictive maintenance strategies and more sophisticated control algorithms that can optimize air quality while minimizing energy consumption.

Looking ahead, the objectives for solenoid valve technology in air quality control systems are multifaceted. There is a push towards even greater precision and responsiveness, with research focusing on faster actuation times and finer control granularity. Additionally, there is a growing emphasis on developing valves that can handle a wider range of air contaminants and operate effectively in diverse environmental conditions.

Another key objective is the further integration of solenoid valves with artificial intelligence and machine learning systems. This aims to create adaptive air quality control systems that can learn from historical data and anticipate air quality issues before they occur. Sustainability remains a central goal, with ongoing efforts to reduce the environmental footprint of solenoid valves through the use of eco-friendly materials and manufacturing processes.

Air Quality Control Market Analysis

The air quality control market has experienced significant growth in recent years, driven by increasing awareness of the health impacts of air pollution and stringent environmental regulations. The global market for air quality control systems is projected to reach substantial value in the coming years, with a compound annual growth rate (CAGR) exceeding industry averages. This growth is attributed to various factors, including urbanization, industrialization, and the rising demand for clean air in both residential and commercial sectors.

The market demand for air quality control systems is particularly strong in regions with high levels of air pollution, such as Asia-Pacific, where rapid industrialization and urban development have led to deteriorating air quality. North America and Europe also represent significant market shares, driven by strict environmental regulations and growing public concern over indoor air quality. The COVID-19 pandemic has further accelerated market growth, as it has heightened awareness of the importance of clean air in preventing the spread of airborne diseases.

Within the air quality control market, solenoid valves play a crucial role in enhancing system performance and efficiency. These components are essential in controlling the flow of air and other gases in various air quality control applications, including HVAC systems, air purifiers, and industrial air filtration systems. The demand for solenoid valves in this sector is expected to grow in tandem with the overall market, as manufacturers seek to improve the precision and responsiveness of their air quality control systems.

Key market segments for air quality control systems include industrial, commercial, and residential applications. The industrial segment, comprising manufacturing facilities, power plants, and chemical processing plants, represents a significant portion of the market. Commercial applications, such as office buildings, healthcare facilities, and educational institutions, are also driving market growth as organizations prioritize employee and occupant health. The residential segment is experiencing rapid growth, fueled by increasing consumer awareness of indoor air quality and the availability of affordable air purification solutions.

Technological advancements are shaping the air quality control market, with a focus on smart, connected systems that offer real-time monitoring and control. Integration of Internet of Things (IoT) technology and artificial intelligence is enabling more efficient and responsive air quality management. These innovations are creating new opportunities for solenoid valve manufacturers to develop advanced, precision-controlled components that can interface with smart systems and contribute to overall system optimization.

The market demand for air quality control systems is particularly strong in regions with high levels of air pollution, such as Asia-Pacific, where rapid industrialization and urban development have led to deteriorating air quality. North America and Europe also represent significant market shares, driven by strict environmental regulations and growing public concern over indoor air quality. The COVID-19 pandemic has further accelerated market growth, as it has heightened awareness of the importance of clean air in preventing the spread of airborne diseases.

Within the air quality control market, solenoid valves play a crucial role in enhancing system performance and efficiency. These components are essential in controlling the flow of air and other gases in various air quality control applications, including HVAC systems, air purifiers, and industrial air filtration systems. The demand for solenoid valves in this sector is expected to grow in tandem with the overall market, as manufacturers seek to improve the precision and responsiveness of their air quality control systems.

Key market segments for air quality control systems include industrial, commercial, and residential applications. The industrial segment, comprising manufacturing facilities, power plants, and chemical processing plants, represents a significant portion of the market. Commercial applications, such as office buildings, healthcare facilities, and educational institutions, are also driving market growth as organizations prioritize employee and occupant health. The residential segment is experiencing rapid growth, fueled by increasing consumer awareness of indoor air quality and the availability of affordable air purification solutions.

