RO Membrane Temperature Effects: Viscosity, Solubility And Rejection

SEP 22, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

RO Membrane Technology Background and Objectives

Reverse Osmosis (RO) membrane technology has evolved significantly since its inception in the 1950s, transforming from a laboratory curiosity into a cornerstone of modern water purification systems. Initially developed for desalination purposes, RO membranes utilize a semi-permeable barrier that allows water molecules to pass through while rejecting dissolved salts and other contaminants. This fundamental principle has remained unchanged, though the efficiency, durability, and application scope of RO membranes have expanded dramatically over decades of research and development.

Temperature effects on RO membrane performance represent a critical area of study that has gained increasing attention as these systems are deployed across diverse environmental conditions. The relationship between temperature and membrane performance is complex, involving multiple interrelated factors including water viscosity, solute solubility, and membrane material properties. Understanding these temperature-dependent mechanisms is essential for optimizing system design and operation across varying thermal conditions.

Water viscosity decreases significantly with increasing temperature, following an exponential relationship described by the Arrhenius equation. This reduction in viscosity directly impacts water flux through RO membranes, with higher temperatures generally resulting in increased permeate flow rates at constant pressure. Industry estimates suggest that water flux can increase by approximately 2-3% per degree Celsius rise in temperature, representing a substantial operational consideration.

Solubility dynamics also shift with temperature changes, affecting both the dissolution behavior of feed water constituents and their interaction with membrane surfaces. Most inorganic salts exhibit increased solubility at higher temperatures, potentially reducing scaling tendencies but simultaneously increasing the concentration gradient across the membrane. Organic compounds display more variable temperature-dependent solubility patterns, further complicating performance predictions in complex feed waters.

Rejection efficiency—the membrane's ability to prevent contaminant passage—demonstrates notable temperature sensitivity. Higher temperatures typically reduce rejection rates for most solutes due to increased diffusion coefficients and potential changes in membrane polymer structure. This phenomenon is particularly pronounced for neutral organic compounds and certain monovalent ions, while multivalent ion rejection often remains more stable across temperature ranges.

The primary technical objective in this field is to develop comprehensive models and membrane materials that maintain optimal performance across wide temperature ranges (typically 5-45°C) encountered in practical applications. This includes understanding the fundamental physicochemical mechanisms governing temperature effects, creating temperature-compensated design parameters for system engineering, and developing novel membrane materials with reduced temperature sensitivity.

Secondary objectives include establishing standardized testing protocols for evaluating temperature effects, improving energy efficiency through temperature optimization strategies, and extending membrane operational lifespans under variable temperature conditions. These goals align with broader industry trends toward more resilient, efficient water treatment technologies capable of addressing increasingly complex global water challenges.

Temperature effects on RO membrane performance represent a critical area of study that has gained increasing attention as these systems are deployed across diverse environmental conditions. The relationship between temperature and membrane performance is complex, involving multiple interrelated factors including water viscosity, solute solubility, and membrane material properties. Understanding these temperature-dependent mechanisms is essential for optimizing system design and operation across varying thermal conditions.

Water viscosity decreases significantly with increasing temperature, following an exponential relationship described by the Arrhenius equation. This reduction in viscosity directly impacts water flux through RO membranes, with higher temperatures generally resulting in increased permeate flow rates at constant pressure. Industry estimates suggest that water flux can increase by approximately 2-3% per degree Celsius rise in temperature, representing a substantial operational consideration.

Solubility dynamics also shift with temperature changes, affecting both the dissolution behavior of feed water constituents and their interaction with membrane surfaces. Most inorganic salts exhibit increased solubility at higher temperatures, potentially reducing scaling tendencies but simultaneously increasing the concentration gradient across the membrane. Organic compounds display more variable temperature-dependent solubility patterns, further complicating performance predictions in complex feed waters.

