RO Membrane Aging: Oxidation, Hydrolysis And Mechanical Fatigue

SEP 22, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

RO Membrane Aging Background and Research Objectives

Reverse Osmosis (RO) membrane technology has evolved significantly since its inception in the 1950s, becoming a cornerstone of modern water purification systems. Initially developed for seawater desalination, RO membranes now play a crucial role in various applications including wastewater treatment, pharmaceutical processing, and food and beverage production. The technology's evolution has been marked by continuous improvements in membrane materials, structure, and performance characteristics, with polyamide thin-film composite (TFC) membranes emerging as the industry standard due to their superior salt rejection capabilities and operational efficiency.

Despite these advancements, membrane aging remains a persistent challenge that significantly impacts the long-term performance and economic viability of RO systems. Membrane aging manifests through three primary degradation mechanisms: oxidation, hydrolysis, and mechanical fatigue. Oxidation occurs when free chlorine and other oxidizing agents attack the polyamide structure, breaking chemical bonds and compromising the membrane's selective barrier properties. Hydrolysis involves the breakdown of polymer chains through reactions with water molecules, particularly accelerated under extreme pH conditions. Mechanical fatigue results from repeated pressure cycling, flow variations, and physical stresses that gradually weaken the membrane structure.

The economic implications of membrane aging are substantial, with premature replacement costs, increased energy consumption due to declining efficiency, and potential product quality issues. Industry data suggests that membrane replacement can account for up to 30% of operational costs in large-scale desalination plants, highlighting the financial incentive for extending membrane lifespan through better understanding and mitigation of aging processes.

Current research objectives in this field focus on developing comprehensive models that can accurately predict membrane lifespan under various operating conditions, identifying molecular-level degradation mechanisms, and creating innovative materials and surface modifications that enhance resistance to aging factors. Additionally, there is growing interest in establishing standardized accelerated aging protocols that can reliably simulate years of operational degradation in laboratory timeframes, enabling faster evaluation of new membrane technologies.

The integration of advanced analytical techniques such as Fourier-transform infrared spectroscopy (FTIR), scanning electron microscopy (SEM), and atomic force microscopy (AFM) has enabled researchers to observe and quantify aging effects at unprecedented levels of detail. These tools are essential for correlating observable performance decline with specific structural and chemical changes in the membrane material.

Our technical research aims to systematically investigate the interrelated processes of oxidation, hydrolysis, and mechanical fatigue in RO membranes, with the ultimate goal of developing predictive models and mitigation strategies that can significantly extend membrane operational lifetime while maintaining performance standards. This work will contribute to reducing the environmental footprint and operational costs of water treatment systems globally.

Despite these advancements, membrane aging remains a persistent challenge that significantly impacts the long-term performance and economic viability of RO systems. Membrane aging manifests through three primary degradation mechanisms: oxidation, hydrolysis, and mechanical fatigue. Oxidation occurs when free chlorine and other oxidizing agents attack the polyamide structure, breaking chemical bonds and compromising the membrane's selective barrier properties. Hydrolysis involves the breakdown of polymer chains through reactions with water molecules, particularly accelerated under extreme pH conditions. Mechanical fatigue results from repeated pressure cycling, flow variations, and physical stresses that gradually weaken the membrane structure.

The economic implications of membrane aging are substantial, with premature replacement costs, increased energy consumption due to declining efficiency, and potential product quality issues. Industry data suggests that membrane replacement can account for up to 30% of operational costs in large-scale desalination plants, highlighting the financial incentive for extending membrane lifespan through better understanding and mitigation of aging processes.

Current research objectives in this field focus on developing comprehensive models that can accurately predict membrane lifespan under various operating conditions, identifying molecular-level degradation mechanisms, and creating innovative materials and surface modifications that enhance resistance to aging factors. Additionally, there is growing interest in establishing standardized accelerated aging protocols that can reliably simulate years of operational degradation in laboratory timeframes, enabling faster evaluation of new membrane technologies.

