RO Membrane Post-Treatment: pH/Hardness Adjustment And Stabilization

SEP 22, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

RO Membrane Post-Treatment Background and Objectives

Reverse Osmosis (RO) membrane technology has evolved significantly since its commercial introduction in the 1960s, becoming a cornerstone of water purification and desalination processes worldwide. The post-treatment phase of RO systems represents a critical yet often overlooked component that ensures the final water quality meets specific requirements for various applications. Historically, RO post-treatment has transitioned from basic disinfection methods to sophisticated chemical adjustment processes that address multiple water quality parameters simultaneously.

The evolution of post-treatment technologies has been driven by increasing regulatory standards for drinking water, industrial process requirements, and the need to extend infrastructure lifespan. Early post-treatment focused primarily on disinfection, while modern approaches incorporate comprehensive stabilization strategies that consider the chemical equilibrium of treated water within distribution systems.

pH and hardness adjustment have emerged as fundamental aspects of RO post-treatment due to the inherently aggressive nature of RO permeate. RO membranes effectively remove minerals that naturally buffer water, resulting in product water that is typically acidic and under-saturated with respect to calcium carbonate. Without proper post-treatment, this water can become corrosive to distribution systems, leading to infrastructure degradation and potential health concerns from leached metals.

The primary technical objectives of modern RO membrane post-treatment include achieving chemical stability to prevent corrosion, meeting regulatory compliance for drinking water parameters, optimizing mineral content for taste in potable applications, and ensuring compatibility with downstream processes in industrial applications. Additionally, post-treatment aims to prevent biological regrowth in distribution systems while minimizing chemical usage and operational costs.

Current technological goals focus on developing more sustainable post-treatment methods that reduce chemical consumption, minimize waste generation, and lower energy requirements. There is growing interest in precise, automated dosing systems that can adjust to fluctuating feed water conditions and maintain consistent finished water quality. Research is also directed toward alternative stabilization approaches that move beyond traditional calcium carbonate saturation indices to more comprehensive models that account for multiple mineral equilibria.

The intersection of water scarcity concerns, stricter environmental regulations, and increasing awareness of water quality impacts on public health continues to drive innovation in this field. As RO technology expands into new applications and regions, post-treatment technologies must adapt to diverse water chemistry challenges while maintaining operational efficiency and cost-effectiveness.

The evolution of post-treatment technologies has been driven by increasing regulatory standards for drinking water, industrial process requirements, and the need to extend infrastructure lifespan. Early post-treatment focused primarily on disinfection, while modern approaches incorporate comprehensive stabilization strategies that consider the chemical equilibrium of treated water within distribution systems.

pH and hardness adjustment have emerged as fundamental aspects of RO post-treatment due to the inherently aggressive nature of RO permeate. RO membranes effectively remove minerals that naturally buffer water, resulting in product water that is typically acidic and under-saturated with respect to calcium carbonate. Without proper post-treatment, this water can become corrosive to distribution systems, leading to infrastructure degradation and potential health concerns from leached metals.

The primary technical objectives of modern RO membrane post-treatment include achieving chemical stability to prevent corrosion, meeting regulatory compliance for drinking water parameters, optimizing mineral content for taste in potable applications, and ensuring compatibility with downstream processes in industrial applications. Additionally, post-treatment aims to prevent biological regrowth in distribution systems while minimizing chemical usage and operational costs.

Current technological goals focus on developing more sustainable post-treatment methods that reduce chemical consumption, minimize waste generation, and lower energy requirements. There is growing interest in precise, automated dosing systems that can adjust to fluctuating feed water conditions and maintain consistent finished water quality. Research is also directed toward alternative stabilization approaches that move beyond traditional calcium carbonate saturation indices to more comprehensive models that account for multiple mineral equilibria.

The intersection of water scarcity concerns, stricter environmental regulations, and increasing awareness of water quality impacts on public health continues to drive innovation in this field. As RO technology expands into new applications and regions, post-treatment technologies must adapt to diverse water chemistry challenges while maintaining operational efficiency and cost-effectiveness.

Market Demand for Advanced Water Treatment Solutions

The global water treatment market is experiencing unprecedented growth, driven by increasing water scarcity, deteriorating water quality, and stricter environmental regulations. The demand for advanced water treatment solutions, particularly those involving RO membrane post-treatment technologies for pH and hardness adjustment, has seen significant expansion across multiple sectors.

