How RO Membranes Maintain Integrity In High-Pressure, High-TDS Operations?

SEP 22, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

RO Membrane Technology Evolution and Performance Goals

Reverse Osmosis (RO) membrane technology has undergone significant evolution since its commercial introduction in the 1960s. Initially developed for seawater desalination, early RO membranes exhibited limited salt rejection capabilities of approximately 85-90% and required operating pressures exceeding 600 psi. These first-generation cellulose acetate membranes suffered from biological degradation, narrow pH tolerance, and limited temperature resistance.

The 1970s marked a pivotal advancement with the introduction of thin-film composite (TFC) polyamide membranes, dramatically improving salt rejection to 95-99% while reducing operating pressures. This innovation established the fundamental architecture still dominant today: a thin polyamide active layer (0.1-0.2 μm) supported by a porous polysulfone layer atop a non-woven fabric substrate.

The 1990s witnessed further refinements focusing on membrane surface chemistry modifications to enhance fouling resistance and chlorine tolerance. Manufacturers began developing specialized membranes for specific applications, including brackish water, seawater, and wastewater reclamation, each optimized for particular feed water characteristics.

Recent technological advancements have concentrated on addressing the challenges of high-pressure, high-TDS operations. Modern RO membranes incorporate nanomaterial technologies, including graphene oxide and carbon nanotubes, to improve mechanical strength while maintaining or enhancing permeability. Surface modification techniques using zwitterionic polymers have significantly improved fouling resistance in challenging environments.

Current performance goals for RO membranes in high-pressure, high-TDS applications focus on several critical parameters. Mechanical integrity under pressures exceeding 1,200 psi remains paramount, requiring membranes to withstand these conditions without compaction or deformation that would compromise performance. Salt rejection targets now exceed 99.8% for seawater applications, with particular emphasis on boron rejection for specialized industrial uses.

Energy efficiency represents another crucial performance metric, with manufacturers striving to develop membranes requiring less than 2 kWh/m³ for seawater desalination. This goal necessitates optimizing the permeability-selectivity trade-off that has traditionally limited membrane performance.

Longevity under extreme conditions has become increasingly important, with performance goals now targeting 5+ years of operational life even in high-fouling environments. This requires enhanced chemical stability across broader pH ranges (2-12) and improved chlorine tolerance to withstand cleaning regimens necessary in high-TDS operations.

The industry trajectory points toward "smart membranes" incorporating real-time monitoring capabilities and self-healing properties to maintain integrity during prolonged exposure to challenging operating conditions. These innovations aim to address the persistent challenges of membrane degradation in high-pressure, high-TDS environments.

The 1970s marked a pivotal advancement with the introduction of thin-film composite (TFC) polyamide membranes, dramatically improving salt rejection to 95-99% while reducing operating pressures. This innovation established the fundamental architecture still dominant today: a thin polyamide active layer (0.1-0.2 μm) supported by a porous polysulfone layer atop a non-woven fabric substrate.

The 1990s witnessed further refinements focusing on membrane surface chemistry modifications to enhance fouling resistance and chlorine tolerance. Manufacturers began developing specialized membranes for specific applications, including brackish water, seawater, and wastewater reclamation, each optimized for particular feed water characteristics.

Recent technological advancements have concentrated on addressing the challenges of high-pressure, high-TDS operations. Modern RO membranes incorporate nanomaterial technologies, including graphene oxide and carbon nanotubes, to improve mechanical strength while maintaining or enhancing permeability. Surface modification techniques using zwitterionic polymers have significantly improved fouling resistance in challenging environments.

Current performance goals for RO membranes in high-pressure, high-TDS applications focus on several critical parameters. Mechanical integrity under pressures exceeding 1,200 psi remains paramount, requiring membranes to withstand these conditions without compaction or deformation that would compromise performance. Salt rejection targets now exceed 99.8% for seawater applications, with particular emphasis on boron rejection for specialized industrial uses.

Energy efficiency represents another crucial performance metric, with manufacturers striving to develop membranes requiring less than 2 kWh/m³ for seawater desalination. This goal necessitates optimizing the permeability-selectivity trade-off that has traditionally limited membrane performance.

Longevity under extreme conditions has become increasingly important, with performance goals now targeting 5+ years of operational life even in high-fouling environments. This requires enhanced chemical stability across broader pH ranges (2-12) and improved chlorine tolerance to withstand cleaning regimens necessary in high-TDS operations.