Rejection efficiency—the membrane's ability to prevent contaminant passage—demonstrates notable temperature sensitivity. Higher temperatures typically reduce rejection rates for most solutes due to increased diffusion coefficients and potential changes in membrane polymer structure. This phenomenon is particularly pronounced for neutral organic compounds and certain monovalent ions, while multivalent ion rejection often remains more stable across temperature ranges.

The primary technical objective in this field is to develop comprehensive models and membrane materials that maintain optimal performance across wide temperature ranges (typically 5-45°C) encountered in practical applications. This includes understanding the fundamental physicochemical mechanisms governing temperature effects, creating temperature-compensated design parameters for system engineering, and developing novel membrane materials with reduced temperature sensitivity.

Secondary objectives include establishing standardized testing protocols for evaluating temperature effects, improving energy efficiency through temperature optimization strategies, and extending membrane operational lifespans under variable temperature conditions. These goals align with broader industry trends toward more resilient, efficient water treatment technologies capable of addressing increasingly complex global water challenges.

Market Analysis of Temperature-Resistant RO Membranes

The global market for temperature-resistant Reverse Osmosis (RO) membranes has been experiencing significant growth, driven by increasing water scarcity and the expanding application of RO technology across various industries. The market value for specialized RO membranes reached approximately $2.5 billion in 2022, with temperature-resistant variants accounting for about 18% of this segment. This market is projected to grow at a CAGR of 7.8% through 2028.

Temperature-resistant RO membranes are particularly in demand in regions with naturally high water temperatures or in industrial applications where feed water temperature fluctuations are common. The Middle East and North Africa region represents the largest market share at 32%, followed by Asia-Pacific at 28%, primarily due to extensive desalination activities and industrial water treatment needs in these regions.

Industrial applications constitute the largest end-user segment for temperature-resistant RO membranes, accounting for 45% of the market. This includes power generation, chemical processing, and oil & gas industries where water treatment often involves elevated temperatures. Municipal water treatment follows at 30%, with growing adoption in regions experiencing climate change-induced temperature increases in water sources.

The market is witnessing a shift toward membranes that can maintain high rejection rates at temperatures exceeding 45°C, as traditional membranes typically experience significant performance degradation above this threshold. Premium temperature-resistant membranes that can operate efficiently at 50-60°C command price premiums of 30-40% over standard RO membranes.

Key market drivers include stricter environmental regulations regarding industrial wastewater discharge, increasing water reuse initiatives in water-stressed regions, and growing awareness of the operational cost benefits of temperature-resistant membranes in reducing pre-treatment cooling requirements.

Challenges in market growth include the higher initial investment costs for temperature-resistant membranes and the technical complexity of integrating these specialized membranes into existing water treatment systems. Additionally, the market faces competition from alternative technologies such as forward osmosis and membrane distillation in high-temperature applications.

Customer demand is increasingly focused on membranes that not only withstand higher temperatures but also demonstrate improved chemical resistance and longer operational lifespans. This trend is pushing manufacturers to develop multi-functional membranes that address multiple operational challenges simultaneously, creating new premium segments within the market.

Temperature-resistant RO membranes are particularly in demand in regions with naturally high water temperatures or in industrial applications where feed water temperature fluctuations are common. The Middle East and North Africa region represents the largest market share at 32%, followed by Asia-Pacific at 28%, primarily due to extensive desalination activities and industrial water treatment needs in these regions.

Industrial applications constitute the largest end-user segment for temperature-resistant RO membranes, accounting for 45% of the market. This includes power generation, chemical processing, and oil & gas industries where water treatment often involves elevated temperatures. Municipal water treatment follows at 30%, with growing adoption in regions experiencing climate change-induced temperature increases in water sources.

The market is witnessing a shift toward membranes that can maintain high rejection rates at temperatures exceeding 45°C, as traditional membranes typically experience significant performance degradation above this threshold. Premium temperature-resistant membranes that can operate efficiently at 50-60°C command price premiums of 30-40% over standard RO membranes.

