RO Membrane Integrity: Pressure Decay, Marker Tests And QA

SEP 22, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

RO Membrane Technology Background and Objectives

Reverse Osmosis (RO) membrane technology has evolved significantly since its inception in the 1950s, transforming from a laboratory curiosity to a cornerstone of modern water purification systems. Initially developed for desalination purposes, RO membranes utilize a semi-permeable barrier that allows water molecules to pass through while rejecting dissolved salts and other contaminants. This fundamental principle has remained unchanged, though the materials, configurations, and performance metrics have undergone substantial improvements over decades.

The global water crisis has accelerated the adoption and advancement of RO technology, with increasing demands for clean water in industrial, municipal, and residential applications. Market projections indicate that the RO membrane market will continue its robust growth trajectory, expected to reach $5.8 billion by 2025, with a compound annual growth rate of approximately 7.9%.

Membrane integrity represents a critical aspect of RO system performance and reliability. The effectiveness of an RO system fundamentally depends on the membrane's ability to maintain its selective barrier properties throughout its operational lifetime. Compromised membrane integrity can lead to contaminant breakthrough, reduced rejection rates, and ultimately system failure, potentially resulting in significant economic losses or health risks in sensitive applications.

Current technological objectives in RO membrane integrity focus on developing more reliable, sensitive, and cost-effective monitoring methods. Pressure decay testing has emerged as a non-destructive technique to detect breaches in membrane integrity by measuring the rate of pressure loss in a pressurized system. Similarly, marker tests using chemical or biological indicators provide valuable data on membrane performance under actual operating conditions.

Quality assurance (QA) protocols for RO membranes have become increasingly sophisticated, incorporating automated monitoring systems, predictive analytics, and standardized testing procedures. These advancements aim to ensure consistent membrane performance, extend operational lifetimes, and reduce the frequency of unexpected failures.

The technological trajectory points toward integrated monitoring systems that combine real-time integrity testing with advanced analytics, allowing for predictive maintenance rather than reactive replacement. Research efforts are increasingly focused on developing non-invasive monitoring techniques that can detect membrane degradation before it reaches critical failure points, thereby optimizing system performance and reducing operational costs.

As water scarcity intensifies globally and regulatory standards become more stringent, the importance of reliable membrane integrity testing and quality assurance will continue to grow, driving innovation in this critical aspect of RO technology.

The global water crisis has accelerated the adoption and advancement of RO technology, with increasing demands for clean water in industrial, municipal, and residential applications. Market projections indicate that the RO membrane market will continue its robust growth trajectory, expected to reach $5.8 billion by 2025, with a compound annual growth rate of approximately 7.9%.

Membrane integrity represents a critical aspect of RO system performance and reliability. The effectiveness of an RO system fundamentally depends on the membrane's ability to maintain its selective barrier properties throughout its operational lifetime. Compromised membrane integrity can lead to contaminant breakthrough, reduced rejection rates, and ultimately system failure, potentially resulting in significant economic losses or health risks in sensitive applications.

Current technological objectives in RO membrane integrity focus on developing more reliable, sensitive, and cost-effective monitoring methods. Pressure decay testing has emerged as a non-destructive technique to detect breaches in membrane integrity by measuring the rate of pressure loss in a pressurized system. Similarly, marker tests using chemical or biological indicators provide valuable data on membrane performance under actual operating conditions.

Quality assurance (QA) protocols for RO membranes have become increasingly sophisticated, incorporating automated monitoring systems, predictive analytics, and standardized testing procedures. These advancements aim to ensure consistent membrane performance, extend operational lifetimes, and reduce the frequency of unexpected failures.

The technological trajectory points toward integrated monitoring systems that combine real-time integrity testing with advanced analytics, allowing for predictive maintenance rather than reactive replacement. Research efforts are increasingly focused on developing non-invasive monitoring techniques that can detect membrane degradation before it reaches critical failure points, thereby optimizing system performance and reducing operational costs.