The industry trajectory points toward "smart membranes" incorporating real-time monitoring capabilities and self-healing properties to maintain integrity during prolonged exposure to challenging operating conditions. These innovations aim to address the persistent challenges of membrane degradation in high-pressure, high-TDS environments.

Market Demand Analysis for High-Pressure RO Applications

The global market for high-pressure reverse osmosis (RO) applications continues to expand rapidly, driven by increasing water scarcity and growing industrial demands for advanced water treatment solutions. Current market valuations indicate that the high-pressure RO membrane sector represents approximately 40% of the overall membrane market, with annual growth rates consistently exceeding 8% over the past five years.

Water scarcity affects more than 2.8 billion people worldwide for at least one month each year, creating urgent demand for desalination technologies that can effectively treat high-TDS (Total Dissolved Solids) water sources. The seawater desalination market, which heavily relies on high-pressure RO systems, has seen compound annual growth rates of 9-10% since 2018, with particularly strong expansion in the Middle East, North Africa, and Asia-Pacific regions.

Industrial applications represent another significant market segment, with oil and gas, mining, and power generation industries increasingly adopting high-pressure RO systems for wastewater treatment and water recovery. These industries generate highly concentrated waste streams with TDS levels often exceeding 50,000 mg/L, requiring specialized membrane solutions that can maintain integrity under extreme operating conditions.

Municipal water authorities in water-stressed regions are increasingly investing in large-scale desalination projects, with over 120 major facilities commissioned globally in the past decade. This trend is expected to continue as climate change exacerbates water scarcity issues, with projections suggesting that desalination capacity will double by 2030 compared to 2020 levels.

The economic drivers for high-pressure RO applications extend beyond mere water production. Energy efficiency improvements in membrane technology have reduced operational costs by approximately 30% over the past decade, making these systems increasingly competitive with conventional water treatment methods. Additionally, regulatory pressures regarding industrial discharge and water reuse are creating new market opportunities for high-recovery RO systems.

Customer requirements in this market segment emphasize membrane durability, fouling resistance, and operational longevity under high-pressure conditions. End users report that membrane replacement costs can represent up to 30% of total operational expenses in high-pressure applications, creating strong demand for membranes that can maintain integrity over extended service periods while operating at pressures exceeding 80 bar.

Market research indicates that customers are willing to pay premium prices for membranes demonstrating superior performance in high-TDS environments, with particular emphasis on salt rejection rates above 99.7% and operational lifespans exceeding three years under challenging conditions.

Water scarcity affects more than 2.8 billion people worldwide for at least one month each year, creating urgent demand for desalination technologies that can effectively treat high-TDS (Total Dissolved Solids) water sources. The seawater desalination market, which heavily relies on high-pressure RO systems, has seen compound annual growth rates of 9-10% since 2018, with particularly strong expansion in the Middle East, North Africa, and Asia-Pacific regions.

Industrial applications represent another significant market segment, with oil and gas, mining, and power generation industries increasingly adopting high-pressure RO systems for wastewater treatment and water recovery. These industries generate highly concentrated waste streams with TDS levels often exceeding 50,000 mg/L, requiring specialized membrane solutions that can maintain integrity under extreme operating conditions.

Municipal water authorities in water-stressed regions are increasingly investing in large-scale desalination projects, with over 120 major facilities commissioned globally in the past decade. This trend is expected to continue as climate change exacerbates water scarcity issues, with projections suggesting that desalination capacity will double by 2030 compared to 2020 levels.

The economic drivers for high-pressure RO applications extend beyond mere water production. Energy efficiency improvements in membrane technology have reduced operational costs by approximately 30% over the past decade, making these systems increasingly competitive with conventional water treatment methods. Additionally, regulatory pressures regarding industrial discharge and water reuse are creating new market opportunities for high-recovery RO systems.

Customer requirements in this market segment emphasize membrane durability, fouling resistance, and operational longevity under high-pressure conditions. End users report that membrane replacement costs can represent up to 30% of total operational expenses in high-pressure applications, creating strong demand for membranes that can maintain integrity over extended service periods while operating at pressures exceeding 80 bar.

Market research indicates that customers are willing to pay premium prices for membranes demonstrating superior performance in high-TDS environments, with particular emphasis on salt rejection rates above 99.7% and operational lifespans exceeding three years under challenging conditions.