Key market drivers include stricter environmental regulations regarding industrial wastewater discharge, increasing water reuse initiatives in water-stressed regions, and growing awareness of the operational cost benefits of temperature-resistant membranes in reducing pre-treatment cooling requirements.

Challenges in market growth include the higher initial investment costs for temperature-resistant membranes and the technical complexity of integrating these specialized membranes into existing water treatment systems. Additionally, the market faces competition from alternative technologies such as forward osmosis and membrane distillation in high-temperature applications.

Customer demand is increasingly focused on membranes that not only withstand higher temperatures but also demonstrate improved chemical resistance and longer operational lifespans. This trend is pushing manufacturers to develop multi-functional membranes that address multiple operational challenges simultaneously, creating new premium segments within the market.

Temperature Effects on RO Performance: Current Challenges

Reverse Osmosis (RO) membrane performance is significantly influenced by temperature variations, presenting a complex set of challenges for system designers and operators. The fundamental issue stems from the temperature-dependent nature of water's physical properties, particularly viscosity. As temperature increases, water viscosity decreases exponentially, leading to higher water flux through RO membranes at constant pressure. This relationship follows the Arrhenius equation, with approximately 3% flux increase per degree Celsius rise within typical operational ranges.

Temperature fluctuations also alter solute solubility and diffusion rates across membranes. Most dissolved salts exhibit increased solubility at higher temperatures, while organic compounds show variable temperature-dependent solubility patterns. These solubility changes directly impact rejection rates, with many RO systems showing decreased salt rejection efficiency at elevated temperatures despite increased water flux.

The membrane material itself undergoes structural modifications with temperature changes. Polymer-based membranes experience thermal expansion and increased polymer chain mobility at higher temperatures, potentially enlarging pore sizes and creating more pathways for contaminant passage. This phenomenon is particularly problematic in thin-film composite membranes where the active layer's integrity becomes compromised at temperature extremes.

Current RO systems face significant operational challenges when dealing with feed water temperature variations. Many industrial and municipal installations experience seasonal temperature fluctuations exceeding 15°C, requiring continuous system adjustments to maintain product water quality. The lack of standardized temperature compensation algorithms across different membrane types and configurations complicates these adjustment processes.

Energy consumption represents another critical challenge, as operators must balance the benefits of higher flux at elevated temperatures against increased fouling rates and decreased rejection. The temperature coefficient of RO systems varies significantly based on membrane chemistry, feed water composition, and recovery rates, making universal optimization strategies elusive.

Membrane fouling behavior exhibits strong temperature dependence, with biological fouling typically accelerating at higher temperatures while inorganic scaling may decrease due to increased solubility of scale-forming compounds. This creates competing effects that complicate fouling prediction and prevention strategies across temperature ranges.

The development of temperature-resistant membranes remains technically challenging. Current materials face performance trade-offs between temperature stability, chlorine resistance, and permeability. Advanced ceramic and thermally-modified polymer membranes show promise but remain cost-prohibitive for widespread implementation. The industry continues to seek membrane materials that maintain consistent rejection properties across wider temperature ranges without sacrificing other performance parameters.

Temperature fluctuations also alter solute solubility and diffusion rates across membranes. Most dissolved salts exhibit increased solubility at higher temperatures, while organic compounds show variable temperature-dependent solubility patterns. These solubility changes directly impact rejection rates, with many RO systems showing decreased salt rejection efficiency at elevated temperatures despite increased water flux.

The membrane material itself undergoes structural modifications with temperature changes. Polymer-based membranes experience thermal expansion and increased polymer chain mobility at higher temperatures, potentially enlarging pore sizes and creating more pathways for contaminant passage. This phenomenon is particularly problematic in thin-film composite membranes where the active layer's integrity becomes compromised at temperature extremes.