The integration of advanced analytical techniques such as Fourier-transform infrared spectroscopy (FTIR), scanning electron microscopy (SEM), and atomic force microscopy (AFM) has enabled researchers to observe and quantify aging effects at unprecedented levels of detail. These tools are essential for correlating observable performance decline with specific structural and chemical changes in the membrane material.

Our technical research aims to systematically investigate the interrelated processes of oxidation, hydrolysis, and mechanical fatigue in RO membranes, with the ultimate goal of developing predictive models and mitigation strategies that can significantly extend membrane operational lifetime while maintaining performance standards. This work will contribute to reducing the environmental footprint and operational costs of water treatment systems globally.

Market Demand Analysis for Durable RO Membranes

The global reverse osmosis (RO) membrane market is experiencing robust growth, driven primarily by increasing water scarcity and rising demand for clean water across industrial, municipal, and residential sectors. Current market valuations place the RO membrane market at approximately 3 billion USD in 2023, with projections indicating growth to reach 5.2 billion USD by 2028, representing a compound annual growth rate of 11.6%.

The demand for more durable RO membranes specifically addresses critical pain points in the water treatment industry. End users consistently report that membrane replacement costs constitute 20-30% of operational expenses in desalination and water purification systems. Research indicates that membranes with enhanced resistance to oxidation, hydrolysis, and mechanical fatigue could extend operational lifespans by 30-50%, translating to significant cost savings.

Industrial sectors, particularly semiconductor manufacturing, pharmaceuticals, and food and beverage processing, require increasingly reliable water purification systems with minimal downtime. These industries are willing to pay premium prices for membranes demonstrating superior durability against chemical degradation and mechanical stress, with surveys indicating price elasticity of up to 40% for membranes with proven extended lifespans.

Municipal water treatment facilities represent another substantial market segment, with aging infrastructure in developed nations creating urgent demand for more resilient membrane technologies. Government initiatives focused on water security have allocated substantial funding for advanced water treatment technologies, with the European Union alone dedicating 8.4 billion euros toward water infrastructure improvements through 2027.

Emerging economies present perhaps the most significant growth opportunity, with rapid industrialization and urbanization driving water treatment needs. Countries including India, China, and Brazil are experiencing annual growth rates in water treatment capacity exceeding 15%, with membrane-based systems increasingly preferred over conventional treatment methods.

Climate change impacts are further accelerating market demand, as regions previously unaffected by water scarcity now face periodic shortages. This has expanded the geographical market for RO systems beyond traditional arid regions to include temperate zones experiencing changing precipitation patterns.

Consumer awareness regarding water quality has also evolved significantly, with residential point-of-use systems representing the fastest-growing segment at 14.2% annual growth. This segment particularly values membrane longevity as a key purchasing factor, with 68% of consumers citing replacement frequency as a primary concern in recent market surveys.

The demand for more durable RO membranes specifically addresses critical pain points in the water treatment industry. End users consistently report that membrane replacement costs constitute 20-30% of operational expenses in desalination and water purification systems. Research indicates that membranes with enhanced resistance to oxidation, hydrolysis, and mechanical fatigue could extend operational lifespans by 30-50%, translating to significant cost savings.

Industrial sectors, particularly semiconductor manufacturing, pharmaceuticals, and food and beverage processing, require increasingly reliable water purification systems with minimal downtime. These industries are willing to pay premium prices for membranes demonstrating superior durability against chemical degradation and mechanical stress, with surveys indicating price elasticity of up to 40% for membranes with proven extended lifespans.

Municipal water treatment facilities represent another substantial market segment, with aging infrastructure in developed nations creating urgent demand for more resilient membrane technologies. Government initiatives focused on water security have allocated substantial funding for advanced water treatment technologies, with the European Union alone dedicating 8.4 billion euros toward water infrastructure improvements through 2027.