Industrial applications represent a major market segment, with manufacturing facilities, power plants, and chemical processing industries requiring high-quality water with specific pH levels and hardness characteristics. These industries are increasingly adopting RO membrane systems with sophisticated post-treatment capabilities to ensure operational efficiency and regulatory compliance.

Municipal water treatment facilities constitute another substantial market driver, as cities worldwide face challenges in providing safe drinking water to growing populations. The ability to precisely adjust pH and stabilize water after RO treatment is critical for preventing pipe corrosion in distribution systems and ensuring water palatability for consumers.

The healthcare and pharmaceutical sectors demand ultrapure water with tightly controlled parameters, creating a premium market segment for advanced post-treatment solutions. These industries require water treatment systems that can deliver consistent quality with minimal variation in pH and mineral content.

Geographically, water-stressed regions in the Middle East, North Africa, and parts of Asia are showing the strongest demand growth for comprehensive water treatment solutions. These regions are investing heavily in desalination and water reuse technologies, where post-RO treatment plays a crucial role in water stabilization.

Market analysis indicates that end-users are increasingly prioritizing total cost of ownership over initial capital expenditure, creating opportunities for more sophisticated post-treatment solutions that offer longer system life and reduced maintenance requirements. This shift has accelerated innovation in pH adjustment and remineralization technologies that are more energy-efficient and consume fewer chemicals.

Consumer awareness regarding water quality has also emerged as a significant market force, particularly in developed economies. This has led to growing demand for residential and commercial water treatment systems that not only remove contaminants but also deliver water with optimal mineral content and pH levels for health and taste considerations.

The market for specialized post-treatment media, such as calcite, dolomite, and engineered mineral blends, has expanded considerably, with manufacturers developing proprietary formulations designed to achieve specific water quality targets while minimizing maintenance requirements.

Industrial applications represent a major market segment, with manufacturing facilities, power plants, and chemical processing industries requiring high-quality water with specific pH levels and hardness characteristics. These industries are increasingly adopting RO membrane systems with sophisticated post-treatment capabilities to ensure operational efficiency and regulatory compliance.

Municipal water treatment facilities constitute another substantial market driver, as cities worldwide face challenges in providing safe drinking water to growing populations. The ability to precisely adjust pH and stabilize water after RO treatment is critical for preventing pipe corrosion in distribution systems and ensuring water palatability for consumers.

The healthcare and pharmaceutical sectors demand ultrapure water with tightly controlled parameters, creating a premium market segment for advanced post-treatment solutions. These industries require water treatment systems that can deliver consistent quality with minimal variation in pH and mineral content.

Geographically, water-stressed regions in the Middle East, North Africa, and parts of Asia are showing the strongest demand growth for comprehensive water treatment solutions. These regions are investing heavily in desalination and water reuse technologies, where post-RO treatment plays a crucial role in water stabilization.

Market analysis indicates that end-users are increasingly prioritizing total cost of ownership over initial capital expenditure, creating opportunities for more sophisticated post-treatment solutions that offer longer system life and reduced maintenance requirements. This shift has accelerated innovation in pH adjustment and remineralization technologies that are more energy-efficient and consume fewer chemicals.

Consumer awareness regarding water quality has also emerged as a significant market force, particularly in developed economies. This has led to growing demand for residential and commercial water treatment systems that not only remove contaminants but also deliver water with optimal mineral content and pH levels for health and taste considerations.

The market for specialized post-treatment media, such as calcite, dolomite, and engineered mineral blends, has expanded considerably, with manufacturers developing proprietary formulations designed to achieve specific water quality targets while minimizing maintenance requirements.

Current Challenges in pH and Hardness Stabilization

Despite significant advancements in reverse osmosis (RO) membrane technology, post-treatment stabilization remains a critical challenge for water treatment facilities worldwide. The permeate produced by RO systems is typically characterized by low pH, low alkalinity, and minimal hardness, creating an aggressive water that can cause corrosion in distribution systems and plumbing fixtures. This instability represents a major operational concern that requires sophisticated adjustment strategies.

One of the primary challenges in pH stabilization is achieving consistent and reliable control across varying influent water qualities. RO permeate typically exhibits pH values between 5.0-6.5, significantly below the recommended range of 7.0-8.5 for drinking water. Traditional alkali addition methods often struggle with precise dosing control, leading to fluctuations that can trigger scaling or corrosion events downstream.