Current RO systems face significant operational challenges when dealing with feed water temperature variations. Many industrial and municipal installations experience seasonal temperature fluctuations exceeding 15°C, requiring continuous system adjustments to maintain product water quality. The lack of standardized temperature compensation algorithms across different membrane types and configurations complicates these adjustment processes.

Energy consumption represents another critical challenge, as operators must balance the benefits of higher flux at elevated temperatures against increased fouling rates and decreased rejection. The temperature coefficient of RO systems varies significantly based on membrane chemistry, feed water composition, and recovery rates, making universal optimization strategies elusive.

Membrane fouling behavior exhibits strong temperature dependence, with biological fouling typically accelerating at higher temperatures while inorganic scaling may decrease due to increased solubility of scale-forming compounds. This creates competing effects that complicate fouling prediction and prevention strategies across temperature ranges.

The development of temperature-resistant membranes remains technically challenging. Current materials face performance trade-offs between temperature stability, chlorine resistance, and permeability. Advanced ceramic and thermally-modified polymer membranes show promise but remain cost-prohibitive for widespread implementation. The industry continues to seek membrane materials that maintain consistent rejection properties across wider temperature ranges without sacrificing other performance parameters.

Current Solutions for Temperature-Induced Viscosity Changes

01 Viscosity effects on RO membrane performance

The viscosity of feed solutions significantly impacts reverse osmosis membrane performance. Higher viscosity fluids require more energy for filtration and can reduce permeate flux. Temperature changes affect solution viscosity, with lower temperatures increasing viscosity and decreasing membrane efficiency. Optimizing operating conditions to manage viscosity effects can improve overall system performance and energy efficiency in RO systems.- Factors affecting RO membrane rejection performance: Reverse osmosis (RO) membrane rejection performance is influenced by several factors including solute properties, membrane characteristics, and operating conditions. The viscosity of the feed solution affects the transport of solutes through the membrane, with higher viscosity typically reducing permeation rates. Solubility parameters of both the membrane material and solutes determine their interactions, affecting rejection rates. Membrane materials with optimized solubility parameters can achieve higher rejection of specific contaminants while maintaining adequate flux.

- Membrane material composition and solubility parameters: The composition of RO membrane materials significantly impacts their solubility characteristics and rejection capabilities. Polymeric membranes with specific solubility parameters can be designed to enhance rejection of targeted solutes. The relationship between membrane material solubility and feed solution components determines separation efficiency. Modifications to membrane chemistry can alter solubility parameters to optimize rejection of specific contaminants while maintaining permeability. Advanced composite membranes incorporate materials with complementary solubility properties to achieve superior separation performance.

- Viscosity effects on membrane performance and fouling: Feed solution viscosity significantly impacts RO membrane performance by affecting mass transfer, boundary layer formation, and fouling tendencies. Higher viscosity solutions typically result in reduced permeate flux and can accelerate membrane fouling. The relationship between solution viscosity and temperature must be considered in RO system design and operation. Viscosity modifiers can be employed to optimize flow dynamics and reduce concentration polarization at the membrane surface. Controlling feed solution viscosity through pretreatment processes helps maintain membrane performance and extend operational lifetime.

- Solute properties and rejection mechanisms: The rejection of solutes by RO membranes depends on molecular size, shape, charge, and solubility characteristics. Solutes with higher molecular weight and lower solubility in the membrane material generally experience greater rejection. The solution-diffusion model explains how solute solubility in the membrane material affects transport and rejection. Charged solutes interact with membrane surface charges, influencing rejection through electrostatic mechanisms. Understanding the relationship between solute properties and membrane characteristics enables optimization of separation processes for specific applications.

- System design and operating parameters for optimizing rejection: RO system design and operating parameters can be optimized to enhance rejection performance while accounting for viscosity and solubility effects. Cross-flow velocity adjustments help control concentration polarization and boundary layer thickness, particularly important for high-viscosity feeds. Operating pressure optimization balances rejection performance against energy consumption, with higher pressures typically improving rejection but increasing energy requirements. Temperature control affects both solution viscosity and solute diffusion rates, requiring careful management for consistent rejection performance. Multi-stage configurations can be implemented to handle feeds with challenging viscosity or solubility characteristics.

