How RO Membranes Balance Flux And Rejection Across Recovery Targets?

SEP 22, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

RO Membrane Technology Background and Performance Goals

Reverse Osmosis (RO) membrane technology has evolved significantly since its inception in the 1950s, transitioning from a laboratory curiosity to a cornerstone of modern water purification systems. Initially developed for seawater desalination, RO membranes have expanded their application scope to include wastewater treatment, pharmaceutical processing, and food and beverage production. The fundamental principle remains consistent: applying pressure to overcome osmotic pressure, forcing water molecules through a semi-permeable membrane while rejecting dissolved solutes.

The technological evolution of RO membranes has been marked by several key advancements. Early cellulose acetate membranes have largely been replaced by thin-film composite (TFC) membranes, which offer superior flux rates, rejection capabilities, and chemical resistance. Recent innovations include the development of biomimetic membranes, graphene-based materials, and nanocomposite structures that aim to further enhance performance metrics.

A critical aspect of RO membrane technology is the inherent trade-off between water flux and solute rejection. Higher flux rates typically come at the expense of reduced rejection efficiency, while enhanced rejection often results in diminished flux. This balance becomes increasingly complex when considering system recovery targets—the percentage of feed water converted to permeate. As recovery increases, concentration polarization intensifies, leading to elevated osmotic pressure and potential scaling issues.

Current performance goals in the RO membrane industry focus on optimizing this delicate balance across varying recovery targets. Manufacturers aim to develop membranes that maintain high rejection rates (typically >99% for monovalent ions) while achieving commercially viable flux rates (>15 GFD) at standard operating pressures. Additionally, there is a growing emphasis on membranes that can maintain consistent performance at higher recovery rates (>85%) without succumbing to fouling or concentration polarization effects.

Energy efficiency represents another crucial performance goal, with research directed toward membranes that can operate at lower pressures while maintaining desirable flux and rejection characteristics. This is particularly important as energy consumption typically accounts for 30-50% of operational costs in RO systems. Membrane durability and chlorine resistance also remain significant areas for improvement, with current membranes requiring replacement every 3-7 years depending on operating conditions.

The industry is increasingly focused on specialized membranes designed for specific recovery targets and feed water compositions. This targeted approach acknowledges that the optimal flux-rejection balance varies significantly based on application requirements, from low-recovery, high-purity pharmaceutical applications to high-recovery wastewater reclamation systems where energy efficiency may take precedence over absolute rejection performance.

The technological evolution of RO membranes has been marked by several key advancements. Early cellulose acetate membranes have largely been replaced by thin-film composite (TFC) membranes, which offer superior flux rates, rejection capabilities, and chemical resistance. Recent innovations include the development of biomimetic membranes, graphene-based materials, and nanocomposite structures that aim to further enhance performance metrics.

A critical aspect of RO membrane technology is the inherent trade-off between water flux and solute rejection. Higher flux rates typically come at the expense of reduced rejection efficiency, while enhanced rejection often results in diminished flux. This balance becomes increasingly complex when considering system recovery targets—the percentage of feed water converted to permeate. As recovery increases, concentration polarization intensifies, leading to elevated osmotic pressure and potential scaling issues.

Current performance goals in the RO membrane industry focus on optimizing this delicate balance across varying recovery targets. Manufacturers aim to develop membranes that maintain high rejection rates (typically >99% for monovalent ions) while achieving commercially viable flux rates (>15 GFD) at standard operating pressures. Additionally, there is a growing emphasis on membranes that can maintain consistent performance at higher recovery rates (>85%) without succumbing to fouling or concentration polarization effects.

Energy efficiency represents another crucial performance goal, with research directed toward membranes that can operate at lower pressures while maintaining desirable flux and rejection characteristics. This is particularly important as energy consumption typically accounts for 30-50% of operational costs in RO systems. Membrane durability and chlorine resistance also remain significant areas for improvement, with current membranes requiring replacement every 3-7 years depending on operating conditions.

The industry is increasingly focused on specialized membranes designed for specific recovery targets and feed water compositions. This targeted approach acknowledges that the optimal flux-rejection balance varies significantly based on application requirements, from low-recovery, high-purity pharmaceutical applications to high-recovery wastewater reclamation systems where energy efficiency may take precedence over absolute rejection performance.