Current Challenges in High-TDS RO Membrane Operations

Reverse Osmosis (RO) membrane systems operating in high-TDS (Total Dissolved Solids) environments face significant challenges that can compromise membrane integrity and system performance. The primary challenge stems from the inherent pressure requirements, where high-TDS waters necessitate operating pressures of 800-1200 psi or higher to overcome osmotic pressure barriers. These extreme pressures place substantial mechanical stress on membrane structures, leading to compaction, deformation, and potential failure points at seals and interconnections.

Membrane fouling represents another critical challenge, particularly accelerated in high-TDS operations. Inorganic scaling occurs when concentrated salts exceed solubility limits and precipitate onto membrane surfaces, with calcium carbonate, calcium sulfate, and silica being predominant culprits. This scaling not only reduces permeate flux but creates localized high-pressure zones that can damage membrane structures. Simultaneously, organic fouling from natural organic matter creates sticky biofilms that trap additional contaminants and microorganisms, further compromising membrane performance.

Concentration polarization presents a unique challenge in high-TDS applications, where rejected solutes accumulate at the membrane-solution interface, creating localized TDS concentrations significantly higher than the bulk solution. This phenomenon increases osmotic pressure at the membrane surface, requiring even higher operating pressures and accelerating scaling potential. The boundary layer formed becomes increasingly difficult to manage as TDS levels rise, creating a self-reinforcing cycle of declining performance.

Chemical degradation mechanisms pose long-term integrity threats in high-TDS environments. Oxidative damage from residual chlorine or other oxidants can attack the polyamide active layer of thin-film composite membranes, while hydrolysis reactions accelerate under high-pressure, high-temperature conditions often associated with high-TDS operations. Additionally, extreme pH fluctuations that may occur during cleaning cycles can permanently alter membrane chemistry and structure.

Temperature management presents significant operational challenges, as high-TDS applications often involve elevated temperatures that accelerate chemical reactions, increase diffusion rates, and alter solution properties. While higher temperatures can improve permeate flux, they simultaneously accelerate membrane degradation mechanisms and exacerbate scaling tendencies, creating a difficult operational balance.

Mechanical integrity issues become particularly pronounced in high-TDS applications. Telescoping (axial movement of membrane leaves within spiral-wound elements) occurs more frequently under high-pressure differentials, while pressure vessel failures and connector integrity become critical concerns. The repeated cycling between operating and cleaning conditions creates fatigue stresses that can lead to catastrophic failures if not properly managed through appropriate system design and operational protocols.

Membrane fouling represents another critical challenge, particularly accelerated in high-TDS operations. Inorganic scaling occurs when concentrated salts exceed solubility limits and precipitate onto membrane surfaces, with calcium carbonate, calcium sulfate, and silica being predominant culprits. This scaling not only reduces permeate flux but creates localized high-pressure zones that can damage membrane structures. Simultaneously, organic fouling from natural organic matter creates sticky biofilms that trap additional contaminants and microorganisms, further compromising membrane performance.

Concentration polarization presents a unique challenge in high-TDS applications, where rejected solutes accumulate at the membrane-solution interface, creating localized TDS concentrations significantly higher than the bulk solution. This phenomenon increases osmotic pressure at the membrane surface, requiring even higher operating pressures and accelerating scaling potential. The boundary layer formed becomes increasingly difficult to manage as TDS levels rise, creating a self-reinforcing cycle of declining performance.

Chemical degradation mechanisms pose long-term integrity threats in high-TDS environments. Oxidative damage from residual chlorine or other oxidants can attack the polyamide active layer of thin-film composite membranes, while hydrolysis reactions accelerate under high-pressure, high-temperature conditions often associated with high-TDS operations. Additionally, extreme pH fluctuations that may occur during cleaning cycles can permanently alter membrane chemistry and structure.

Temperature management presents significant operational challenges, as high-TDS applications often involve elevated temperatures that accelerate chemical reactions, increase diffusion rates, and alter solution properties. While higher temperatures can improve permeate flux, they simultaneously accelerate membrane degradation mechanisms and exacerbate scaling tendencies, creating a difficult operational balance.

Mechanical integrity issues become particularly pronounced in high-TDS applications. Telescoping (axial movement of membrane leaves within spiral-wound elements) occurs more frequently under high-pressure differentials, while pressure vessel failures and connector integrity become critical concerns. The repeated cycling between operating and cleaning conditions creates fatigue stresses that can lead to catastrophic failures if not properly managed through appropriate system design and operational protocols.