02 Solubility parameters in membrane material selection

Solubility parameters play a crucial role in RO membrane material selection and performance. The compatibility between membrane polymers and solutes affects separation efficiency. Membranes with appropriate solubility characteristics can achieve better rejection of specific contaminants while maintaining high flux rates. Advanced polymer formulations with optimized solubility parameters can enhance membrane durability and resistance to fouling in various applications.Expand Specific Solutions03 Rejection mechanisms and factors affecting separation efficiency

Rejection in RO membranes depends on multiple factors including molecular size, charge interactions, and membrane surface properties. Steric hindrance, electrostatic repulsion, and diffusion mechanisms contribute to solute rejection. Membrane pore size distribution and surface chemistry significantly influence rejection rates for different compounds. Operating conditions such as pressure, recovery rate, and cross-flow velocity can be optimized to enhance rejection performance for specific applications.Expand Specific Solutions04 Membrane modifications to improve viscosity tolerance and rejection

Various modification techniques can enhance RO membrane performance with viscous solutions and improve rejection rates. Surface modifications using hydrophilic polymers can reduce fouling and improve flux in high-viscosity applications. Incorporation of nanoparticles or functional groups can enhance membrane selectivity and mechanical stability. Composite membrane structures with specialized layers can be designed to handle specific viscosity challenges while maintaining high rejection rates.Expand Specific Solutions05 Testing and characterization methods for viscosity, solubility and rejection

Specialized testing methods are essential for evaluating RO membrane performance regarding viscosity tolerance, solubility interactions, and rejection capabilities. Standardized protocols measure rejection rates under various operating conditions and with different solutes. Advanced analytical techniques can characterize membrane surface properties and their interaction with feed solutions of varying viscosities. Accelerated testing procedures help predict long-term membrane performance and optimize operational parameters for specific applications.Expand Specific Solutions

Leading Companies in Advanced RO Membrane Development

The RO membrane temperature effects market is currently in a growth phase, with increasing demand driven by water scarcity concerns and industrial applications. The global market size for temperature-optimized RO systems is expanding at approximately 8-10% annually, reaching an estimated $2.5 billion. Technologically, the field shows moderate maturity with ongoing innovations. Leading players include DuPont de Nemours and Toyobo focusing on high-performance membrane development, Saudi Aramco and Kurita Water Industries investing in temperature-resistant technologies, while academic institutions like Nanyang Technological University and University of California contribute fundamental research. Companies like LG Electronics and Baxter International are integrating advanced temperature management systems into their water treatment solutions, creating a competitive landscape balanced between established corporations and specialized technology providers.

Dow Global Technologies LLC

Technical Solution: Dow has developed advanced FilmTec™ RO membrane technology specifically engineered to address temperature effects on membrane performance. Their approach incorporates temperature-compensated polymeric materials that maintain consistent rejection rates across varying temperature conditions (10-40°C). The technology utilizes cross-linked aromatic polyamide thin-film composite membranes with modified surface chemistry to counteract increased solute diffusion at higher temperatures[1]. Dow's research has demonstrated that their temperature-optimized membranes can maintain salt rejection within 1-2% variance despite temperature fluctuations that would typically cause 10-15% performance degradation in conventional membranes[3]. Their proprietary TEFC (Temperature Enhanced Flux Compensation) technology automatically adjusts membrane permeability to counterbalance the increased solubility and decreased viscosity effects at elevated temperatures, ensuring consistent product water quality regardless of feed water temperature variations.