Market Analysis of High-Recovery RO Applications

The high-recovery reverse osmosis (RO) market has experienced significant growth over the past decade, driven primarily by increasing water scarcity concerns and stringent environmental regulations. The global market for high-recovery RO systems was valued at approximately $5.2 billion in 2022 and is projected to reach $8.7 billion by 2028, representing a compound annual growth rate of 8.9%.

Industrial applications constitute the largest segment of this market, accounting for roughly 45% of the total market share. Within this segment, power generation, semiconductor manufacturing, and pharmaceutical industries are the primary adopters of high-recovery RO systems. These industries require ultra-pure water for their operations and are willing to invest in advanced membrane technologies that can achieve higher recovery rates while maintaining quality standards.

Municipal water treatment represents the second-largest market segment at 30%, with rapid growth observed in regions facing severe water stress. The Middle East and North Africa (MENA) region leads in adoption rates due to limited freshwater resources, followed by parts of Asia-Pacific and North America. In these regions, high-recovery RO systems are increasingly deployed in desalination plants and wastewater reclamation facilities.

The commercial segment, comprising approximately 15% of the market, includes applications in hotels, hospitals, and commercial buildings. This segment is characterized by smaller-scale systems with recovery rates typically ranging from 75% to 85%. The remaining 10% is distributed across specialized applications such as emergency response units and mobile water treatment solutions.

Market dynamics are heavily influenced by operational expenditure considerations, particularly energy consumption. End-users increasingly prioritize systems that can achieve higher recovery rates without proportional increases in energy requirements. This has spurred innovation in energy recovery devices and membrane configurations designed specifically for high-recovery operations.

Regulatory frameworks also significantly impact market growth. Regions with stringent discharge regulations or water reuse incentives show accelerated adoption of high-recovery systems. For instance, California's Title 22 water recycling criteria have catalyzed the implementation of high-recovery RO systems in water reuse applications throughout the state.

Customer preferences are evolving toward integrated solutions that combine high-recovery RO with complementary technologies such as ultrafiltration pretreatment and brine concentration systems. This trend reflects a holistic approach to water management, where maximizing recovery is just one component of overall system optimization.

Industrial applications constitute the largest segment of this market, accounting for roughly 45% of the total market share. Within this segment, power generation, semiconductor manufacturing, and pharmaceutical industries are the primary adopters of high-recovery RO systems. These industries require ultra-pure water for their operations and are willing to invest in advanced membrane technologies that can achieve higher recovery rates while maintaining quality standards.

Municipal water treatment represents the second-largest market segment at 30%, with rapid growth observed in regions facing severe water stress. The Middle East and North Africa (MENA) region leads in adoption rates due to limited freshwater resources, followed by parts of Asia-Pacific and North America. In these regions, high-recovery RO systems are increasingly deployed in desalination plants and wastewater reclamation facilities.

The commercial segment, comprising approximately 15% of the market, includes applications in hotels, hospitals, and commercial buildings. This segment is characterized by smaller-scale systems with recovery rates typically ranging from 75% to 85%. The remaining 10% is distributed across specialized applications such as emergency response units and mobile water treatment solutions.

Market dynamics are heavily influenced by operational expenditure considerations, particularly energy consumption. End-users increasingly prioritize systems that can achieve higher recovery rates without proportional increases in energy requirements. This has spurred innovation in energy recovery devices and membrane configurations designed specifically for high-recovery operations.

Regulatory frameworks also significantly impact market growth. Regions with stringent discharge regulations or water reuse incentives show accelerated adoption of high-recovery systems. For instance, California's Title 22 water recycling criteria have catalyzed the implementation of high-recovery RO systems in water reuse applications throughout the state.

Customer preferences are evolving toward integrated solutions that combine high-recovery RO with complementary technologies such as ultrafiltration pretreatment and brine concentration systems. This trend reflects a holistic approach to water management, where maximizing recovery is just one component of overall system optimization.

Current Challenges in Flux-Rejection Balance

The fundamental challenge in RO membrane technology lies in the inherent trade-off between water flux and solute rejection. As recovery targets increase, this balance becomes increasingly difficult to maintain due to concentration polarization effects. Higher recovery rates lead to increased salt concentration at the membrane surface, which reduces the effective driving force for water transport while simultaneously increasing salt passage.