Emerging economies present perhaps the most significant growth opportunity, with rapid industrialization and urbanization driving water treatment needs. Countries including India, China, and Brazil are experiencing annual growth rates in water treatment capacity exceeding 15%, with membrane-based systems increasingly preferred over conventional treatment methods.

Climate change impacts are further accelerating market demand, as regions previously unaffected by water scarcity now face periodic shortages. This has expanded the geographical market for RO systems beyond traditional arid regions to include temperate zones experiencing changing precipitation patterns.

Consumer awareness regarding water quality has also evolved significantly, with residential point-of-use systems representing the fastest-growing segment at 14.2% annual growth. This segment particularly values membrane longevity as a key purchasing factor, with 68% of consumers citing replacement frequency as a primary concern in recent market surveys.

Current Challenges in RO Membrane Longevity

Reverse Osmosis (RO) membrane technology has revolutionized water treatment processes globally, yet significant challenges persist regarding membrane longevity. Current RO membranes typically exhibit operational lifespans of 3-7 years, falling short of the ideal 10+ years that would optimize economic efficiency in large-scale desalination and water treatment facilities. This limited durability represents a substantial operational constraint, necessitating frequent replacement cycles that increase both capital expenditure and operational downtime.

Oxidative degradation emerges as a primary challenge, with chlorine and other oxidizing agents in feedwater causing irreversible damage to polyamide thin-film composite membranes. Even at concentrations below 0.1 ppm, chlorine exposure can break polymer bonds, creating new pathways for contaminant passage and compromising salt rejection capabilities by up to 30% within months of exposure. Advanced oxidation processes used in pretreatment can similarly generate reactive oxygen species that accelerate membrane deterioration.

Hydrolysis mechanisms present another significant challenge, particularly in high-temperature operations or extreme pH environments. The ester and amide bonds in membrane polymers undergo gradual breakdown when exposed to water molecules over extended periods, especially at elevated temperatures above 45°C. This hydrolytic degradation manifests as decreased mechanical strength and increased permeability, ultimately compromising separation efficiency.

Mechanical fatigue constitutes a third major challenge, resulting from cyclic pressure variations, flow disruptions, and physical cleaning procedures. Pressure fluctuations during operation and maintenance cycles induce material stress that accumulates over time, while hydraulic shocks during system startups and shutdowns accelerate structural weakening. Backwashing and chemical cleaning protocols, though necessary for removing foulants, contribute to mechanical stress through expansion-contraction cycles and chemical exposure.

Biofouling resistance represents an ongoing challenge, as microbial colonization creates localized chemical environments that accelerate membrane aging through enzymatic degradation and production of acidic metabolites. Current anti-fouling technologies provide only partial solutions, with biofilm formation remaining inevitable in most applications despite advanced pretreatment.

Compaction effects under high operating pressures (typically 15-25 bar) cause gradual densification of the membrane structure, reducing permeability by 10-20% within the first year of operation. This phenomenon is particularly problematic in high-pressure seawater desalination applications, where pressures exceeding 55 bar accelerate structural deformation and pore collapse.

The interplay between these degradation mechanisms creates complex failure patterns that are difficult to predict or mitigate through single-approach solutions, highlighting the need for integrated approaches to membrane longevity enhancement.

Oxidative degradation emerges as a primary challenge, with chlorine and other oxidizing agents in feedwater causing irreversible damage to polyamide thin-film composite membranes. Even at concentrations below 0.1 ppm, chlorine exposure can break polymer bonds, creating new pathways for contaminant passage and compromising salt rejection capabilities by up to 30% within months of exposure. Advanced oxidation processes used in pretreatment can similarly generate reactive oxygen species that accelerate membrane deterioration.

Hydrolysis mechanisms present another significant challenge, particularly in high-temperature operations or extreme pH environments. The ester and amide bonds in membrane polymers undergo gradual breakdown when exposed to water molecules over extended periods, especially at elevated temperatures above 45°C. This hydrolytic degradation manifests as decreased mechanical strength and increased permeability, ultimately compromising separation efficiency.