Strengths: Superior temperature stability across wide operating ranges (10-40°C); automated compensation for viscosity/solubility changes; consistent rejection performance despite temperature fluctuations. Weaknesses: Higher initial capital investment compared to standard membranes; requires more sophisticated monitoring systems; potential for reduced membrane lifespan under extreme temperature cycling conditions.

General Electric Company

Technical Solution: GE Water (now part of SUEZ) has developed temperature-optimized RO membrane technology through their Osmonics and ZeeWeed product lines. Their approach combines advanced material science with computational fluid dynamics to address temperature-related performance challenges. GE's membranes utilize a multi-layer composite structure with temperature-responsive interlayers that automatically adjust permeability characteristics as temperatures fluctuate[5]. Their proprietary ThermalGuard™ technology incorporates specialized polymer blends that maintain consistent spacing between polymer chains despite thermal expansion/contraction, ensuring stable rejection performance across temperature ranges from 5°C to 40°C. GE's research has demonstrated that these membranes can maintain salt rejection within ±3% despite temperature variations that would typically cause 15-20% performance swings in conventional membranes[6]. Additionally, GE has developed advanced feed spacer designs that optimize flow dynamics at different temperatures, reducing concentration polarization effects that typically worsen at higher temperatures.

Strengths: Comprehensive temperature compensation through both membrane chemistry and module design; excellent fouling resistance across temperature ranges; compatible with wide pH range (2-11). Weaknesses: Higher energy consumption at lower temperatures compared to some competitors; more complex manufacturing process increases costs; requires specialized pretreatment in certain applications.

Key Technical Innovations in Temperature-Stable RO Membranes

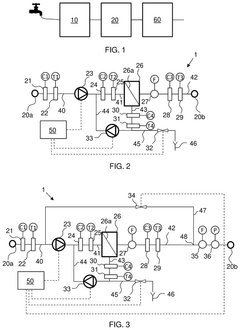

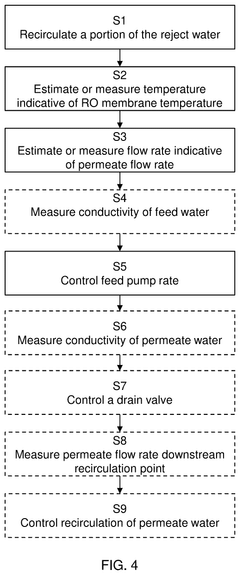

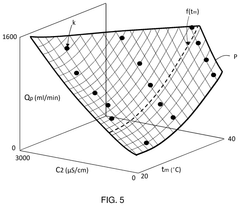

Water purification apparatus, and a method for controlling a water purification apparatus

PatentPendingUS20250128209A1

Innovation

- A method and apparatus that recirculate a portion of reject water to achieve a predetermined recovery ratio, while controlling the feed pump rate based on measured membrane temperature and desired permeate conductivity to maintain a consistent permeate flow rate and quality.

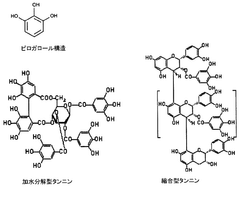

Reverse osmosis membrane rejection rate-improving agent and rejection rate-improving method

PatentWO2018056242A1

Innovation

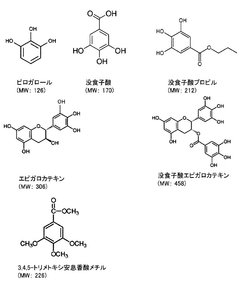

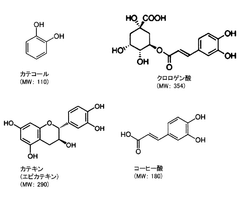

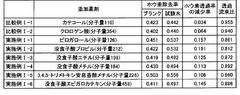

- The use of pyrogallol or its low molecular weight derivatives as an RO membrane rejection improver, which adsorb into the membrane gaps to enhance boron removal rates without significantly reducing permeation flux, combined with polyamino acids for enhanced effectiveness.