Material limitations present significant obstacles in achieving optimal flux-rejection balance. Current polymeric membranes, predominantly based on polyamide thin-film composites, face inherent permeability-selectivity trade-offs. When membrane structures are modified to increase water permeability, they often experience decreased salt rejection capabilities, creating a technological ceiling that limits performance across varying recovery targets.

Fouling and scaling phenomena dramatically impact membrane performance at higher recovery rates. As water recovery increases, the concentration of sparingly soluble salts and organic matter near the membrane surface rises exponentially, accelerating fouling processes. This fouling not only reduces flux but also creates localized areas of compromised rejection, leading to inconsistent performance across the membrane surface and throughout the operational lifetime.

Energy consumption optimization presents another critical challenge. Higher pressure is required to overcome increased osmotic pressure at elevated recovery rates, but excessive pressure can lead to membrane compaction, reducing permeability over time. Finding the optimal pressure profile that maintains flux without compromising membrane integrity or rejection capabilities remains difficult, particularly in variable feed water conditions.

Operational stability across fluctuating conditions represents a persistent challenge. RO systems must maintain consistent flux-rejection balance despite variations in feed water temperature, pH, and composition. Current membrane technologies often exhibit significant performance variations under changing conditions, making it difficult to optimize for specific recovery targets while maintaining operational reliability.

Monitoring and control limitations further complicate the management of flux-rejection balance. Real-time measurement of localized membrane performance remains technically challenging, resulting in operational decisions based on system-wide parameters rather than specific membrane conditions. This lack of granular data makes it difficult to implement adaptive control strategies that could optimize the flux-rejection balance across varying recovery targets.

The economic viability of high-recovery operations faces constraints due to increased pretreatment requirements, higher energy consumption, and accelerated membrane replacement schedules. Finding cost-effective solutions that maintain optimal flux-rejection balance while achieving higher recovery targets remains a significant industry challenge, particularly for applications with strict water quality requirements.

Material limitations present significant obstacles in achieving optimal flux-rejection balance. Current polymeric membranes, predominantly based on polyamide thin-film composites, face inherent permeability-selectivity trade-offs. When membrane structures are modified to increase water permeability, they often experience decreased salt rejection capabilities, creating a technological ceiling that limits performance across varying recovery targets.

Fouling and scaling phenomena dramatically impact membrane performance at higher recovery rates. As water recovery increases, the concentration of sparingly soluble salts and organic matter near the membrane surface rises exponentially, accelerating fouling processes. This fouling not only reduces flux but also creates localized areas of compromised rejection, leading to inconsistent performance across the membrane surface and throughout the operational lifetime.

Energy consumption optimization presents another critical challenge. Higher pressure is required to overcome increased osmotic pressure at elevated recovery rates, but excessive pressure can lead to membrane compaction, reducing permeability over time. Finding the optimal pressure profile that maintains flux without compromising membrane integrity or rejection capabilities remains difficult, particularly in variable feed water conditions.

Operational stability across fluctuating conditions represents a persistent challenge. RO systems must maintain consistent flux-rejection balance despite variations in feed water temperature, pH, and composition. Current membrane technologies often exhibit significant performance variations under changing conditions, making it difficult to optimize for specific recovery targets while maintaining operational reliability.

Monitoring and control limitations further complicate the management of flux-rejection balance. Real-time measurement of localized membrane performance remains technically challenging, resulting in operational decisions based on system-wide parameters rather than specific membrane conditions. This lack of granular data makes it difficult to implement adaptive control strategies that could optimize the flux-rejection balance across varying recovery targets.

The economic viability of high-recovery operations faces constraints due to increased pretreatment requirements, higher energy consumption, and accelerated membrane replacement schedules. Finding cost-effective solutions that maintain optimal flux-rejection balance while achieving higher recovery targets remains a significant industry challenge, particularly for applications with strict water quality requirements.

Current Approaches to Optimize Flux-Rejection Trade-offs

01 Membrane composition and structure for improved flux and rejection

The composition and structure of reverse osmosis (RO) membranes significantly impact their flux and rejection properties. Advanced materials such as thin-film composite membranes with specialized polymer compositions can enhance water permeability while maintaining high salt rejection. Modifications to the membrane surface chemistry and internal structure, including pore size distribution and thickness, can optimize the balance between flux and rejection performance.- Membrane composition and structure for improved flux and rejection: The composition and structure of reverse osmosis (RO) membranes significantly impact their flux and rejection properties. Various polymeric materials, such as polyamide thin-film composites, are used to create membranes with optimal pore size and distribution. Modifications to the membrane surface chemistry and incorporation of nanomaterials can enhance both water permeability and solute rejection. The cross-linking density and thickness of the active layer are critical factors that determine the balance between flux and rejection performance.