Current Engineering Solutions for Membrane Integrity Maintenance

01 Integrity testing methods for RO membranes

Various methods are employed to test the integrity of reverse osmosis (RO) membranes, ensuring they function properly without defects. These methods include pressure decay tests, bubble point tests, and conductivity measurements. These testing procedures help identify breaches, leaks, or imperfections in the membrane structure that could compromise filtration efficiency and water quality. Regular integrity testing is essential for maintaining optimal performance of RO systems in water treatment applications.- Integrity testing methods for RO membranes: Various methods are employed to test the integrity of reverse osmosis (RO) membranes to ensure their proper functioning and detect any defects. These methods include pressure decay tests, bubble point tests, and conductivity monitoring. These testing procedures help identify breaches in membrane integrity that could compromise filtration efficiency and water quality. Regular integrity testing is essential for maintaining the performance of RO systems in water treatment applications.

- Membrane protection and damage prevention systems: Systems designed to protect RO membranes from damage and maintain their integrity over time. These include pre-filtration systems, anti-scaling treatments, and physical protection mechanisms that prevent membrane fouling and mechanical damage. Protective housings and support structures help maintain membrane integrity under operational pressure conditions. These preventive measures significantly extend membrane lifespan and maintain filtration efficiency.

- Monitoring and detection systems for membrane integrity: Advanced monitoring systems that continuously assess RO membrane integrity during operation. These systems utilize sensors, real-time data analysis, and automated detection algorithms to identify integrity breaches before they cause system failure. Monitoring parameters include pressure differentials, flow rates, and permeate quality indicators. Early detection of integrity issues allows for timely intervention and prevents contamination of treated water.

- Membrane repair and restoration techniques: Methods and compositions for repairing damaged RO membranes to restore their integrity and extend their operational life. These techniques include in-situ repair procedures, application of sealants to small breaches, and regeneration treatments that remove fouling without compromising membrane structure. Restoration techniques can significantly reduce replacement costs and system downtime while maintaining water quality standards.

- Innovative membrane designs for enhanced integrity: Novel RO membrane designs and materials engineered specifically to improve integrity and resistance to damage. These innovations include reinforced membrane structures, composite materials with superior mechanical strength, and self-healing membrane technologies. Advanced manufacturing techniques produce membranes with fewer defects and greater durability under operational stress. These design improvements result in longer-lasting membranes with more consistent filtration performance.

02 Membrane protection and damage prevention systems

Systems designed to protect RO membranes from physical damage and extend their operational lifespan. These include specialized housing structures, pressure regulation mechanisms, and anti-fouling technologies that prevent membrane degradation. Protective systems often incorporate sensors that monitor operating conditions and automatically adjust parameters to prevent damage from pressure spikes, chemical exposure, or mechanical stress. These preventive measures significantly reduce membrane replacement frequency and maintenance costs.Expand Specific Solutions03 Monitoring and detection systems for membrane integrity

Advanced monitoring systems that continuously assess RO membrane integrity during operation. These systems utilize sensors, real-time data analysis, and automated detection algorithms to identify potential integrity breaches before they cause system failure. Monitoring technologies include conductivity sensors, particle counters, and pressure differential measurements that can detect microscopic membrane defects. Early detection capabilities allow for timely intervention, preventing contamination events and ensuring consistent water quality.Expand Specific Solutions04 Membrane repair and restoration techniques

Methods and compositions for repairing damaged RO membranes to restore their integrity and performance. These techniques include application of sealants, patching materials, and regenerative treatments that can address minor defects without requiring complete membrane replacement. Some repair approaches involve chemical treatments that can heal small breaches or restore membrane surface properties. These restoration methods extend membrane service life and reduce operational costs in water treatment facilities.Expand Specific Solutions05 Structural innovations for enhanced membrane integrity

Novel structural designs and material compositions that inherently improve RO membrane integrity. These innovations include reinforced membrane structures, composite materials with superior mechanical strength, and advanced manufacturing techniques that minimize defect formation. Some designs incorporate self-healing capabilities or multiple barrier layers that maintain integrity even when one layer is compromised. These structural improvements result in membranes with greater durability, longer service life, and more consistent filtration performance under challenging operating conditions.Expand Specific Solutions