Technological advancements are shaping the air quality control market, with a focus on smart, connected systems that offer real-time monitoring and control. Integration of Internet of Things (IoT) technology and artificial intelligence is enabling more efficient and responsive air quality management. These innovations are creating new opportunities for solenoid valve manufacturers to develop advanced, precision-controlled components that can interface with smart systems and contribute to overall system optimization.

Solenoid Valve Challenges in AQC Systems

Solenoid valves play a crucial role in air quality control (AQC) systems, but they face several challenges that can impact their performance and reliability. One of the primary issues is the harsh operating environment often encountered in AQC applications. These valves are frequently exposed to corrosive gases, particulate matter, and extreme temperatures, which can lead to premature wear and degradation of valve components.

The precision and speed of solenoid valve operation are critical in AQC systems, particularly for rapid response to changing air quality conditions. However, achieving consistent high-speed actuation while maintaining accuracy can be challenging, especially in systems that require frequent cycling. This demand for quick response times and precise control can lead to increased wear on valve components and potential reliability issues over time.

Another significant challenge is the need for energy efficiency in AQC systems. Solenoid valves consume power during operation, and in large-scale industrial applications, this energy consumption can be substantial. Balancing the need for rapid response and precise control with energy efficiency requirements presents a complex engineering challenge for valve designers and system integrators.

Contamination and clogging are persistent issues in AQC applications. Particulate matter and other pollutants can accumulate in valve mechanisms, affecting their operation and potentially leading to system failures. This necessitates regular maintenance and cleaning, which can be time-consuming and costly, especially in large-scale industrial settings.

The diversity of AQC applications also presents challenges for solenoid valve design. Different industries and environments may require valves with varying specifications, materials, and performance characteristics. This diversity makes it difficult to develop standardized solutions and often requires custom-engineered valves for specific applications, increasing costs and complexity.

Regulatory compliance and safety standards pose additional challenges. As environmental regulations become more stringent, AQC systems and their components, including solenoid valves, must meet increasingly demanding performance and reliability criteria. This often necessitates ongoing research and development to improve valve designs and materials.

Lastly, the integration of solenoid valves with modern control systems and IoT technologies presents both opportunities and challenges. While these advancements can enhance system monitoring and control, they also introduce complexities in terms of compatibility, data security, and the need for specialized expertise in system design and maintenance.

The precision and speed of solenoid valve operation are critical in AQC systems, particularly for rapid response to changing air quality conditions. However, achieving consistent high-speed actuation while maintaining accuracy can be challenging, especially in systems that require frequent cycling. This demand for quick response times and precise control can lead to increased wear on valve components and potential reliability issues over time.

Another significant challenge is the need for energy efficiency in AQC systems. Solenoid valves consume power during operation, and in large-scale industrial applications, this energy consumption can be substantial. Balancing the need for rapid response and precise control with energy efficiency requirements presents a complex engineering challenge for valve designers and system integrators.

Contamination and clogging are persistent issues in AQC applications. Particulate matter and other pollutants can accumulate in valve mechanisms, affecting their operation and potentially leading to system failures. This necessitates regular maintenance and cleaning, which can be time-consuming and costly, especially in large-scale industrial settings.

The diversity of AQC applications also presents challenges for solenoid valve design. Different industries and environments may require valves with varying specifications, materials, and performance characteristics. This diversity makes it difficult to develop standardized solutions and often requires custom-engineered valves for specific applications, increasing costs and complexity.

Regulatory compliance and safety standards pose additional challenges. As environmental regulations become more stringent, AQC systems and their components, including solenoid valves, must meet increasingly demanding performance and reliability criteria. This often necessitates ongoing research and development to improve valve designs and materials.

Lastly, the integration of solenoid valves with modern control systems and IoT technologies presents both opportunities and challenges. While these advancements can enhance system monitoring and control, they also introduce complexities in terms of compatibility, data security, and the need for specialized expertise in system design and maintenance.