- Operating conditions affecting RO membrane performance: Operating conditions such as pressure, temperature, feed water characteristics, and cross-flow velocity significantly influence RO membrane flux and rejection rates. Higher operating pressures typically increase water flux but may lead to membrane compaction over time. Temperature affects both water viscosity and solute diffusion rates, with higher temperatures generally increasing flux but potentially reducing rejection. Feed water pH and the presence of scaling or fouling agents can also impact membrane performance, requiring careful optimization of operating parameters to maintain efficiency.

- Fouling prevention and membrane cleaning techniques: Membrane fouling is a major challenge that reduces flux and affects rejection performance in RO systems. Various pretreatment methods, anti-fouling membrane modifications, and cleaning protocols are employed to maintain optimal performance. Feed water pretreatment using filtration, coagulation, or UV disinfection helps reduce foulant load. Regular cleaning procedures using chemical agents remove accumulated foulants and restore membrane performance. Advanced anti-fouling strategies include surface modifications with hydrophilic materials and incorporation of antimicrobial agents to prevent biofouling.

- Novel membrane configurations and module designs: Innovative membrane configurations and module designs enhance flux and rejection performance while minimizing concentration polarization and fouling. Spiral-wound, hollow fiber, and plate-and-frame configurations offer different advantages in terms of packing density, pressure drop, and fouling resistance. Advanced spacer designs improve flow distribution and reduce concentration polarization at the membrane surface. Multi-stage systems with optimized flow patterns can achieve higher overall recovery rates while maintaining rejection performance. These configurations often incorporate features to enhance turbulence and reduce boundary layer thickness.

- Monitoring and control systems for optimizing RO performance: Advanced monitoring and control systems are essential for optimizing RO membrane flux and rejection performance. Real-time sensors measure key parameters such as pressure differential, conductivity, flow rates, and temperature across the membrane system. Automated control systems adjust operating conditions to maintain optimal performance despite variations in feed water quality or membrane condition. Predictive maintenance algorithms analyze performance trends to schedule cleaning or replacement before significant performance degradation occurs. These systems enable precise balancing of flux and rejection to meet specific water quality requirements while minimizing energy consumption.

02 Operating conditions affecting RO membrane performance

Various operating conditions directly influence RO membrane flux and rejection rates. These include feed pressure, temperature, crossflow velocity, and recovery ratio. Higher operating pressures typically increase flux but may impact rejection negatively beyond certain thresholds. Temperature affects both water viscosity and membrane properties, while optimized crossflow velocity helps reduce concentration polarization and fouling, thereby maintaining consistent flux and rejection performance.Expand Specific Solutions03 Fouling prevention and membrane cleaning techniques

Membrane fouling significantly reduces flux and can impact rejection performance of RO systems. Various techniques have been developed to prevent fouling, including pretreatment of feed water, surface modifications to create anti-fouling membrane properties, and optimized hydrodynamic conditions. Effective cleaning protocols using chemical agents and physical methods can restore membrane performance when fouling occurs, extending membrane life while maintaining desired flux and rejection characteristics.Expand Specific Solutions04 Membrane module design and system configuration

The design of membrane modules and overall system configuration plays a crucial role in optimizing flux and rejection performance. Innovations in spacer design, feed channel geometry, and module arrangement can improve hydrodynamics and reduce concentration polarization. Multi-stage configurations with pressure vessels arranged in series or parallel can be optimized for specific water quality requirements, balancing flux and rejection across the system while minimizing energy consumption.Expand Specific Solutions05 Performance enhancement through membrane modification

Various modification techniques can enhance RO membrane flux and rejection properties. These include surface modifications through coating, grafting, or incorporation of nanomaterials such as graphene oxide or metal-organic frameworks. Chemical modifications that alter hydrophilicity, surface charge, or introduce functional groups can improve both water permeability and solute rejection. Post-fabrication treatments like thermal annealing or chemical conditioning can further optimize membrane performance characteristics.Expand Specific Solutions