Mechanical fatigue constitutes a third major challenge, resulting from cyclic pressure variations, flow disruptions, and physical cleaning procedures. Pressure fluctuations during operation and maintenance cycles induce material stress that accumulates over time, while hydraulic shocks during system startups and shutdowns accelerate structural weakening. Backwashing and chemical cleaning protocols, though necessary for removing foulants, contribute to mechanical stress through expansion-contraction cycles and chemical exposure.

Biofouling resistance represents an ongoing challenge, as microbial colonization creates localized chemical environments that accelerate membrane aging through enzymatic degradation and production of acidic metabolites. Current anti-fouling technologies provide only partial solutions, with biofilm formation remaining inevitable in most applications despite advanced pretreatment.

Compaction effects under high operating pressures (typically 15-25 bar) cause gradual densification of the membrane structure, reducing permeability by 10-20% within the first year of operation. This phenomenon is particularly problematic in high-pressure seawater desalination applications, where pressures exceeding 55 bar accelerate structural deformation and pore collapse.

The interplay between these degradation mechanisms creates complex failure patterns that are difficult to predict or mitigate through single-approach solutions, highlighting the need for integrated approaches to membrane longevity enhancement.

Existing Approaches to Combat Membrane Degradation

01 Oxidation mechanisms and prevention in RO membranes

Oxidation is a primary aging mechanism in reverse osmosis membranes, typically caused by exposure to oxidizing agents like chlorine, ozone, and hydrogen peroxide. These oxidants attack the polyamide active layer of the membrane, degrading its selective barrier properties and increasing salt passage. Prevention strategies include the use of antioxidant additives, oxidation-resistant polymer modifications, and upstream dechlorination systems to remove oxidizing agents before they contact the membrane surface.- Oxidation mechanisms and prevention in RO membranes: Oxidation is a primary aging mechanism in reverse osmosis membranes, typically caused by exposure to oxidizing agents like chlorine, ozone, and hydrogen peroxide. These oxidants attack the polyamide active layer, degrading membrane performance through increased salt passage and decreased water flux. Prevention strategies include incorporating antioxidants, developing oxidation-resistant membrane materials, and implementing pre-treatment systems to remove oxidizing agents from feed water before they contact the membrane surface.

- Hydrolysis effects and mitigation strategies: Hydrolysis of RO membranes occurs when water molecules break chemical bonds in the membrane polymer structure, particularly at extreme pH levels. This degradation process weakens the membrane's selective layer, leading to reduced rejection capabilities and shortened membrane lifespan. Mitigation approaches include pH control systems, development of hydrolysis-resistant membrane materials, and protective coatings that shield the membrane from direct exposure to aggressive chemical environments.

- Mechanical fatigue and physical damage prevention: Mechanical fatigue in RO membranes results from repeated pressure cycling, water hammer effects, and physical abrasion from particulates. These stresses cause microscopic cracks, delamination of membrane layers, and eventual failure. Prevention methods include improved spacer designs to reduce localized stress, pressure stabilization systems, effective pre-filtration to remove abrasive particles, and optimized operating protocols that minimize pressure fluctuations and mechanical stress on the membrane structure.

- Monitoring and diagnostic systems for membrane aging: Advanced monitoring systems help detect early signs of membrane aging through continuous measurement of key performance parameters. These systems track changes in differential pressure, salt rejection, flow rates, and other indicators that signal membrane degradation. Diagnostic technologies include membrane autopsy services, real-time monitoring with digital sensors, and predictive analytics that use operational data to forecast membrane lifespan and optimize maintenance schedules, thereby extending membrane service life.