Current Solenoid Solutions for AQC

01 Solenoid valve design for air quality control systems

Specialized solenoid valve designs are implemented in air quality control systems to regulate airflow and manage contaminants. These valves are engineered for precise control, durability, and efficiency in various environmental conditions. The designs may incorporate features for rapid response, low power consumption, and compatibility with different air handling units.- Solenoid valve design for air quality control systems: Specialized solenoid valve designs are implemented in air quality control systems to regulate airflow and manage contaminants. These valves are engineered to provide precise control over air pressure and flow rates, enabling efficient filtration and purification processes. The designs often incorporate features for rapid response times and durability to withstand frequent cycling in air quality management applications.

- Integration of solenoid valves in HVAC systems for air quality improvement: Solenoid valves are integrated into heating, ventilation, and air conditioning (HVAC) systems to enhance air quality control. These valves facilitate the regulation of fresh air intake, exhaust, and recirculation, allowing for optimal balance of indoor air quality and energy efficiency. Advanced control algorithms may be employed to adjust valve operations based on real-time air quality measurements and occupancy patterns.

- Solenoid valve-controlled air purification systems: Air purification systems utilize solenoid valves to direct airflow through various filtration and treatment stages. These valves enable the system to switch between different purification modes, such as particulate filtration, gas adsorption, or UV sterilization. The precise control offered by solenoid valves ensures that air is effectively treated while optimizing energy consumption and filter life.

- Solenoid valve applications in industrial emission control: In industrial settings, solenoid valves play a crucial role in emission control systems. These valves are used to regulate the flow of exhaust gases through scrubbers, catalytic converters, and other air pollution control devices. The rapid and accurate operation of solenoid valves ensures that emissions are properly treated before being released into the atmosphere, helping industries comply with air quality regulations.

- Maintenance and monitoring of solenoid valves for consistent air quality control: Effective maintenance and monitoring strategies are essential for ensuring the reliable operation of solenoid valves in air quality control systems. This includes regular inspection, cleaning, and replacement of valve components to prevent leaks or malfunctions. Advanced monitoring systems may incorporate sensors to detect valve performance issues and predict maintenance needs, ensuring consistent air quality control and system efficiency.

02 Integration of solenoid valves in HVAC systems

Solenoid valves are integrated into heating, ventilation, and air conditioning (HVAC) systems to enhance air quality control. These valves play a crucial role in managing airflow, temperature, and humidity levels. The integration allows for automated control of air circulation, filtration, and purification processes, contributing to improved indoor air quality.Expand Specific Solutions03 Solenoid valve control mechanisms for air purification

Advanced control mechanisms are developed for solenoid valves used in air purification systems. These mechanisms may include electronic controllers, sensors, and feedback systems to optimize valve operation. The control systems enable precise adjustment of airflow rates, pressure levels, and cycling frequencies to enhance air purification efficiency.Expand Specific Solutions04 Solenoid valve applications in industrial air quality management

Solenoid valves are utilized in industrial settings for managing air quality in manufacturing processes, clean rooms, and exhaust systems. These valves are designed to handle high-volume airflow, corrosive environments, and particulate matter. They play a critical role in maintaining air purity standards and controlling emissions in industrial facilities.Expand Specific Solutions05 Innovative materials and coatings for solenoid valves in air quality applications

New materials and coatings are developed for solenoid valves to enhance their performance and longevity in air quality control systems. These innovations may include corrosion-resistant alloys, low-friction coatings, and self-cleaning surfaces. The use of advanced materials improves valve reliability, reduces maintenance requirements, and extends operational life in challenging air quality management environments.Expand Specific Solutions

Key Solenoid Valve Manufacturers

The role of solenoid valves in enhancing air quality control systems is gaining prominence in a rapidly evolving market. The industry is in a growth phase, with increasing demand driven by stringent air quality regulations and growing awareness of indoor air quality. The global market size for solenoid valves in air quality control applications is expanding, with key players like Robert Bosch GmbH, Eaton Corp., and Mitsubishi Electric Corp. leading technological advancements. These companies are investing heavily in R&D to improve valve efficiency, durability, and smart control capabilities. The technology is maturing, with innovations focusing on miniaturization, energy efficiency, and integration with IoT systems for real-time monitoring and control of air quality parameters.