As water scarcity intensifies globally and regulatory standards become more stringent, the importance of reliable membrane integrity testing and quality assurance will continue to grow, driving innovation in this critical aspect of RO technology.

Market Demand for Reliable RO Membrane Integrity Testing

The global market for reverse osmosis (RO) membrane integrity testing solutions has experienced significant growth in recent years, driven primarily by increasing water scarcity concerns and stringent regulatory requirements for water quality. The demand for reliable RO membrane integrity testing methods has surged across various industries including municipal water treatment, pharmaceuticals, food and beverage, and semiconductor manufacturing.

Water treatment facilities worldwide are facing mounting pressure to ensure consistent water quality while optimizing operational costs. This has created a substantial market for advanced integrity testing solutions that can detect membrane failures before they compromise system performance. According to recent market analyses, the global water treatment membrane market is projected to grow at a compound annual growth rate of 10.8% through 2028, with integrity testing equipment and services representing a critical segment within this expansion.

The pharmaceutical and biotechnology sectors have emerged as particularly strong drivers of demand for membrane integrity testing. These industries require ultra-pure water for production processes and face strict regulatory compliance requirements. Any compromise in membrane integrity can lead to contamination issues with potentially severe consequences, including product recalls and regulatory penalties.

Municipal water treatment plants represent another significant market segment, especially in regions implementing advanced water reuse and desalination projects. As these facilities increasingly adopt RO technology for drinking water production, the need for reliable integrity monitoring has become paramount to ensure public health protection and regulatory compliance.

Geographically, North America and Europe currently dominate the market for membrane integrity testing solutions, primarily due to well-established regulatory frameworks and higher adoption rates of advanced water treatment technologies. However, the Asia-Pacific region is witnessing the fastest growth, driven by rapid industrialization, increasing water stress, and growing investments in water infrastructure development.

The market is also being shaped by evolving end-user preferences for automated, continuous monitoring systems rather than manual, periodic testing approaches. This shift reflects the industry's focus on minimizing downtime, reducing labor costs, and preventing catastrophic failures through early detection of membrane integrity issues.

Cost considerations remain a significant factor influencing market dynamics. While large municipal and industrial operations can justify investments in sophisticated integrity testing systems, smaller facilities often seek more affordable solutions that still provide reliable performance data. This has created market opportunities for tiered product offerings catering to different budget constraints and operational requirements.

Water treatment facilities worldwide are facing mounting pressure to ensure consistent water quality while optimizing operational costs. This has created a substantial market for advanced integrity testing solutions that can detect membrane failures before they compromise system performance. According to recent market analyses, the global water treatment membrane market is projected to grow at a compound annual growth rate of 10.8% through 2028, with integrity testing equipment and services representing a critical segment within this expansion.

The pharmaceutical and biotechnology sectors have emerged as particularly strong drivers of demand for membrane integrity testing. These industries require ultra-pure water for production processes and face strict regulatory compliance requirements. Any compromise in membrane integrity can lead to contamination issues with potentially severe consequences, including product recalls and regulatory penalties.

Municipal water treatment plants represent another significant market segment, especially in regions implementing advanced water reuse and desalination projects. As these facilities increasingly adopt RO technology for drinking water production, the need for reliable integrity monitoring has become paramount to ensure public health protection and regulatory compliance.

Geographically, North America and Europe currently dominate the market for membrane integrity testing solutions, primarily due to well-established regulatory frameworks and higher adoption rates of advanced water treatment technologies. However, the Asia-Pacific region is witnessing the fastest growth, driven by rapid industrialization, increasing water stress, and growing investments in water infrastructure development.

The market is also being shaped by evolving end-user preferences for automated, continuous monitoring systems rather than manual, periodic testing approaches. This shift reflects the industry's focus on minimizing downtime, reducing labor costs, and preventing catastrophic failures through early detection of membrane integrity issues.

Cost considerations remain a significant factor influencing market dynamics. While large municipal and industrial operations can justify investments in sophisticated integrity testing systems, smaller facilities often seek more affordable solutions that still provide reliable performance data. This has created market opportunities for tiered product offerings catering to different budget constraints and operational requirements.