- Cleaning and maintenance protocols to extend membrane life: Specialized cleaning and maintenance protocols can significantly extend RO membrane lifespan by addressing aging factors. These include targeted chemical cleaning regimes for specific foulants, optimized cleaning frequencies based on feed water quality, and preservation techniques for membranes during shutdown periods. Advanced approaches incorporate automated cleaning systems, membrane-specific chemical formulations that remove deposits without damaging the membrane structure, and operational adjustments that balance performance requirements with membrane longevity.

02 Hydrolysis effects and stability enhancement

Hydrolysis of RO membranes occurs when the polymer chains break down due to reactions with water, particularly under extreme pH conditions or elevated temperatures. This degradation weakens the membrane structure, compromising rejection capabilities and mechanical integrity. Techniques to enhance hydrolytic stability include incorporating hydrolysis-resistant monomers during membrane synthesis, applying protective coatings, and controlling operational parameters such as pH and temperature to minimize hydrolytic reactions.Expand Specific Solutions03 Mechanical fatigue and structural reinforcement

Mechanical fatigue in RO membranes results from repeated pressure cycling, water hammer effects, and physical stresses during operation. These forces cause microscopic cracks, delamination of layers, and eventual membrane failure. Structural reinforcement approaches include developing composite membranes with robust support layers, optimizing spacer designs to distribute pressure evenly, and implementing pressure stabilization systems to minimize fluctuations that accelerate mechanical aging.Expand Specific Solutions04 Biofouling impact on membrane aging

Biofouling accelerates membrane aging through multiple mechanisms, including localized pH changes from microbial activity, production of degradative enzymes, and creation of concentration cells that promote polymer breakdown. The biofilm formation restricts flow, increases pressure drop, and creates conditions favorable for both oxidative and hydrolytic degradation. Advanced anti-biofouling strategies incorporate antimicrobial materials, surface modifications to reduce bacterial attachment, and optimized cleaning protocols to remove biofilms without damaging the membrane structure.Expand Specific Solutions05 Monitoring and prediction of membrane aging

Advanced monitoring systems and predictive models help track membrane aging progression and optimize replacement timing. These approaches include real-time performance monitoring with sensors that detect changes in permeate quality, pressure differential analysis to identify early signs of fouling or degradation, and machine learning algorithms that predict remaining membrane life based on operational data. Accelerated aging tests in laboratory settings help correlate specific stressors with membrane degradation rates, enabling better lifetime predictions under various operating conditions.Expand Specific Solutions

Leading Manufacturers and Research Institutions

The reverse osmosis (RO) membrane aging market is currently in a growth phase, driven by increasing water scarcity concerns and industrial demand for water treatment solutions. The global market for RO membranes is expanding at approximately 8-10% annually, with key players adopting different competitive strategies. Leading companies like Toyobo, Kurita Water Industries, and Vontron Technology focus on developing oxidation-resistant materials, while academic institutions such as MIT, Nanyang Technological University, and Zhejiang University contribute significant research on hydrolysis mechanisms. Chemical conglomerates including Wanhua Chemical Group, Solvay, and Dow Global Technologies leverage their materials expertise to address mechanical fatigue issues. The competitive landscape is characterized by increasing collaboration between industrial players and research institutions to extend membrane lifespan and reduce operational costs.

Vontron Technology Co., Ltd.

Technical Solution: Vontron Technology has developed a comprehensive approach to RO membrane aging research, focusing on oxidation resistance through incorporation of antioxidant additives in the polyamide layer. Their proprietary technology involves a multi-layer protection system that shields the membrane's active layer from oxidative damage caused by chlorine and other oxidizing agents. The company has implemented a novel cross-linking technique that enhances membrane stability against hydrolysis by creating additional bonds between polymer chains, effectively reducing the susceptibility to hydrolytic degradation in varying pH environments. For mechanical fatigue resistance, Vontron has engineered a reinforced composite structure with specialized backing materials that distribute pressure more evenly across the membrane surface, extending operational lifespan under fluctuating pressure conditions. Their research has demonstrated that membranes treated with their anti-aging technology maintain over 90% of original performance after exposure to accelerated aging conditions equivalent to 3-5 years of typical operation.