Robert Bosch GmbH

Technical Solution: Bosch has developed advanced solenoid valve technology for air quality control systems, focusing on precision and efficiency. Their latest solenoid valves feature fast response times of less than 5 milliseconds and high flow rates up to 1000 l/min [1]. The company utilizes innovative materials and designs to reduce power consumption by up to 30% compared to conventional valves [3]. Bosch's solenoid valves incorporate smart diagnostics and predictive maintenance capabilities, enabling real-time monitoring and optimization of air quality control systems [5]. The valves are designed with a modular architecture, allowing for easy integration into various HVAC and industrial air purification systems.

Strengths: High precision, energy efficiency, and smart capabilities. Weaknesses: Potentially higher initial cost due to advanced features.

Eaton Corp.

Technical Solution: Eaton's approach to solenoid valves in air quality control systems focuses on durability and versatility. Their valves feature a robust design capable of withstanding harsh environments, with operating temperatures ranging from -40°C to 120°C [2]. Eaton has developed a proprietary sealing technology that reduces leakage by up to 50% compared to industry standards [4]. The company's solenoid valves incorporate a unique flow path design that minimizes pressure drop, resulting in improved system efficiency. Eaton's valves also feature an integrated filtration system, which extends the life of the valve and improves overall air quality control performance [6].

Strengths: Durability in harsh conditions, improved sealing technology. Weaknesses: May have limitations in ultra-precise applications.

Innovative Solenoid Valve Designs

Systems for reducing exhalation pressure in a mask system

PatentInactiveEP2063944A1

Innovation

- A mechanical or electromechanical system that reduces exhalation pressure and adjusts the pressure-time waveform to enhance breathing comfort, compatible with existing mask systems and flow generators, using mechanisms like demand valves, pressure relief valves, and flow diversion to manage pressure and flow during inhalation and exhalation.

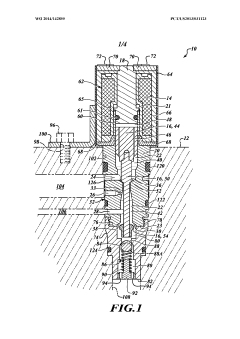

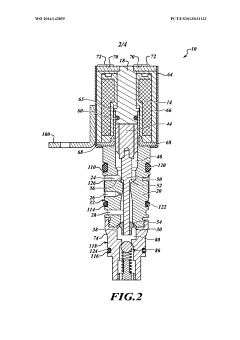

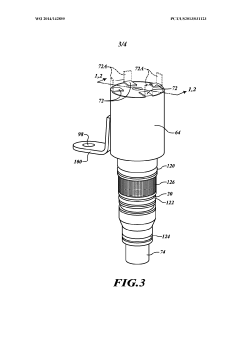

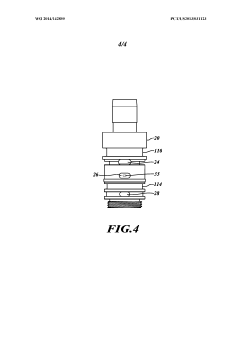

Solenoid valve assembly with pilot pressure control

PatentWO2014142855A1

Innovation

- A solenoid valve assembly with a selectively energizable coil, armature assembly, and regulator body that maintains a continuous pilot pressure in the control passage, preventing air entry and allowing fluid flow at predetermined pressures to optimize actuation speed and precision.

Environmental Regulations Impact

Environmental regulations play a crucial role in shaping the development and implementation of air quality control systems, including those utilizing solenoid valves. These regulations, established by governmental bodies and international organizations, set standards for air quality and emissions, driving the need for more efficient and effective control mechanisms.