Hardness stabilization presents equally complex challenges. The near-complete removal of calcium and magnesium ions during the RO process creates water that lacks the protective scaling potential needed to prevent metal leaching from pipes. Current remineralization approaches frequently result in uneven distribution of hardness minerals, creating localized areas of either excessive scaling or insufficient protection.

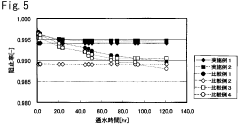

The chemical dynamics between pH adjustment and hardness stabilization compounds these difficulties. When calcium carbonate is used for remineralization, its dissolution kinetics are highly pH-dependent, creating a complex feedback loop that makes stable equilibrium difficult to maintain. Many facilities report that achieving the delicate balance between Langelier Saturation Index (LSI) and Calcium Carbonate Precipitation Potential (CCPP) remains more art than science.

Energy efficiency represents another significant hurdle. Conventional post-treatment systems often require substantial mixing energy and contact time to achieve proper dissolution of stabilizing chemicals. This energy demand contradicts the industry's push toward more sustainable water treatment processes and adds considerable operational costs.

Automation and real-time control systems face limitations in responding to rapid water quality changes. Current sensor technologies for continuous monitoring of parameters like alkalinity and calcium hardness lack the reliability and accuracy needed for truly responsive control systems. This technological gap forces many operations to rely on periodic grab sampling and manual adjustments, introducing delays and inconsistencies in treatment.

The economic implications of these challenges are substantial. Facilities must balance the capital costs of sophisticated post-treatment systems against the long-term expenses associated with infrastructure damage from unstabilized water. This cost-benefit analysis is further complicated by regional variations in water quality regulations and infrastructure materials.

One of the primary challenges in pH stabilization is achieving consistent and reliable control across varying influent water qualities. RO permeate typically exhibits pH values between 5.0-6.5, significantly below the recommended range of 7.0-8.5 for drinking water. Traditional alkali addition methods often struggle with precise dosing control, leading to fluctuations that can trigger scaling or corrosion events downstream.

Hardness stabilization presents equally complex challenges. The near-complete removal of calcium and magnesium ions during the RO process creates water that lacks the protective scaling potential needed to prevent metal leaching from pipes. Current remineralization approaches frequently result in uneven distribution of hardness minerals, creating localized areas of either excessive scaling or insufficient protection.

The chemical dynamics between pH adjustment and hardness stabilization compounds these difficulties. When calcium carbonate is used for remineralization, its dissolution kinetics are highly pH-dependent, creating a complex feedback loop that makes stable equilibrium difficult to maintain. Many facilities report that achieving the delicate balance between Langelier Saturation Index (LSI) and Calcium Carbonate Precipitation Potential (CCPP) remains more art than science.

Energy efficiency represents another significant hurdle. Conventional post-treatment systems often require substantial mixing energy and contact time to achieve proper dissolution of stabilizing chemicals. This energy demand contradicts the industry's push toward more sustainable water treatment processes and adds considerable operational costs.

Automation and real-time control systems face limitations in responding to rapid water quality changes. Current sensor technologies for continuous monitoring of parameters like alkalinity and calcium hardness lack the reliability and accuracy needed for truly responsive control systems. This technological gap forces many operations to rely on periodic grab sampling and manual adjustments, introducing delays and inconsistencies in treatment.

The economic implications of these challenges are substantial. Facilities must balance the capital costs of sophisticated post-treatment systems against the long-term expenses associated with infrastructure damage from unstabilized water. This cost-benefit analysis is further complicated by regional variations in water quality regulations and infrastructure materials.

Existing pH and Hardness Adjustment Techniques

01 pH adjustment systems for RO permeate

Post-treatment systems for adjusting the pH of reverse osmosis (RO) permeate water to achieve desired alkalinity levels. These systems typically include dosing equipment for adding alkaline substances to neutralize the acidity of RO permeate water. The pH adjustment helps to prevent corrosion in downstream piping and equipment while improving water taste and quality for consumption or industrial use.- pH adjustment systems for RO permeate: Post-treatment systems for adjusting the pH of reverse osmosis (RO) permeate water to achieve optimal drinking water quality. These systems typically include dosing equipment for adding alkaline substances to neutralize the acidic nature of RO permeate, bringing the pH to more acceptable levels for consumption. The adjustment helps prevent corrosion in distribution systems and improves taste characteristics of the treated water.