Current Challenges in RO Membrane Integrity Verification

Despite significant advancements in reverse osmosis (RO) membrane technology, the industry continues to face substantial challenges in ensuring membrane integrity verification. Current verification methods such as pressure decay tests, marker tests, and quality assurance protocols each present unique limitations that impede reliable performance assessment and quality control.

Pressure decay testing, while widely adopted, suffers from sensitivity issues when detecting minor defects in large-scale systems. The test's effectiveness diminishes proportionally with system size, creating a significant blind spot for industrial-scale operations. Additionally, pressure decay tests often fail to differentiate between membrane defects and seal leaks, leading to ambiguous results that complicate troubleshooting efforts.

Marker tests, including dye tests and particle counting methods, face challenges related to detection limits and environmental concerns. Many marker compounds lack sufficient sensitivity to identify nanoscale defects that can still compromise system performance. Furthermore, certain dyes and markers raise environmental and regulatory concerns, particularly in applications involving potable water or pharmaceutical production.

The standardization gap presents another critical challenge. Despite widespread implementation, the industry lacks universally accepted protocols for conducting integrity tests, resulting in inconsistent methodologies and incomparable results across different facilities and manufacturers. This absence of standardization complicates quality benchmarking and technology comparison.

Real-time monitoring capabilities remain underdeveloped, with most integrity verification methods requiring system shutdown for testing. This operational disruption creates significant economic impacts, especially in continuous process industries where downtime directly translates to production losses. The inability to detect membrane failures during operation increases contamination risks and reduces overall system reliability.

Automation integration challenges further complicate integrity verification. Many current testing methods require manual intervention and interpretation, introducing human error potential and limiting testing frequency. The industry has yet to develop fully automated, integrated testing systems that can provide continuous integrity monitoring without human oversight.

Cost-effectiveness remains a significant barrier, particularly for smaller operations. Sophisticated integrity testing equipment often requires substantial capital investment and specialized training, creating accessibility issues for small and medium-sized enterprises. This economic barrier results in suboptimal testing practices that may compromise product quality and regulatory compliance.

Pressure decay testing, while widely adopted, suffers from sensitivity issues when detecting minor defects in large-scale systems. The test's effectiveness diminishes proportionally with system size, creating a significant blind spot for industrial-scale operations. Additionally, pressure decay tests often fail to differentiate between membrane defects and seal leaks, leading to ambiguous results that complicate troubleshooting efforts.

Marker tests, including dye tests and particle counting methods, face challenges related to detection limits and environmental concerns. Many marker compounds lack sufficient sensitivity to identify nanoscale defects that can still compromise system performance. Furthermore, certain dyes and markers raise environmental and regulatory concerns, particularly in applications involving potable water or pharmaceutical production.

The standardization gap presents another critical challenge. Despite widespread implementation, the industry lacks universally accepted protocols for conducting integrity tests, resulting in inconsistent methodologies and incomparable results across different facilities and manufacturers. This absence of standardization complicates quality benchmarking and technology comparison.

Real-time monitoring capabilities remain underdeveloped, with most integrity verification methods requiring system shutdown for testing. This operational disruption creates significant economic impacts, especially in continuous process industries where downtime directly translates to production losses. The inability to detect membrane failures during operation increases contamination risks and reduces overall system reliability.

Automation integration challenges further complicate integrity verification. Many current testing methods require manual intervention and interpretation, introducing human error potential and limiting testing frequency. The industry has yet to develop fully automated, integrated testing systems that can provide continuous integrity monitoring without human oversight.

Cost-effectiveness remains a significant barrier, particularly for smaller operations. Sophisticated integrity testing equipment often requires substantial capital investment and specialized training, creating accessibility issues for small and medium-sized enterprises. This economic barrier results in suboptimal testing practices that may compromise product quality and regulatory compliance.