In recent years, there has been a global trend towards stricter environmental regulations, particularly concerning air pollution. This has led to increased pressure on industries to adopt advanced air quality control systems. Solenoid valves, with their precise control capabilities, have become integral components in meeting these stringent requirements.

The impact of environmental regulations on solenoid valve technology in air quality control systems is multifaceted. Firstly, these regulations have spurred innovation in valve design, leading to the development of more efficient and responsive solenoid valves. Manufacturers are now focusing on creating valves with faster response times, improved sealing capabilities, and enhanced durability to meet the demands of continuous operation in air quality control applications.

Furthermore, environmental regulations have influenced the materials used in solenoid valve construction. With an emphasis on reducing harmful emissions, there is a growing demand for valves made from environmentally friendly materials that do not contribute to air pollution. This has led to the development of new alloys and coatings that are both durable and environmentally compatible.

The regulations have also driven the integration of smart technologies into solenoid valves. Advanced sensors and control systems are now being incorporated to enable real-time monitoring and adjustment of air quality parameters. This allows for more precise control and rapid response to changes in air quality, ensuring compliance with regulatory standards.

Another significant impact is the increased focus on energy efficiency. Environmental regulations often include provisions for reducing energy consumption, which has led to the development of low-power solenoid valves. These valves consume less energy while maintaining high performance, contributing to overall system efficiency and reduced environmental impact.

The global nature of environmental regulations has also influenced the standardization of solenoid valve specifications across different regions. This has facilitated the development of universal valve designs that can be used in air quality control systems worldwide, streamlining manufacturing processes and reducing costs for both manufacturers and end-users.

In conclusion, environmental regulations have been a driving force in the evolution of solenoid valve technology for air quality control systems. They have spurred innovation, improved efficiency, and promoted the adoption of environmentally friendly practices in valve design and manufacturing. As regulations continue to evolve, solenoid valve technology is expected to advance further, playing an increasingly important role in enhancing air quality control systems globally.

In recent years, there has been a global trend towards stricter environmental regulations, particularly concerning air pollution. This has led to increased pressure on industries to adopt advanced air quality control systems. Solenoid valves, with their precise control capabilities, have become integral components in meeting these stringent requirements.

The impact of environmental regulations on solenoid valve technology in air quality control systems is multifaceted. Firstly, these regulations have spurred innovation in valve design, leading to the development of more efficient and responsive solenoid valves. Manufacturers are now focusing on creating valves with faster response times, improved sealing capabilities, and enhanced durability to meet the demands of continuous operation in air quality control applications.

Furthermore, environmental regulations have influenced the materials used in solenoid valve construction. With an emphasis on reducing harmful emissions, there is a growing demand for valves made from environmentally friendly materials that do not contribute to air pollution. This has led to the development of new alloys and coatings that are both durable and environmentally compatible.

The regulations have also driven the integration of smart technologies into solenoid valves. Advanced sensors and control systems are now being incorporated to enable real-time monitoring and adjustment of air quality parameters. This allows for more precise control and rapid response to changes in air quality, ensuring compliance with regulatory standards.

Another significant impact is the increased focus on energy efficiency. Environmental regulations often include provisions for reducing energy consumption, which has led to the development of low-power solenoid valves. These valves consume less energy while maintaining high performance, contributing to overall system efficiency and reduced environmental impact.

The global nature of environmental regulations has also influenced the standardization of solenoid valve specifications across different regions. This has facilitated the development of universal valve designs that can be used in air quality control systems worldwide, streamlining manufacturing processes and reducing costs for both manufacturers and end-users.

In conclusion, environmental regulations have been a driving force in the evolution of solenoid valve technology for air quality control systems. They have spurred innovation, improved efficiency, and promoted the adoption of environmentally friendly practices in valve design and manufacturing. As regulations continue to evolve, solenoid valve technology is expected to advance further, playing an increasingly important role in enhancing air quality control systems globally.