Leading Manufacturers and Research Institutions in RO Technology

The reverse osmosis (RO) membrane integrity market in high-pressure, high-TDS operations is currently in a growth phase, with an estimated global market size exceeding $2 billion annually. The technology maturity varies across applications, with seawater desalination being more established than industrial wastewater treatment. Leading players include Gradiant Corp., which has pioneered innovative membrane technologies for extreme conditions, and Sinopec, which has developed specialized RO membranes for petrochemical applications. Hunan Qinsen High-Tech has emerged as a significant manufacturer with high-pressure membrane solutions, while IBM and Fraunhofer-Gesellschaft are advancing computational modeling for membrane integrity prediction. University research partnerships, particularly with National University of Singapore and Indian Institute of Science, are driving next-generation membrane materials designed specifically for high-TDS environments.

China Petroleum & Chemical Corp.

Technical Solution: China Petroleum & Chemical Corp. (Sinopec) has developed proprietary RO membrane technology specifically for oil and gas produced water treatment with extremely high TDS levels (up to 70,000 mg/L). Their approach combines specialized pre-treatment systems with modified polyamide thin-film composite membranes featuring enhanced chlorine resistance and mechanical stability. The membranes incorporate nano-silica reinforcement within the polymer matrix, increasing tensile strength by approximately 40% while maintaining permeability. Sinopec's pressure vessel design includes innovative spacer technology that creates controlled turbulence patterns to minimize concentration polarization while distributing pressure loads evenly across the membrane surface. Their integrated system also employs proprietary antiscalant formulations specifically designed for high-calcium, high-silica waters typical in petroleum operations.

Strengths: Exceptional durability in hydrocarbon-contaminated waters, specialized for oilfield applications, and proven performance in extreme TDS environments. Weaknesses: Higher energy consumption compared to standard RO systems and limited application outside petroleum industry contexts.

Gradiant Corp.

Technical Solution: Gradiant has developed Counter-Flow Reverse Osmosis (CFRO) technology specifically designed for high-pressure, high-TDS operations. Their system employs a unique recirculation mechanism that equalizes osmotic pressure across the membrane surface, allowing operation at significantly higher recovery rates (up to 98%) compared to conventional RO systems. The technology incorporates specialized pressure vessels with internal flow distributors that minimize concentration polarization and scaling, while their proprietary membrane cleaning protocols use targeted chemical formulations to remove specific foulants without compromising membrane integrity. Gradiant's systems also feature real-time monitoring with AI-based predictive analytics that detect early signs of membrane degradation, allowing for preventive maintenance before catastrophic failure occurs.

Strengths: Superior recovery rates in high-TDS environments, reduced energy consumption, and extended membrane life through advanced fouling control. Weaknesses: Higher initial capital costs compared to conventional systems and requires specialized technical expertise for operation and maintenance.

Key Innovations in High-Pressure RO Membrane Materials

Hybrid desalination system

PatentWO2013033841A1

Innovation

- A hybrid desalination system combining reverse osmosis and nanofiltration with an evaporator/distiller unit, powered by renewable energy, to treat contaminated water streams, reducing reject brine volumes and energy consumption, and incorporating energy recovery and pre-treatment processes to enhance membrane efficiency and extend their lifespan.

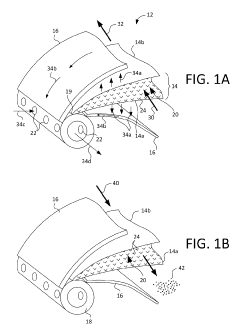

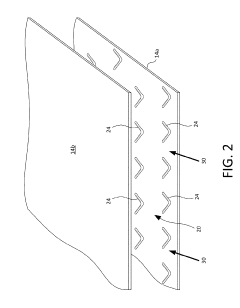

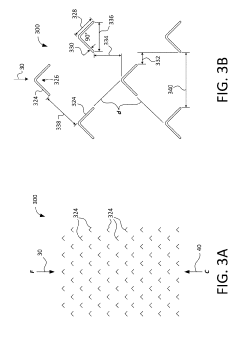

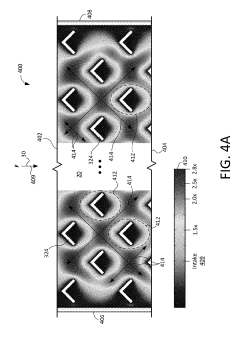

Filter Membrane with Bi-Directional Flow Enhancing Features

PatentActiveUS20190151799A1

Innovation

- The integration of raised features directly on the membrane surface, optimized for both filtration and cleaning directions, creates a feed channel that enhances fluid flow, turbulence, and scouring, eliminating the need for chemical cleaning by using reverse water flow for maintenance.