Pressure Decay and Marker Test Implementation Strategies

01 Integrity testing methods for RO membranes

Various methods are employed to test the integrity of reverse osmosis (RO) membranes to ensure their proper functioning and detect any defects or damages. These methods include pressure decay tests, bubble point tests, and conductivity measurements. Regular integrity testing helps maintain the efficiency of water treatment systems and prevents contamination by identifying membrane breaches before they cause system failures.- Integrity testing methods for RO membranes: Various methods are employed to test the integrity of reverse osmosis (RO) membranes to ensure their proper functioning and detect any defects. These methods include pressure decay tests, bubble point tests, and conductivity measurements. Regular integrity testing helps maintain the efficiency of water treatment systems by identifying membrane breaches or damages before they lead to system failure or contamination.

- Membrane protection and anti-fouling technologies: Technologies designed to protect RO membranes from fouling and physical damage, thereby maintaining their integrity over time. These include pre-treatment systems, anti-scaling agents, and specialized coatings that prevent biological growth and mineral deposition on membrane surfaces. Such protective measures extend membrane lifespan and preserve separation efficiency by preventing the accumulation of contaminants that could compromise membrane integrity.

- Monitoring systems for continuous integrity assessment: Automated monitoring systems that continuously assess RO membrane integrity during operation. These systems utilize sensors, real-time data analysis, and alarm mechanisms to detect integrity breaches as they occur. Continuous monitoring allows for immediate response to integrity issues, preventing contamination of treated water and reducing downtime for maintenance or replacement.

- Structural reinforcement of RO membranes: Design innovations focused on enhancing the physical structure of RO membranes to improve their mechanical integrity and resistance to damage. These include composite materials, support layers, and specialized membrane configurations that distribute pressure more evenly across the membrane surface. Structurally reinforced membranes can withstand higher operating pressures and mechanical stresses without compromising their filtration capabilities.

- Repair and restoration techniques for compromised membranes: Methods and materials used to repair or restore RO membranes that have suffered integrity breaches. These techniques include specialized sealants, patching materials, and in-situ repair procedures that can address localized damage without requiring complete membrane replacement. Effective repair techniques extend membrane service life and reduce operational costs associated with frequent replacements due to integrity failures.

02 Membrane protection and damage prevention systems

Systems designed to protect RO membranes from physical damage and extend their operational lifespan. These include pre-filtration mechanisms, pressure regulation devices, and anti-scaling treatments that prevent membrane fouling. Protective housings and support structures are also implemented to shield membranes from mechanical stress during operation, thereby maintaining membrane integrity over longer periods.Expand Specific Solutions03 Monitoring and control systems for RO membrane integrity

Advanced monitoring systems that continuously assess RO membrane performance and integrity in real-time. These systems utilize sensors, automated controllers, and data analysis to detect changes in membrane performance that might indicate integrity issues. Early warning mechanisms alert operators to potential membrane failures, allowing for timely intervention before complete system breakdown occurs.Expand Specific Solutions04 Membrane cleaning and maintenance solutions

Specialized cleaning protocols and maintenance solutions designed to restore and preserve RO membrane integrity. These include chemical cleaning agents, backwashing techniques, and periodic maintenance procedures that remove fouling materials without damaging the membrane structure. Proper maintenance significantly extends membrane life and maintains optimal filtration performance.Expand Specific Solutions05 Innovative membrane materials and structures for enhanced integrity

Development of advanced materials and structural designs that improve the inherent integrity of RO membranes. These innovations include composite materials with higher mechanical strength, self-healing membrane technologies, and novel membrane configurations that distribute pressure more evenly. These advancements result in membranes with greater resistance to physical damage, chemical degradation, and biofouling.Expand Specific Solutions

Leading Manufacturers and Research Institutions in RO Technology

The RO membrane integrity market is currently in a growth phase, characterized by increasing demand for reliable quality assurance methods in water treatment applications. The global market size for membrane integrity testing is expanding steadily, driven by stringent regulatory requirements and growing adoption of reverse osmosis systems across industries. Technologically, pressure decay and marker tests represent mature methodologies, with companies like FilmTec Corp. (DuPont), Dow Global Technologies, and EMD Millipore leading innovation in this space. Emerging players such as Gradiant Corp. are introducing novel approaches, while established entities including Siemens Water Technologies and Degremont SA are integrating advanced QA protocols into comprehensive water treatment solutions. Academic institutions like Nanyang Technological University and University of Southern California are contributing significant research to enhance detection sensitivity and reliability of integrity testing methods.