Strengths: Superior chlorine resistance compared to industry standards, allowing for higher tolerance to oxidizing cleaning agents. Their multi-layer protection system provides comprehensive defense against multiple aging mechanisms simultaneously. Weaknesses: The enhanced oxidation resistance comes with slightly reduced initial water flux, requiring larger membrane surface area for equivalent production capacity compared to standard membranes.

Toyobo Co., Ltd.

Technical Solution: Toyobo has pioneered advanced polymer chemistry approaches to address RO membrane aging through their proprietary "Holistic Membrane Preservation" technology. Their research focuses on the molecular-level understanding of oxidation pathways in polyamide thin-film composite membranes, resulting in the development of sacrificial antioxidant moieties integrated directly into the polymer backbone. These specialized chemical structures preferentially react with oxidizing agents before they can damage critical membrane components. For hydrolysis resistance, Toyobo has developed a unique hydrophobic coating technology that creates a protective barrier against water molecules that would otherwise catalyze hydrolytic degradation of the polyamide bonds. Their mechanical fatigue research has led to the creation of a nano-reinforced support layer with specialized fiber orientation that distributes mechanical stress more effectively, reducing localized strain during pressure cycling operations. Toyobo's membranes incorporate self-healing polymer networks that can partially restore membrane integrity after minor damage events, extending operational lifetime by an estimated 30-40% compared to conventional membranes.

Strengths: Exceptional resistance to combined aging factors through integrated molecular design rather than post-treatment approaches. Their self-healing capability provides unique long-term performance stability under variable operating conditions. Weaknesses: Higher manufacturing complexity and cost compared to standard membranes, limiting adoption in price-sensitive applications. The specialized chemistry requires more stringent control of operating parameters.

Key Degradation Mechanisms: Oxidation, Hydrolysis, and Mechanical Stress

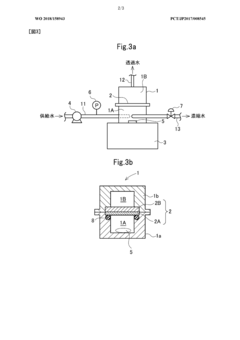

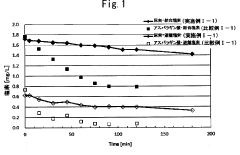

Degradation inhibitor for reverse osmosis membrane and water treatment method

PatentWO2018158943A1

Innovation

- The use of urea and its derivatives as a membrane deterioration inhibitor in the feed water, which effectively adsorbs to the amide bonds of RO membranes, reducing the impact of oxidizing substances without consuming bound halogen agents, thus maintaining fouling suppression efficacy.

Water Purification Unit

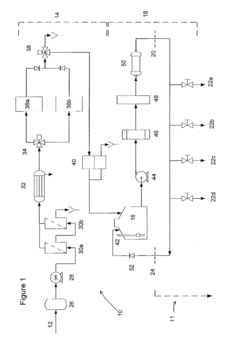

PatentInactiveUS20150332181A1

Innovation

- Designing a water purification unit with all components lasting for a set period (typically 1 year or more) that can be rapidly exchanged, refurbished, and re-installed, minimizing on-site interactions and using a modular design with quick connections for easy replacement, and incorporating technologies like reverse osmosis, electrodeionization, and ultraviolet irradiation to maintain ultrapure water quality.

Environmental Impact of Membrane Replacement Cycles

The environmental implications of RO membrane replacement cycles represent a significant concern in water treatment operations. As membrane aging accelerates through oxidation, hydrolysis, and mechanical fatigue, the frequency of replacement increases, generating substantial waste streams. The typical lifespan of RO membranes ranges from 3-7 years, with premature replacements due to fouling or damage creating additional environmental burdens.