Environmental Impact and Sustainability of Advanced RO Systems

The environmental footprint of reverse osmosis (RO) systems operating under high-pressure and high-TDS conditions extends far beyond their immediate operational parameters. Advanced RO membrane technologies designed for these challenging environments have demonstrated significant improvements in sustainability metrics compared to conventional treatment methods.

Energy consumption remains a critical environmental consideration, as high-pressure operations typically demand substantial power inputs. However, modern high-integrity membrane systems incorporate energy recovery devices that can recapture up to 60% of the pressure energy, substantially reducing the carbon footprint associated with these operations. This advancement has transformed RO from an energy-intensive process to a more sustainable option for treating high-TDS waters.

Brine management presents another significant environmental challenge. High-TDS operations generate concentrated waste streams that can disrupt marine ecosystems when discharged improperly. Leading-edge RO systems now implement zero liquid discharge (ZLD) approaches, crystallizing salts for beneficial reuse and minimizing environmental discharge. These closed-loop systems represent a paradigm shift in how high-pressure RO operations interact with surrounding ecosystems.

Chemical usage in membrane cleaning and pretreatment has traditionally posed environmental concerns. Next-generation high-integrity membranes feature biofouling-resistant surface modifications that reduce cleaning frequency and chemical requirements by up to 40%. Additionally, green chemistry approaches have yielded biodegradable antiscalants and cleaning compounds specifically formulated for high-TDS applications, further reducing environmental impact.

The lifecycle assessment of advanced RO membranes reveals significant sustainability improvements. Modern high-pressure membranes demonstrate extended operational lifespans of 5-7 years compared to the 2-3 years typical of earlier generations, substantially reducing waste generation and replacement frequency. Furthermore, emerging membrane recycling programs can recover up to 90% of membrane materials for reuse, addressing end-of-life concerns.

Water recovery rates in high-TDS operations have improved dramatically with advanced membrane technologies, now achieving 85-90% recovery in applications where previous systems managed only 60-70%. This efficiency gain translates directly to reduced freshwater withdrawal requirements and smaller environmental footprints per unit of treated water.

Carbon emissions associated with high-pressure RO operations have decreased by approximately 30% over the past decade through combined improvements in membrane performance, energy efficiency, and system design. This progress positions advanced RO systems as increasingly viable components of sustainable water management strategies, even when operating under the most challenging high-TDS conditions.

Energy consumption remains a critical environmental consideration, as high-pressure operations typically demand substantial power inputs. However, modern high-integrity membrane systems incorporate energy recovery devices that can recapture up to 60% of the pressure energy, substantially reducing the carbon footprint associated with these operations. This advancement has transformed RO from an energy-intensive process to a more sustainable option for treating high-TDS waters.

Brine management presents another significant environmental challenge. High-TDS operations generate concentrated waste streams that can disrupt marine ecosystems when discharged improperly. Leading-edge RO systems now implement zero liquid discharge (ZLD) approaches, crystallizing salts for beneficial reuse and minimizing environmental discharge. These closed-loop systems represent a paradigm shift in how high-pressure RO operations interact with surrounding ecosystems.

Chemical usage in membrane cleaning and pretreatment has traditionally posed environmental concerns. Next-generation high-integrity membranes feature biofouling-resistant surface modifications that reduce cleaning frequency and chemical requirements by up to 40%. Additionally, green chemistry approaches have yielded biodegradable antiscalants and cleaning compounds specifically formulated for high-TDS applications, further reducing environmental impact.

The lifecycle assessment of advanced RO membranes reveals significant sustainability improvements. Modern high-pressure membranes demonstrate extended operational lifespans of 5-7 years compared to the 2-3 years typical of earlier generations, substantially reducing waste generation and replacement frequency. Furthermore, emerging membrane recycling programs can recover up to 90% of membrane materials for reuse, addressing end-of-life concerns.

Water recovery rates in high-TDS operations have improved dramatically with advanced membrane technologies, now achieving 85-90% recovery in applications where previous systems managed only 60-70%. This efficiency gain translates directly to reduced freshwater withdrawal requirements and smaller environmental footprints per unit of treated water.