Dow Global Technologies LLC

Technical Solution: Dow has developed comprehensive RO membrane integrity testing solutions that integrate both pressure decay and marker test methodologies. Their Direct Integrity Testing (DIT) protocol utilizes automated pressure decay testing with proprietary algorithms to detect breaches as small as 3 microns. The company's FILMTEC™ membrane technology incorporates built-in integrity monitoring systems that continuously evaluate membrane performance through differential pressure monitoring and conductivity measurements. Dow's approach combines real-time monitoring with predictive analytics to anticipate potential membrane failures before they occur. Their QA protocol includes multi-point verification using both air pressure decay tests and marker-based challenge tests with sensitive molecular tracers to validate membrane integrity across various operating conditions. The system automatically logs test data and generates compliance reports for regulatory requirements.

Strengths: Industry-leading detection sensitivity for micron-level breaches; integrated monitoring systems with predictive capabilities; comprehensive data management for regulatory compliance. Weaknesses: Higher implementation costs compared to basic systems; requires specialized training for operators; some solutions may be overengineered for smaller applications.

EMD Millipore Corp.

Technical Solution: EMD Millipore has developed the Integritest® system for RO membrane integrity verification, which represents one of the most sophisticated approaches in the industry. Their technology utilizes a combination of diffusive airflow measurements and pressure decay testing to provide comprehensive membrane evaluation. The system features automated test sequencing that can detect breaches down to 2-3 microns with high reliability. Their marker test methodology employs proprietary challenge organisms and particles that simulate potential contaminants while providing quantifiable results through laser particle counting and fluorescence detection. EMD Millipore's QA framework incorporates statistical process control with defined acceptance criteria based on extensive validation studies. Their integrity testing approach is particularly notable for its application in pharmaceutical water systems where regulatory compliance requirements are stringent. The company has also developed specialized software that integrates test data with production parameters to optimize membrane performance and lifespan.

Strengths: Pharmaceutical-grade validation protocols; highly automated testing procedures; excellent documentation capabilities for regulatory compliance. Weaknesses: Higher cost structure than basic testing systems; requires specialized technical expertise; system complexity can present maintenance challenges.

Critical Patents and Research in Membrane Integrity Testing

Reverse osmosis membrane

PatentInactiveJP2019166510A

Innovation

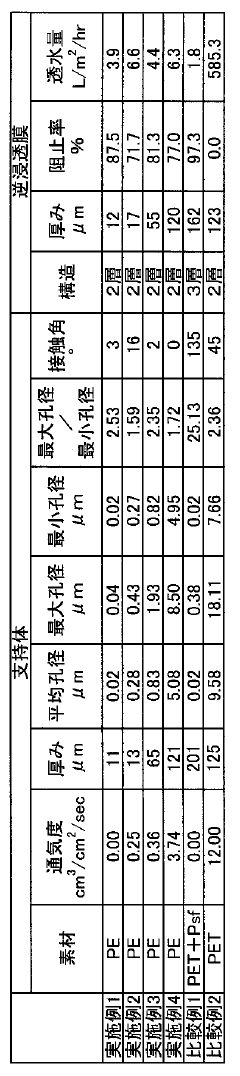

- A reverse osmosis membrane comprising a microporous polymer membrane support and a polyamide-based separation functional layer, utilizing ultra-high molecular weight polyethylene for the microporous polymer membrane and a crosslinked polyamide for the separation functional layer, optimized through interfacial polymerization.