- Remineralization techniques for RO treated water: Methods and systems for adding essential minerals back into RO treated water to increase hardness and improve water quality. After RO filtration removes beneficial minerals along with contaminants, remineralization processes introduce calcium, magnesium and other minerals through contact with mineral-rich media or controlled dosing systems. This process enhances water taste and provides health benefits while maintaining appropriate hardness levels.

- Integrated post-treatment systems combining pH and hardness adjustment: Comprehensive post-treatment solutions that simultaneously address both pH and hardness issues in RO permeate water. These integrated systems combine multiple treatment stages including calcite contactors, CO2 injection, and alkaline dosing to achieve balanced water chemistry. The systems are designed to provide consistent water quality regardless of feed water variations, ensuring stable pH and appropriate mineral content in the final product water.

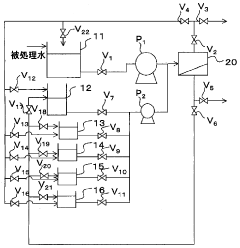

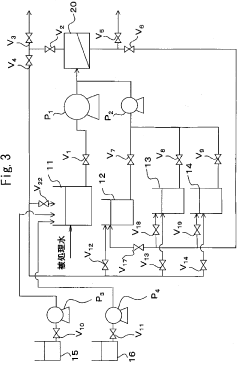

- Automated monitoring and control systems for post-RO treatment: Advanced control systems that continuously monitor and automatically adjust post-treatment parameters for RO permeate. These systems utilize sensors to measure pH, conductivity, and hardness in real-time, with programmable controllers that regulate chemical dosing pumps or mineral contact time. The automation ensures consistent water quality despite variations in feed water or operating conditions, optimizing chemical usage while maintaining target water quality parameters.

- Eco-friendly and sustainable post-treatment approaches: Environmentally conscious methods for post-treatment of RO permeate that minimize chemical usage and environmental impact. These approaches include natural mineral contactors, recirculation systems that reduce waste, and energy-efficient designs. Some systems utilize naturally occurring minerals or byproducts from other processes as remineralization media, creating more sustainable water treatment solutions while still achieving desired pH and hardness levels.

02 Remineralization techniques for RO treated water

Methods and systems for adding essential minerals back into demineralized RO water to improve hardness and mineral content. These techniques involve the controlled addition of calcium and magnesium compounds to increase water hardness to appropriate levels. Remineralization is crucial for improving water palatability, providing health benefits from essential minerals, and preventing corrosion in distribution systems.Expand Specific Solutions03 Integrated post-treatment systems combining pH and hardness adjustment

Comprehensive post-treatment solutions that simultaneously address both pH and hardness issues in RO permeate water. These integrated systems combine multiple treatment stages including remineralization, pH adjustment, and sometimes disinfection in a single process train. The integrated approach ensures optimal water quality while minimizing footprint and operational complexity.Expand Specific Solutions04 Automated monitoring and control systems for RO post-treatment

Advanced control systems that continuously monitor and automatically adjust pH and hardness parameters in RO post-treatment processes. These systems utilize sensors, controllers, and dosing equipment to maintain water quality parameters within specified ranges. Automation improves consistency in water quality, reduces operator intervention, and optimizes chemical usage in the post-treatment process.Expand Specific Solutions05 Sustainable and energy-efficient post-treatment methods

Environmentally friendly approaches to RO post-treatment that focus on energy efficiency and sustainable operation. These methods include using naturally occurring minerals for remineralization, energy recovery devices, and optimized chemical dosing systems. The sustainable techniques aim to reduce the environmental footprint of water treatment while maintaining high water quality standards for pH and hardness control.Expand Specific Solutions

Leading Companies in Water Treatment Technology

The RO membrane post-treatment market for pH/hardness adjustment and stabilization is currently in a growth phase, with increasing demand driven by water scarcity concerns and stricter water quality regulations. The global market size is expanding steadily, estimated to reach several billion dollars by 2025. Technologically, the field shows moderate maturity with established solutions, but continuous innovation is evident. Leading players include Kurita Water Industries and Organo Corp. from Japan, who offer comprehensive water treatment solutions; Chinese entities like Sinopec and Hunan Qinsen focusing on industrial applications; and specialized Western companies such as Hydranautics and LG NanoH2O developing advanced membrane technologies. The competitive landscape features both diversified conglomerates and specialized water treatment firms competing through technological differentiation and regional market penetration.