Leading Manufacturers and Research Institutions

The reverse osmosis (RO) membrane technology market is currently in a growth phase, with increasing demand driven by water scarcity challenges globally. The market size is projected to expand significantly, reaching approximately $12 billion by 2026, with a CAGR of 8-10%. Technologically, RO membranes are evolving toward higher flux-rejection balance optimization across various recovery targets. Leading players like Saudi Aramco, Gradiant Corp, and MIT are developing advanced materials and processes, while established manufacturers such as Kurita Water Industries, Veolia, and Hitachi are focusing on system integration. Chinese entities including SINOPEC and Tongji University are rapidly advancing their technological capabilities, particularly in industrial applications. The competitive landscape shows a mix of specialized technology developers and large industrial conglomerates collaborating to address the technical challenges of balancing flux performance with rejection rates.

Ide Water Technologies Ltd

Technical Solution: IDE Technologies has developed an innovative approach to RO membrane operation called "Pulse Flow Reverse Osmosis" (PFRO) that fundamentally changes how flux and rejection are balanced across recovery targets. Rather than maintaining constant pressure and flow, their system introduces controlled pressure pulses that periodically disrupt the concentration polarization layer at the membrane surface. This pulsation technique allows for higher average flux rates while maintaining rejection performance even at elevated recovery rates. Their membrane systems incorporate specialized flow distributors that ensure uniform distribution of these pressure pulses across the entire membrane surface. IDE's technology also features a proprietary anti-scaling pretreatment system that works synergistically with the pulsed flow to minimize scaling at high recovery operations. The company has implemented advanced computational fluid dynamics modeling to optimize the frequency and amplitude of pressure pulses for different feed water qualities and desired recovery rates.

Strengths: The PFRO technology enables operation at higher recovery rates without the typical decline in rejection performance, reducing energy consumption and brine disposal requirements. Weaknesses: The pulsation mechanism adds mechanical complexity to the system, potentially increasing maintenance requirements and capital costs compared to conventional steady-state RO systems.

Gradiant Corp.

Technical Solution: Gradiant has developed a comprehensive approach to balancing flux and rejection across recovery targets through their Counter-Flow Reverse Osmosis (CFRO) technology. This innovative system fundamentally reconfigures traditional RO processes by creating a counter-current flow arrangement that distributes osmotic pressure more evenly throughout the membrane system. Their technology employs a cascade of membrane stages with interstage brine recirculation that allows for precise control of concentration gradients across each membrane element. This approach enables operation at higher overall recovery rates while maintaining flux and rejection performance. Gradiant's system incorporates real-time monitoring of concentration polarization effects through specialized sensors that measure localized conditions at the membrane surface. Their membrane elements feature proprietary feed spacer designs that enhance mass transfer even at high recovery conditions where boundary layer effects typically limit performance. Additionally, Gradiant has developed advanced control algorithms that continuously optimize operating parameters based on feed water quality fluctuations and desired product water specifications.

Strengths: The CFRO technology enables significantly higher recovery rates (up to 98%) compared to conventional RO systems while maintaining product water quality, substantially reducing brine disposal requirements. Weaknesses: The system's complexity requires more sophisticated controls and potentially higher capital costs than conventional RO systems, though these may be offset by operational savings in challenging applications.

Key Innovations in Membrane Material Science

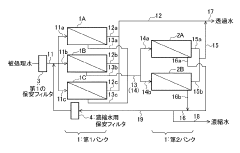

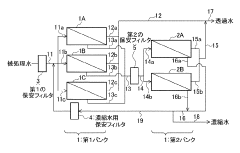

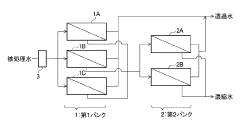

Reverse osmosis membrane apparatus and operational method of the same

PatentActiveJP2017170405A

Innovation

- The concentrated water from the last bank is passed through a turbidity removal filter and returned to the first stage bank, utilizing turbidity removal filters in the concentrated water return pipes to remove turbidity and scale, thereby stabilizing the operation and enhancing water recovery.