Regulatory Standards for Water Treatment Membrane Systems

Regulatory standards for water treatment membrane systems have evolved significantly over the past decades, with increasing focus on ensuring public health protection through stringent quality control measures. The United States Environmental Protection Agency (EPA) has established comprehensive frameworks under the Safe Drinking Water Act (SDWA) that specifically address membrane integrity testing requirements, including pressure decay tests and marker-based verification methods.

The EPA's Long Term 2 Enhanced Surface Water Treatment Rule (LT2ESWTR) stands as a cornerstone regulation for membrane filtration systems, mandating direct integrity testing procedures to verify log removal values (LRV) for pathogen reduction. These standards require water treatment facilities to demonstrate a minimum 4-log removal of Cryptosporidium through membrane filtration processes, with regular integrity testing to ensure continued performance.

In Europe, the European Drinking Water Directive (98/83/EC, updated in 2020) has incorporated similar requirements, though with regional variations in implementation. The directive emphasizes a risk-based approach to water safety, requiring water suppliers to conduct regular integrity assessments of treatment barriers, including RO membrane systems.

For pharmaceutical and healthcare applications, more stringent standards apply. The United States Pharmacopeia (USP) and European Pharmacopoeia (Ph. Eur.) provide detailed specifications for water purification systems, including requirements for RO membrane integrity verification. These standards mandate more frequent testing protocols and lower tolerance thresholds for membrane breaches compared to municipal water treatment regulations.

International standards organizations have also contributed significantly to the regulatory landscape. ISO 22000 series standards address water safety management systems, while NSF/ANSI standards (particularly NSF/ANSI 61 and 58) provide certification requirements for membrane materials and systems used in drinking water applications. These standards specify acceptable testing methodologies for pressure decay tests and marker-based integrity verification.

Regulatory compliance documentation requirements have become increasingly sophisticated, with electronic record-keeping systems now standard in most jurisdictions. Modern regulations require water treatment facilities to maintain comprehensive testing logs, calibration records, and validation documentation for membrane integrity testing equipment and procedures.

Recent regulatory trends indicate movement toward real-time monitoring requirements, with continuous integrity verification systems gaining regulatory acceptance as alternatives to periodic direct testing. This shift reflects technological advancements in sensor technology and automation, allowing for more responsive quality assurance protocols while maintaining or enhancing public health protection.

The EPA's Long Term 2 Enhanced Surface Water Treatment Rule (LT2ESWTR) stands as a cornerstone regulation for membrane filtration systems, mandating direct integrity testing procedures to verify log removal values (LRV) for pathogen reduction. These standards require water treatment facilities to demonstrate a minimum 4-log removal of Cryptosporidium through membrane filtration processes, with regular integrity testing to ensure continued performance.

In Europe, the European Drinking Water Directive (98/83/EC, updated in 2020) has incorporated similar requirements, though with regional variations in implementation. The directive emphasizes a risk-based approach to water safety, requiring water suppliers to conduct regular integrity assessments of treatment barriers, including RO membrane systems.

For pharmaceutical and healthcare applications, more stringent standards apply. The United States Pharmacopeia (USP) and European Pharmacopoeia (Ph. Eur.) provide detailed specifications for water purification systems, including requirements for RO membrane integrity verification. These standards mandate more frequent testing protocols and lower tolerance thresholds for membrane breaches compared to municipal water treatment regulations.

International standards organizations have also contributed significantly to the regulatory landscape. ISO 22000 series standards address water safety management systems, while NSF/ANSI standards (particularly NSF/ANSI 61 and 58) provide certification requirements for membrane materials and systems used in drinking water applications. These standards specify acceptable testing methodologies for pressure decay tests and marker-based integrity verification.

Regulatory compliance documentation requirements have become increasingly sophisticated, with electronic record-keeping systems now standard in most jurisdictions. Modern regulations require water treatment facilities to maintain comprehensive testing logs, calibration records, and validation documentation for membrane integrity testing equipment and procedures.