Kurita Water Industries Ltd.

Technical Solution: Kurita Water Industries has developed a comprehensive RO membrane post-treatment system called "S.sensing™ RO Stabilization" that addresses both pH and hardness adjustment through an integrated approach. Their technology utilizes a proprietary blend of buffering agents and mineral supplements specifically formulated to achieve optimal Langelier Saturation Index (LSI) values while minimizing chemical usage. The system features Kurita's patented "Dynamic Dosing Control" which continuously adjusts chemical addition based on real-time monitoring of multiple water quality parameters including pH, conductivity, alkalinity, and hardness. For remineralization, Kurita employs a unique two-stage contactor system with different media compositions to achieve precise control over calcium, magnesium, and bicarbonate levels. Their approach includes specialized anti-corrosion additives that form protective films on downstream piping without impacting water taste or quality. The entire system is designed for minimal maintenance with automated cleaning cycles and chemical optimization algorithms that adapt to changing feed water conditions, ensuring consistent permeate quality while reducing operational costs through optimized chemical usage.

Strengths: Highly integrated system provides comprehensive water stabilization with minimal operator intervention. Proprietary chemical formulations are specifically designed for post-RO applications, ensuring optimal performance. Weaknesses: Reliance on Kurita's proprietary chemicals may increase long-term operational costs. System optimization requires extensive initial calibration period to achieve maximum efficiency.

Hitachi Ltd.

Technical Solution: Hitachi has developed an advanced RO membrane post-treatment system that combines electrochemical pH adjustment with precision mineral dosing technology. Their approach eliminates the need for conventional acid/base chemicals through an innovative electrolysis unit that generates hydroxide ions for pH elevation without introducing external contaminants. The system incorporates Hitachi's proprietary "Aqua-Stability" technology, which uses real-time water quality sensors and predictive algorithms to determine optimal mineral addition rates based on multiple parameters including temperature, flow rate, and incoming water composition. For hardness adjustment, Hitachi employs a fluidized bed crystallization process that precisely controls calcium and magnesium concentrations while preventing scaling. This technology maintains consistent Calcium Carbonate Precipitation Potential (CCPP) values between 3-5 mg/L, ensuring water stability without excessive mineralization. The entire system is integrated with Hitachi's digital water management platform, allowing for remote monitoring, predictive maintenance, and automated adjustment based on machine learning algorithms that continuously optimize treatment parameters based on historical performance data.

Strengths: Electrochemical pH adjustment eliminates chemical handling and storage requirements. Advanced digital control systems provide precise water quality management with minimal operator intervention. Weaknesses: Higher energy consumption compared to conventional chemical dosing systems. Complex technology may present challenges for troubleshooting and maintenance in facilities without specialized technical staff.

Key Innovations in Membrane Stabilization Chemistry

Water treatment apparatus and method of water treatment

PatentWO2008059824A1

Innovation

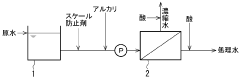

- A water treatment apparatus and method that supplies raw water to an RO unit at a pH of 7 or less, using a reverse osmosis membrane treated with a rejection rate improving agent, such as an ionic polymer, to enhance the rejection of inorganic electrolytes and water-soluble organic substances, and includes pretreatment devices like activated carbon towers and pH adjustment to prevent fouling and scale formation.

Method of treating waste water containing organic substance and treating apparatus

PatentWO2005049501A1

Innovation

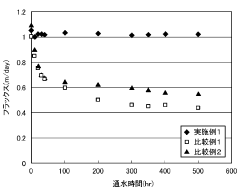

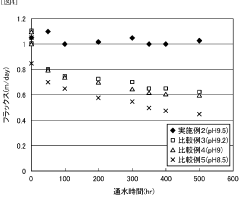

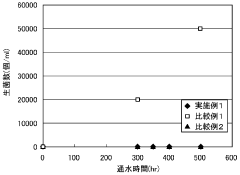

- A method and apparatus that involves adding a scale inhibitor in amounts five times or more the weight of calcium ions and adjusting the pH to 9.5 or higher to inhibit biofouling and scale formation, using low-fouling RO membranes and activated carbon treatment to stabilize membrane flux and reduce TOC concentration.