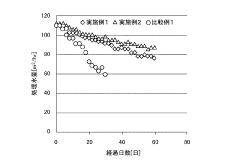

Method for improving rejection rate of reverse osmosis membrane, rejection rate improving agent, and reverse osmosis membrane

PatentWO2014103822A1

Innovation

- A method involving the use of an aqueous solution containing polyphenol, modified polyvinyl alcohol, high-molecular-weight polysaccharides, or polyamino acids is passed through the RO membrane to improve rejection rates, with the addition of low-molecular-weight amino compounds to enhance adsorption stability and repair deteriorated areas.

Energy Efficiency Considerations in High-Recovery Systems

Energy efficiency represents a critical factor in the design and operation of high-recovery reverse osmosis (RO) systems. As recovery rates increase, the energy consumption per unit volume of permeate typically rises due to the need to overcome higher osmotic pressures. This relationship creates a fundamental trade-off that system designers must carefully navigate to achieve optimal performance while minimizing operational costs.

In high-recovery RO systems, energy consumption is primarily driven by the feed pressure requirements. As water passes through the membrane and recovery increases, the concentration of dissolved solids in the remaining feed water escalates, leading to higher osmotic pressure. This phenomenon necessitates progressively higher operating pressures to maintain the desired flux rates, resulting in increased energy demand.

The specific energy consumption (SEC), measured in kWh per cubic meter of permeate, typically follows a non-linear curve as recovery increases. At recovery rates above 75%, the energy efficiency often deteriorates rapidly due to the exponential relationship between concentration and osmotic pressure. This inflection point varies based on feed water characteristics but represents a critical consideration in system design.

Energy recovery devices (ERDs) have emerged as a transformative technology for high-recovery systems. Modern pressure exchangers can recover up to 98% of the energy from the high-pressure concentrate stream, substantially reducing the overall energy footprint. The implementation of ERDs has made higher recovery operations economically viable in many applications where energy costs would otherwise be prohibitive.

Membrane configuration also plays a significant role in energy efficiency. Multi-stage designs with interstage booster pumps can optimize energy distribution across the system, allowing for more efficient operation at elevated recovery rates. Tapered configurations, where fewer membrane elements are used in subsequent stages, help maintain optimal cross-flow velocities as the feed volume decreases through the system.

Advanced control strategies further enhance energy efficiency in high-recovery systems. Variable frequency drives (VFDs) enable precise adjustment of pump speeds to match changing osmotic pressure requirements, while real-time monitoring systems can optimize operating parameters based on feed water conditions and desired recovery targets. These adaptive control mechanisms can yield energy savings of 10-25% compared to fixed-parameter operation.

The economic analysis of energy efficiency must consider both capital and operational expenditures. While higher recovery systems may require more sophisticated components and control systems, the reduced feed water requirements and concentrate disposal costs often offset these investments over the system lifecycle, particularly in regions with limited water resources or stringent discharge regulations.

In high-recovery RO systems, energy consumption is primarily driven by the feed pressure requirements. As water passes through the membrane and recovery increases, the concentration of dissolved solids in the remaining feed water escalates, leading to higher osmotic pressure. This phenomenon necessitates progressively higher operating pressures to maintain the desired flux rates, resulting in increased energy demand.

The specific energy consumption (SEC), measured in kWh per cubic meter of permeate, typically follows a non-linear curve as recovery increases. At recovery rates above 75%, the energy efficiency often deteriorates rapidly due to the exponential relationship between concentration and osmotic pressure. This inflection point varies based on feed water characteristics but represents a critical consideration in system design.

Energy recovery devices (ERDs) have emerged as a transformative technology for high-recovery systems. Modern pressure exchangers can recover up to 98% of the energy from the high-pressure concentrate stream, substantially reducing the overall energy footprint. The implementation of ERDs has made higher recovery operations economically viable in many applications where energy costs would otherwise be prohibitive.

Membrane configuration also plays a significant role in energy efficiency. Multi-stage designs with interstage booster pumps can optimize energy distribution across the system, allowing for more efficient operation at elevated recovery rates. Tapered configurations, where fewer membrane elements are used in subsequent stages, help maintain optimal cross-flow velocities as the feed volume decreases through the system.

Advanced control strategies further enhance energy efficiency in high-recovery systems. Variable frequency drives (VFDs) enable precise adjustment of pump speeds to match changing osmotic pressure requirements, while real-time monitoring systems can optimize operating parameters based on feed water conditions and desired recovery targets. These adaptive control mechanisms can yield energy savings of 10-25% compared to fixed-parameter operation.