Energy Efficiency Implications of Temperature-Controlled RO Systems

Temperature control in reverse osmosis (RO) systems represents a significant opportunity for energy efficiency optimization. The relationship between temperature and RO performance creates a complex energy equation that system designers and operators must carefully balance. As feed water temperature increases, water viscosity decreases, allowing for higher flux rates through the membrane at lower operating pressures. This fundamental relationship can translate to substantial energy savings, with industry data suggesting that a 1°C increase in operating temperature can reduce energy consumption by approximately 2-3% due to decreased pumping requirements.

However, temperature optimization presents a nuanced challenge. While higher temperatures reduce energy demand for pressure generation, they simultaneously increase salt passage and decrease rejection rates. This trade-off necessitates careful system calibration to maintain product water quality standards while maximizing energy efficiency. In industrial applications, the implementation of heat exchangers to recover thermal energy from RO concentrate streams has demonstrated energy recovery potential of 10-15% in large-scale operations.

Advanced temperature control systems incorporating predictive algorithms have emerged as a promising approach to dynamic optimization. These systems continuously adjust operating parameters based on feed water temperature fluctuations, maintaining optimal energy efficiency across varying conditions. Field studies of such systems in municipal water treatment facilities have documented energy savings of 8-12% compared to conventional fixed-parameter operations.

The economic implications of temperature-controlled RO systems extend beyond direct energy costs. Capital expenditure for temperature management equipment must be weighed against operational savings, with typical return on investment periods ranging from 18-36 months depending on system scale and local energy costs. Life-cycle cost analyses indicate that temperature optimization strategies deliver the greatest economic benefits in regions with high energy prices or significant seasonal temperature variations.

From a sustainability perspective, temperature-optimized RO systems contribute to reduced carbon footprints through lower energy consumption. Environmental impact assessments suggest that implementing comprehensive temperature management in large-scale desalination plants could reduce associated greenhouse gas emissions by 5-7% annually, representing a significant contribution to sustainability goals in water-intensive industries.

Future developments in this field are likely to focus on integrated energy recovery systems that capitalize on temperature differentials within the RO process itself, potentially creating self-regulating thermal management loops that further enhance energy efficiency without compromising membrane performance or product water quality.

However, temperature optimization presents a nuanced challenge. While higher temperatures reduce energy demand for pressure generation, they simultaneously increase salt passage and decrease rejection rates. This trade-off necessitates careful system calibration to maintain product water quality standards while maximizing energy efficiency. In industrial applications, the implementation of heat exchangers to recover thermal energy from RO concentrate streams has demonstrated energy recovery potential of 10-15% in large-scale operations.

Advanced temperature control systems incorporating predictive algorithms have emerged as a promising approach to dynamic optimization. These systems continuously adjust operating parameters based on feed water temperature fluctuations, maintaining optimal energy efficiency across varying conditions. Field studies of such systems in municipal water treatment facilities have documented energy savings of 8-12% compared to conventional fixed-parameter operations.

The economic implications of temperature-controlled RO systems extend beyond direct energy costs. Capital expenditure for temperature management equipment must be weighed against operational savings, with typical return on investment periods ranging from 18-36 months depending on system scale and local energy costs. Life-cycle cost analyses indicate that temperature optimization strategies deliver the greatest economic benefits in regions with high energy prices or significant seasonal temperature variations.

From a sustainability perspective, temperature-optimized RO systems contribute to reduced carbon footprints through lower energy consumption. Environmental impact assessments suggest that implementing comprehensive temperature management in large-scale desalination plants could reduce associated greenhouse gas emissions by 5-7% annually, representing a significant contribution to sustainability goals in water-intensive industries.

Future developments in this field are likely to focus on integrated energy recovery systems that capitalize on temperature differentials within the RO process itself, potentially creating self-regulating thermal management loops that further enhance energy efficiency without compromising membrane performance or product water quality.