Environmental Impact Assessment of Treatment Chemicals

The chemicals used in RO membrane post-treatment processes for pH/hardness adjustment and stabilization have significant environmental implications that must be carefully assessed. These chemicals, including acids, bases, anti-scalants, and corrosion inhibitors, eventually enter natural water systems through discharge streams, potentially affecting aquatic ecosystems and water quality.

Acidic chemicals like sulfuric acid and hydrochloric acid used for pH adjustment can cause localized acidification in receiving water bodies if not properly neutralized before discharge. This acidification may harm aquatic organisms and disrupt ecosystem balance. Similarly, alkaline substances such as sodium hydroxide and calcium hydroxide can elevate pH levels in natural waters, creating equally detrimental conditions for aquatic life adapted to specific pH ranges.

Anti-scalants containing phosphonates and polymers present particular environmental concerns due to their persistence in the environment. Studies indicate that some phosphonate-based compounds have biodegradation half-lives exceeding 200 days, potentially accumulating in sediments and bioaccumulating in aquatic organisms. Newer "green" anti-scalants with improved biodegradability profiles are emerging, but their market penetration remains limited.

Corrosion inhibitors, particularly those containing zinc compounds, introduce heavy metals into the environment that can be toxic to aquatic organisms even at low concentrations. Research has demonstrated that zinc concentrations as low as 0.1 mg/L can adversely affect fish reproduction and development. Alternative formulations using organic phosphates offer reduced environmental impact but may still contribute to eutrophication issues.

The cumulative effect of these treatment chemicals must be considered within the context of watershed management. Regulatory frameworks worldwide are increasingly implementing stricter discharge limits for treatment chemicals. The European Water Framework Directive, for instance, has established Environmental Quality Standards for priority substances that include several compounds used in water treatment processes.

Life cycle assessment (LCA) studies comparing different post-treatment chemical regimes indicate that environmental impacts extend beyond direct aquatic effects to include the carbon footprint associated with chemical production and transportation. A comprehensive 2021 study revealed that the manufacturing of conventional anti-scalants generates approximately 2.5 kg CO2 equivalent per kilogram of product, highlighting the importance of considering upstream environmental impacts.

Emerging technologies for chemical recovery and closed-loop systems offer promising approaches to mitigate environmental impacts. Advanced oxidation processes can degrade persistent compounds in discharge streams, while ion exchange systems enable the recovery and reuse of certain treatment chemicals, substantially reducing environmental discharge loads.

Acidic chemicals like sulfuric acid and hydrochloric acid used for pH adjustment can cause localized acidification in receiving water bodies if not properly neutralized before discharge. This acidification may harm aquatic organisms and disrupt ecosystem balance. Similarly, alkaline substances such as sodium hydroxide and calcium hydroxide can elevate pH levels in natural waters, creating equally detrimental conditions for aquatic life adapted to specific pH ranges.

Anti-scalants containing phosphonates and polymers present particular environmental concerns due to their persistence in the environment. Studies indicate that some phosphonate-based compounds have biodegradation half-lives exceeding 200 days, potentially accumulating in sediments and bioaccumulating in aquatic organisms. Newer "green" anti-scalants with improved biodegradability profiles are emerging, but their market penetration remains limited.

Corrosion inhibitors, particularly those containing zinc compounds, introduce heavy metals into the environment that can be toxic to aquatic organisms even at low concentrations. Research has demonstrated that zinc concentrations as low as 0.1 mg/L can adversely affect fish reproduction and development. Alternative formulations using organic phosphates offer reduced environmental impact but may still contribute to eutrophication issues.

The cumulative effect of these treatment chemicals must be considered within the context of watershed management. Regulatory frameworks worldwide are increasingly implementing stricter discharge limits for treatment chemicals. The European Water Framework Directive, for instance, has established Environmental Quality Standards for priority substances that include several compounds used in water treatment processes.

Life cycle assessment (LCA) studies comparing different post-treatment chemical regimes indicate that environmental impacts extend beyond direct aquatic effects to include the carbon footprint associated with chemical production and transportation. A comprehensive 2021 study revealed that the manufacturing of conventional anti-scalants generates approximately 2.5 kg CO2 equivalent per kilogram of product, highlighting the importance of considering upstream environmental impacts.