The economic analysis of energy efficiency must consider both capital and operational expenditures. While higher recovery systems may require more sophisticated components and control systems, the reduced feed water requirements and concentrate disposal costs often offset these investments over the system lifecycle, particularly in regions with limited water resources or stringent discharge regulations.

Environmental Impact and Sustainability Factors

Reverse osmosis (RO) membrane systems face significant environmental and sustainability challenges that must be addressed when balancing flux and rejection across recovery targets. The energy consumption of RO systems represents a major environmental concern, with high-pressure operations requiring substantial electricity inputs that contribute to carbon emissions when derived from fossil fuel sources. Notably, systems optimized for maximum rejection often demand higher operating pressures, creating a direct trade-off between water quality and energy efficiency.

Water recovery rates significantly impact the environmental footprint of RO operations. Higher recovery targets reduce the volume of concentrate discharge but increase scaling and fouling risks, necessitating more frequent chemical cleaning. These cleaning processes introduce additional environmental considerations through chemical usage and disposal requirements. The environmental impact of concentrate management varies dramatically based on discharge location, with marine environments showing different sensitivity profiles compared to inland water bodies.

Membrane manufacturing processes themselves carry environmental implications through raw material extraction, polymer production, and fabrication energy requirements. Recent life cycle assessments indicate that membrane longevity significantly affects sustainability metrics, with higher-durability membranes offering improved environmental performance despite potentially higher initial rejection-flux trade-offs. The development of chlorine-resistant membranes has reduced replacement frequency and associated material consumption.

Emerging sustainable design approaches focus on optimizing the entire system rather than just membrane properties. Energy recovery devices have become standard in large-scale applications, recovering pressure energy from concentrate streams and reducing overall energy consumption by 25-40%. Renewable energy integration, particularly solar-powered RO systems, offers promising pathways to carbon-neutral operation while accommodating the variable flux requirements across different recovery targets.

Biofouling management represents another critical sustainability factor, with traditional biocides presenting environmental concerns. Novel membrane materials incorporating antimicrobial properties aim to reduce chemical usage while maintaining optimal flux-rejection balances throughout the membrane lifecycle. These innovations demonstrate how environmental considerations are increasingly integrated into fundamental membrane design parameters rather than treated as secondary concerns.

The circular economy perspective is gaining traction in membrane technology development, with research exploring end-of-life recycling options and bio-based polymer alternatives. These approaches seek to minimize waste generation while maintaining the delicate balance between flux performance and rejection capabilities that defines effective RO operation across varying recovery targets.

Water recovery rates significantly impact the environmental footprint of RO operations. Higher recovery targets reduce the volume of concentrate discharge but increase scaling and fouling risks, necessitating more frequent chemical cleaning. These cleaning processes introduce additional environmental considerations through chemical usage and disposal requirements. The environmental impact of concentrate management varies dramatically based on discharge location, with marine environments showing different sensitivity profiles compared to inland water bodies.

Membrane manufacturing processes themselves carry environmental implications through raw material extraction, polymer production, and fabrication energy requirements. Recent life cycle assessments indicate that membrane longevity significantly affects sustainability metrics, with higher-durability membranes offering improved environmental performance despite potentially higher initial rejection-flux trade-offs. The development of chlorine-resistant membranes has reduced replacement frequency and associated material consumption.

Emerging sustainable design approaches focus on optimizing the entire system rather than just membrane properties. Energy recovery devices have become standard in large-scale applications, recovering pressure energy from concentrate streams and reducing overall energy consumption by 25-40%. Renewable energy integration, particularly solar-powered RO systems, offers promising pathways to carbon-neutral operation while accommodating the variable flux requirements across different recovery targets.

Biofouling management represents another critical sustainability factor, with traditional biocides presenting environmental concerns. Novel membrane materials incorporating antimicrobial properties aim to reduce chemical usage while maintaining optimal flux-rejection balances throughout the membrane lifecycle. These innovations demonstrate how environmental considerations are increasingly integrated into fundamental membrane design parameters rather than treated as secondary concerns.

The circular economy perspective is gaining traction in membrane technology development, with research exploring end-of-life recycling options and bio-based polymer alternatives. These approaches seek to minimize waste generation while maintaining the delicate balance between flux performance and rejection capabilities that defines effective RO operation across varying recovery targets.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!