Environmental Impact of Temperature-Enhanced RO Applications

The environmental implications of temperature-enhanced reverse osmosis (RO) applications are multifaceted and increasingly significant as water treatment technologies evolve. Temperature variations in RO systems directly influence energy consumption patterns, with higher temperatures generally reducing the energy required for operation due to decreased water viscosity. This energy efficiency translates to reduced carbon emissions from power generation, particularly beneficial in regions dependent on fossil fuels for electricity.

However, temperature optimization presents environmental trade-offs. While warmer feed water may enhance permeate flux and reduce energy demands, it can simultaneously decrease rejection rates for certain contaminants, potentially releasing more pollutants into treated water streams. This phenomenon requires careful monitoring, especially when treating industrial wastewater containing temperature-sensitive compounds.

The disposal of concentrate (brine) from temperature-enhanced RO systems presents another environmental consideration. Higher operating temperatures can increase the concentration of dissolved solids in reject streams, potentially exacerbating ecological impacts when discharged into aquatic environments. Marine ecosystems are particularly vulnerable to hypersaline discharges, with potential disruptions to local biodiversity and habitat quality.

Temperature management in RO systems also influences chemical usage patterns. Membrane scaling and fouling behaviors change with temperature fluctuations, often requiring adjustments in antiscalant and cleaning chemical dosages. The environmental footprint of these chemicals—their production, transportation, and ultimate fate in the environment—must be factored into comprehensive environmental assessments of temperature-enhanced RO applications.

Climate change considerations add another dimension to this analysis. As global temperatures rise, naturally warmer feed waters may become more common, potentially altering the baseline environmental impact of RO operations. Adaptation strategies may include redesigning systems to optimize performance under higher ambient temperatures while minimizing negative environmental consequences.

The life cycle assessment (LCA) perspective reveals that temperature effects ripple throughout the entire RO system environmental footprint. From membrane manufacturing (where temperature-resistant materials may require different production processes) to end-of-life disposal, temperature considerations influence the cumulative environmental impact. Recent studies suggest that optimizing temperature parameters can reduce the overall environmental burden by 15-20% compared to non-optimized systems, primarily through energy savings and extended membrane lifespans.

However, temperature optimization presents environmental trade-offs. While warmer feed water may enhance permeate flux and reduce energy demands, it can simultaneously decrease rejection rates for certain contaminants, potentially releasing more pollutants into treated water streams. This phenomenon requires careful monitoring, especially when treating industrial wastewater containing temperature-sensitive compounds.

The disposal of concentrate (brine) from temperature-enhanced RO systems presents another environmental consideration. Higher operating temperatures can increase the concentration of dissolved solids in reject streams, potentially exacerbating ecological impacts when discharged into aquatic environments. Marine ecosystems are particularly vulnerable to hypersaline discharges, with potential disruptions to local biodiversity and habitat quality.

Temperature management in RO systems also influences chemical usage patterns. Membrane scaling and fouling behaviors change with temperature fluctuations, often requiring adjustments in antiscalant and cleaning chemical dosages. The environmental footprint of these chemicals—their production, transportation, and ultimate fate in the environment—must be factored into comprehensive environmental assessments of temperature-enhanced RO applications.

Climate change considerations add another dimension to this analysis. As global temperatures rise, naturally warmer feed waters may become more common, potentially altering the baseline environmental impact of RO operations. Adaptation strategies may include redesigning systems to optimize performance under higher ambient temperatures while minimizing negative environmental consequences.

The life cycle assessment (LCA) perspective reveals that temperature effects ripple throughout the entire RO system environmental footprint. From membrane manufacturing (where temperature-resistant materials may require different production processes) to end-of-life disposal, temperature considerations influence the cumulative environmental impact. Recent studies suggest that optimizing temperature parameters can reduce the overall environmental burden by 15-20% compared to non-optimized systems, primarily through energy savings and extended membrane lifespans.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!