Recent regulatory trends indicate movement toward real-time monitoring requirements, with continuous integrity verification systems gaining regulatory acceptance as alternatives to periodic direct testing. This shift reflects technological advancements in sensor technology and automation, allowing for more responsive quality assurance protocols while maintaining or enhancing public health protection.

Economic Impact of Membrane Failure Prevention

The economic implications of membrane failure in reverse osmosis (RO) systems extend far beyond the immediate replacement costs. When membrane integrity is compromised, organizations face cascading financial consequences that impact operational efficiency, product quality, and regulatory compliance. Industry data suggests that unplanned membrane replacements can cost facilities between $50,000 and $500,000 depending on system size, not including production losses during downtime.

Preventive integrity testing through pressure decay tests and marker methods delivers substantial return on investment by identifying potential failures before they occur. A comprehensive integrity monitoring program typically costs 2-5% of the total membrane system investment annually but can reduce emergency replacement incidents by up to 70% according to recent industry studies. This translates to significant savings, particularly in critical applications like pharmaceutical manufacturing where a single contamination event can result in batch losses exceeding millions of dollars.

The economic value of quality assurance in membrane systems becomes evident when examining total cost of ownership models. Facilities implementing rigorous integrity testing protocols report extended membrane lifespans of 20-30% beyond manufacturer specifications, representing considerable capital expenditure deferrals. Additionally, consistent monitoring enables optimization of cleaning cycles, reducing chemical usage by approximately 15% while maintaining performance parameters.

Energy consumption represents another major economic factor influenced by membrane integrity. Compromised membranes often require higher operating pressures to maintain production rates, increasing energy costs by 10-25%. Early detection of integrity issues through marker tests allows for targeted interventions that preserve optimal energy efficiency, particularly important as energy costs continue to rise globally.

For water treatment facilities serving municipalities, the economic stakes of membrane failure prevention are particularly high. A single boil water advisory resulting from membrane breach can cost communities between $100,000 and $1 million in emergency response measures, not including reputational damage and potential legal liabilities. Systematic integrity monitoring provides a form of economic insurance against such scenarios.

The business case for investment in advanced membrane integrity technologies strengthens as regulatory requirements become more stringent worldwide. Organizations implementing comprehensive QA programs for membrane systems report regulatory compliance cost reductions of approximately 30% through decreased sampling requirements and avoidance of violation penalties, which can reach seven figures in severe cases.

Preventive integrity testing through pressure decay tests and marker methods delivers substantial return on investment by identifying potential failures before they occur. A comprehensive integrity monitoring program typically costs 2-5% of the total membrane system investment annually but can reduce emergency replacement incidents by up to 70% according to recent industry studies. This translates to significant savings, particularly in critical applications like pharmaceutical manufacturing where a single contamination event can result in batch losses exceeding millions of dollars.

The economic value of quality assurance in membrane systems becomes evident when examining total cost of ownership models. Facilities implementing rigorous integrity testing protocols report extended membrane lifespans of 20-30% beyond manufacturer specifications, representing considerable capital expenditure deferrals. Additionally, consistent monitoring enables optimization of cleaning cycles, reducing chemical usage by approximately 15% while maintaining performance parameters.

Energy consumption represents another major economic factor influenced by membrane integrity. Compromised membranes often require higher operating pressures to maintain production rates, increasing energy costs by 10-25%. Early detection of integrity issues through marker tests allows for targeted interventions that preserve optimal energy efficiency, particularly important as energy costs continue to rise globally.

For water treatment facilities serving municipalities, the economic stakes of membrane failure prevention are particularly high. A single boil water advisory resulting from membrane breach can cost communities between $100,000 and $1 million in emergency response measures, not including reputational damage and potential legal liabilities. Systematic integrity monitoring provides a form of economic insurance against such scenarios.

The business case for investment in advanced membrane integrity technologies strengthens as regulatory requirements become more stringent worldwide. Organizations implementing comprehensive QA programs for membrane systems report regulatory compliance cost reductions of approximately 30% through decreased sampling requirements and avoidance of violation penalties, which can reach seven figures in severe cases.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!