The disposal of spent RO membranes presents multiple environmental challenges. These composite materials contain various polymers (primarily polyamide, polysulfone, and polyester), which are not readily biodegradable and may persist in landfills for decades. Additionally, membranes accumulate contaminants during operation, potentially introducing concentrated pollutants into disposal environments if not properly managed.

Carbon footprint assessments of membrane lifecycle reveal that manufacturing new membranes requires significant energy inputs and raw materials derived from petrochemical sources. Each replacement cycle contributes to greenhouse gas emissions through production, transportation, and disposal processes. Studies indicate that extending membrane life by just 20% through improved anti-aging technologies could reduce carbon emissions by approximately 15-18% across the total system lifecycle.

Water treatment facilities in water-stressed regions face particular sustainability challenges, as frequent membrane replacements represent both economic and environmental costs. The embedded water footprint in membrane manufacturing further compounds this issue, with estimates suggesting that producing one square meter of RO membrane requires between 80-120 liters of water.

Recent life cycle assessment (LCA) studies comparing conventional replacement schedules with optimized maintenance protocols demonstrate that addressing aging mechanisms can yield substantial environmental benefits. Facilities implementing advanced cleaning regimes and operating parameters optimized to minimize oxidative damage have reported 30-40% reductions in membrane waste generation without compromising water quality.

Emerging circular economy approaches offer promising alternatives to traditional disposal methods. Membrane recycling technologies that recover valuable components from spent membranes are gaining traction, with pilot programs demonstrating recovery rates of up to 70% for certain membrane materials. Additionally, repurposing aged RO membranes for less demanding applications represents an innovative waste reduction strategy being adopted by forward-thinking water utilities.

The environmental calculus of membrane replacement must also consider the energy efficiency losses associated with aged membranes. As membranes degrade, they typically require higher operating pressures to maintain throughput, resulting in increased energy consumption that carries its own environmental footprint.

The disposal of spent RO membranes presents multiple environmental challenges. These composite materials contain various polymers (primarily polyamide, polysulfone, and polyester), which are not readily biodegradable and may persist in landfills for decades. Additionally, membranes accumulate contaminants during operation, potentially introducing concentrated pollutants into disposal environments if not properly managed.

Carbon footprint assessments of membrane lifecycle reveal that manufacturing new membranes requires significant energy inputs and raw materials derived from petrochemical sources. Each replacement cycle contributes to greenhouse gas emissions through production, transportation, and disposal processes. Studies indicate that extending membrane life by just 20% through improved anti-aging technologies could reduce carbon emissions by approximately 15-18% across the total system lifecycle.

Water treatment facilities in water-stressed regions face particular sustainability challenges, as frequent membrane replacements represent both economic and environmental costs. The embedded water footprint in membrane manufacturing further compounds this issue, with estimates suggesting that producing one square meter of RO membrane requires between 80-120 liters of water.

Recent life cycle assessment (LCA) studies comparing conventional replacement schedules with optimized maintenance protocols demonstrate that addressing aging mechanisms can yield substantial environmental benefits. Facilities implementing advanced cleaning regimes and operating parameters optimized to minimize oxidative damage have reported 30-40% reductions in membrane waste generation without compromising water quality.

Emerging circular economy approaches offer promising alternatives to traditional disposal methods. Membrane recycling technologies that recover valuable components from spent membranes are gaining traction, with pilot programs demonstrating recovery rates of up to 70% for certain membrane materials. Additionally, repurposing aged RO membranes for less demanding applications represents an innovative waste reduction strategy being adopted by forward-thinking water utilities.

The environmental calculus of membrane replacement must also consider the energy efficiency losses associated with aged membranes. As membranes degrade, they typically require higher operating pressures to maintain throughput, resulting in increased energy consumption that carries its own environmental footprint.