Emerging technologies for chemical recovery and closed-loop systems offer promising approaches to mitigate environmental impacts. Advanced oxidation processes can degrade persistent compounds in discharge streams, while ion exchange systems enable the recovery and reuse of certain treatment chemicals, substantially reducing environmental discharge loads.

Regulatory Compliance for Drinking Water Standards

Regulatory compliance for drinking water standards is a critical consideration in RO membrane post-treatment processes, particularly regarding pH and hardness adjustment. The Safe Drinking Water Act (SDWA) in the United States, along with the European Drinking Water Directive in the EU, establish comprehensive frameworks for ensuring water quality parameters meet public health requirements.

The US Environmental Protection Agency (EPA) has established National Primary Drinking Water Regulations (NPDWRs) that set legally enforceable standards for various contaminants, including those affected by post-treatment processes. These regulations specify acceptable pH ranges (typically 6.5-8.5) and hardness levels that water utilities must maintain. Non-compliance can result in significant penalties, operational restrictions, and potential public health advisories.

Secondary standards, though not federally enforceable, provide guidelines for aesthetic considerations such as taste, odor, and mineral content that are directly impacted by post-treatment stabilization processes. Water utilities must carefully balance these parameters to meet both regulatory requirements and consumer expectations.

The Lead and Copper Rule (LCR) represents a particularly important regulatory consideration for post-treatment stabilization. Improper pH adjustment can lead to increased corrosivity, potentially causing lead and copper leaching from distribution systems. The revised LCR has strengthened requirements for corrosion control treatment, making proper post-RO stabilization even more critical from a compliance perspective.

International standards, including those from the World Health Organization (WHO), provide additional guidance that many countries adopt into their national regulations. These standards typically address calcium carbonate precipitation potential, Langelier Saturation Index (LSI), and other stability indicators that must be controlled through post-treatment processes.

Regulatory monitoring and reporting requirements present operational challenges for water utilities. Most regulations mandate regular testing and documentation of water quality parameters throughout the distribution system, with particular attention to pH stability and mineral content. Advanced monitoring technologies, including online analyzers and remote sensing equipment, are increasingly being deployed to ensure continuous compliance.

Emerging regulations concerning per- and polyfluoroalkyl substances (PFAS) and other contaminants of emerging concern may indirectly impact post-treatment requirements, as removal strategies for these compounds can affect overall water chemistry and stability parameters. Water utilities must remain vigilant about evolving regulatory landscapes and adapt their post-treatment protocols accordingly.

The US Environmental Protection Agency (EPA) has established National Primary Drinking Water Regulations (NPDWRs) that set legally enforceable standards for various contaminants, including those affected by post-treatment processes. These regulations specify acceptable pH ranges (typically 6.5-8.5) and hardness levels that water utilities must maintain. Non-compliance can result in significant penalties, operational restrictions, and potential public health advisories.

Secondary standards, though not federally enforceable, provide guidelines for aesthetic considerations such as taste, odor, and mineral content that are directly impacted by post-treatment stabilization processes. Water utilities must carefully balance these parameters to meet both regulatory requirements and consumer expectations.

The Lead and Copper Rule (LCR) represents a particularly important regulatory consideration for post-treatment stabilization. Improper pH adjustment can lead to increased corrosivity, potentially causing lead and copper leaching from distribution systems. The revised LCR has strengthened requirements for corrosion control treatment, making proper post-RO stabilization even more critical from a compliance perspective.

International standards, including those from the World Health Organization (WHO), provide additional guidance that many countries adopt into their national regulations. These standards typically address calcium carbonate precipitation potential, Langelier Saturation Index (LSI), and other stability indicators that must be controlled through post-treatment processes.

Regulatory monitoring and reporting requirements present operational challenges for water utilities. Most regulations mandate regular testing and documentation of water quality parameters throughout the distribution system, with particular attention to pH stability and mineral content. Advanced monitoring technologies, including online analyzers and remote sensing equipment, are increasingly being deployed to ensure continuous compliance.

Emerging regulations concerning per- and polyfluoroalkyl substances (PFAS) and other contaminants of emerging concern may indirectly impact post-treatment requirements, as removal strategies for these compounds can affect overall water chemistry and stability parameters. Water utilities must remain vigilant about evolving regulatory landscapes and adapt their post-treatment protocols accordingly.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!