Energy Efficiency Considerations

Energy efficiency is a critical consideration in the implementation of solenoid valves within air quality control systems. These valves play a pivotal role in regulating airflow and controlling the distribution of clean air, but their operation can significantly impact overall system energy consumption. Modern solenoid valve designs incorporate features that minimize power usage while maintaining optimal performance.

One key aspect of energy efficiency in solenoid valves is the reduction of holding current. Advanced valve designs utilize latching mechanisms or permanent magnets to maintain the valve's position once actuated, requiring minimal or no power to hold the state. This approach dramatically reduces the continuous energy demand compared to traditional solenoid valves that require constant power to remain open or closed.

The materials used in solenoid valve construction also contribute to energy efficiency. High-performance magnetic materials and optimized coil designs allow for more efficient electromagnetic conversion, reducing the power required for valve actuation. Additionally, low-friction seals and precision-engineered components minimize energy losses due to mechanical resistance.

Intelligent control systems further enhance the energy efficiency of solenoid valves in air quality control applications. By implementing adaptive algorithms and real-time monitoring, these systems can optimize valve operation based on current air quality conditions and system demands. This dynamic approach ensures that valves are only actuated when necessary, minimizing unnecessary energy expenditure.

Integration of solenoid valves with variable frequency drives (VFDs) in air handling units can lead to substantial energy savings. By precisely controlling airflow rates, VFDs allow for more efficient operation of fans and pumps, while solenoid valves provide rapid and accurate flow control. This synergy results in a more responsive and energy-efficient air quality control system.

The size and placement of solenoid valves within the air quality control system also impact energy efficiency. Properly sized valves reduce pressure drops and minimize the energy required to maintain desired airflow rates. Strategic valve placement can optimize system layout, reducing the overall energy needed for air distribution and filtration processes.

In conclusion, the energy efficiency of solenoid valves in air quality control systems is a multifaceted consideration that encompasses valve design, materials, control strategies, and system integration. By addressing these aspects, manufacturers and system designers can significantly reduce the energy footprint of air quality control systems while maintaining or improving their effectiveness in ensuring clean air delivery.

One key aspect of energy efficiency in solenoid valves is the reduction of holding current. Advanced valve designs utilize latching mechanisms or permanent magnets to maintain the valve's position once actuated, requiring minimal or no power to hold the state. This approach dramatically reduces the continuous energy demand compared to traditional solenoid valves that require constant power to remain open or closed.

The materials used in solenoid valve construction also contribute to energy efficiency. High-performance magnetic materials and optimized coil designs allow for more efficient electromagnetic conversion, reducing the power required for valve actuation. Additionally, low-friction seals and precision-engineered components minimize energy losses due to mechanical resistance.

Intelligent control systems further enhance the energy efficiency of solenoid valves in air quality control applications. By implementing adaptive algorithms and real-time monitoring, these systems can optimize valve operation based on current air quality conditions and system demands. This dynamic approach ensures that valves are only actuated when necessary, minimizing unnecessary energy expenditure.

Integration of solenoid valves with variable frequency drives (VFDs) in air handling units can lead to substantial energy savings. By precisely controlling airflow rates, VFDs allow for more efficient operation of fans and pumps, while solenoid valves provide rapid and accurate flow control. This synergy results in a more responsive and energy-efficient air quality control system.

The size and placement of solenoid valves within the air quality control system also impact energy efficiency. Properly sized valves reduce pressure drops and minimize the energy required to maintain desired airflow rates. Strategic valve placement can optimize system layout, reducing the overall energy needed for air distribution and filtration processes.

In conclusion, the energy efficiency of solenoid valves in air quality control systems is a multifaceted consideration that encompasses valve design, materials, control strategies, and system integration. By addressing these aspects, manufacturers and system designers can significantly reduce the energy footprint of air quality control systems while maintaining or improving their effectiveness in ensuring clean air delivery.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!