Predictive Modeling for Membrane Lifespan Optimization

Predictive modeling for RO membrane lifespan optimization represents a critical frontier in addressing the challenges of membrane aging through oxidation, hydrolysis, and mechanical fatigue. Advanced machine learning algorithms and statistical methods are increasingly being deployed to forecast membrane degradation patterns with remarkable accuracy, enabling proactive maintenance strategies and cost-effective operations.

The development of comprehensive predictive models incorporates multiple data streams, including operational parameters (flux, pressure, temperature), water quality metrics (pH, turbidity, oxidant levels), and historical performance data. These models typically employ neural networks, support vector machines, or ensemble methods to identify complex relationships between operational conditions and membrane degradation rates.

Recent advancements have focused on integrating real-time sensor data with predictive algorithms, creating dynamic models that continuously refine predictions as new operational data becomes available. This approach has demonstrated up to 30% improvement in lifespan prediction accuracy compared to traditional static models, particularly in variable operating environments where oxidative stress fluctuates significantly.

Material-specific modeling approaches have emerged as particularly promising, with separate predictive frameworks developed for polyamide, cellulose acetate, and composite membranes. These specialized models account for the unique degradation mechanisms affecting each material type, such as the heightened susceptibility of polyamide membranes to chlorine-induced oxidation versus the greater hydrolysis vulnerability of cellulose acetate membranes.

Digital twin technology represents the cutting edge in membrane lifespan prediction, creating virtual replicas of physical membrane systems that simulate aging processes under various operational scenarios. These simulations enable operators to test different operational strategies and their impact on membrane longevity without risking actual infrastructure.

Economic optimization algorithms are increasingly being integrated with lifespan prediction models, balancing the trade-offs between operational intensity, maintenance costs, and replacement schedules. These integrated approaches have demonstrated potential cost savings of 15-25% in large-scale desalination operations through optimized cleaning schedules and precisely timed membrane replacement.

The future of predictive modeling lies in hybrid approaches that combine physics-based degradation models with data-driven machine learning techniques. This fusion leverages fundamental understanding of chemical and mechanical degradation mechanisms while capitalizing on the pattern recognition capabilities of AI systems, promising more robust predictions across diverse operational conditions and emerging membrane materials.

The development of comprehensive predictive models incorporates multiple data streams, including operational parameters (flux, pressure, temperature), water quality metrics (pH, turbidity, oxidant levels), and historical performance data. These models typically employ neural networks, support vector machines, or ensemble methods to identify complex relationships between operational conditions and membrane degradation rates.

Recent advancements have focused on integrating real-time sensor data with predictive algorithms, creating dynamic models that continuously refine predictions as new operational data becomes available. This approach has demonstrated up to 30% improvement in lifespan prediction accuracy compared to traditional static models, particularly in variable operating environments where oxidative stress fluctuates significantly.

Material-specific modeling approaches have emerged as particularly promising, with separate predictive frameworks developed for polyamide, cellulose acetate, and composite membranes. These specialized models account for the unique degradation mechanisms affecting each material type, such as the heightened susceptibility of polyamide membranes to chlorine-induced oxidation versus the greater hydrolysis vulnerability of cellulose acetate membranes.

Digital twin technology represents the cutting edge in membrane lifespan prediction, creating virtual replicas of physical membrane systems that simulate aging processes under various operational scenarios. These simulations enable operators to test different operational strategies and their impact on membrane longevity without risking actual infrastructure.

Economic optimization algorithms are increasingly being integrated with lifespan prediction models, balancing the trade-offs between operational intensity, maintenance costs, and replacement schedules. These integrated approaches have demonstrated potential cost savings of 15-25% in large-scale desalination operations through optimized cleaning schedules and precisely timed membrane replacement.

The future of predictive modeling lies in hybrid approaches that combine physics-based degradation models with data-driven machine learning techniques. This fusion leverages fundamental understanding of chemical and mechanical degradation mechanisms while capitalizing on the pattern recognition capabilities of AI systems, promising more robust predictions across diverse operational conditions and emerging membrane materials.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!