Carbon emissions associated with high-pressure RO operations have decreased by approximately 30% over the past decade through combined improvements in membrane performance, energy efficiency, and system design. This progress positions advanced RO systems as increasingly viable components of sustainable water management strategies, even when operating under the most challenging high-TDS conditions.

Economic Feasibility and ROI Analysis of High-Integrity Membranes

The economic viability of implementing high-integrity RO membranes in high-pressure, high-TDS operations represents a critical consideration for water treatment facilities and industrial applications. Initial investment costs for advanced membrane technologies typically range from $500,000 to $3 million, depending on system capacity and specific operational requirements.

These premium membrane solutions demonstrate extended operational lifespans of 3-5 years compared to conventional membranes' 1-2 years when operating under extreme conditions. This longevity translates to reduced replacement frequency and associated labor costs, contributing significantly to long-term economic benefits.

Operational expenditure analysis reveals that high-integrity membranes can reduce energy consumption by 15-20% through improved permeability and fouling resistance. In high-TDS environments, this energy efficiency becomes particularly valuable, as pumping requirements constitute 30-40% of total operational costs.

Maintenance cost reductions present another substantial economic advantage. Advanced membrane systems require cleaning cycles at approximately half the frequency of standard membranes, reducing chemical usage by 30-45% annually. Facilities implementing these technologies report maintenance labor reductions of 25-35%, allowing for reallocation of technical resources.

Return on investment calculations indicate payback periods ranging from 14 to 24 months for most industrial applications. Desalination plants processing over 10,000 m³/day typically achieve ROI breakpoints at the lower end of this spectrum due to economies of scale and higher operational intensity.

Risk assessment factors must be incorporated into economic feasibility studies. While high-integrity membranes reduce the probability of catastrophic failure by 60-70%, the financial implications of even brief system downtime can range from $5,000 to $50,000 per day depending on the application. This risk mitigation value significantly enhances the economic case for premium membrane solutions.

Comparative lifecycle cost analysis demonstrates that despite 30-50% higher initial acquisition costs, high-integrity membranes deliver 20-35% lower total ownership costs over a 10-year operational period. This calculation incorporates all direct expenses including energy, maintenance, replacement, and downtime costs.

Emerging financing models, including performance-based contracts and equipment leasing options, are increasingly available to mitigate initial capital requirements. These arrangements allow facilities to realize immediate operational savings while distributing acquisition costs over extended timeframes, further enhancing economic feasibility for budget-constrained operations.

These premium membrane solutions demonstrate extended operational lifespans of 3-5 years compared to conventional membranes' 1-2 years when operating under extreme conditions. This longevity translates to reduced replacement frequency and associated labor costs, contributing significantly to long-term economic benefits.

Operational expenditure analysis reveals that high-integrity membranes can reduce energy consumption by 15-20% through improved permeability and fouling resistance. In high-TDS environments, this energy efficiency becomes particularly valuable, as pumping requirements constitute 30-40% of total operational costs.

Maintenance cost reductions present another substantial economic advantage. Advanced membrane systems require cleaning cycles at approximately half the frequency of standard membranes, reducing chemical usage by 30-45% annually. Facilities implementing these technologies report maintenance labor reductions of 25-35%, allowing for reallocation of technical resources.

Return on investment calculations indicate payback periods ranging from 14 to 24 months for most industrial applications. Desalination plants processing over 10,000 m³/day typically achieve ROI breakpoints at the lower end of this spectrum due to economies of scale and higher operational intensity.

Risk assessment factors must be incorporated into economic feasibility studies. While high-integrity membranes reduce the probability of catastrophic failure by 60-70%, the financial implications of even brief system downtime can range from $5,000 to $50,000 per day depending on the application. This risk mitigation value significantly enhances the economic case for premium membrane solutions.

Comparative lifecycle cost analysis demonstrates that despite 30-50% higher initial acquisition costs, high-integrity membranes deliver 20-35% lower total ownership costs over a 10-year operational period. This calculation incorporates all direct expenses including energy, maintenance, replacement, and downtime costs.

Emerging financing models, including performance-based contracts and equipment leasing options, are increasingly available to mitigate initial capital requirements. These arrangements allow facilities to realize immediate operational savings while distributing acquisition costs over extended timeframes, further enhancing economic feasibility for budget-constrained operations.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!